Patents

Literature

37results about How to "Increase the number of jobs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

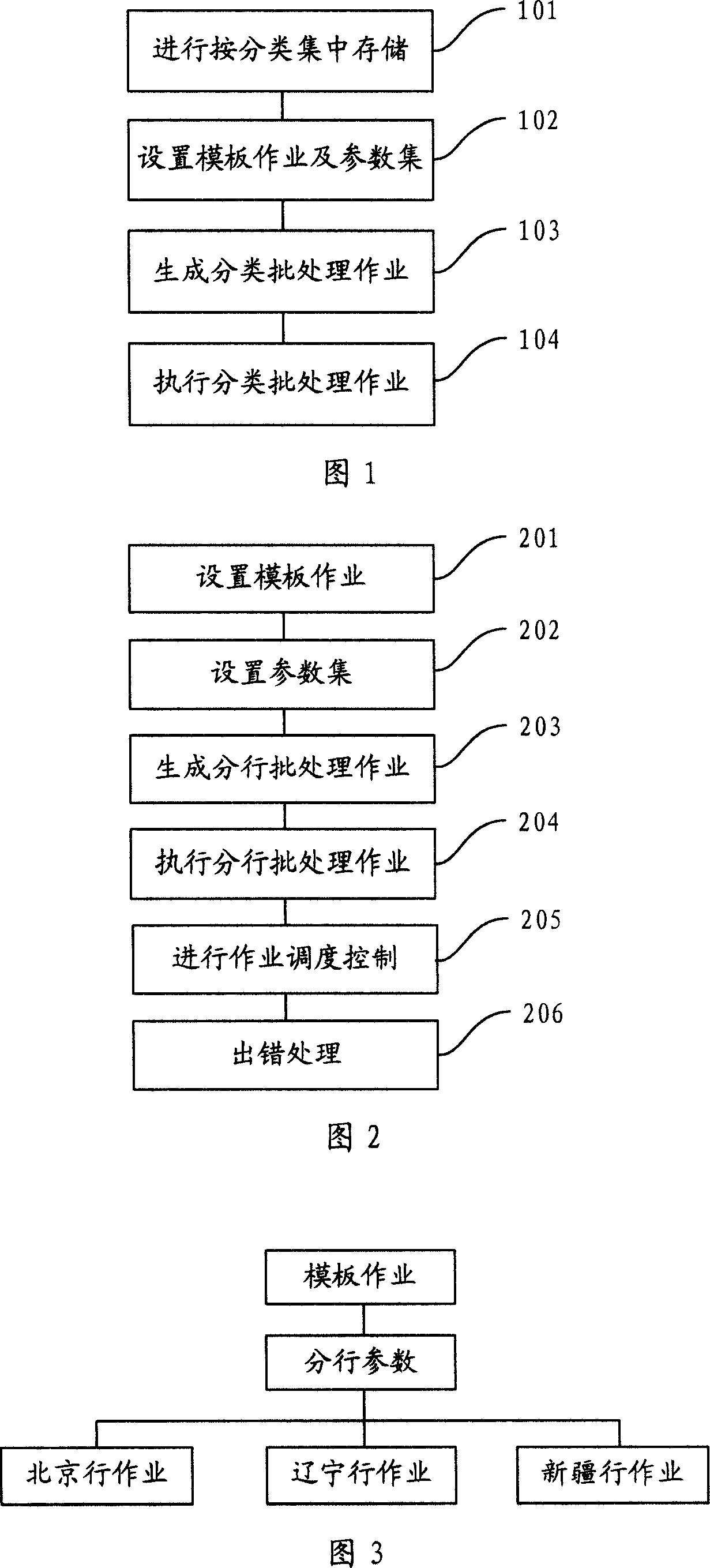

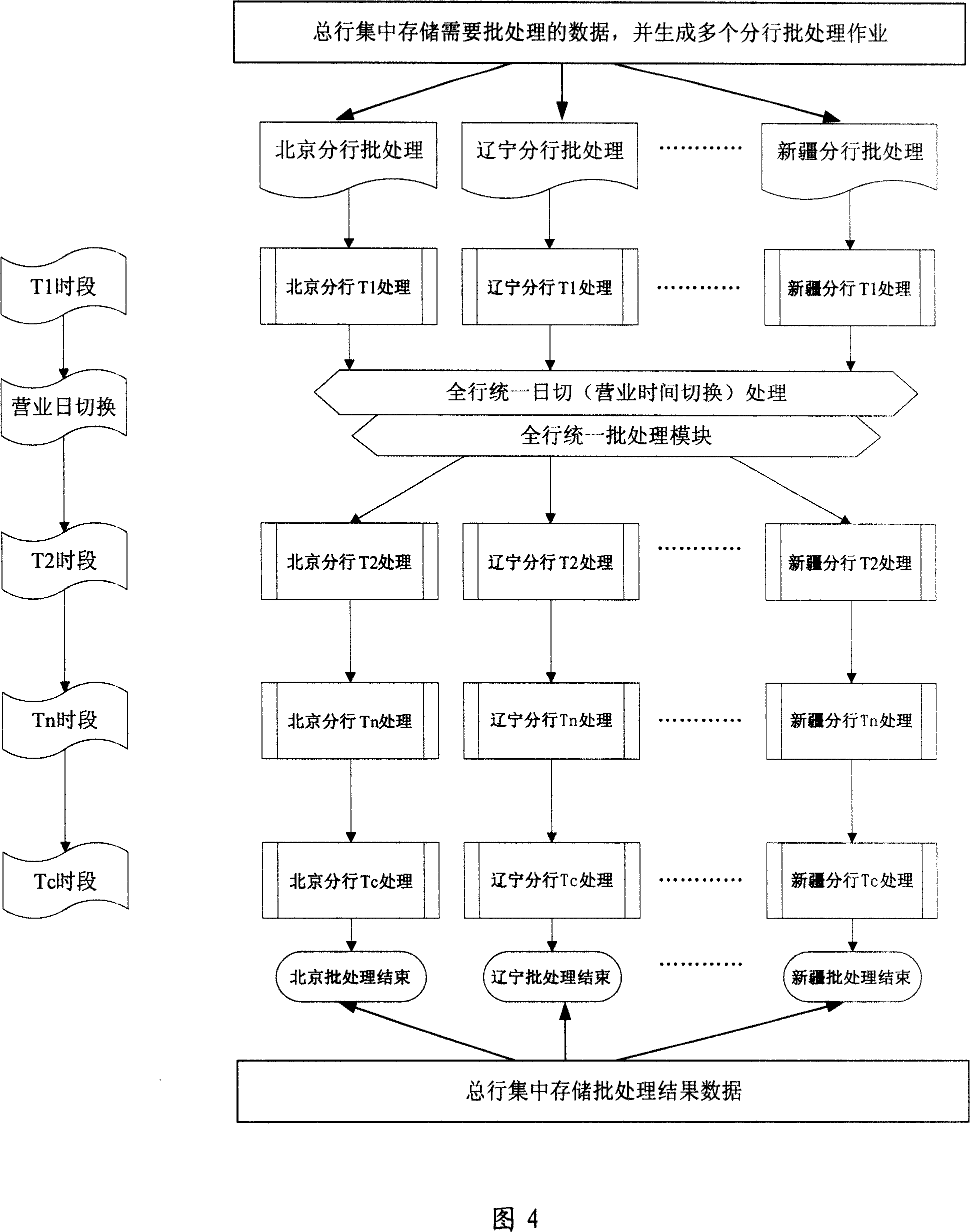

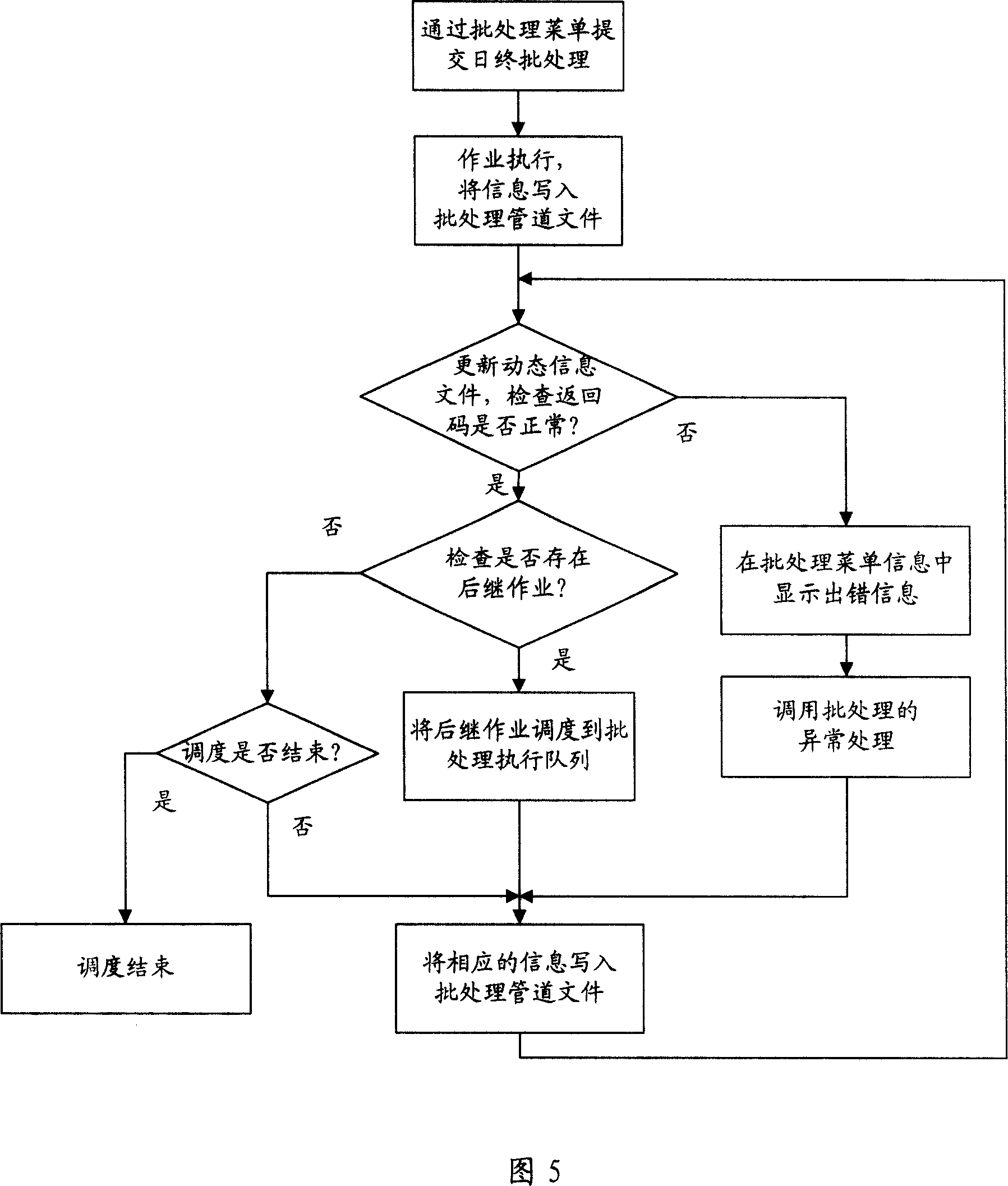

Method and device for categorical data batch processing

InactiveCN101017546AImprove processing efficiencyGood processing effectivenessFinanceMultiprogramming arrangementsBatch processingData mining

This invention discloses one method and device to sort data batch process, which comprises the following steps: integrating and storing disperse stored data; setting mode operation and parameters set to store different sorts of data process parameters; the said mode board is to generate different sort data batch process; according to the mode operation and the said parameters generation different sort of data batch; executing the said operations. This invention legally uses systematic materials to quicken process operation speed.

