Cable elbow type head with test interface

A test interface and testing technology, applied in the direction of testing/measuring connectors, measuring electricity, measuring electrical variables, etc., can solve the problems of cable running left, contact oxidation, safety hazards, etc., to achieve safe and stable operation, reliable guarantee, The effect of avoiding oxidative burning and avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

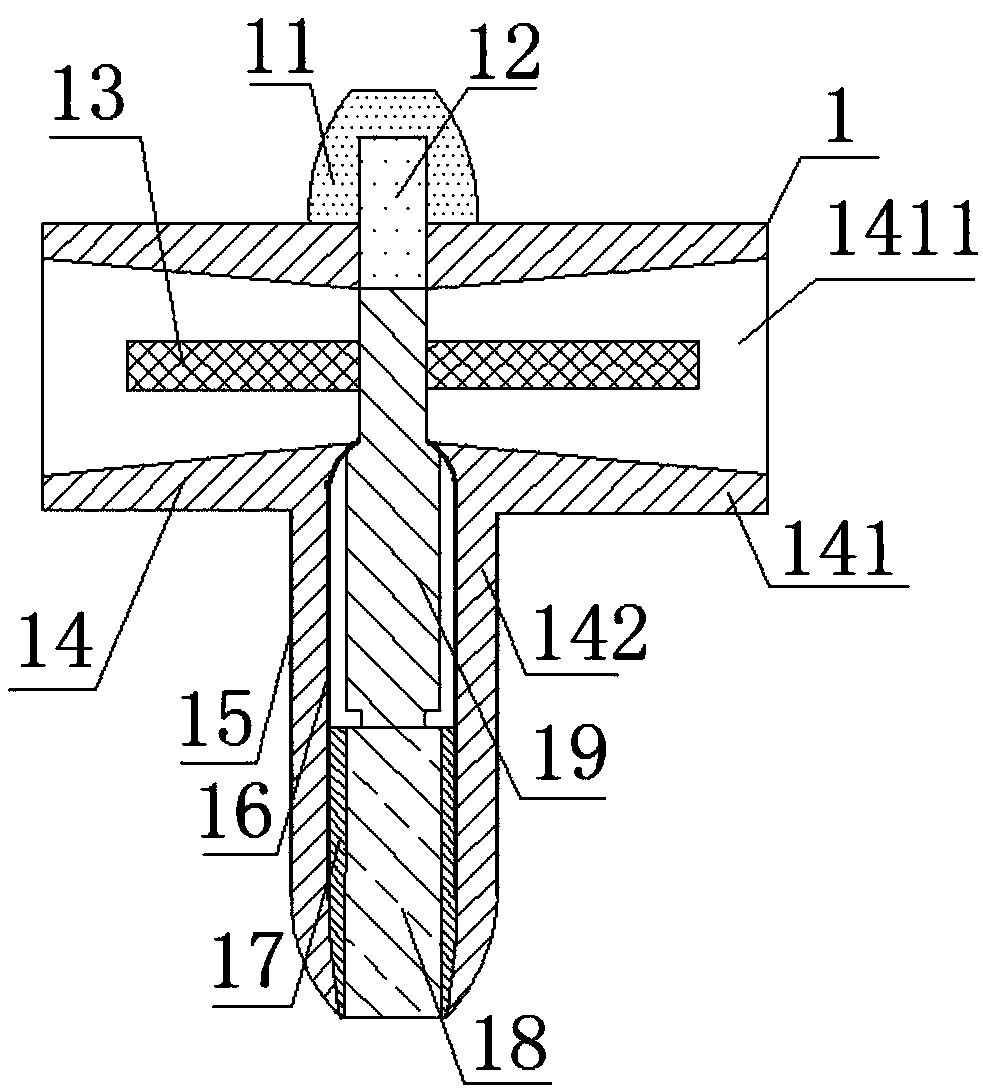

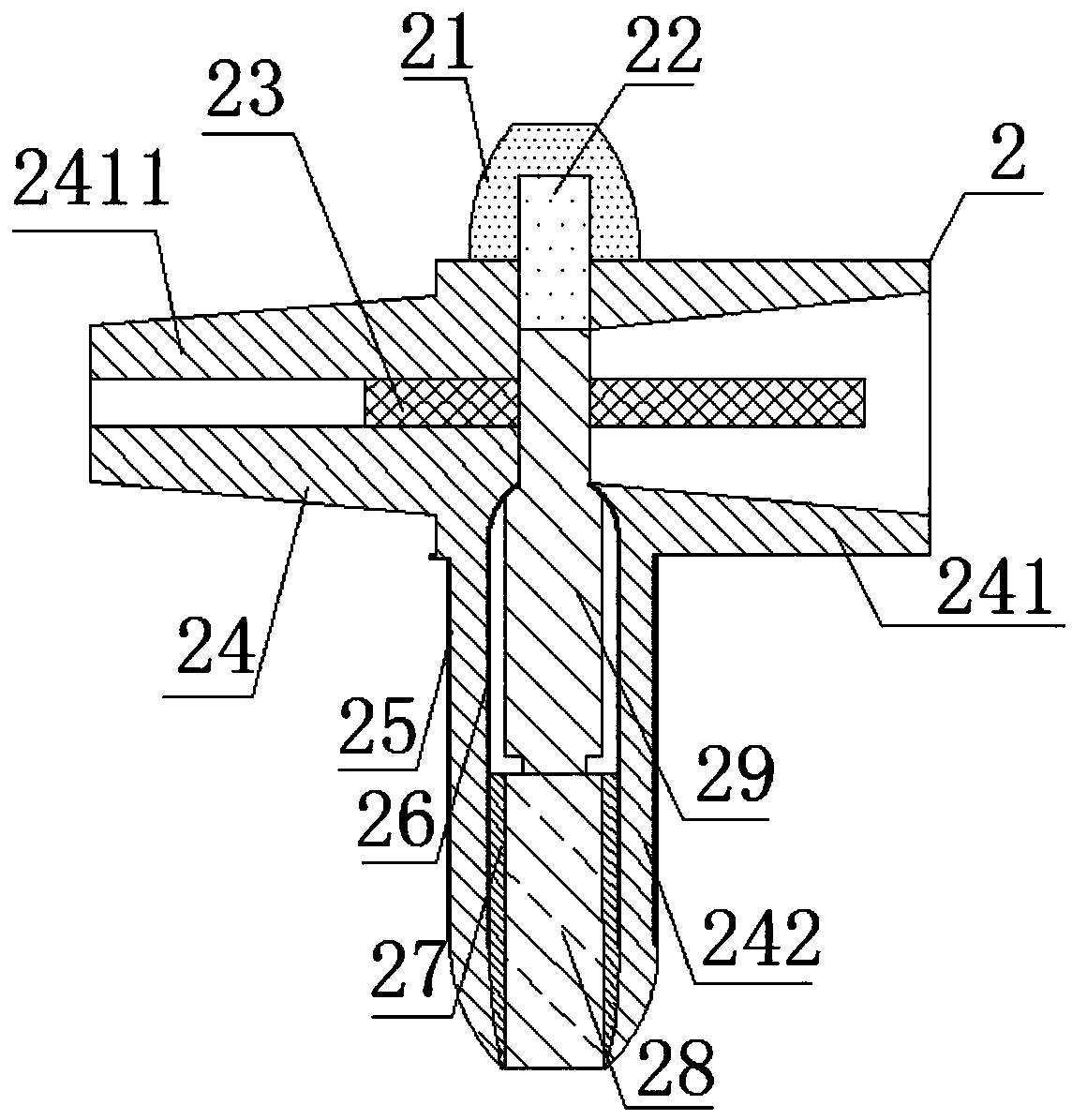

