High speed welding device

A welding device and high-speed technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of reducing the number of welding work and efficiency, and can not be carried out at the same time, to achieve the effect of simple structure, easy operation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0015] The first embodiment of the present invention provides a high-speed welding device, the purpose is to set the cutting device for cutting the silver contact strip and the welding device for welding the silver contact strip on the reed strip into two independent The device mechanism can independently perform cutting and welding work without interfering with each other, which increases the number of cutting and welding operations per minute, improves the overall welding work efficiency, and has a simple structure and is easy to operate.

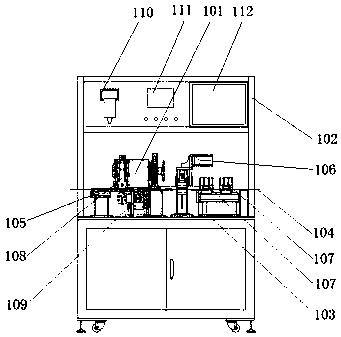

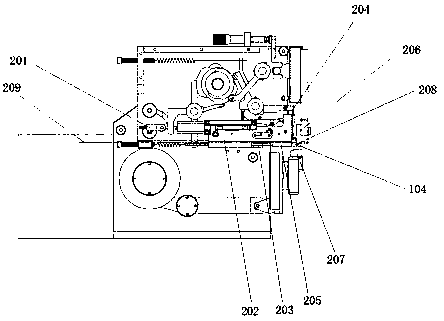

[0016] like figure 1 As shown, a high-speed welding device is used to weld the silver contact strip 209 on the reed strip 104, including a high-speed welding machine 101, a frame 102, a workbench 103 and a control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com