Owner:CHINA CONSTRUCTION BANK

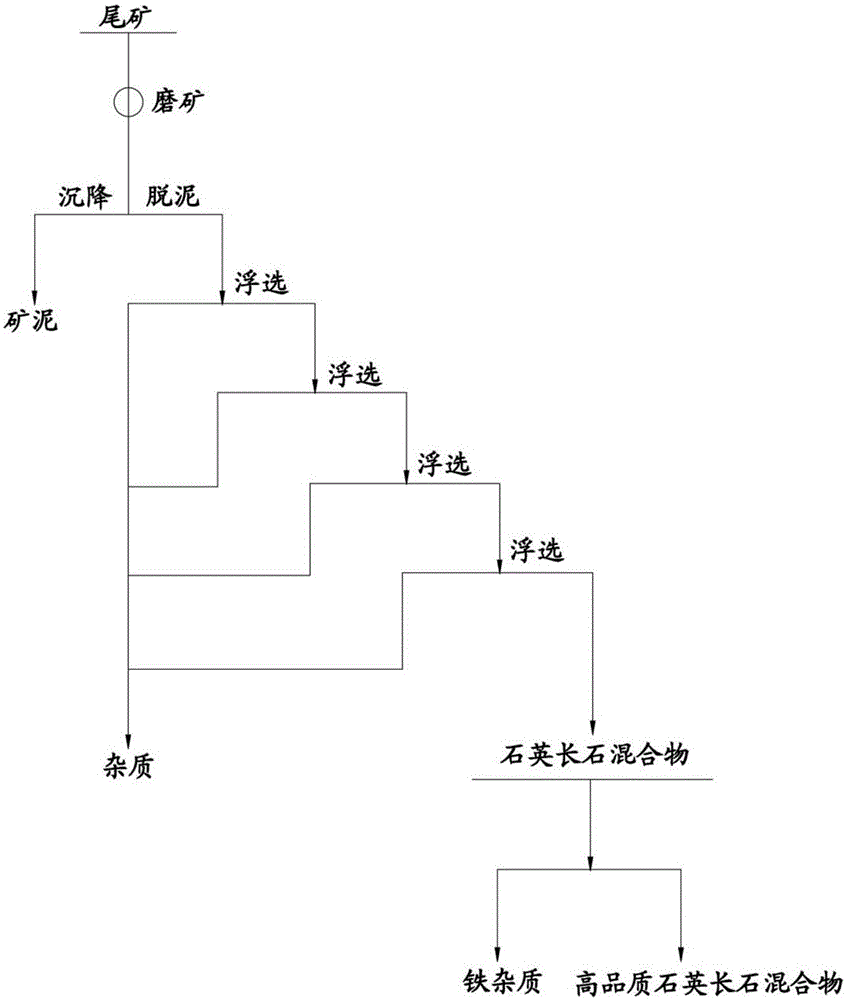

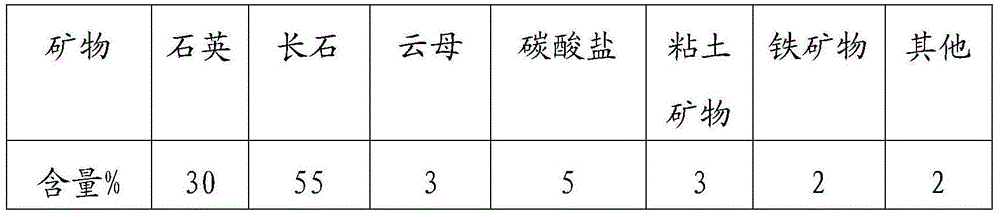

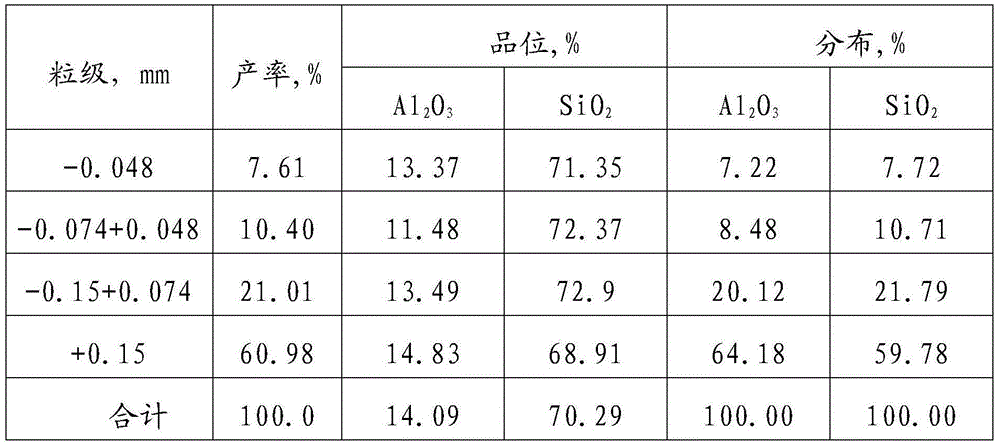

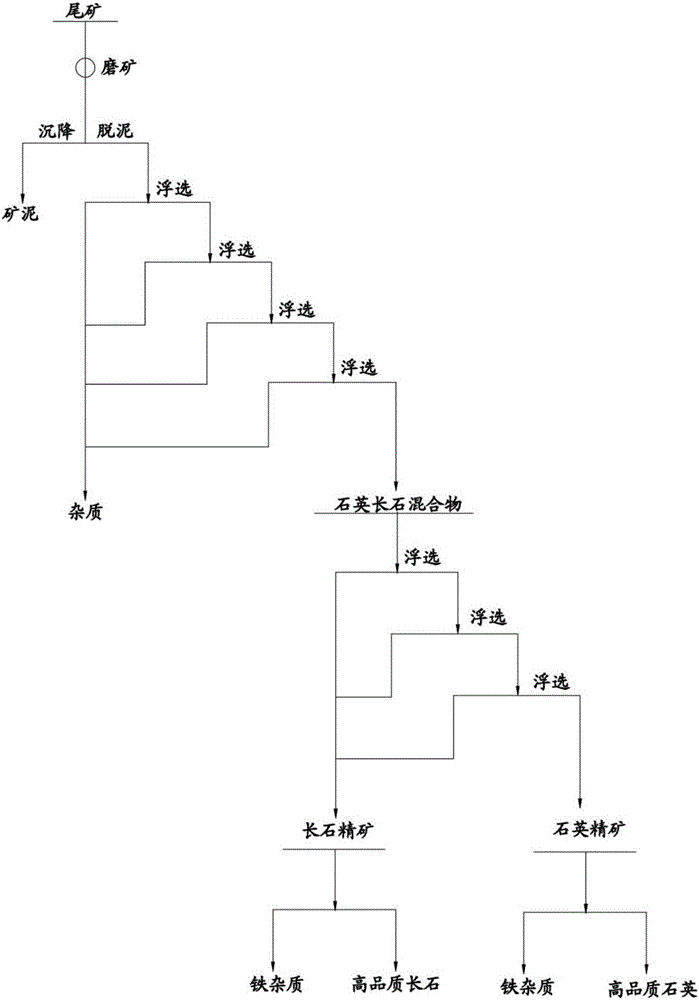

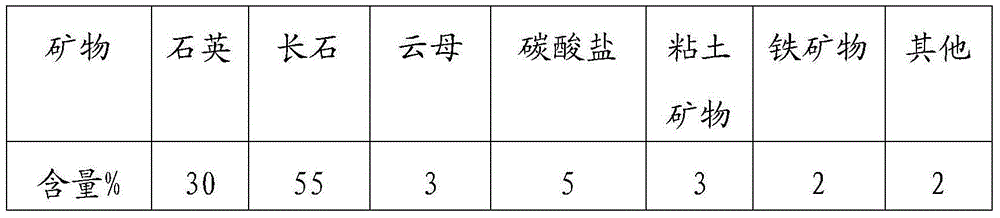

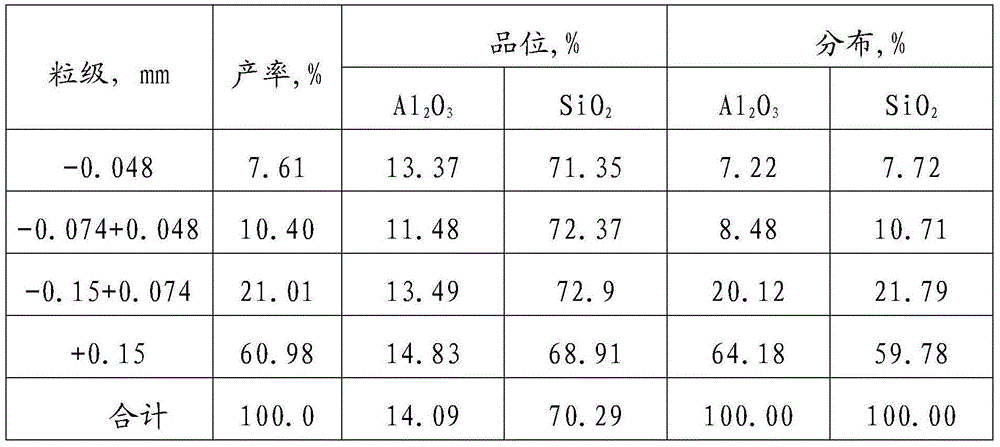

Method for recycling quartz and feldspar mixtures from gold flotation tailings

The invention belongs to the technical field of tailing treatment and particularly relates to a method for recycling quartz and feldspar mixtures from gold flotation tailings. A sedimentation desliming method is adopted for removing harmful slime and meanwhile part of iron impurities are removed. Sodium carbonate is adopted for a regulating agent for restraining flotation of quartz and feldspar. YOA is adopted as a collecting agent for obviously removing carbonate mineral impurities in the tailings and part of iron impurities at the same time. The frequency of operation of flotation impurity removal is increased, so that the removing rate of iron and other impurities is obviously increased, and the levels of aluminum oxide and silicon oxide are greatly improved. By the adoption of the method, the recycling rate of recycled quartz and feldspar mixture products is over 75%, and the quality of the products is close to that of second-level feldspar products or glass-level albite products. The process flow of the method is simple, production cost is low, secondary environmental pollution is avoided, and quartz and feldspar resources in the gold flotation tailings can be used to the maximum extent.

Owner:SHANDONG HUASHENG INVESTMENT CO LTD

Austenitic stainless steel continuous tube with low carbon and high strength and preparation method thereof

The invention discloses an austenitic stainless steel continuous tube with low carbon and high strength and a preparation method thereof. The austenitic stainless steel continuous tube comprises the components in percentage by mass: at most 0.03% of C, at most 1.00% of Si, 4.00-8.00% of Mn, at most 0.050% of P, at most 0.005% of S, 18-20% of Cr, 3-5.0% of Ni, 1.2-3.5% of Cu, 0.20-0.30% of N, at most 0.3% of Mo and the rest Fe and unavoidable impurities. The preparation method comprises the steps of (1) manufacturing a coil plate; (2) longitudinally shearing the coil plate and lengthening a steel band; and (3) forming the steel band, using laser welding, conducting rapid cooling after welding, and thus obtaining the stainless steel continuous tube. The produced continuous tube has high strength, low cost and good corrosion resistance by optimizing the alloy content and improving the manufacturing process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

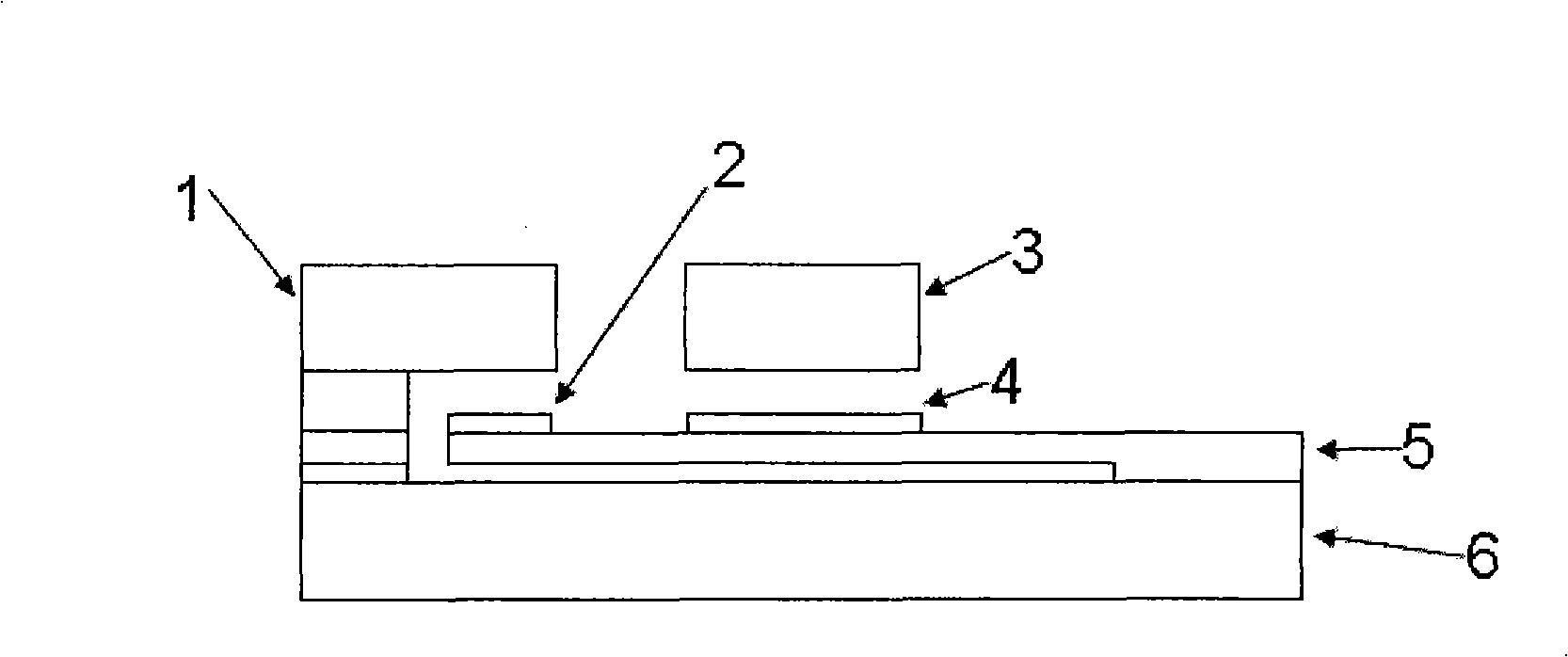

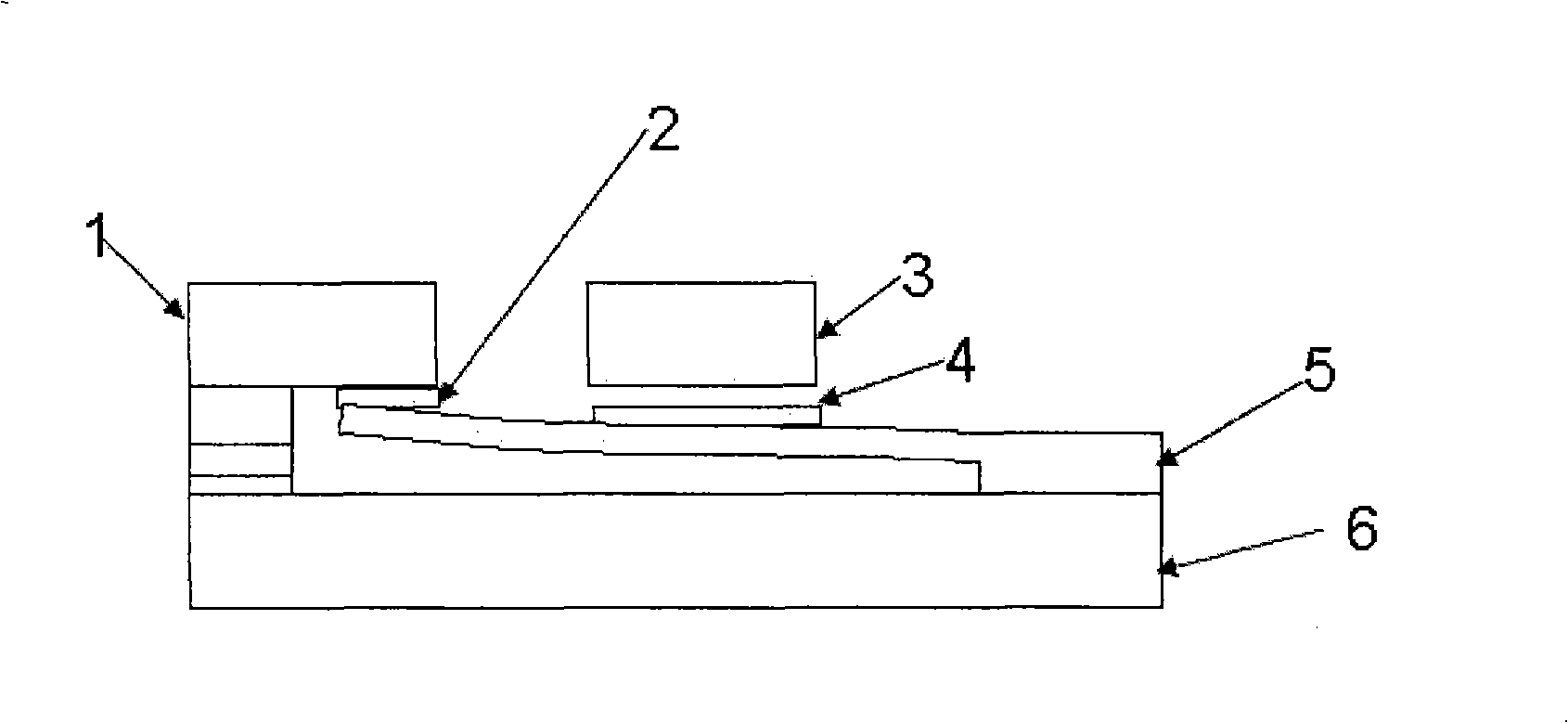

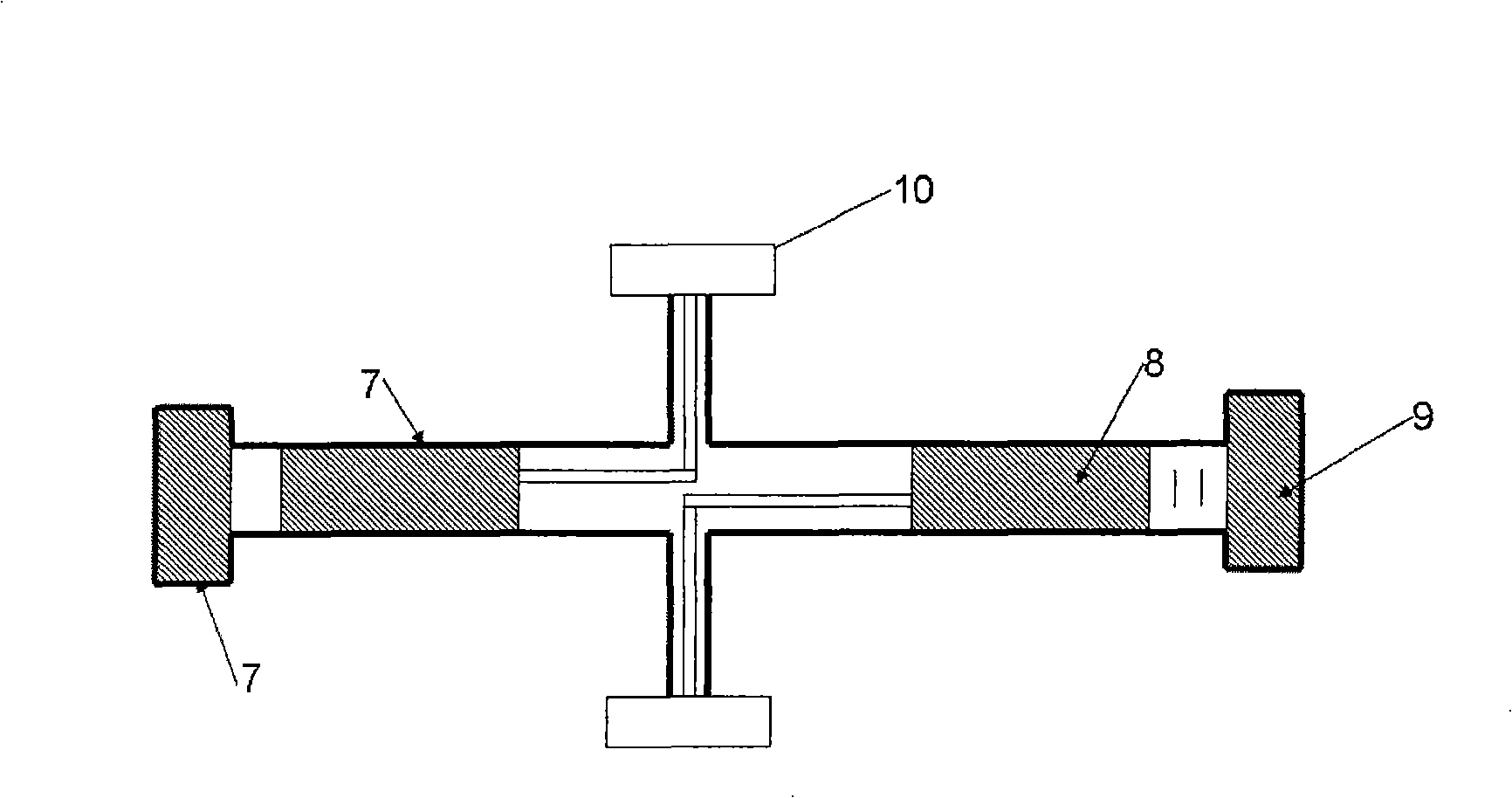

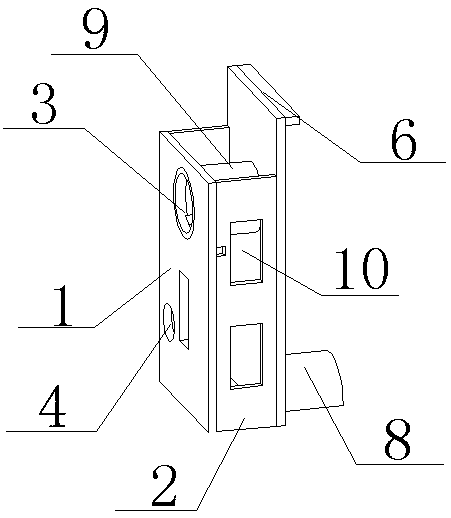

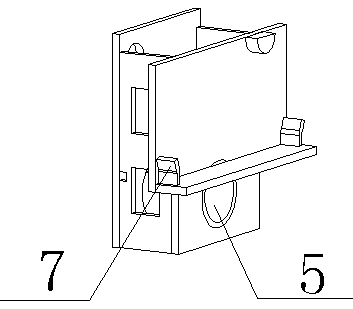

Radio frequency micro electromechanical system switch of electrostatic push-draw type monocrystaline silicon beam

ActiveCN101276708AReduce spacingReduce the driving voltageElectrostatic/electro-adhesion relaysRadio frequency microelectromechanical systemPush pull

The invention relates to the technical field of radio frequency electromechanical system, and discloses an electrostatic push-pull type mono-crystal silicon beam radio frequency micro-electromechanical system switch comprising a switch movable portion and a switch immovable portion; the switch movable portion is formed by a top layer mono-crystal silicon of SOI, upper sides of two ends of the switch movable portion is respectively provided with a lower electrode and a contact; the switch immovable portion is fixedly connected with the top layer mono-crystal silicon of SOI, lower sides of two ends of the switch immovable portion and the position corresponding to the lower electrode of the switch movable portion are provided with upper electrodes, lower sides of two ends of the switch immovable portion and the position corresponding to the contact of the switch movable portion are provided with transmission wires; the upper electrodes and the lower electrodes form a push-pull type structure by respectively applying voltage to the upper electrodes and the lower electrodes of two ends in order to contact or disconnect the transmission wires and the contacts, thus realizing the switch movement. Usage of the invention can reduce the drive voltage, prolong the service life of the switch and make RF MEMS become products more likely.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for recycling single quartz and feldspar from gold flotation tailings

The invention relates to a method for recycling single quartz and feldspar from gold flotation tailings. Harmful slurry and part of iron impurities are removed through a settlement desliming method; sodium carbonate is adopted as regulators and plays a role in restricting flotation of the quartz and the feldspar, YOA is adopted as a collecting agent and removes carbonate mineral impurities in the tailings more obviously, and meanwhile part of iron impurities are removed; the removal rate of iron and other impurities is increased obviously by increasing the number of times of operations of flotation and impurity removal, and the grade of aluminum oxide and silicon oxide is greatly improved; sulfuric acid, hydrofluoric acid and lauryl amine are combined, so that the feldspar is activated sufficiently, the amount of the hydrofluoric acid is reduced, and the cost for dealing with environmental pollution and beneficiation wastewater is reduced. The quartz and the feldspar are dissociated sufficiently, the recovery rate of the feldspar is 47.01%, the recovery rate of the quartz is 22.54%, and the index reaches the quality standard of second-grade ceramic raw materials or the third-grade glass standard.

