Power torque converter for electric vehicle

A technology of electric vehicles and torque converters, which is applied in the direction of transmission devices, fluid transmission devices, belts/chains/gears, etc., can solve the problems that the torque cannot be released quickly, and achieve the effects of easy maintenance, preventing dry grinding, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

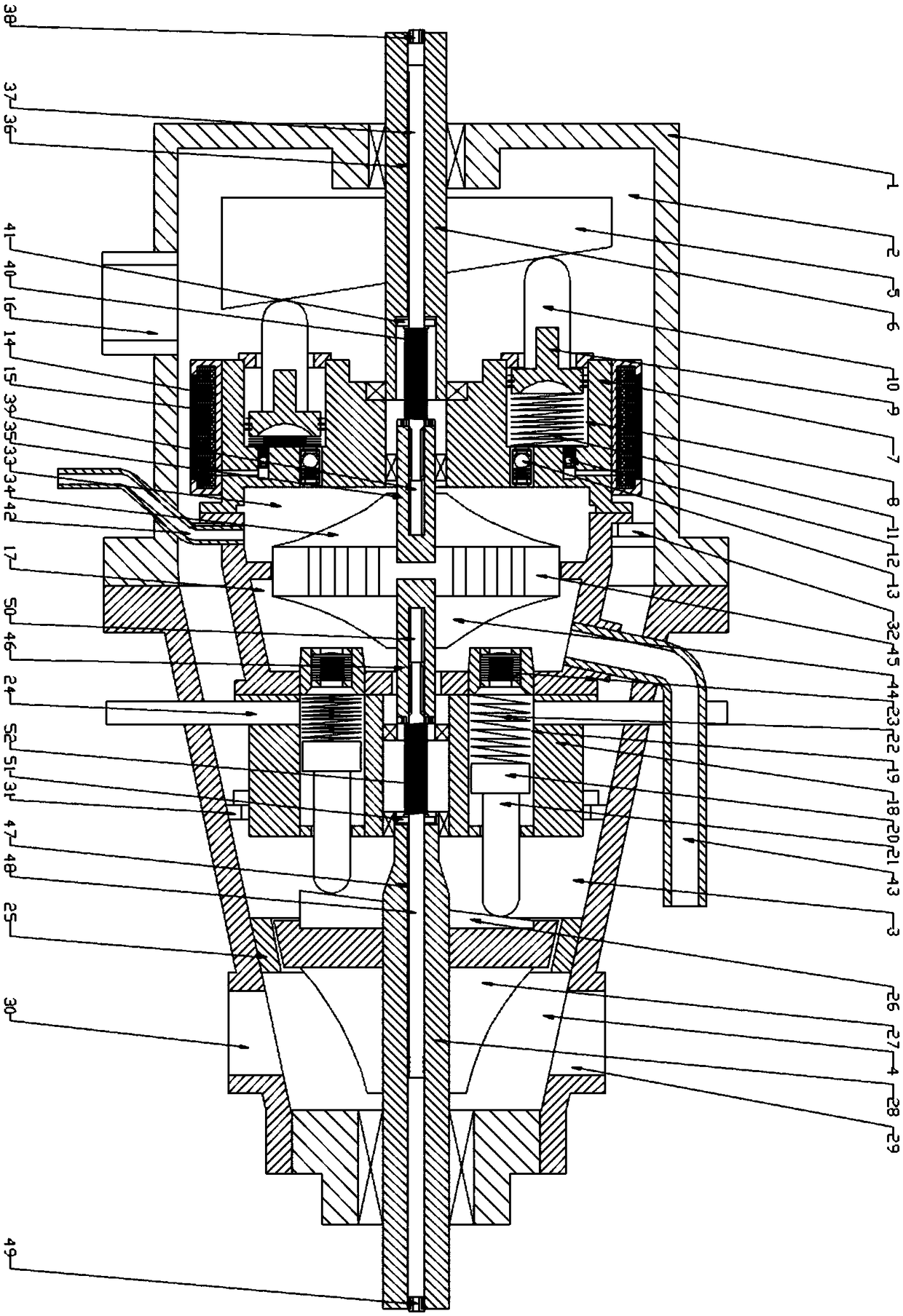

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] Such as figure 1As shown, the present invention is a power torque converter for electric vehicles, including a buffer housing 1, in which a power input chamber 2, a buffer chamber, a power output chamber 3 and a liquid flow drive chamber 4 are sequentially arranged. Wherein the power input chamber 2 is provided with a power input mechanism, and the side wall of the power input chamber 2 is provided with a main oil inlet 16, and the power input mechanism includes a power input shaft 6 and a power input piston mechanism, and the power input shaft 6 passes through one axial end of the buffer housing 1 and is rotationally connected with the buffer housing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap