Water-cooling fan

A cooling fan and water cooling technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low cooling efficiency, inability to transmit cold air, and the influence of high temperature shafts, so as to improve service life and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

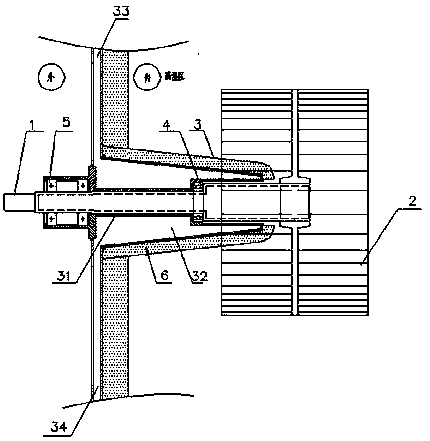

[0032] like figure 1 Shown: a water-cooled fan, including a shaft 1, a bearing and a water-cooled main body, the shaft 1 is connected to the fan impeller 2; The part of the shaft in the high temperature zone passes through the inner cavity of the water-cooled main body.

[0033]In this embodiment, the main body of the water cooling is the shaft seat 3, and the bearing includes an inner bearing 4 and an outer bearing 5, and the inner bearing 4 is located in the high temperature zone of the furnace body, and the outer bearing 5 is arranged outside the furnace body. Since the fan impeller 2 is relatively large, the bearing capacity is greatly improved by arranging inner and outer bearings. In addition, due to the existing high-temperature fans, the shaft seat is generally far away from the fan impeller, so that the shaft between the bearing and the fan impeller is relatively long, resulting in poor stability of the fan during rotation. Therefore, the present embodiment has take...

Embodiment 2

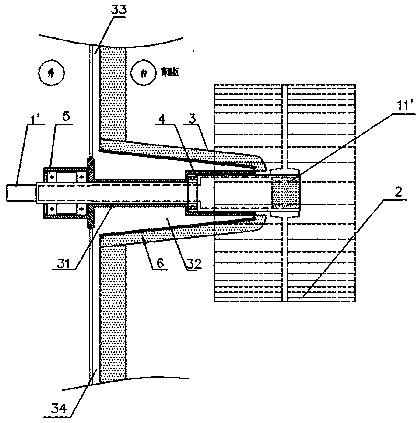

[0041] Such as figure 2 Shown: On the basis of Example 1, the shaft 1' of this embodiment is a hollow shaft, and the hollow shaft is provided with an insulating material 11', and the insulating material 11' is filled on the top of the hollow shaft, that is, the shaft 1' and the The position of the connection of fan impeller 2. The thermal insulation material 11' of the present embodiment is rock wool.

[0042] By arranging the thermal insulation material 11' in the shaft 1', especially the thermal insulation material 11' at the top of the shaft 1', that is, the end close to the center of the fan impeller 2, on the one hand, because the shaft seat 3 is close to the center of the fan impeller However, the cooling effect of the top of the shaft is slightly worse than that of other positions of the shaft. By filling the top with insulation material 11', a certain heat insulation effect can be achieved; on the other hand, due to the high temperature of the fan impeller 2 , then ...

Embodiment 3

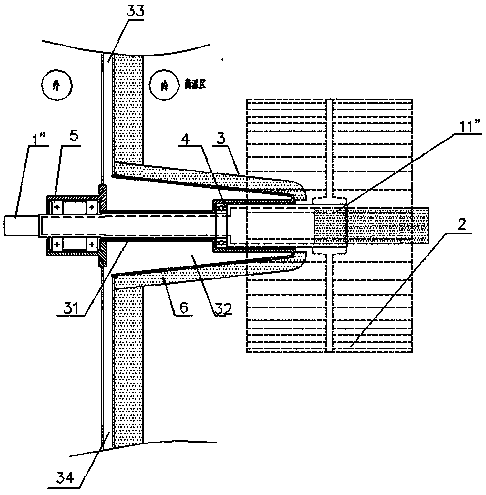

[0045] The difference from Embodiment 1 or Embodiment 2 is that a fan casing is provided outside the fan impeller, and the fan casing is connected to the shaft seat.

[0046] Other structures are with embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com