Owner:SHANDONG HUASHENG INVESTMENT CO LTD

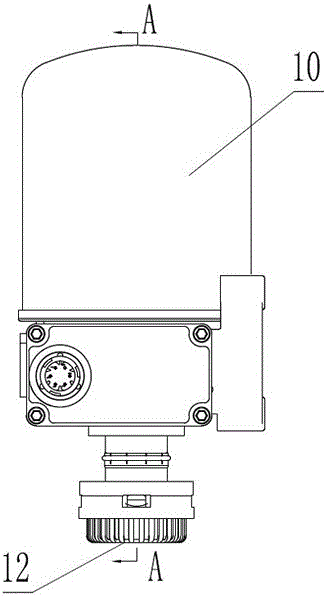

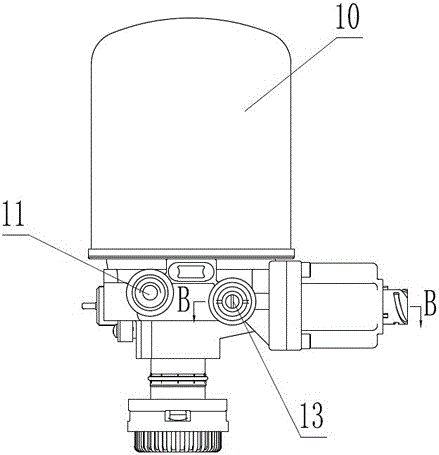

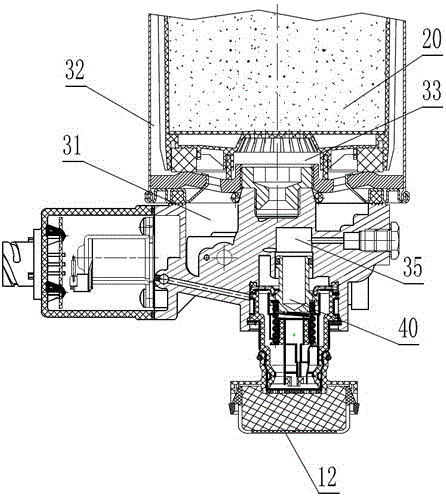

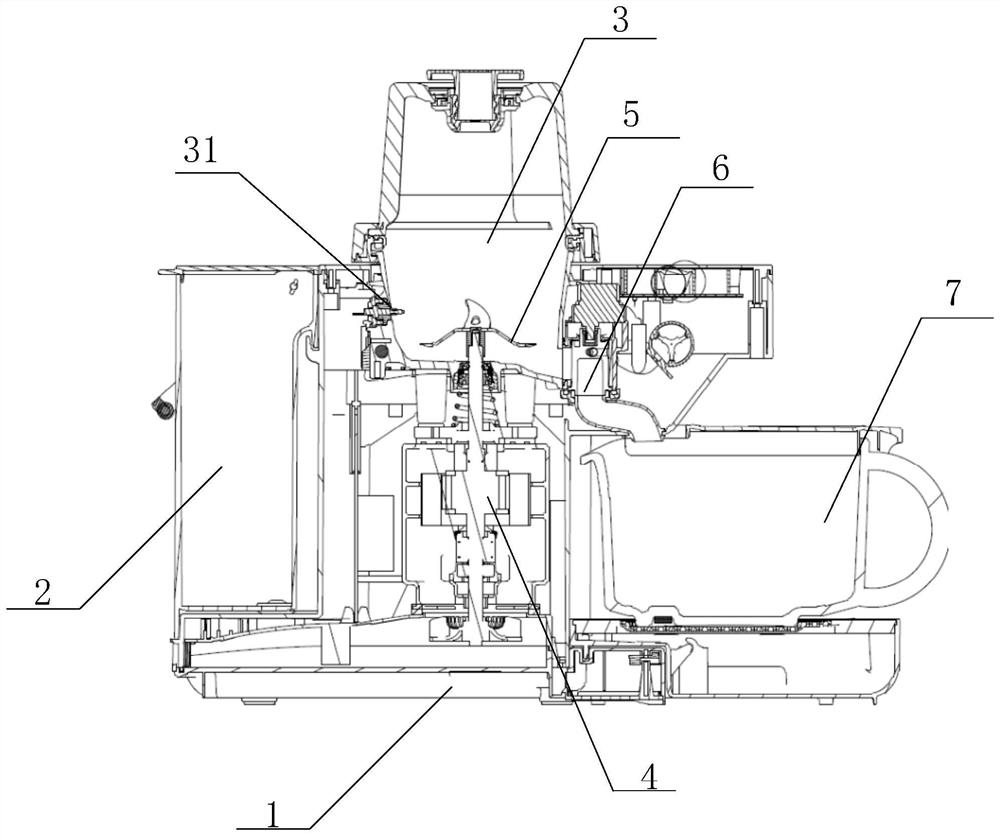

Electrically controlled dryer assembly with ECU (Electronic Control Unit) controller and control method

ActiveCN106512669AIncrease the number of jobsDispersed particle separationMolecular sieveControl theory

The invention relates to a dryer belonging to the field of automobiles, and specifically discloses an electrically controlled dryer assembly with an ECU (Electronic Control Unit) controller and a control method. The electrically controlled dryer assembly with the ECU controller has a protection function, namely when the pressure value of the dryer assembly is less than unloading pressure for a long time and reaches a set forced unloading pressure value for a period of time exceeding set time, the ECU controller controls an unloading electromagnetic valve assembly to be started to realize forced unloading and back flushing to protect the regeneration effect of a drying tank molecular sieve, and the service life of a dryer is greatly prolonged.

Owner:ZHEJIANG VIE SCI & TECH

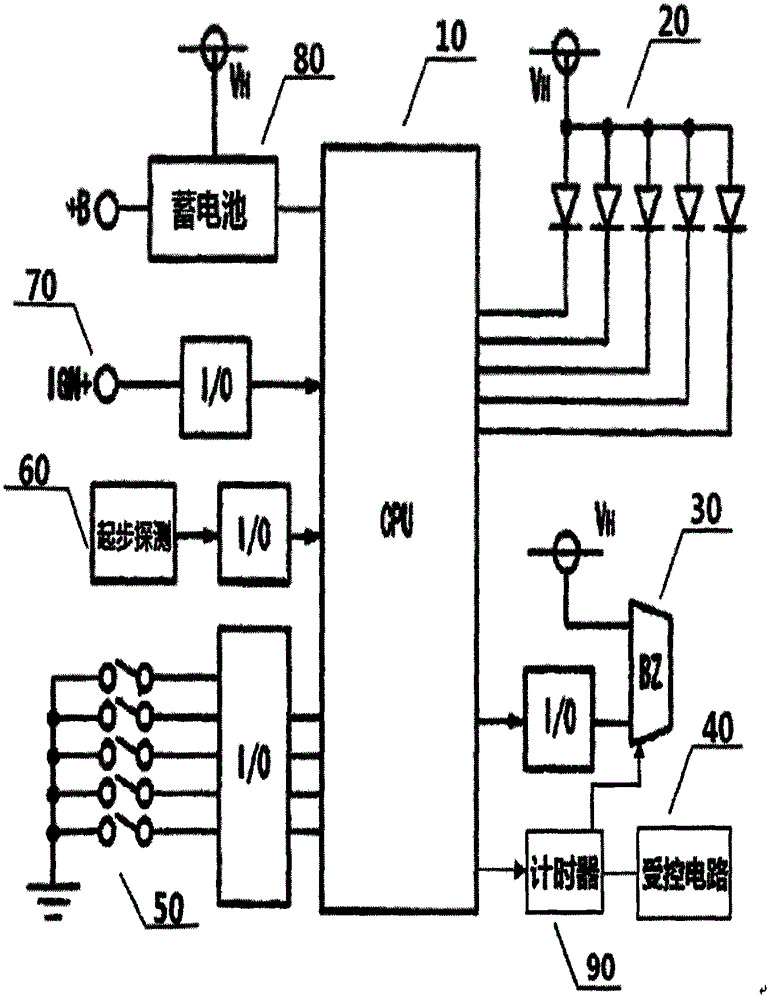

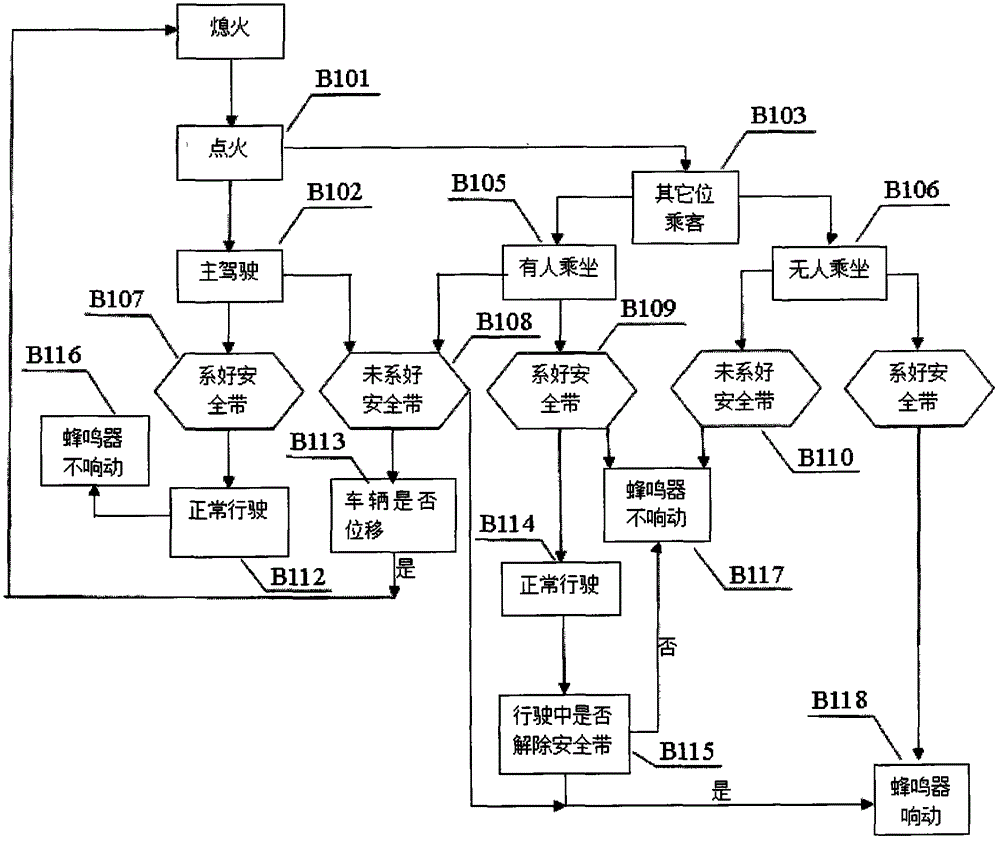

Safety belt mandatory usage device and safety belt mandatory usage method

The invention provides a safety belt mandatory usage device and a safety belt mandatory usage method of the safety belt mandatory usage device. By means of the safety belt mandatory usage device, a driver can start a car, but the car will be stopped after the car is started to run from a static state under the condition that the driver and other passengers do not fasten safety belts, and a buzzer gives out an alarm for prompting in the period. The car can normally run only when the driver and the other passengers start the car and fasten the safety belts. If someone on a seat except a seat of the driver releases the safety belt in the traveling process, the buzzer will continuously give out the alarm for prompting until the safety belt is fastened. If no person exists on a seat except the seat of the driver, but the safety belt is fastened, the buzzer will continuously give out the alarm for prompting until the safety belt is released.

