Silver sheet feeding device for silver spot riveting machine

A technology for riveting silver dot machines and silver flakes, which is applied in the field of silver flake feeding devices, can solve problems such as unfavorable promotion and application of riveting silver dot machines, affecting the processing efficiency of riveting silver dot machines, and the probability of silver flakes falling, and achieves effective Facilitate popularization and application, reduce the probability of falling, and ensure the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

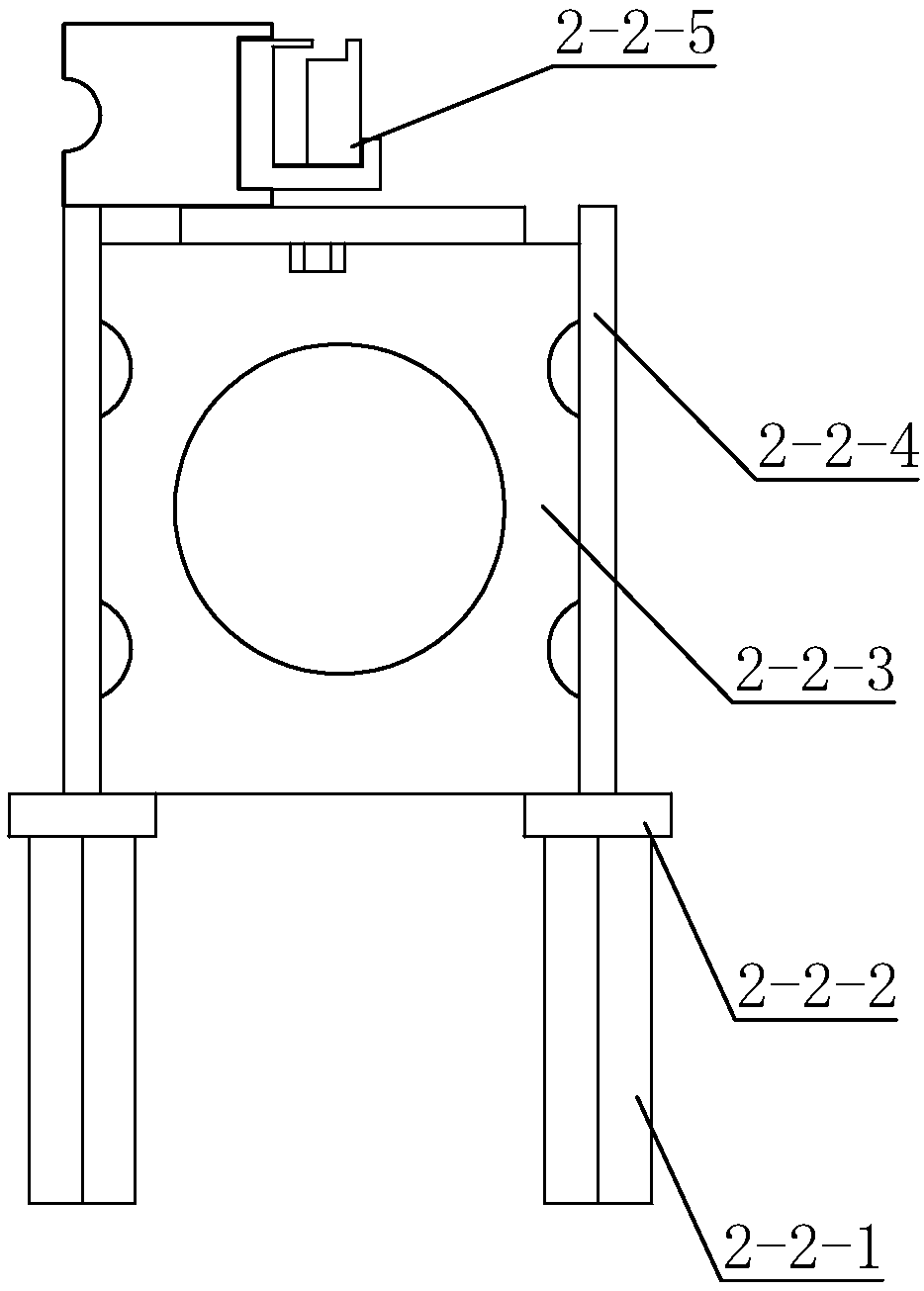

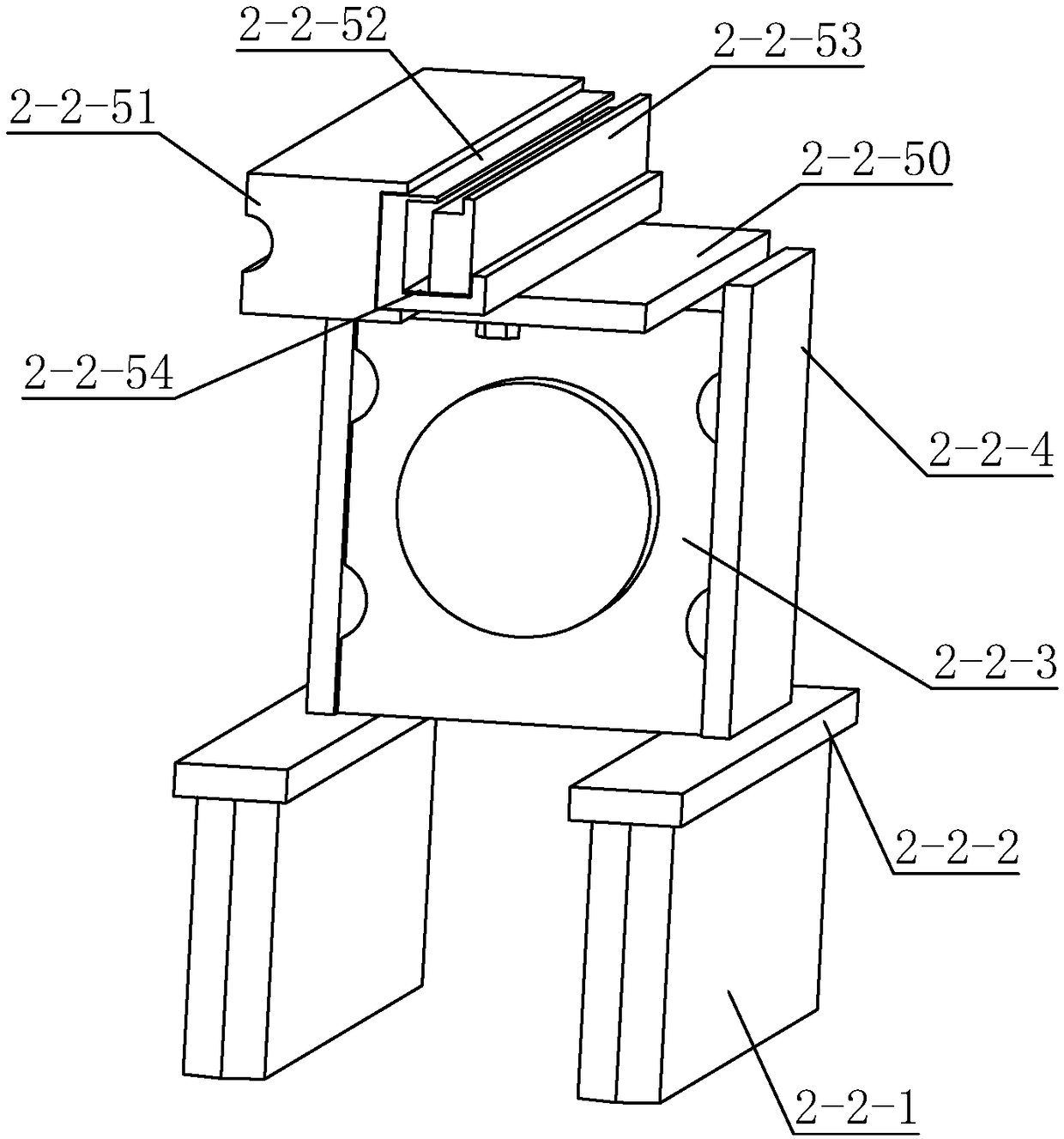

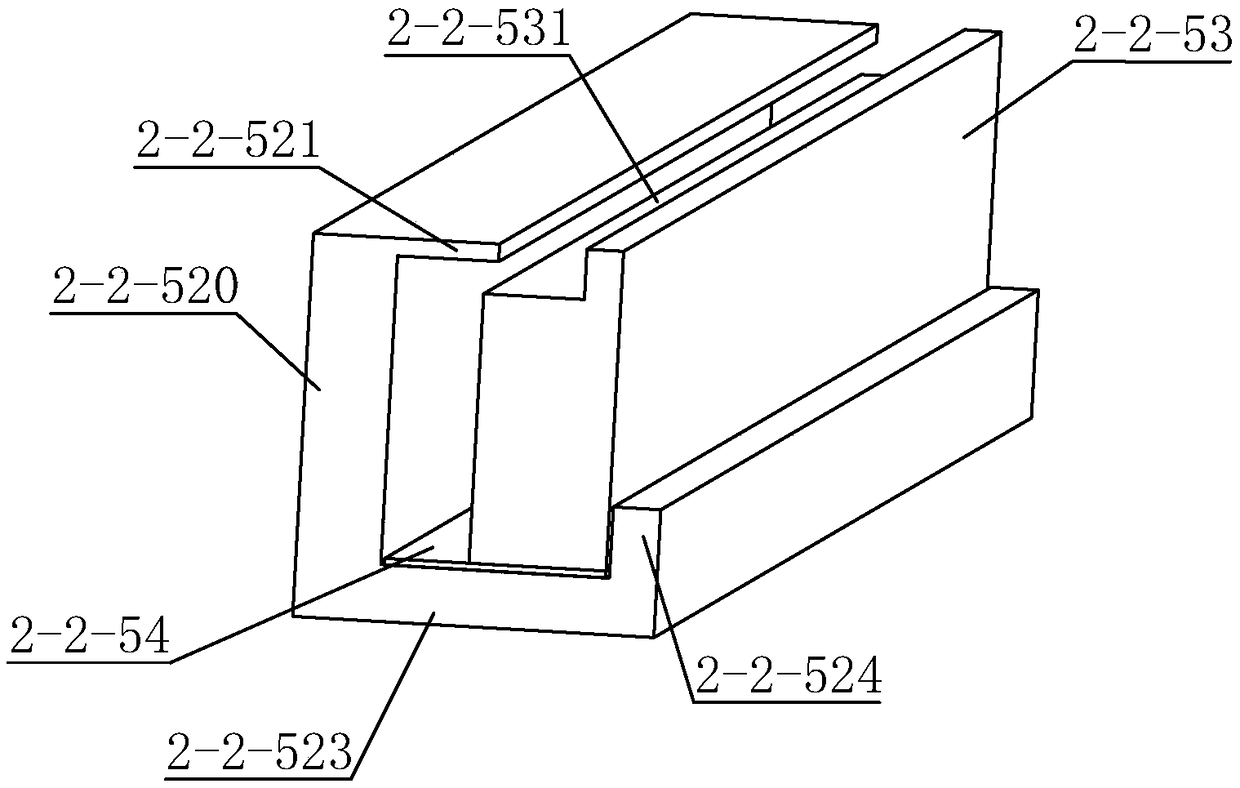

[0026] Example: such as Figure 1 to Figure 4 As shown, the silver sheet feeding device for the riveting silver point machine includes a silver sheet feeding frame 2-2-1, a silver sheet feeding divider 2-2-3 and a silver sheet feeding mechanism 2-2-5. The material frame 2-2-1 is fixedly installed on the frame of the riveting silver point machine, which is convenient for operating the silver point silver pieces. The silver piece feeding divider 2-2-3 is a cam divider, which is a high-precision In the present embodiment, the use of the divider is particularly important for the automation of the riveting silver point machine, which is used to drive the silver sheet feeding mechanism 2-2-5 to transport the silver sheet.

[0027] The silver sheet feeding divider 2-2-3 is fixedly installed on the above-mentioned silver sheet feeding frame 2-2-1 to ensure the stability of the silver sheet feeding divider 2-2-3 during use, and the silver sheet feeding mechanism 2 -2-5 is installed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com