Traction rectifier transformer isolation grounding system

A rectifier transformer, isolation and grounding technology, used in grounding switches, high-voltage air circuit breakers, electrical components, etc., can solve the problem that the real-time status of personnel and equipment safety locks cannot be transmitted, the work intensity of hanging ground wires and removing ground wires is high, and recovery is difficult. and other problems to achieve the effect of ensuring electrical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

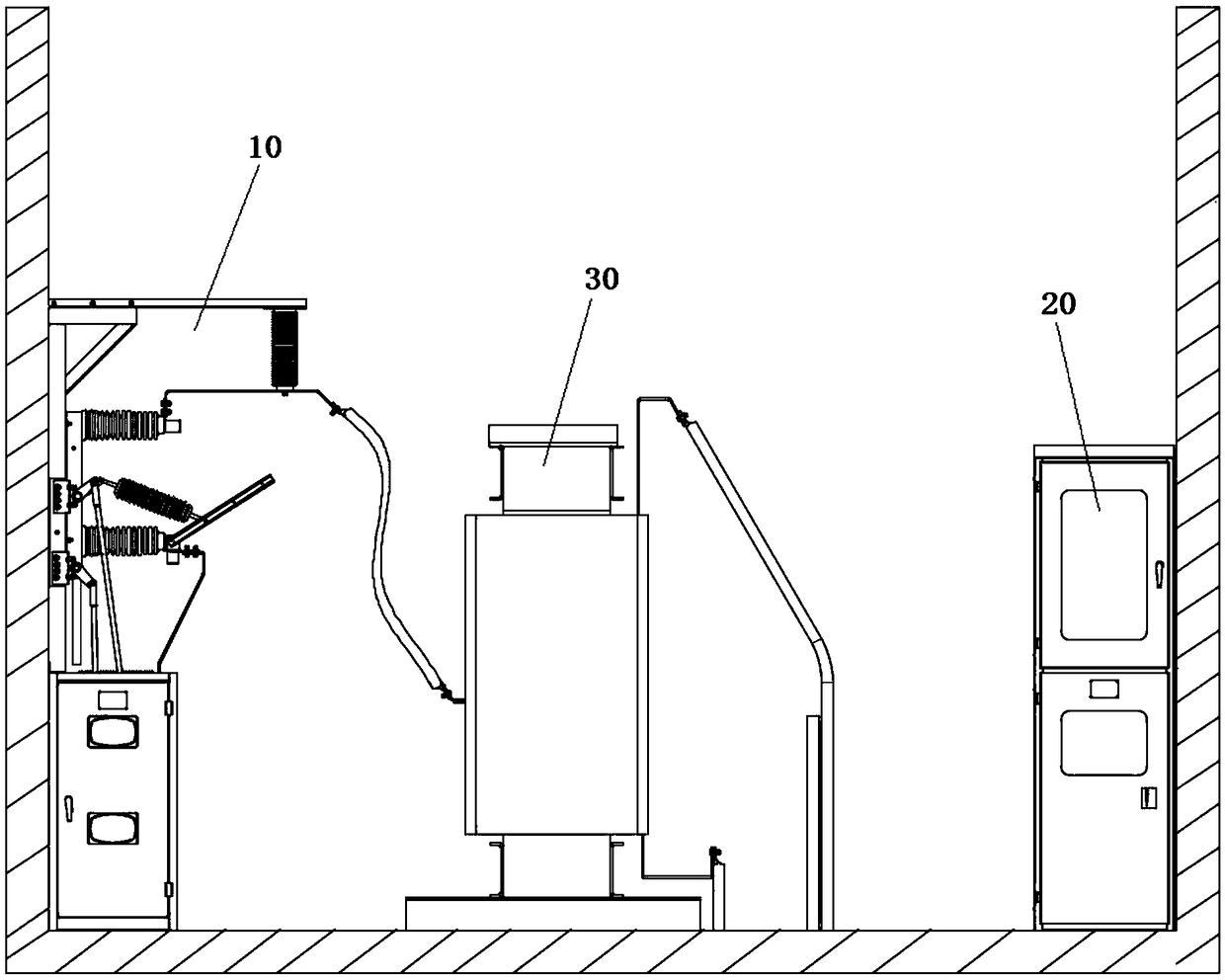

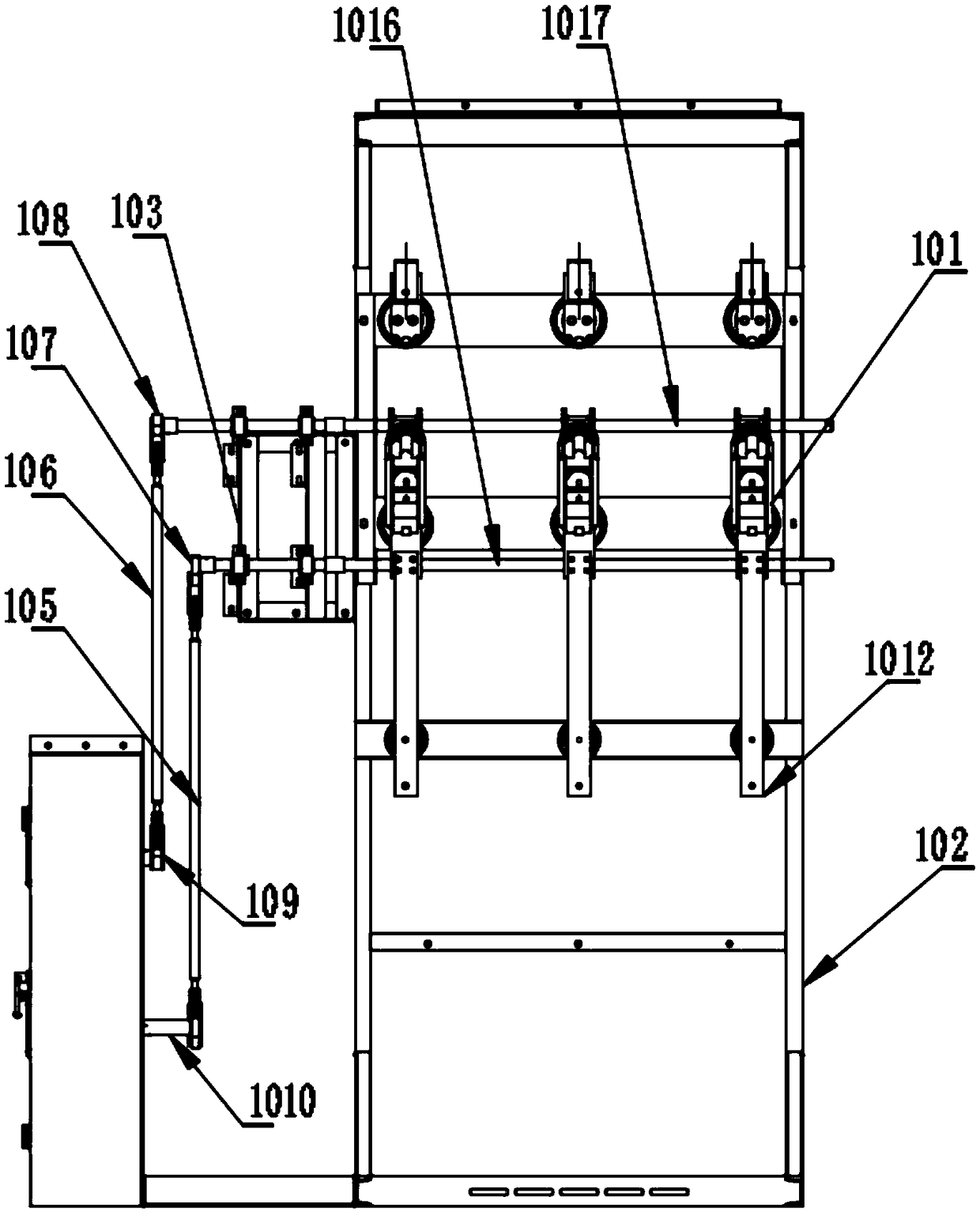

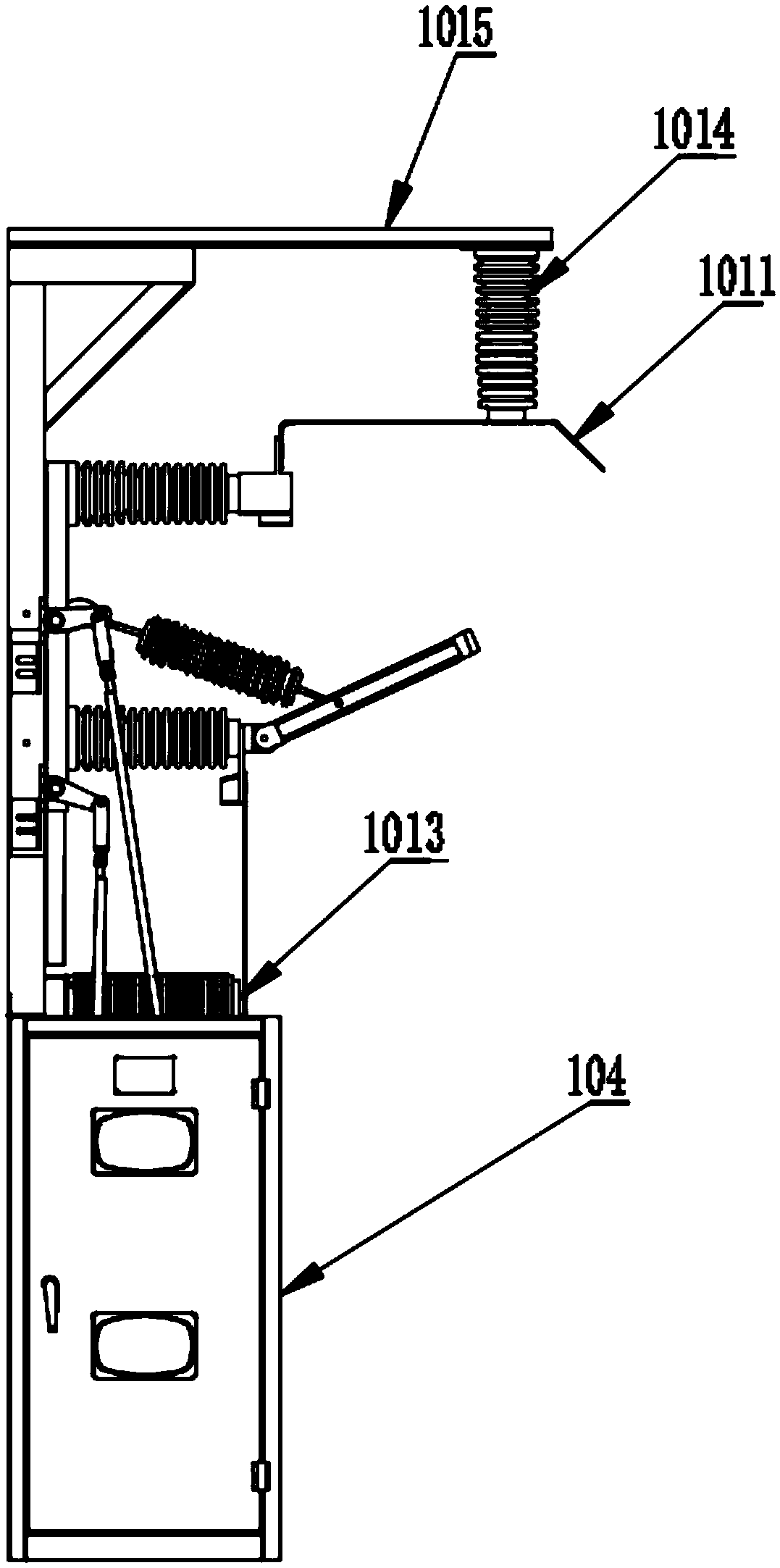

[0059] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. The interpretation of each label in the figure is: 10-three-pole traction rectifier transformer isolation and grounding system, 20-six-pole traction rectification transformer isolation and grounding system, 30-traction rectification transformer, 101-ZGD1 three-pole isolation grounding device, 102-ZGD1 installation base frame, 103-ZGD1 tie rod fixing frame, 104-ZGD1 electric operating mechanism box, 105-ZGD1 grounding switch transmission rod, 106-ZGD1 isolation switch transmission rod, 107-ZGD1 Grounding switch arm, 108-ZGD1 isolating switch arm, 109-ZGD1 isolating switch mechanism arm, 1010-ZGD1 grounding switch mechanism arm, 1011-ZGD1 outgoing busbar, 1012-ZGD1 incoming busbar, 1013-ZGD1 voltage Sensor, 1014-ZGD1 first support insulator, 1015-ZGD1 insulator support frame, 1016-ZGD1 grounding switch shaft, 1017-ZGD1 isolation switch shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com