Owner:仲自强

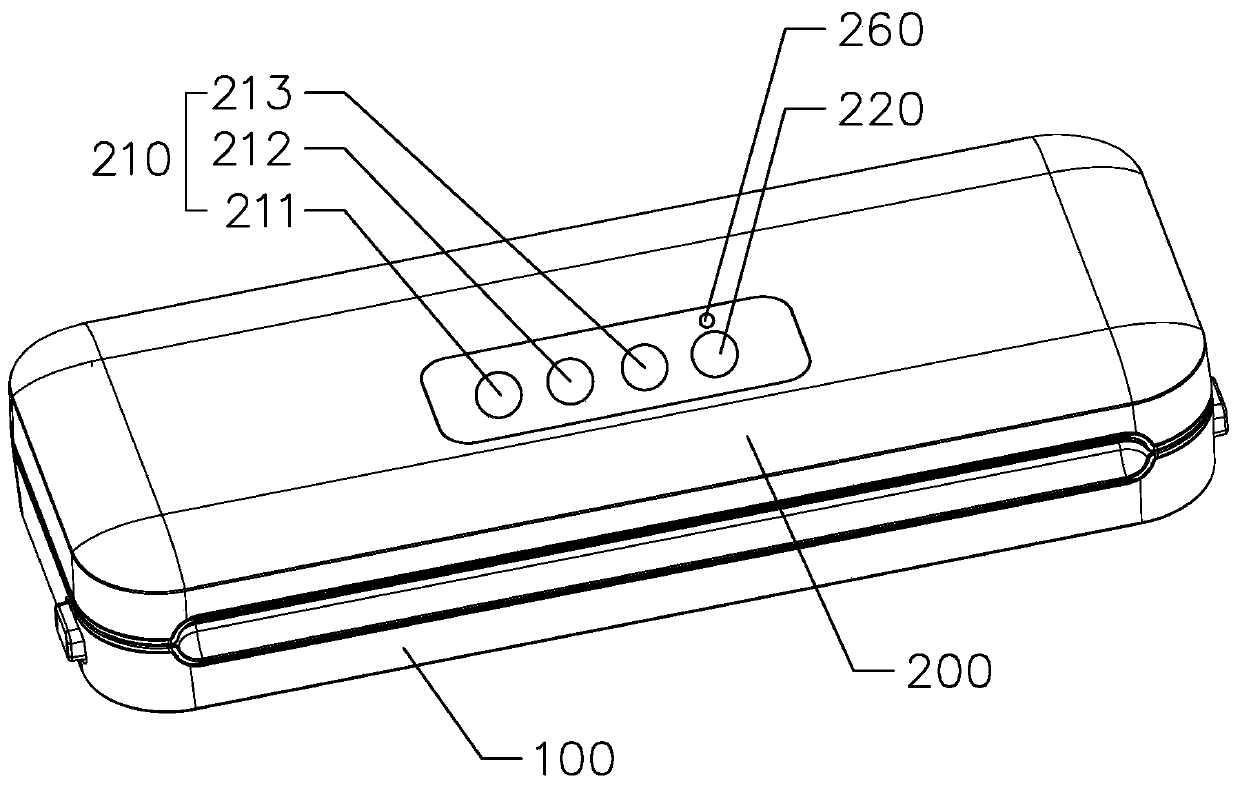

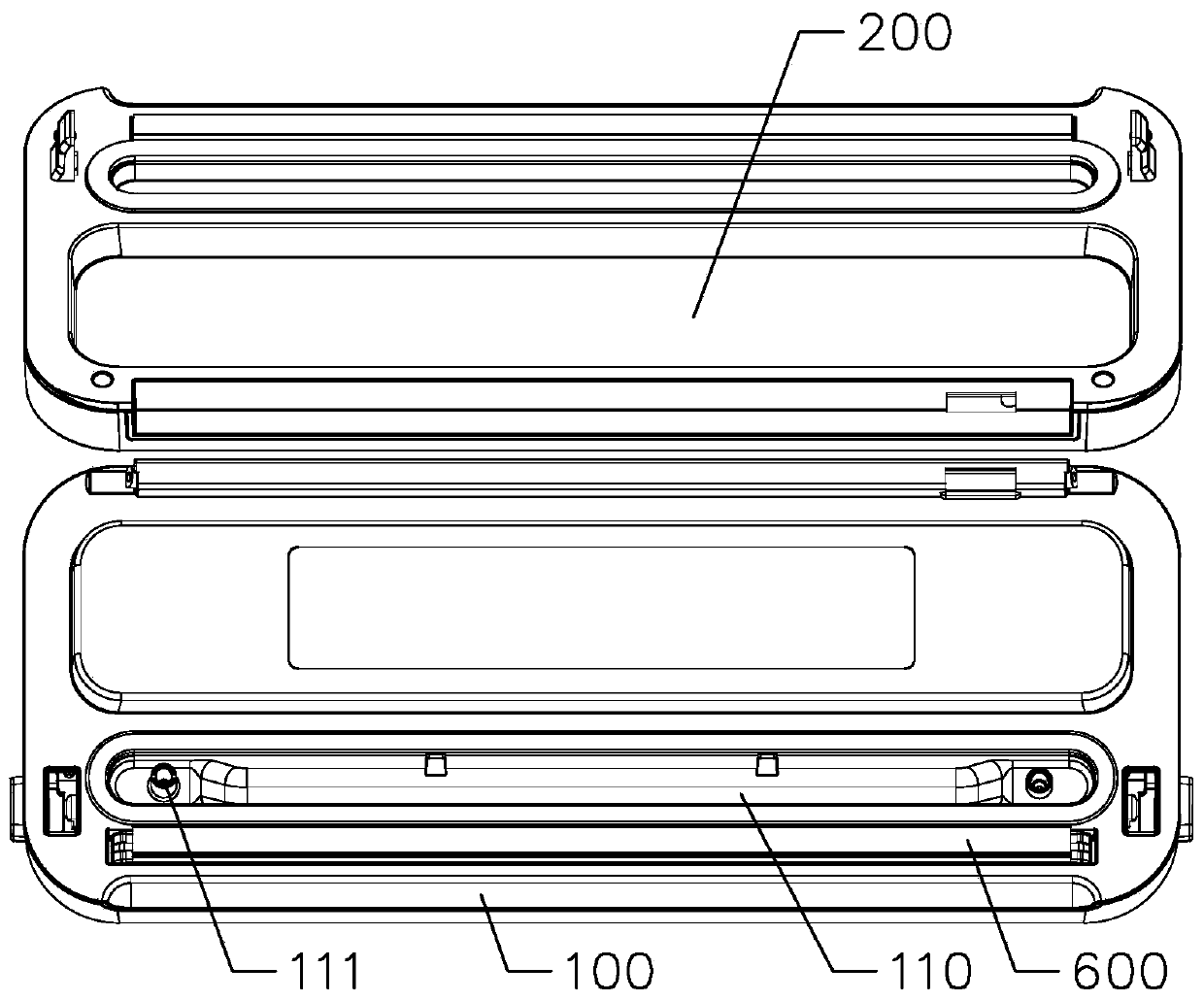

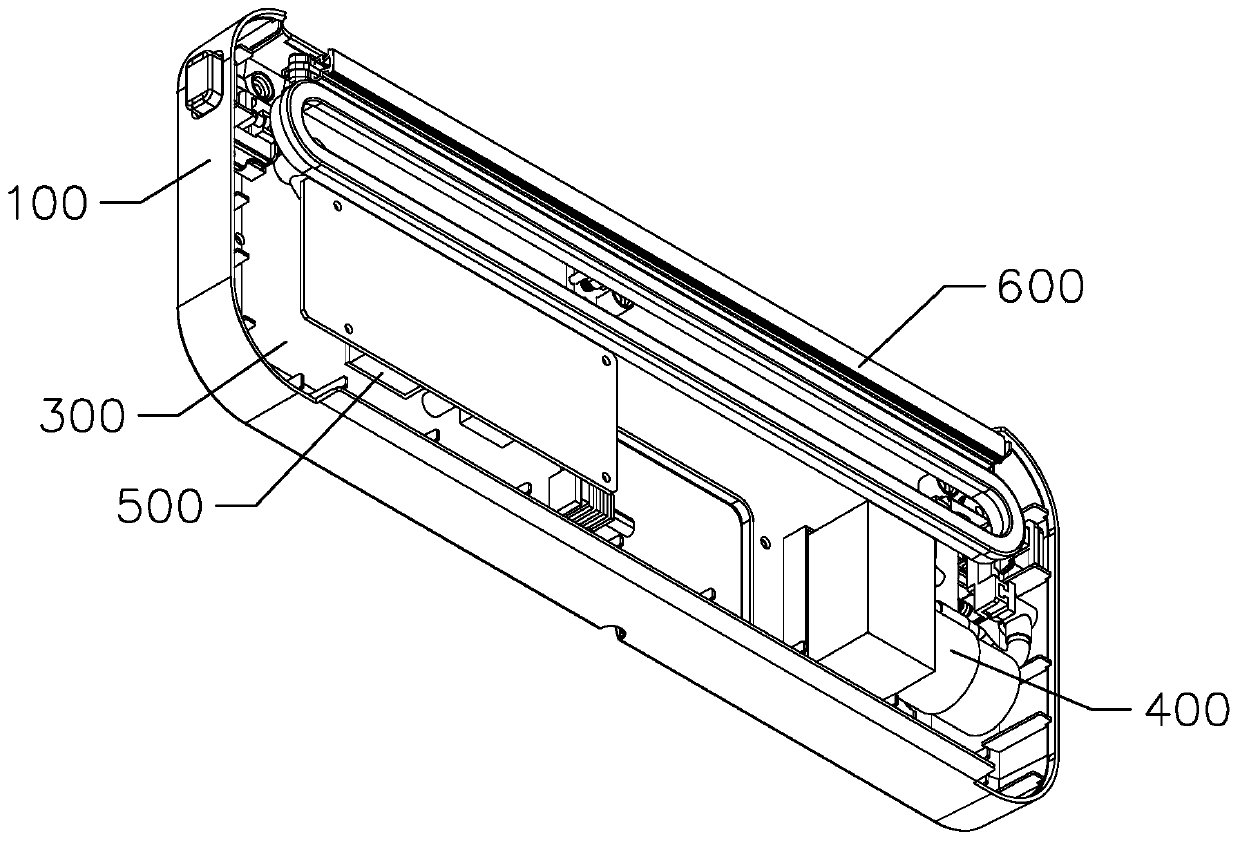

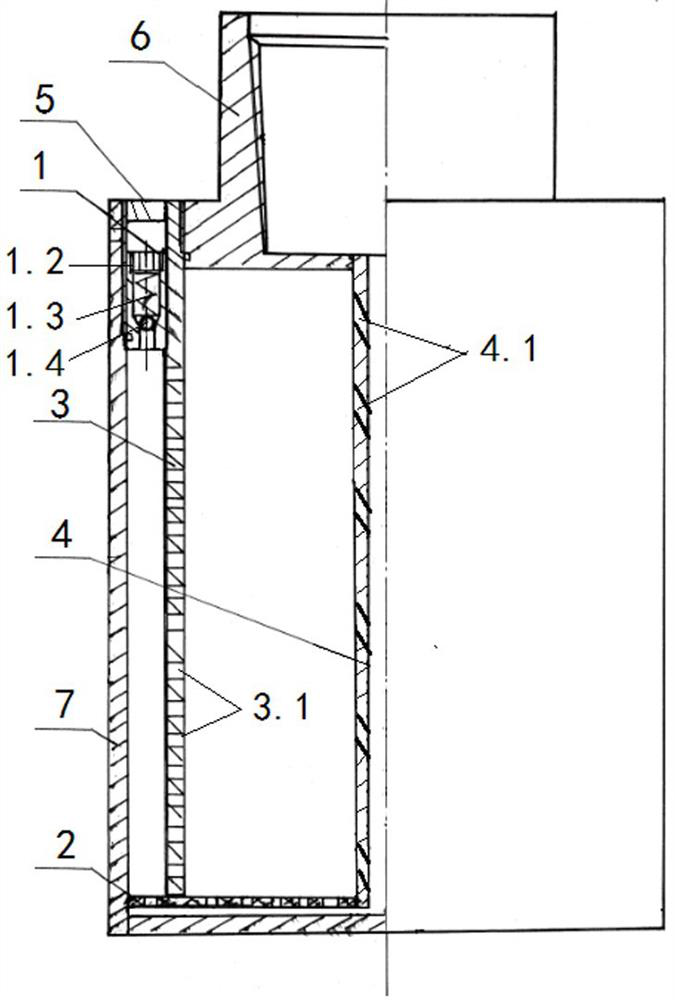

Vacuum packaging machine and use method thereof

InactiveCN110356625AVarious operating modesMeet different usage needsPackaging by pressurising/gasifyingWrapper twisting/gatheringOperation modeVacuum pump

The invention provides a vacuum packaging machine and a use method thereof. The vacuum packaging machine comprises a machine body, a gland rotatably connected to the machine body, a control plate, a vacuum pump, a pressure switch, a vacuumizing groove and a sealing device, wherein the pressure switch and the vacuum pump respectively communicate with the vacuumizing groove; the pressure switch, thevacuum pump and the sealing device are respectively electrically connected with the control plate; a function switching key and mode switching key are arranged on the gland; the function switching key is capable of switching among vacuum sealing function, vacuumizing function and sealing function according to needs to diversify operating modes of the vacuum packaging machine; the mode switching key is capable of switching between wet mode and dry mode according to the dry and wet states inside the package; and the mode switching key is electrically connected with the control plate and the working parameters of the vacuum pump and the sealing device are controlled through the control plate, so that the application range of the vacuum packaging machine is wider to meet different requirements of users. According to the vacuum packaging machine and the use method, different packages can be packaged, the application range is wider, and the operation is simple and convenient.

Owner:杭州青晓白科技有限公司

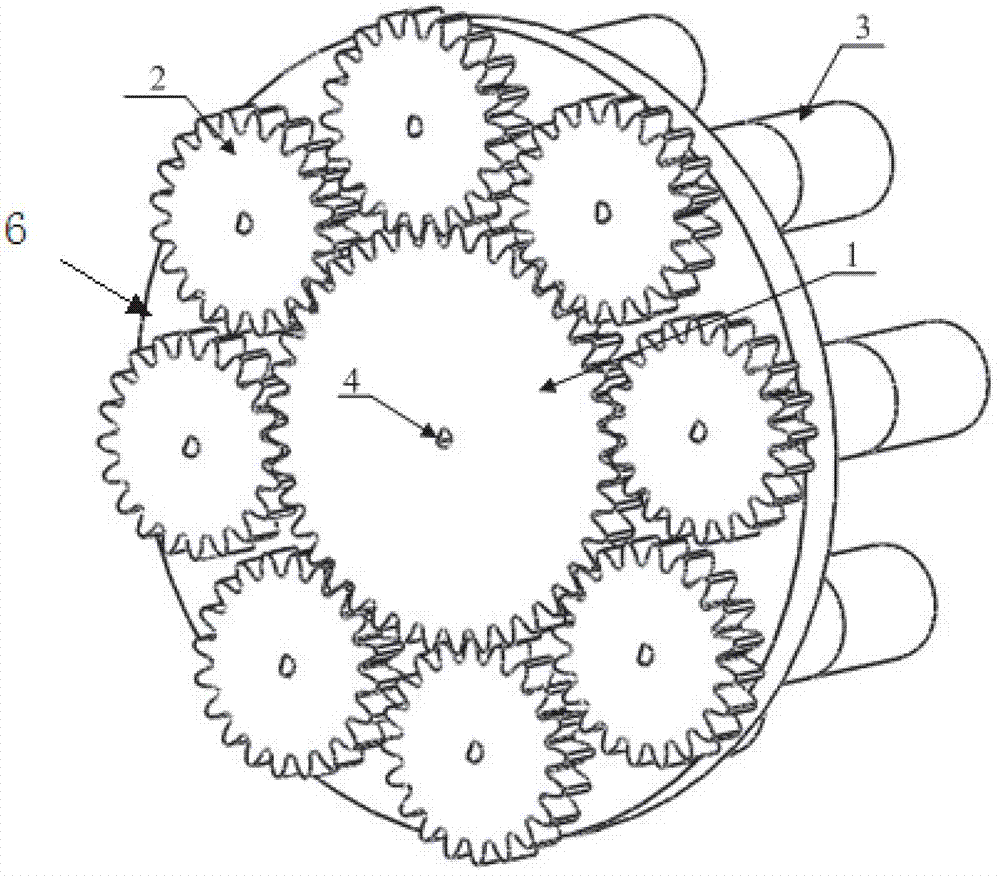

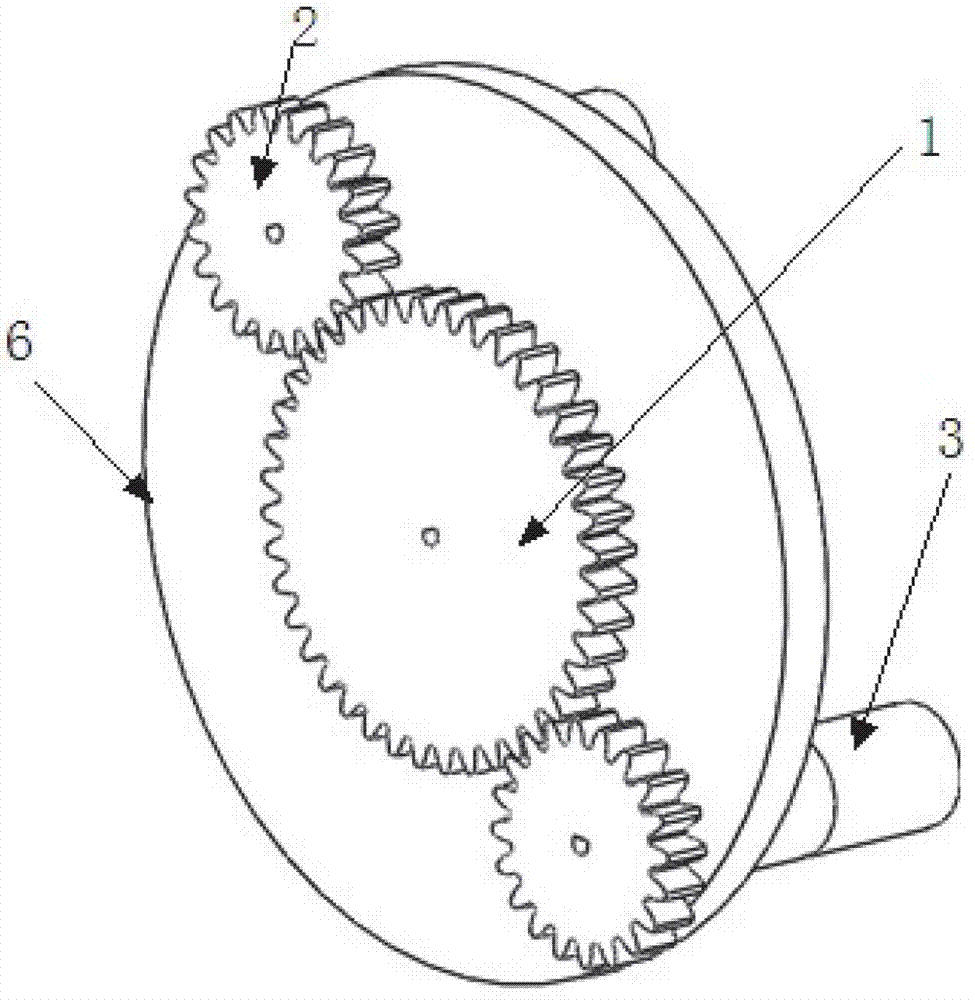

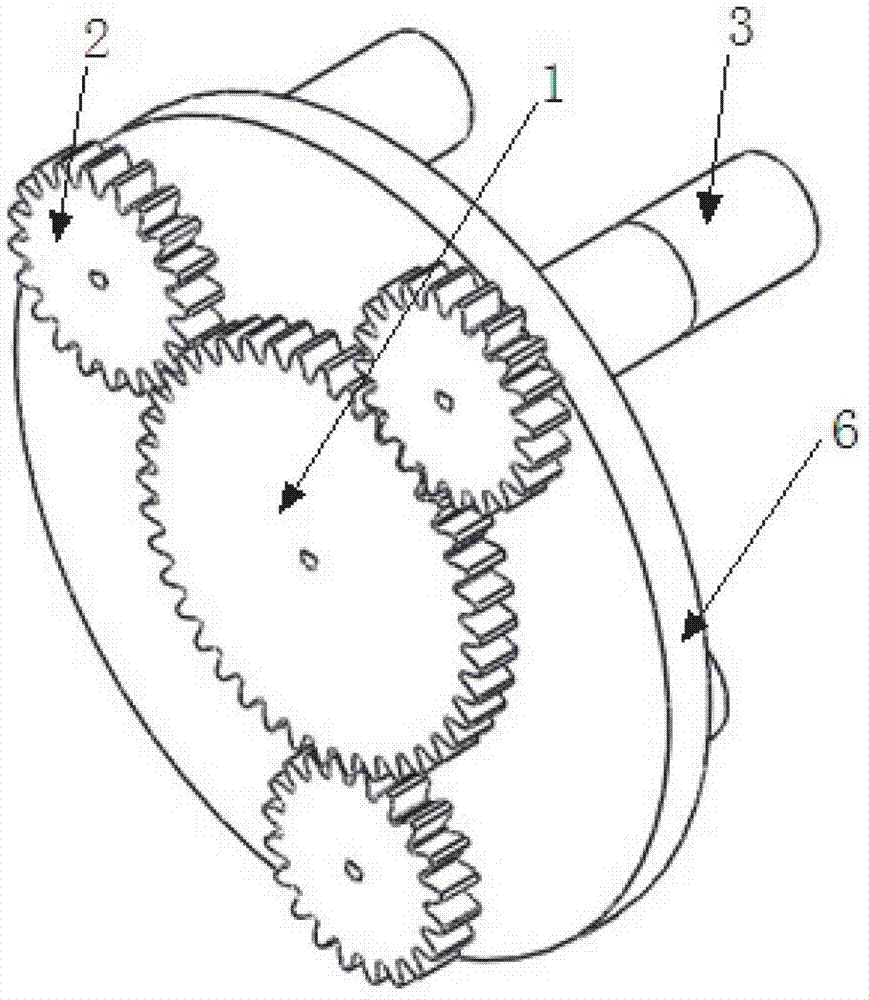

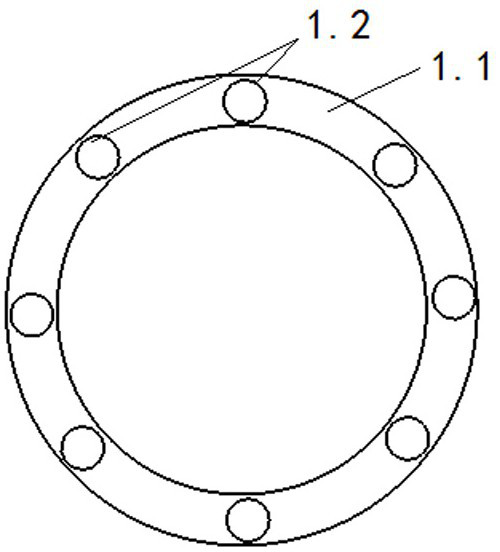

Gear-driven device

InactiveCN102931765ADirect forceSmall time lagMechanical energy handlingResultant forceElectrical and Electronics engineering

The invention relates to a gear-driven device which is a resultant-force device taking a plurality of small motors as power sources. The gear-driven device comprises a motor, driving gears and a driven gear; the motor and the driving gears are matched closely and provide power for the gear-driven device; two or more driving gears are arranged at the periphery of the driven gear and meshed with the driven gear respectively; the driving gears rotate synchronously and concertedly, so that the driven gear rotates, and the driving gears act on the driven gear jointly so as to drive the driven gear; and the driven gear is used to transfer force to the outside of the gear-driven device. The gear-driven device is a good power-driven device and can be used for the equipment needing to be provided with power.

