Waste reinforcing steel bar cut-off machine capable of conducting cut-off twice

A steel bar cutting machine and cutting machine technology, which is applied in the field of steel bar processing equipment, can solve the problems of high power, increase the production and use cost of the steel bar cutting machine, and high bearing strength requirements, achieve low power, low bearing strength requirements, and save energy. The effect of the cutting knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

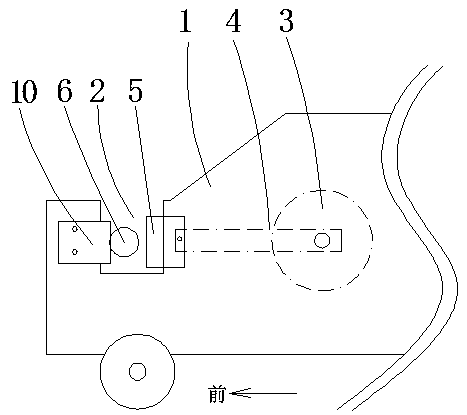

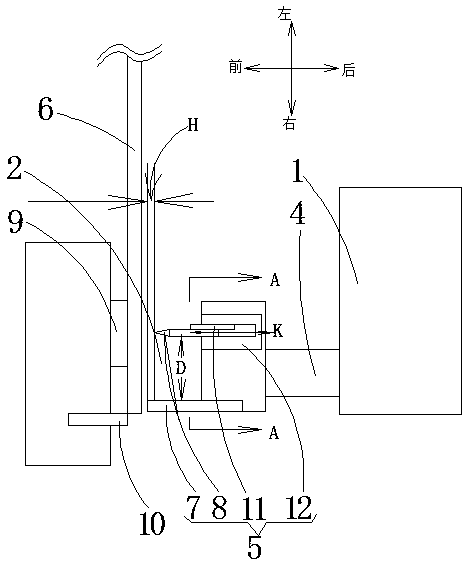

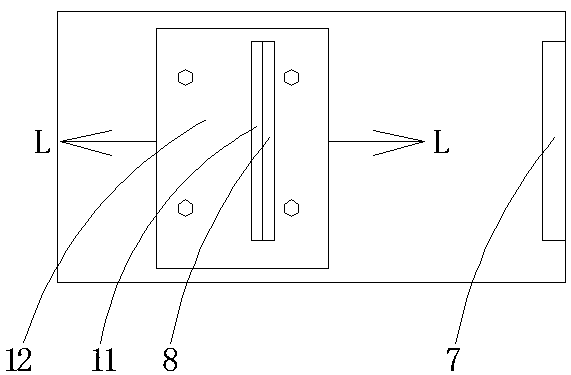

[0022] like figure 1 , 2 . As shown in 3, the scrap steel cutting machine for secondary cutting includes a cutting machine body, and the cutting machine body includes a casing 1, which has a knife edge 2 for cutting steel bars on the casing, and a cutting knife installed on the knife edge On the side, the motor is also connected to the cutting knife 5 through the speed change gear 3 and the connecting rod 4. The cutting knife has a cut-off position, and the length direction of the cut-off position according to the steel bar 6 is from left to right. It is characterized in that: The cutting knife described has the first blade portion 7 on the right side and the second blade portion 8 on the left side, the second blade portion is at a distance of 10-12 centimeters behind the first blade portion, figure 2 D in is the distance between the second blade behind the first bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com