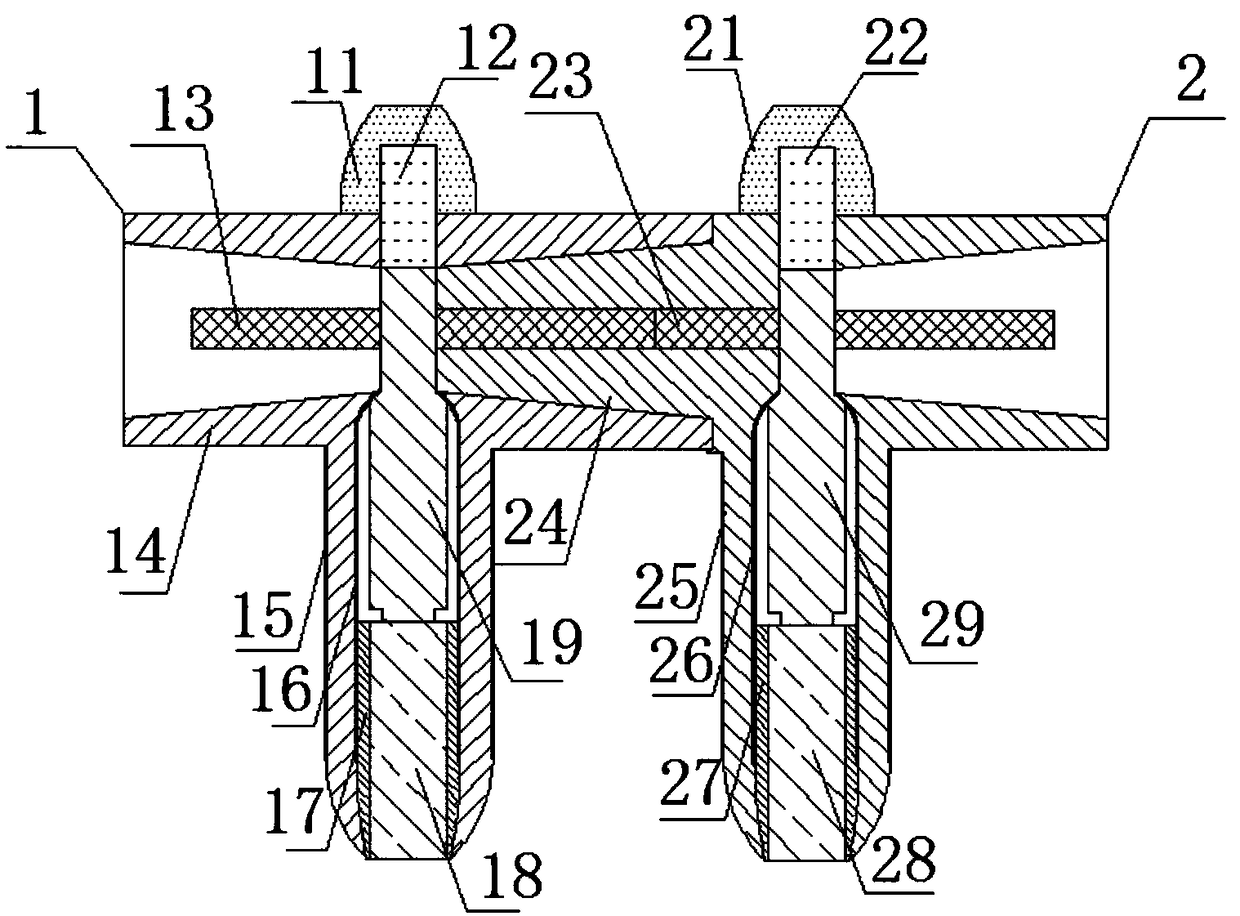

[0021] see Figure 1 to Figure 3 , the embodiment of the present application provides a cable elbow with a test interface, including a cable elbow front connector 1 and a cable elbow rear connector 2, the cable elbow front connector 1 and the cable elbow rear connector 2 can be Disconnect the connection.

[0022] Wherein, the cable elbow front connector 1 includes a front connector insulating cap 11 , a front connector test interface 12 , a front connector stud 13 , a front connector insulating sleeve 14 and a front connector crimping terminal 19 . The front joint insulating cover 14 comprises a first joint connection part 141 and a first cable connection part 142, and the first cable connection part 142 is vertically connected to the bottom middle position of the first joint connection part 141, and the inside of the first joint connection part 141 is connected to the first joint connection part 142. The inside of a cable connection part 142 is connected; the front connector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com