Owner:SOUTHWEST UNIVERSITY

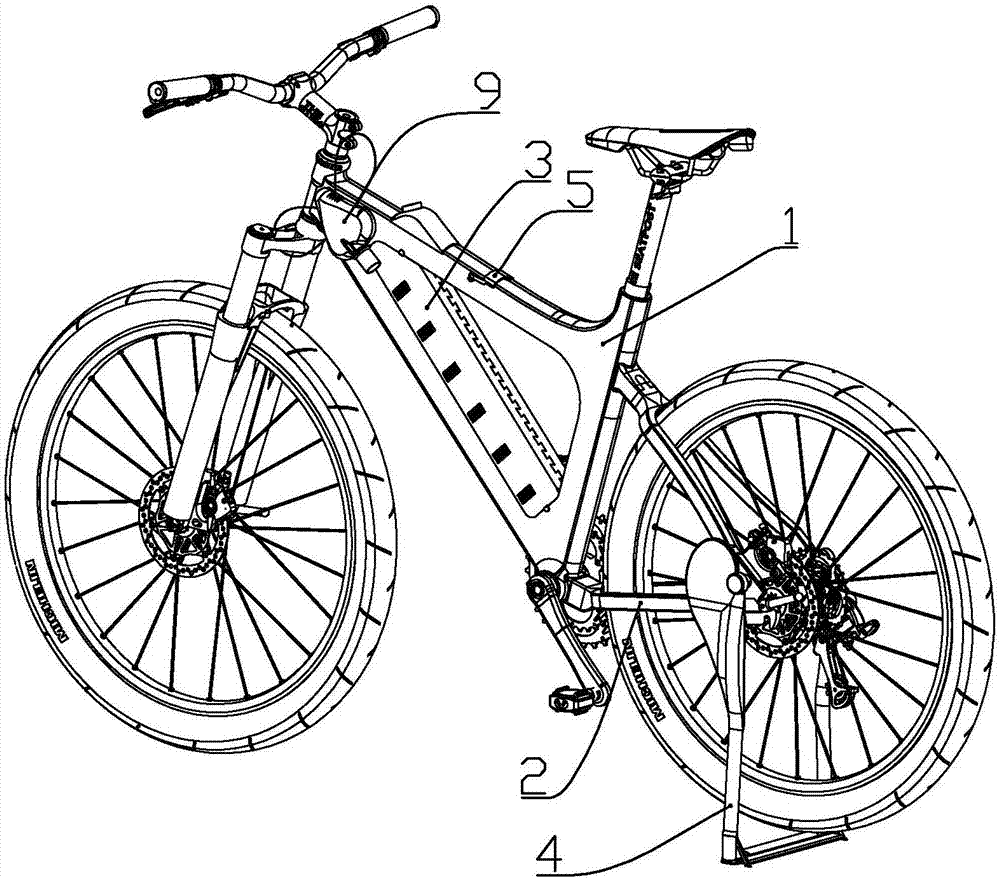

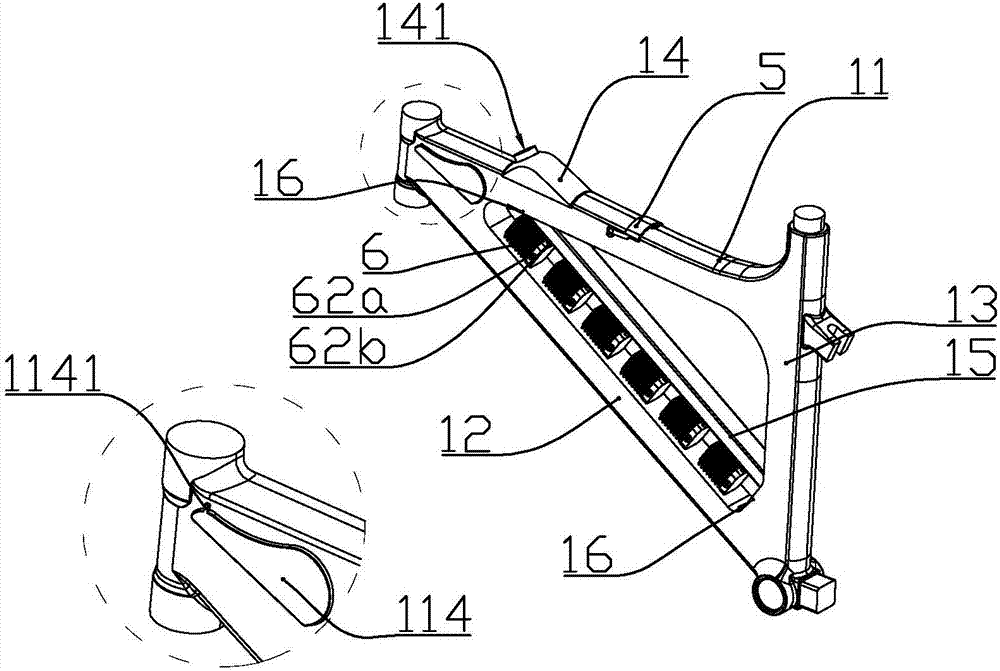

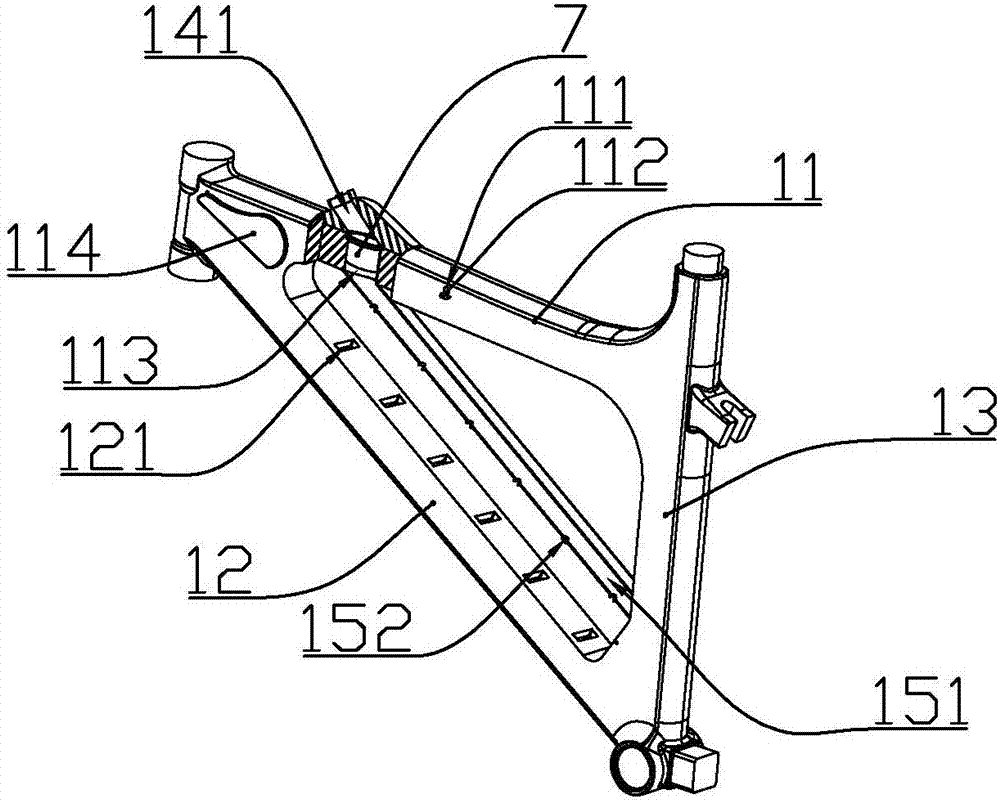

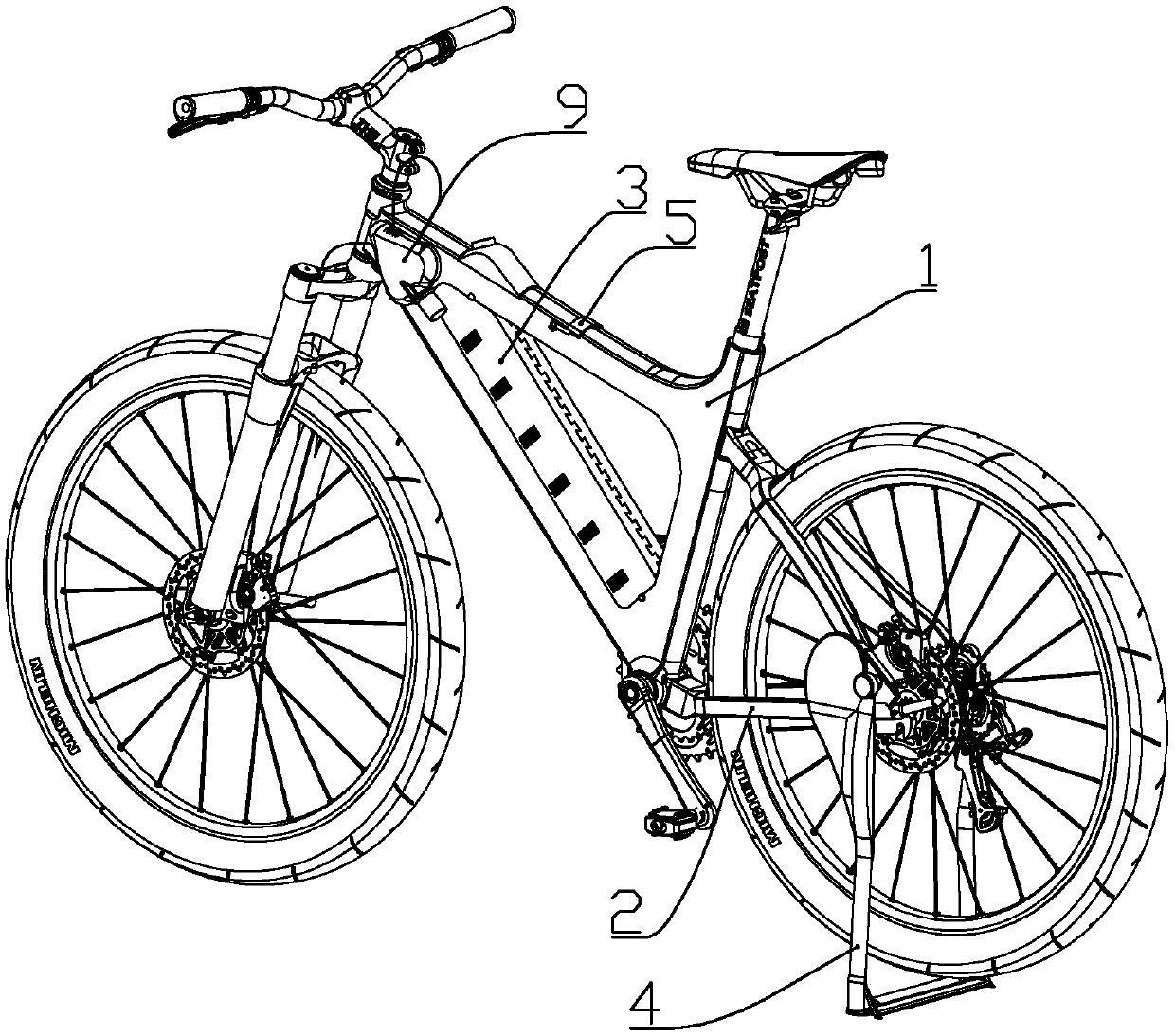

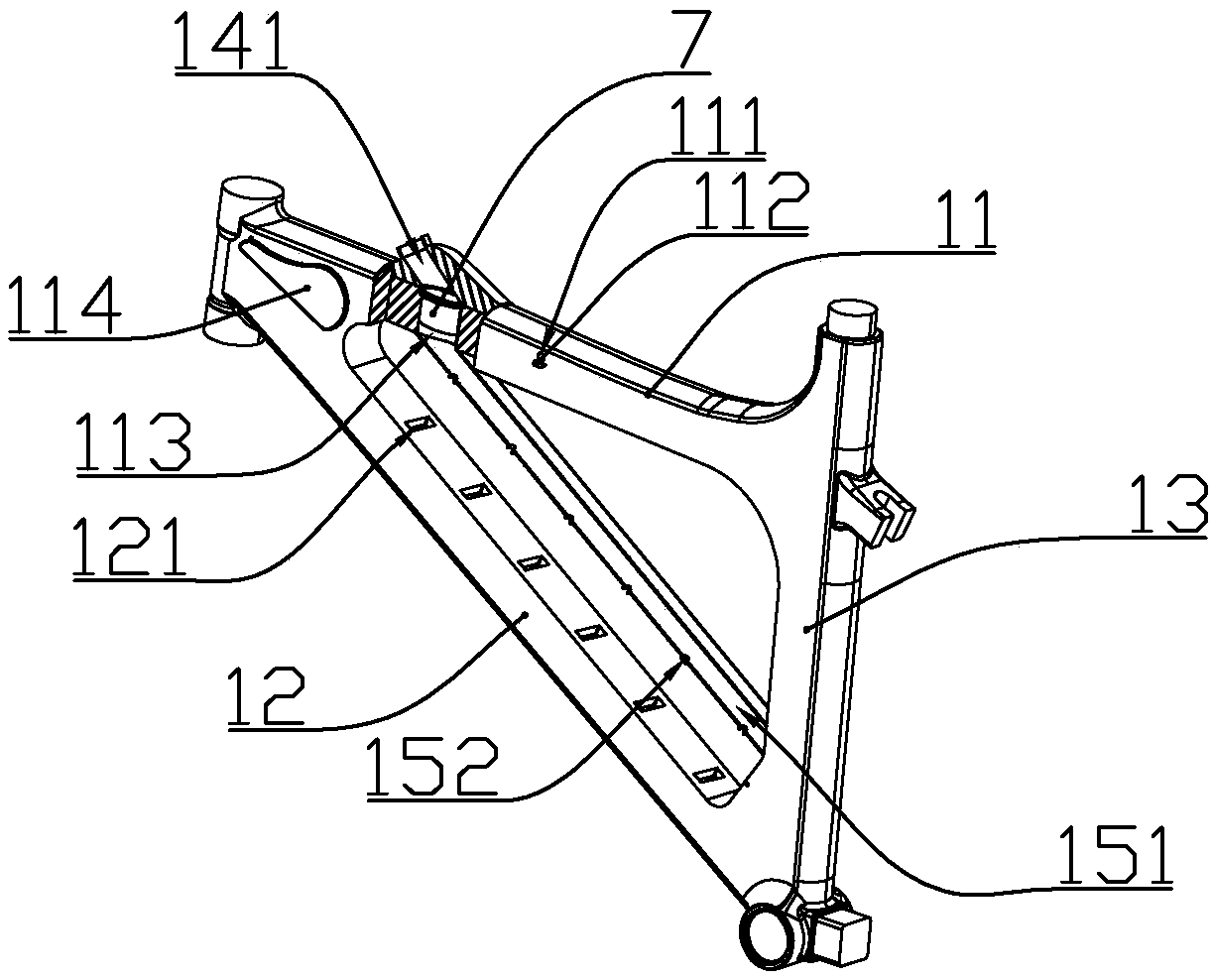

Shared bicycle with rapid returning function

ActiveCN107054509AReduce the numberIncrease the number ofAnti-theft cycle devicesCycle standsReturn functionElectromagnetic lock

The invention belongs to the field of shared bicycles and particularly relates to a shared bicycle with a rapid returning function. The shared bicycle comprises a triangular front bicycle frame, a rear bicycle frame fixedly mounted behind the front bicycle frame and a double support leg mounted at the rear end of the rear bicycle frame; a filtering channel is formed in an upper pipe; a filtering piece is inserted in the filtering channel; a plurality of air pump assemblies distributed at equal intervals in the length direction of a lower pipe are mounted on the lower pipe; two baffles are symmetrically mounted on the two sides, located at the air pump assemblies, of the front bicycle frame; the upper pipe is rotatably connected with a clamping plate; an electromagnetic lock is mounted between the double support leg and the rear bicycle frame. After parking of the bicycle and locking of the electromagnetic lock, the bicycle is returned, the situation that a user forgets to lock or confirm bicycle returning to cause a failure of bicycle returning is avoided; when the shared bicycle is locked, because the double support leg enables a rear wheel to be separated from the ground, other people cannot use the bicycle in a non-unlocking state, and the shared bicycle can be prevented from being embezzled illegally by the other people.

Owner:江苏杭源机电设备有限公司

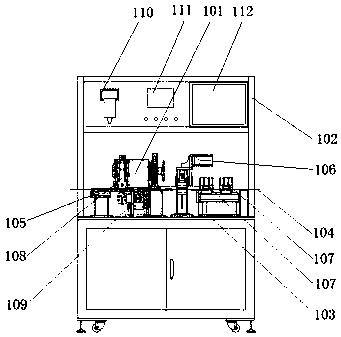

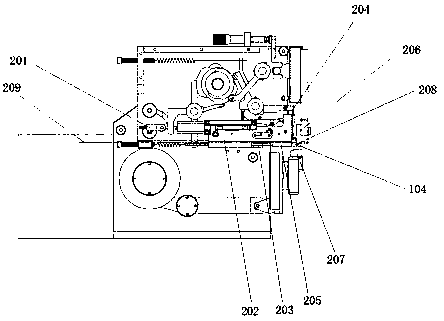

High speed welding device

PendingCN108942243AImprove work efficiencyIncrease the number of jobsOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a high speed welding device. The high speed welding device is used for welding a silver contact material belt to a reed material belt. The high speed welding device comprises ahigh speed welding machine, a machine frame, a working table and a control device, wherein the silver contact material belt is arranged inside the high speed welding machine, and the high speed welding machine is arranged at the top end of the working table; the working table and the control device are arranged on the machine frame, the control device is connected with the high speed welding machine in a controlling mode, wherein a positioner and a defective product remover are correspondingly connected to the two sides of the high speed welding machine, and the positioner is used for locating the reed material belt; transverse conveyors are connected to the side, deviating from the high speed welding machine, of the defective product remover, and the transverse conveyors are used for transversely conveying the reed material belt; a welding head and a CCD detection machine are arranged at the two ends of the high speed welding machine correspondingly, the welding head is arranged at the end, close to the positioner, of the high speed welding machine, and a longitudinal conveyor for longitudinally conveying the silver contact material belt is arranged inside the welding head; the welding head is used for welding the silver contact material belt to the reed material belt, and the CCD detection machine is arranged at the end, close to the defective product remover, of the high speed welding machine.

