Eccentric tooth-type permanent magnet vernier motor

A vernier motor, eccentric technology, applied in the direction of motors, synchronous motors with stationary armatures and rotating magnets, magnetic circuits, etc., can solve the problems of small output torque, trapezoidal back EMF waveform, etc. , The effect of large output torque and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

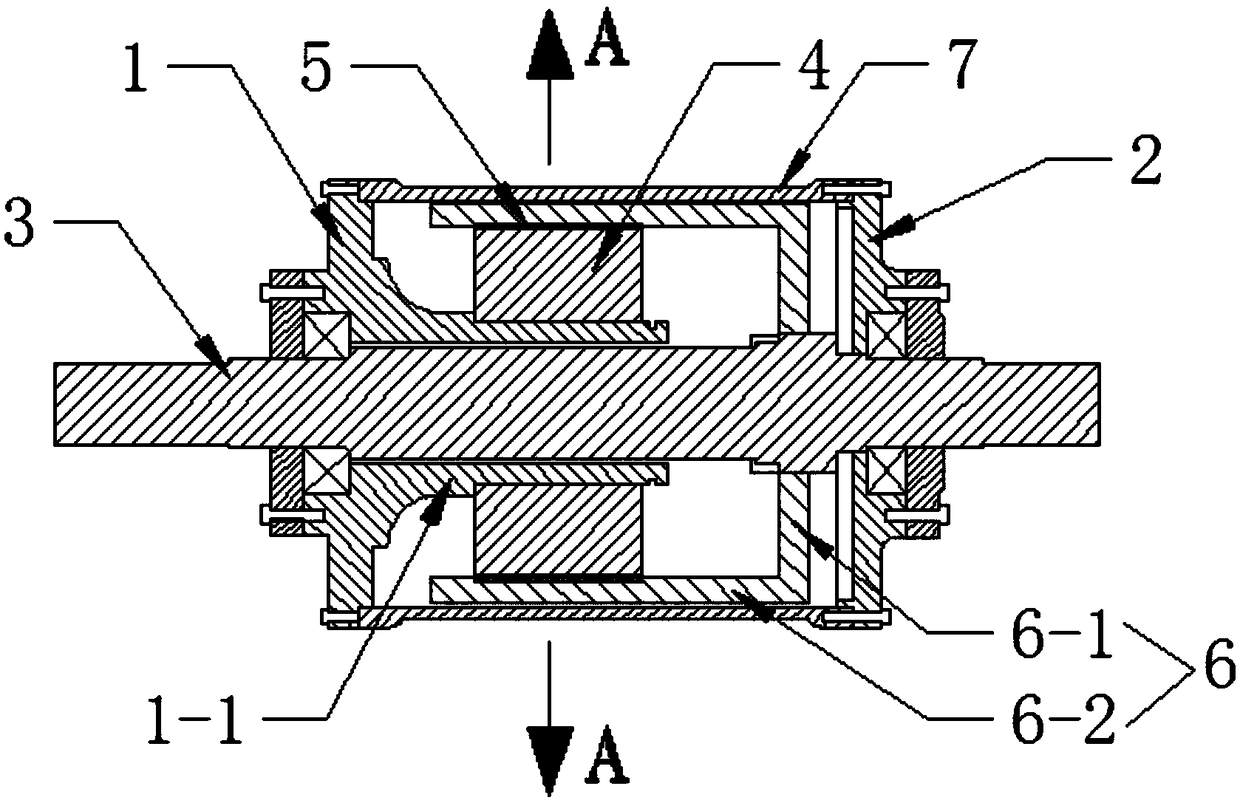

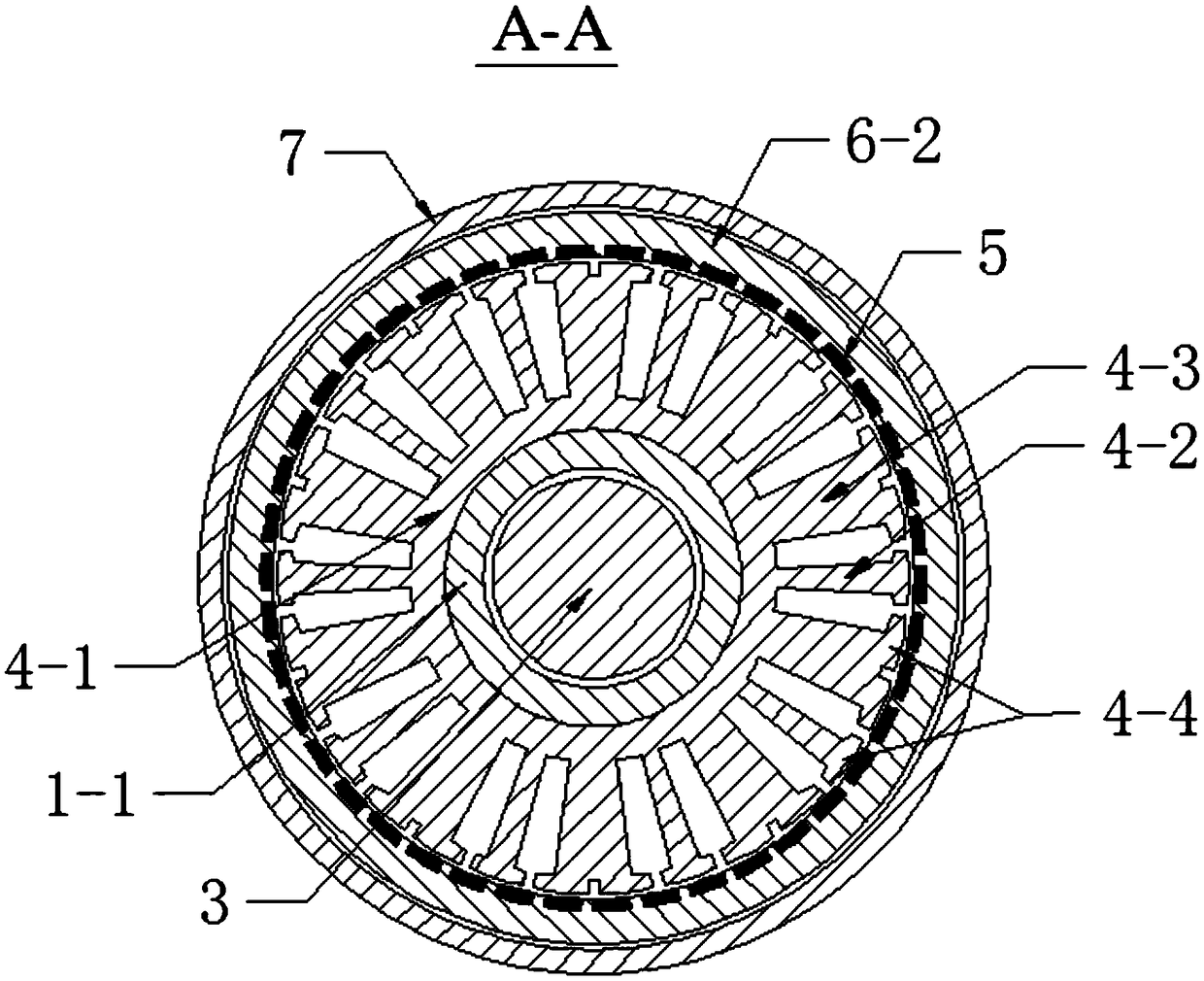

[0019] Specific implementation mode one, see figure 1 with figure 2 Describe this embodiment, the eccentric gear permanent magnet vernier motor described in this embodiment includes a casing 7, a stator 4, a cup-shaped rotor 6 and an output shaft 3; the casing 7 is a cylindrical structure, and the two ends of the casing 7 It is blocked by the left end cover 1 and the right end cover 2 respectively, the output shaft 3 runs through the two end covers, the left end cover 1 extends to the inside of the casing 7 around the output shaft 3 to form a base 1-1, and the base 1-1 and the output shaft 3 There is an air gap between them; the stator 4 is fixed on the outside of the base 1-1, the cup bottom 6-1 of the cup-shaped rotor 6 is fixed on the output shaft 3, and the cup body 6-2 of the cup-shaped rotor 6 is set on the machine Between the shell 7 and the stator 4, and the opening end faces the left end cover 1, there is an air gap between the stator 4 and the casing 7 and the cup-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com