Owner:太仓市智鑫自动化设备有限公司

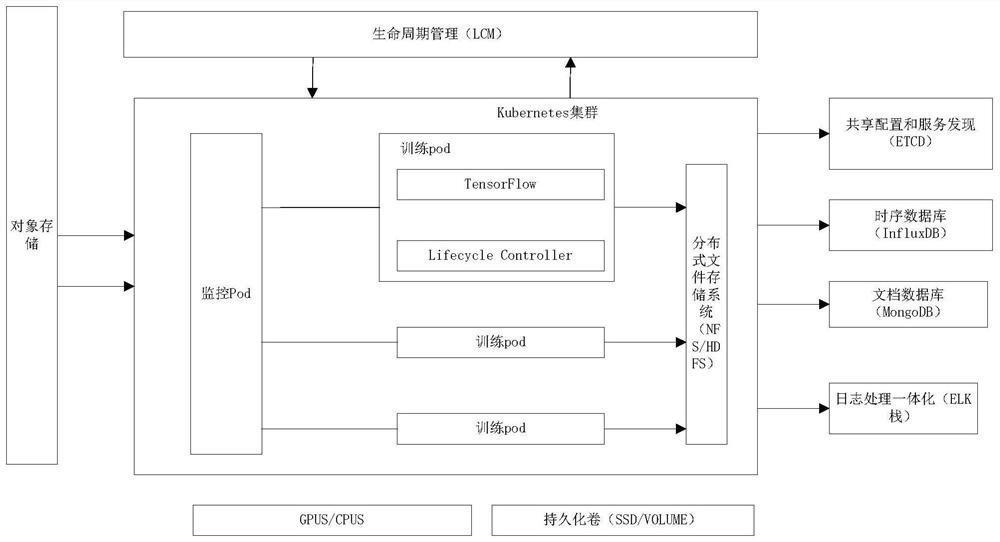

A container-based parallel deep learning scheduling training method and system

ActiveCN109885389BSpeed up iterationImprove resource utilizationProgram initiation/switchingResource allocationPERQResource isolation

The invention discloses a container-based parallel deep learning scheduling training method and system, belonging to the technical field of cloud computing and deep learning. The technical solution adopted is: this method uses Kubernetes containers to realize the configuration and scheduling of computing resources for tasks, and provides ResourceQuota, LimitRanger A variety of resource management mechanisms, through the communication between pod nodes in the container cluster, to achieve resource isolation between tasks; the same training node starts the training pod and life cycle management pod at the same time, and the LCM uniformly performs resource job scheduling, microservices The architecture itself is deployed as a POD, relying on the features of the latest version of Kubernetes to effectively mobilize the use of GPUs. The invention also discloses a container-based parallel deep learning scheduling training system.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

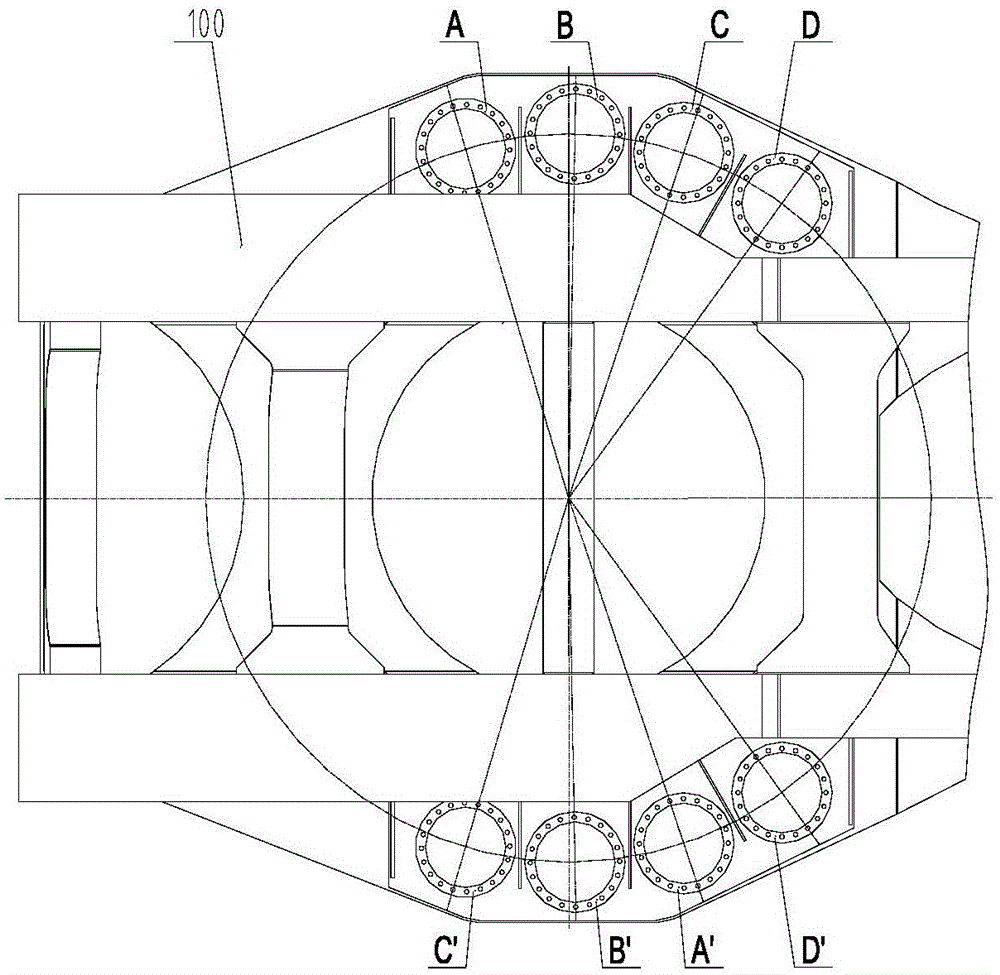

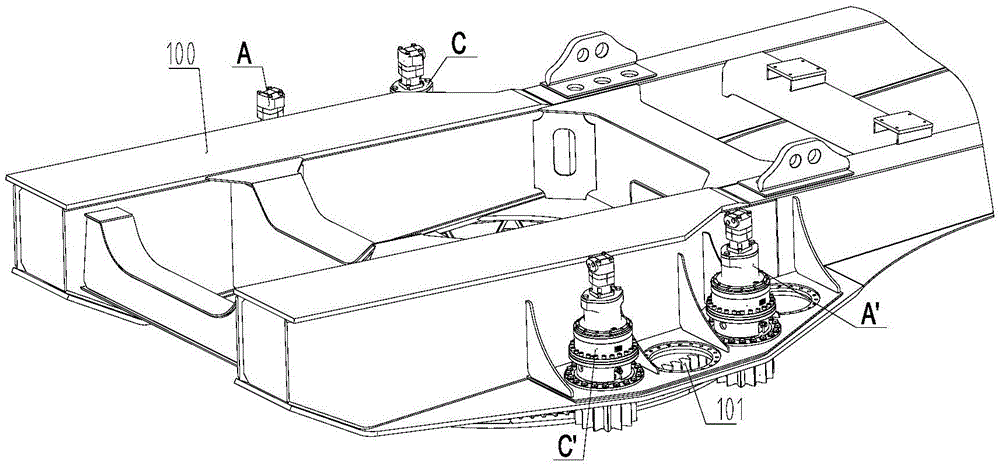

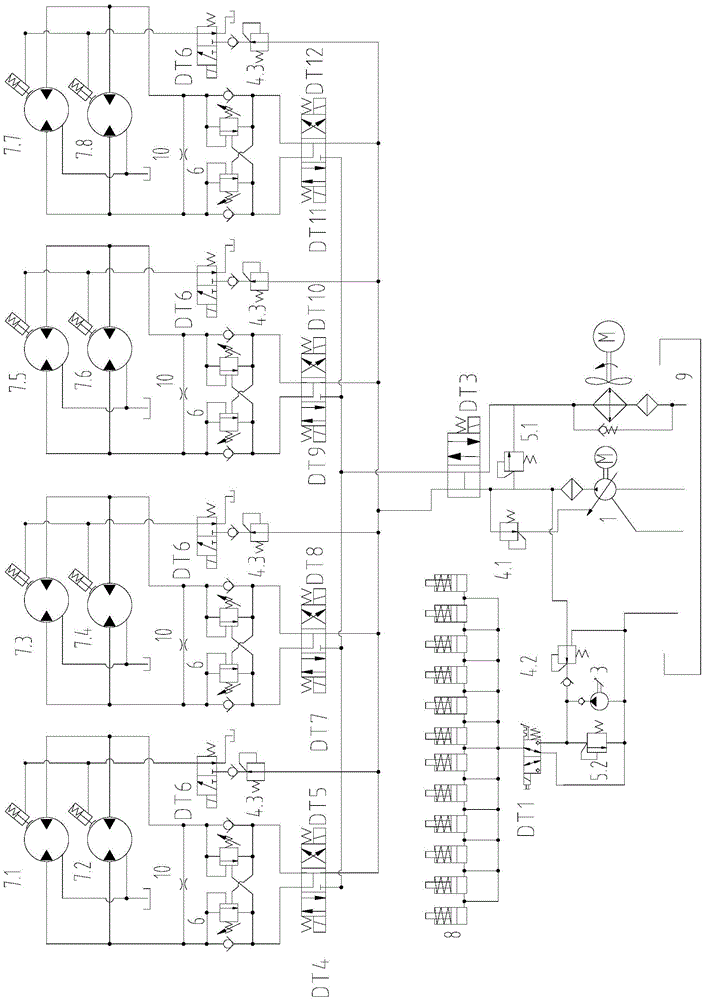

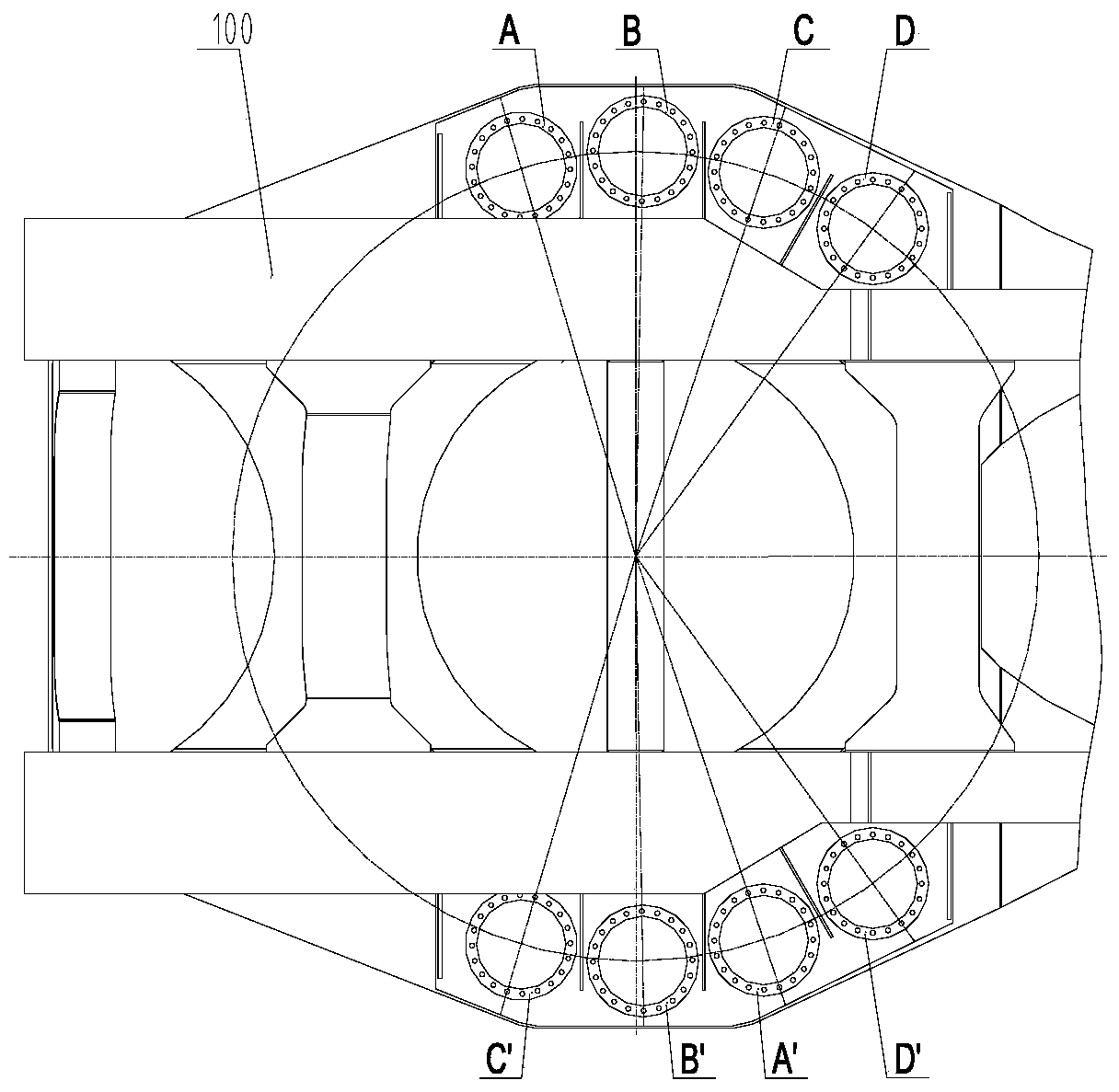

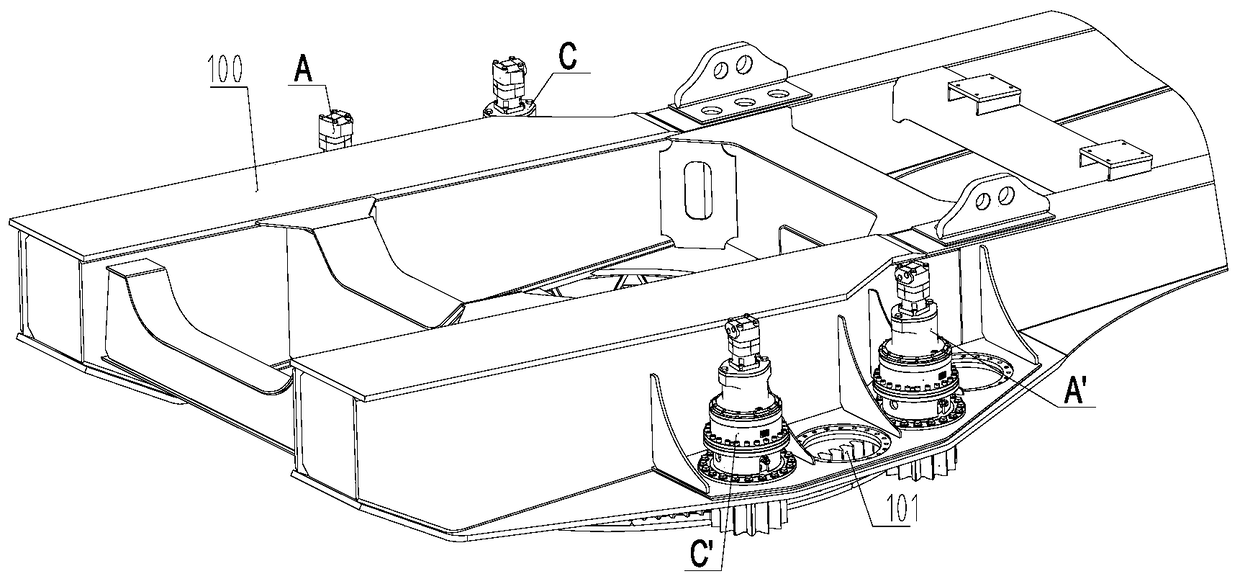

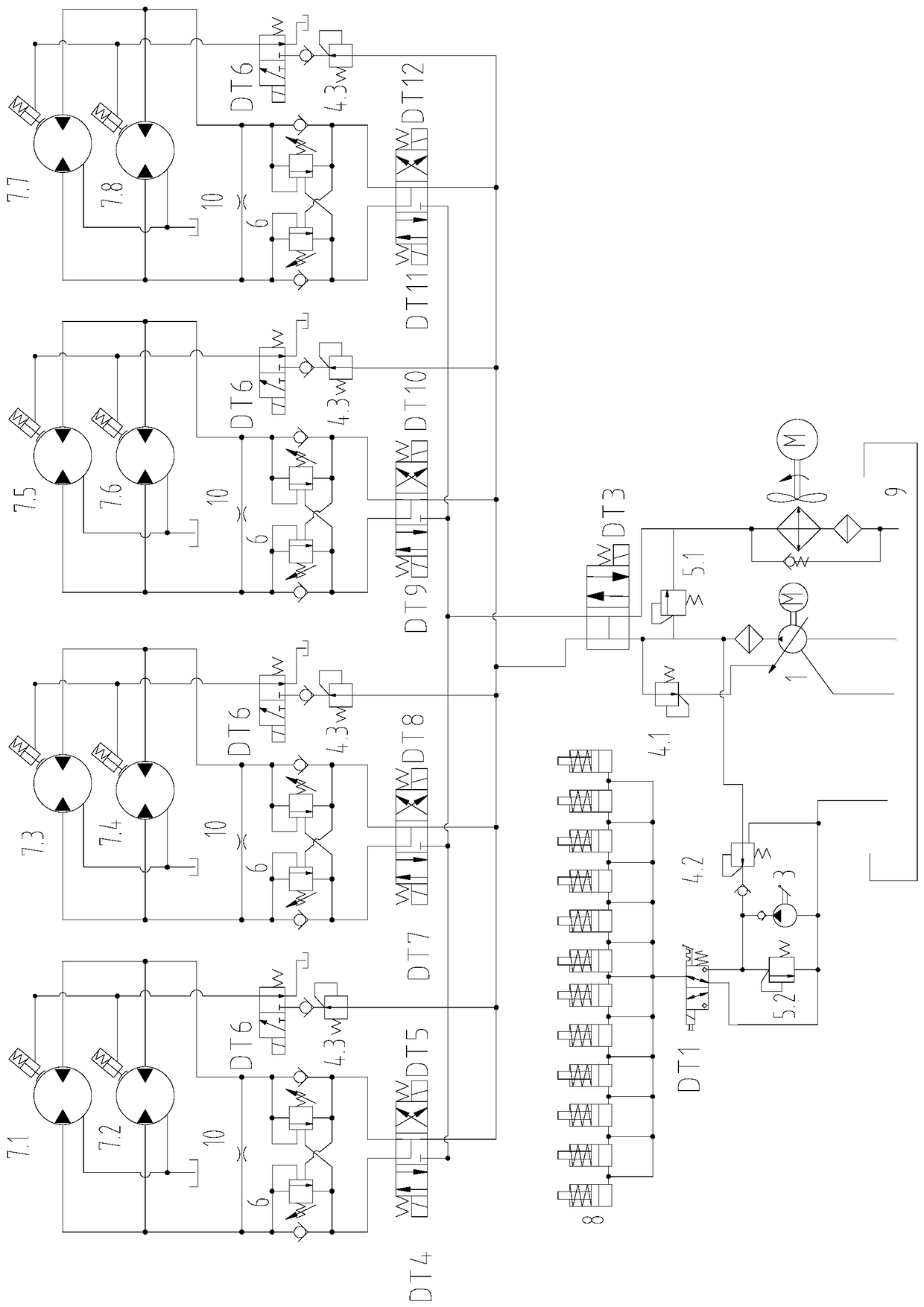

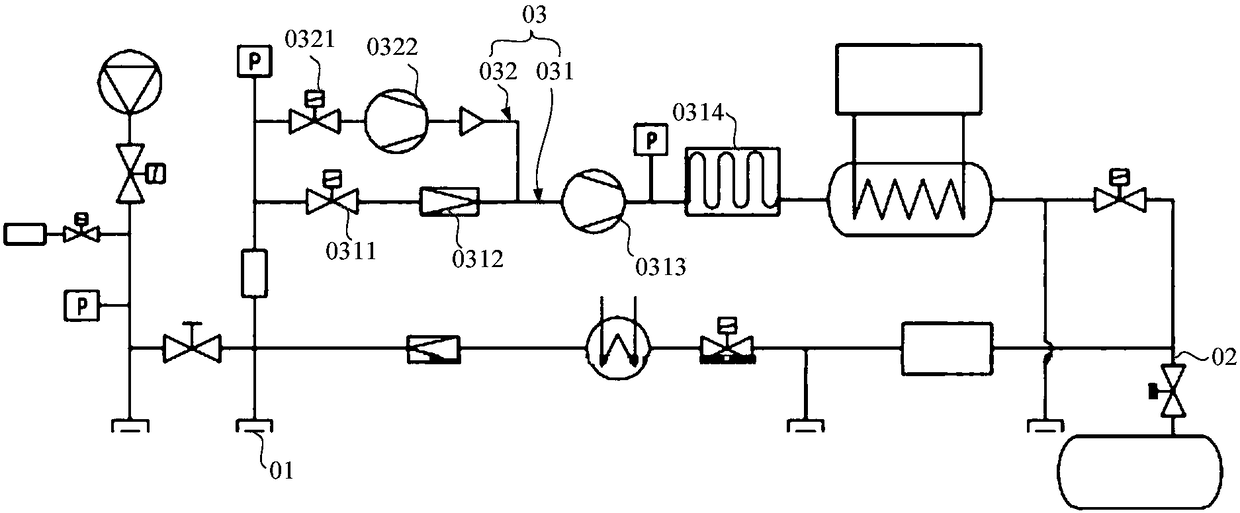

Yaw control method and yaw hydraulic control system of wind driven generator

ActiveCN105089930AIncrease the number of jobsSmall yaw errorWind motor controlFinal product manufactureWind drivenMaintainability

The invention discloses a yaw control method for a wind driven generator. At least two yaw driving devices driving yaw of the wind driven generator are arranged. The number of the started yaw driving devices is controlled according to the air speed of a wind field; the number of the started yaw driving devices is controlled to be increased while the air speed of the wind field is increased; and the number of the started yaw driving devices is controlled to be decreased while the air speed of the wind field is decreased. The invention further discloses a yaw hydraulic control system of the wind driven generator. The yaw control method and the aw hydraulic control system of the wind driven generator are achieved on the basis of the yaw driving force needed by loads. Thus, the wind field adaptability is high, real-time wind alignment can be achieved, yaw errors are small, maintainability is good, manufacturing cost is low, and the requirement for an external environment is low.

Owner:SANY ELECTRIC CO LTD

Cleaning and turnover clamp

PendingCN108312062AImprove work motivationIncrease incomeEdge grinding machinesGrinding drivesMechanical engineeringCasting

The invention discloses a cleaning and turnover clamp. The cleaning and turnover clamp comprises a clamp base arranged on a cylinder body horizontal turnover and cleaning table; one side of the clampbase is adjacent to a tool plate on the cylinder body horizontal turnover and cleaning table, the other side of the clamp base is in contact with a casting, and when the clamp base is located on the cylinder body horizontal turnover and cleaning table, the edge of the clamp base can make contact with a pedal at the bottom of the cylinder body horizontal turnover and cleaning table; and the clamp base is composed of a pair of clamping plates and a reinforcing plate connected between the two sides of the pair of clamping plates, a communicating pipe is arranged between the pair of clamping plates, and a clamping assembly for clamping the casting is arranged on the outer side of the clamping plate on the side, in contact with the casting, of the clamp base. By means of the cleaning and turnover clamp, the problems that in the prior art, the cleaning efficiency is low, the cleaning quality is unstable, the operation intensity of staff is high, and certain potential safety hazards exist inthe manual turnover process are solved.

Owner:山西三联顺驰汽车配件有限公司

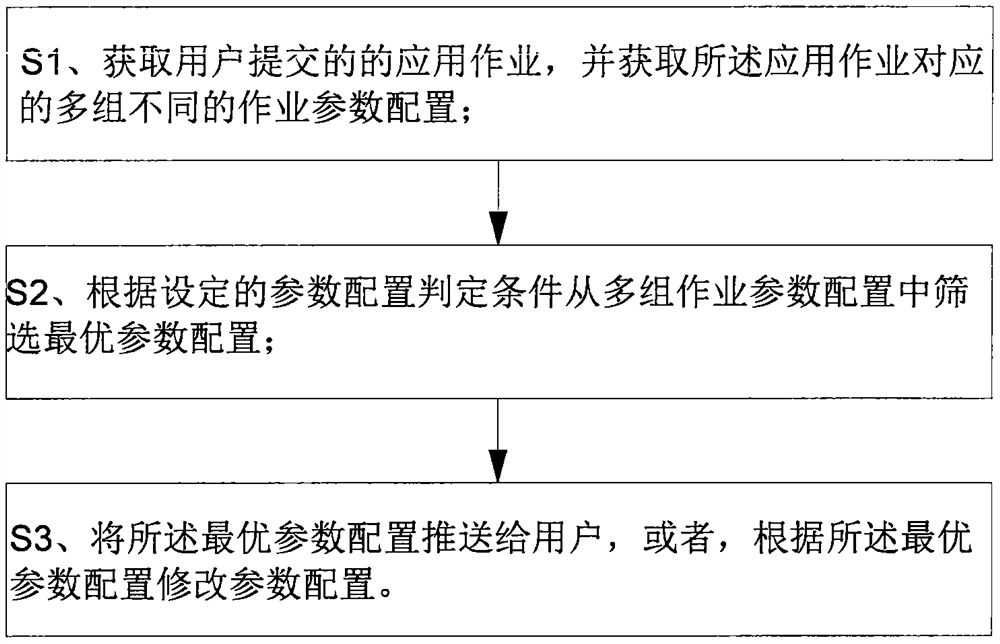

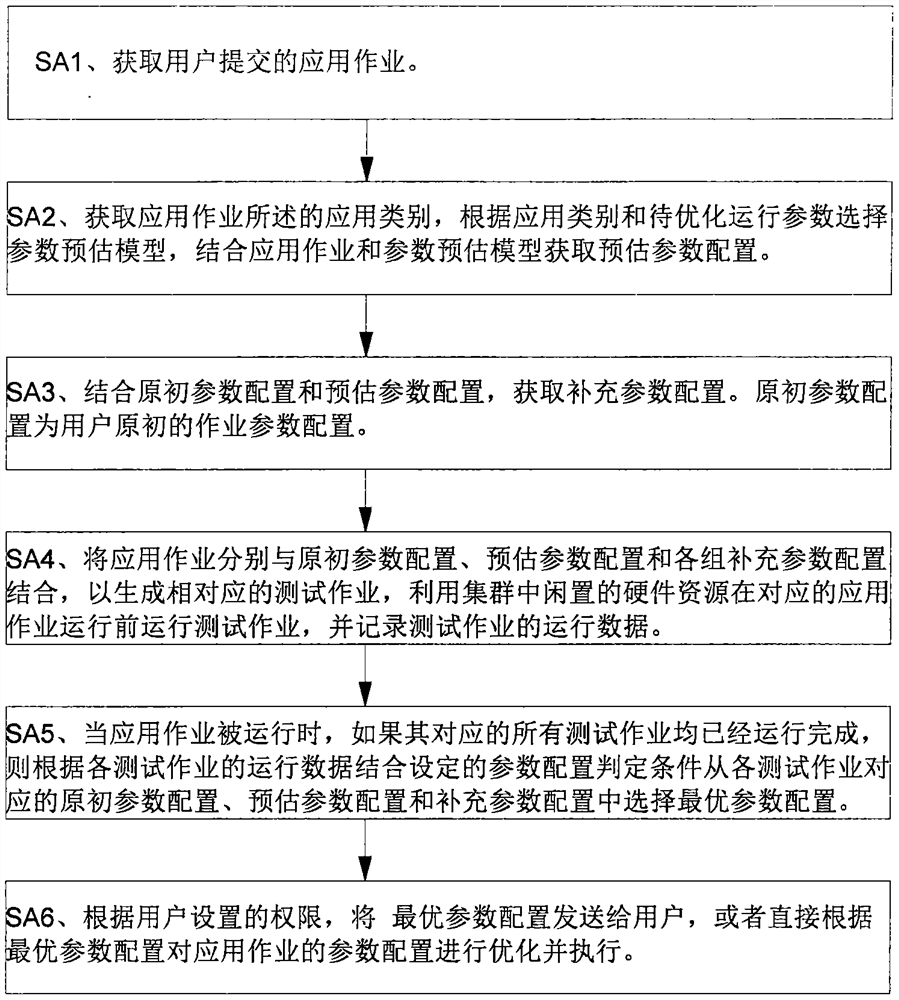

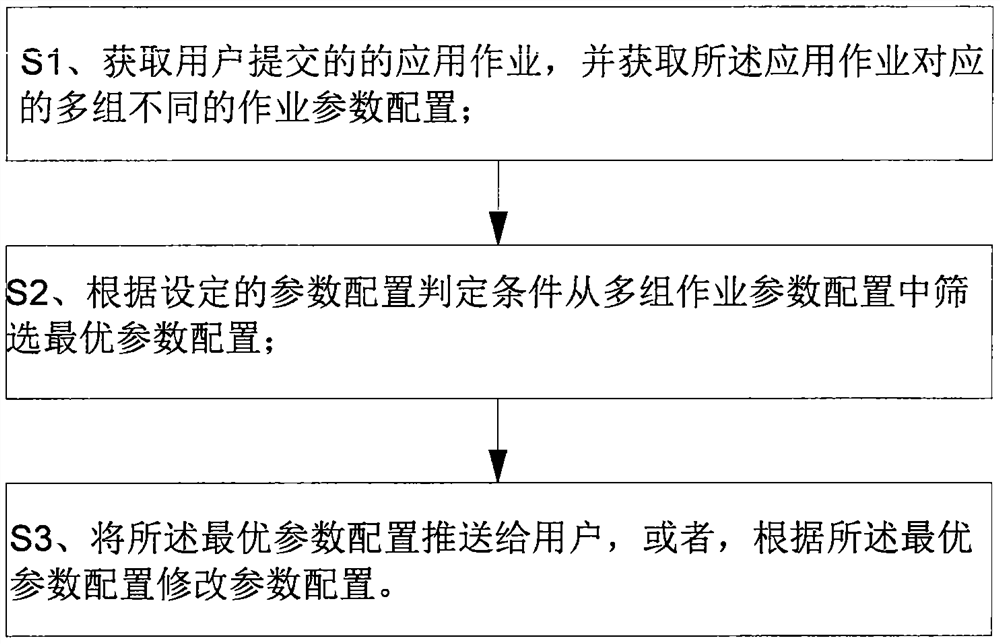

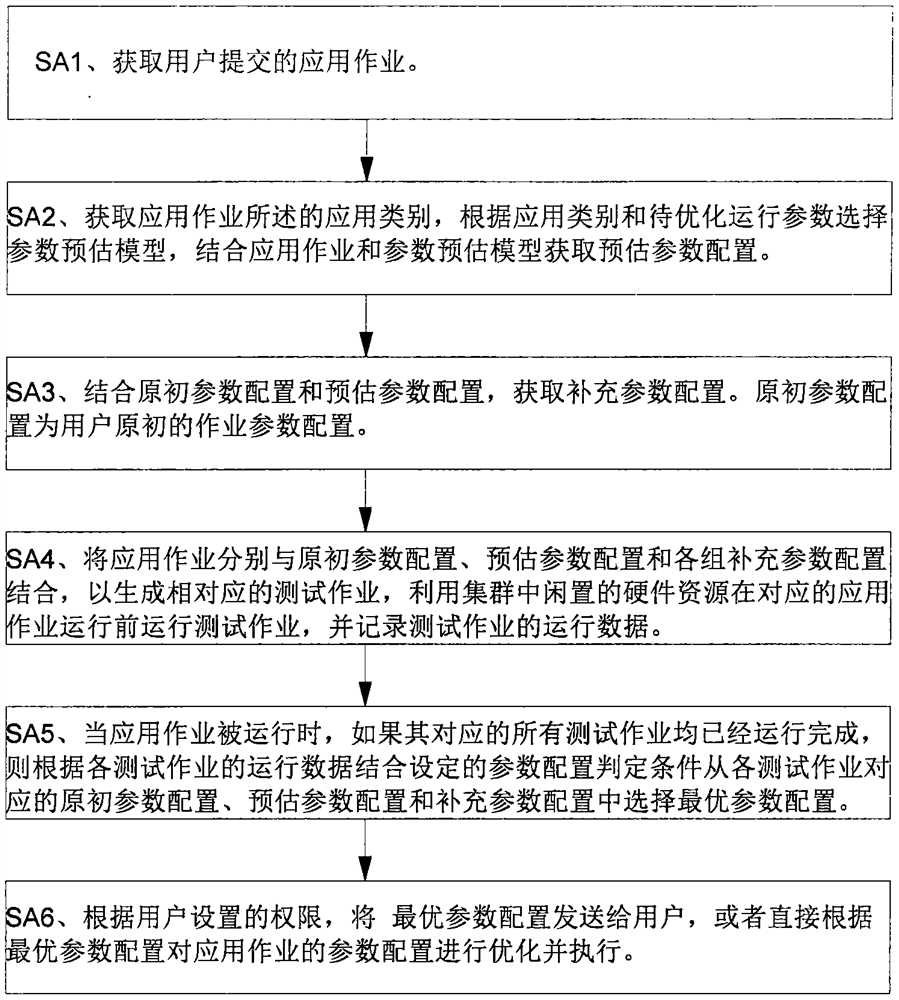

Job operation parameter optimization method applied to super-computing cluster scheduling

ActiveCN114048027AGood calculation efficiencyMake up for the lack of parameter configuration optimization capabilitiesResource allocationConfiguration optimizationScheduling (computing)

A job operation parameter optimization method applied to super-computing cluster scheduling comprises the following steps: acquiring an application job submitted by a user, and acquiring multiple groups of different job parameter configurations corresponding to the application job; screening an optimal parameter configuration from the multiple groups of operation parameter configurations according to a set parameter configuration judgment condition; and pushing the optimal parameter configuration to the user, or modifying the job parameter configuration of the application job submitted by the user according to the optimal parameter configuration. According to the method, automatic optimization of the parameter configuration of the application job submitted by the super-computing cluster user is realized, the defect that most users do not have the parameter configuration optimization capability is made up, and the calculation efficiency of the super-computing cluster is improved on the whole.

Owner:UNIV OF SCI & TECH OF CHINA

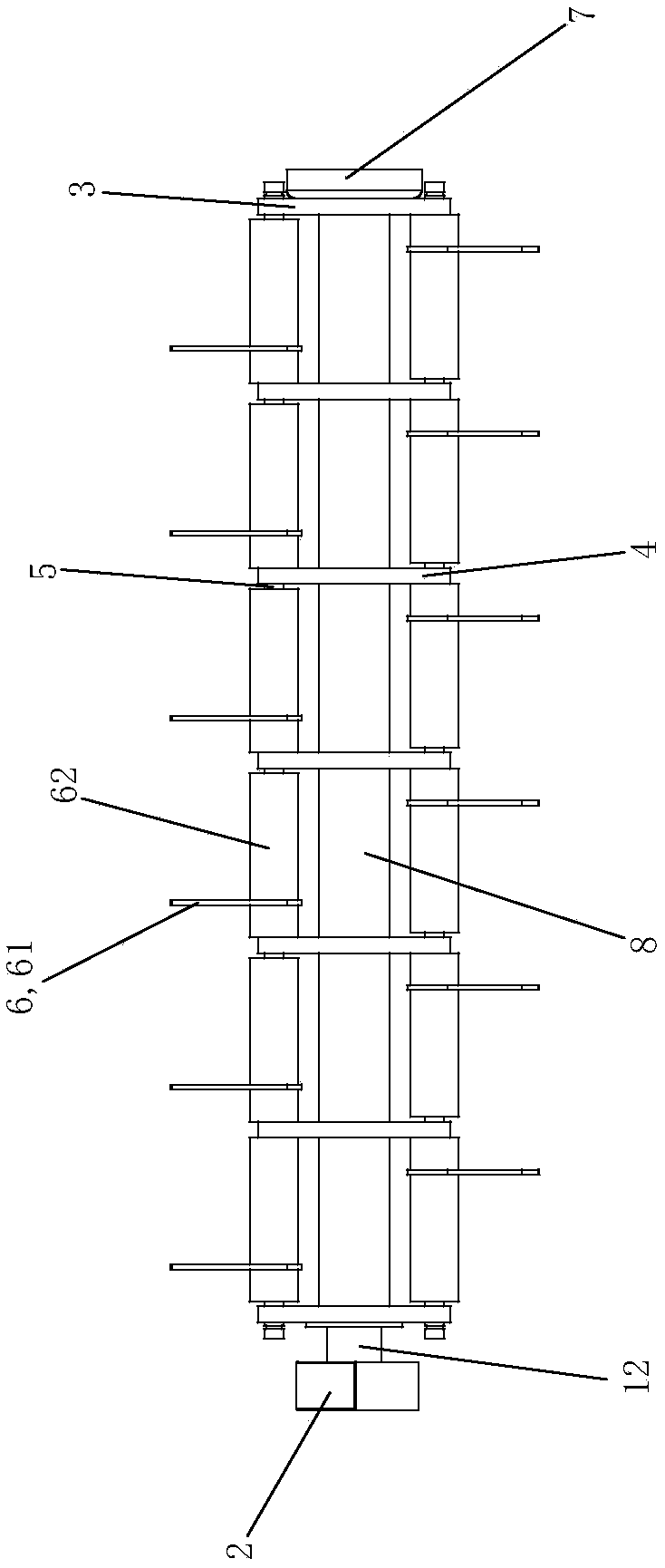

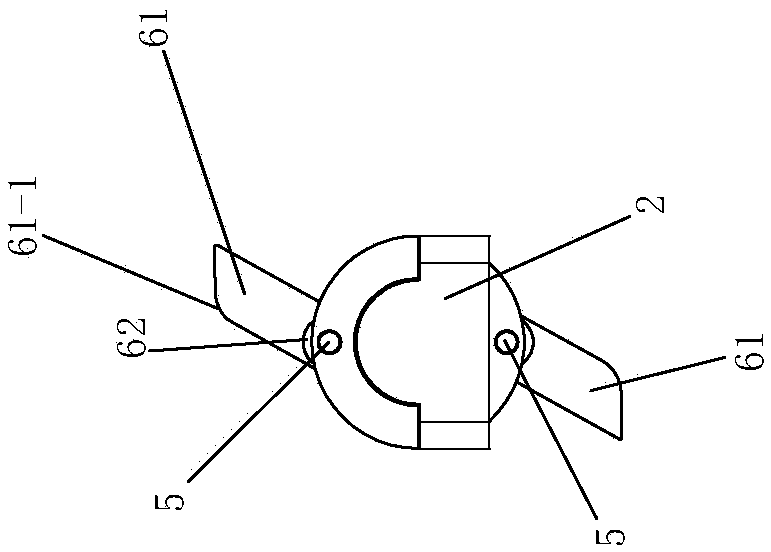

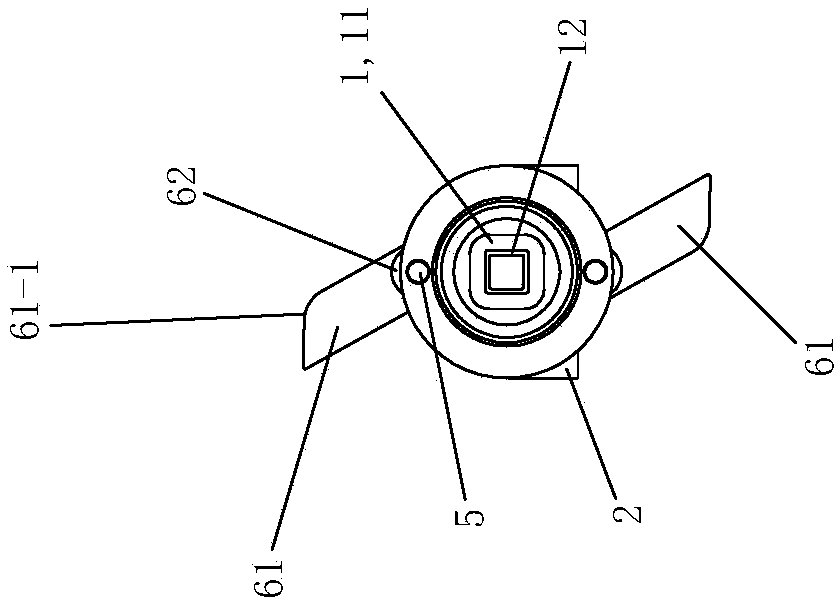

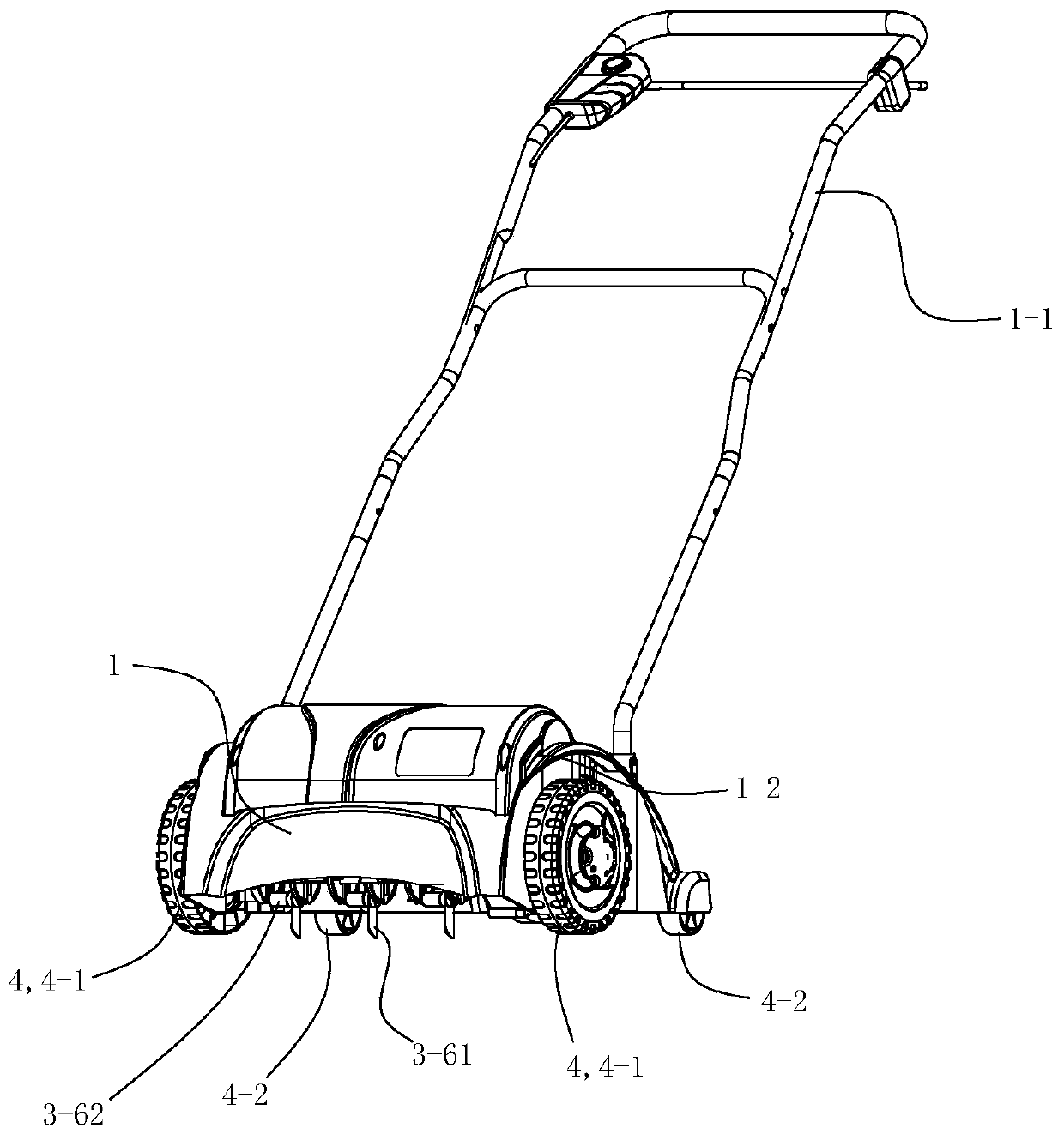

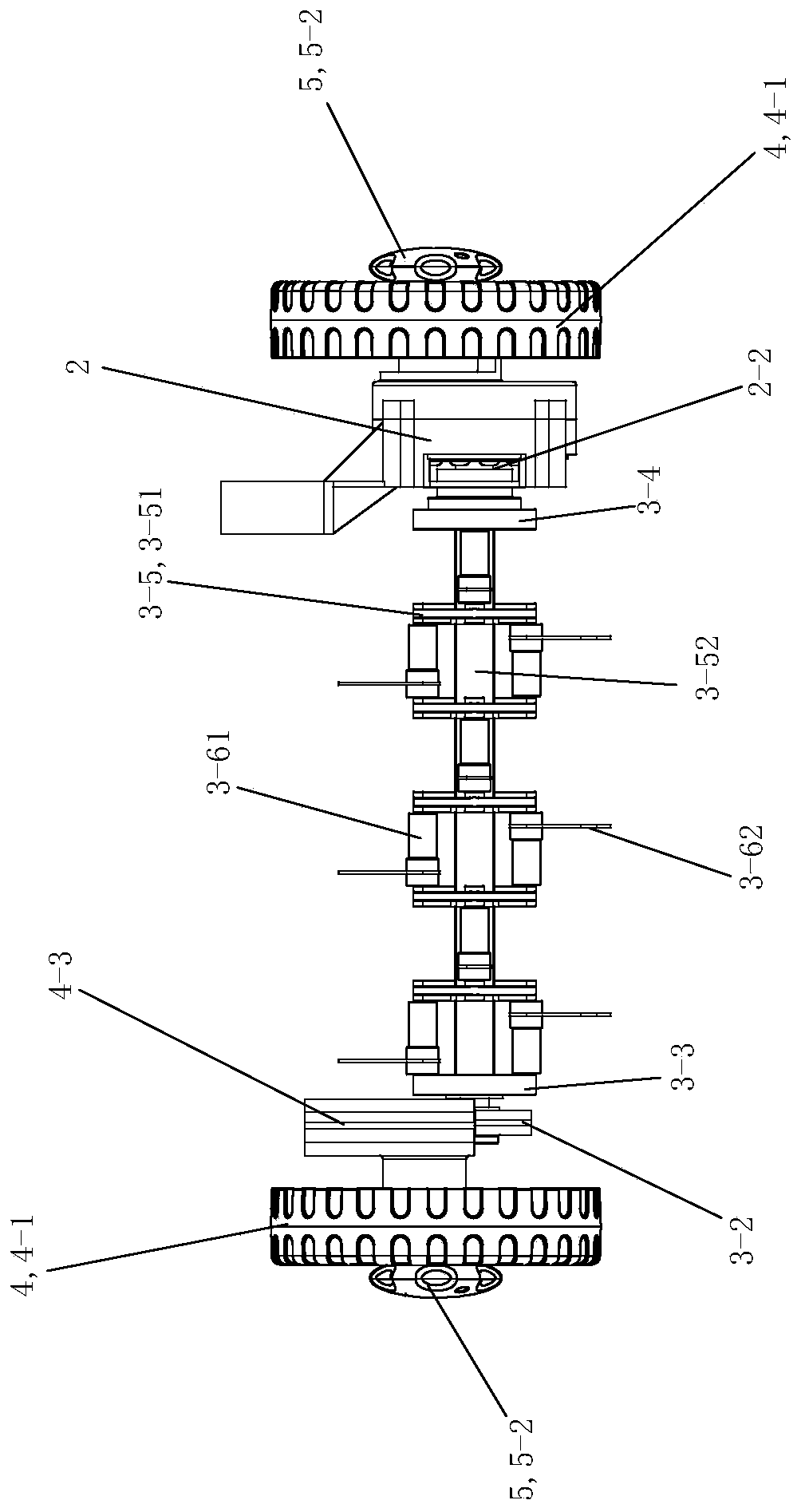

Cutter for lawn ventilator

The invention discloses a cutter for a lawn ventilator. The main points of the cutter provided by the invention are as follows: the cutter comprises a rotating shaft, a hitching leg support, mountingdisks, supporting disks, cutter shafts and blade assemblies; the left end of a short axis of the rotating shaft is rotatably arranged in the hitching leg support through a corresponding bearing; two mounting disks are respectively and fixedly arranged at the left and right ends of a square-tube long axis of the rotating shaft; the supporting disks are arranged on the square-tube long axis of the rotating shaft in a uniformly-spaced manner from left to right; the cutter shafts are arranged on the mounting disks and the supporting disks; each blade assembly comprises a blade and a connecting sleeve; each blade is fixedly embedded on a connecting sleeve; blades are rotatably arranged on the cutter shafts through connecting sleeves; and the blades are spirally arranged in the axial direction of the square-tube long axis of the rotating shaft.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

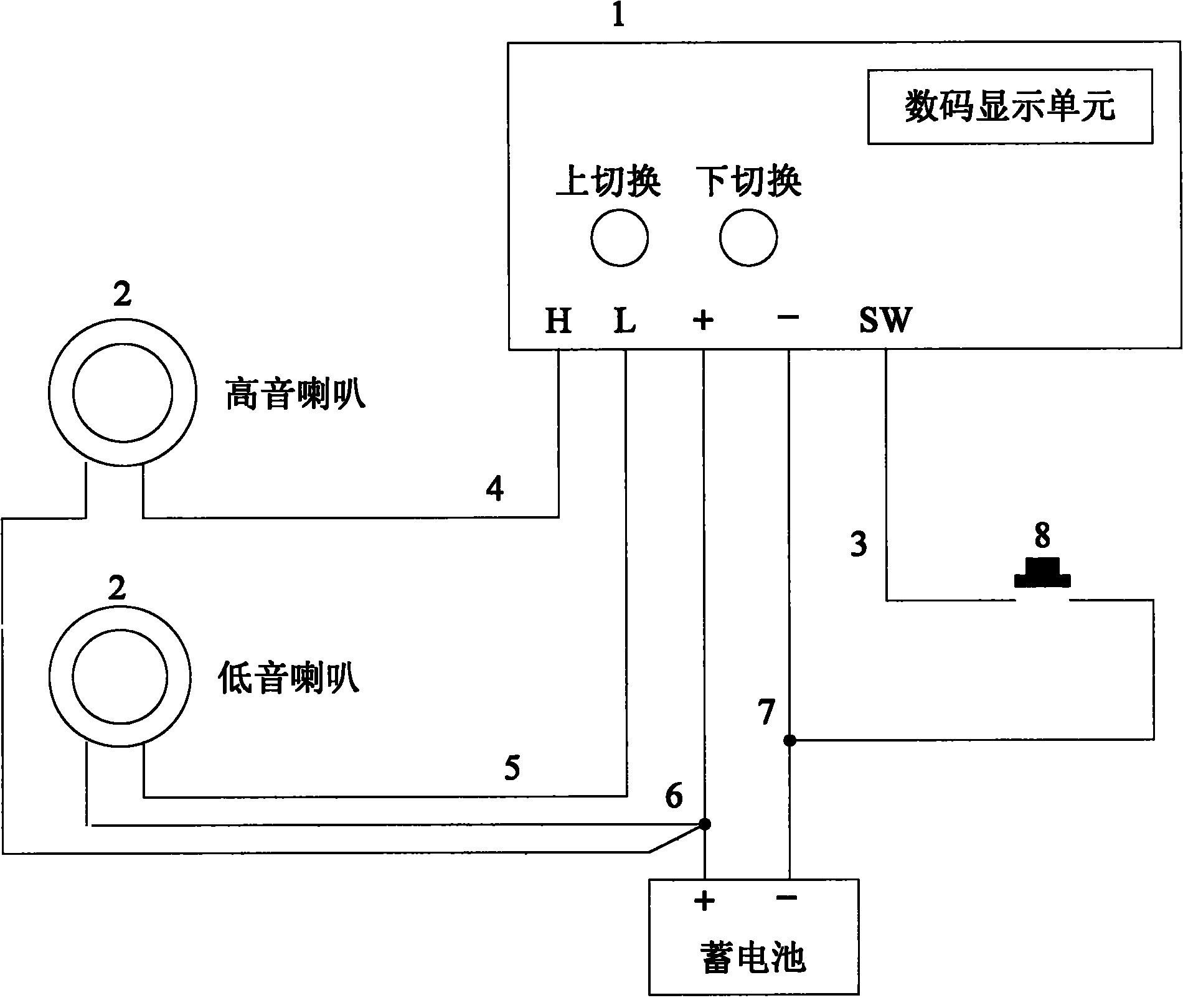

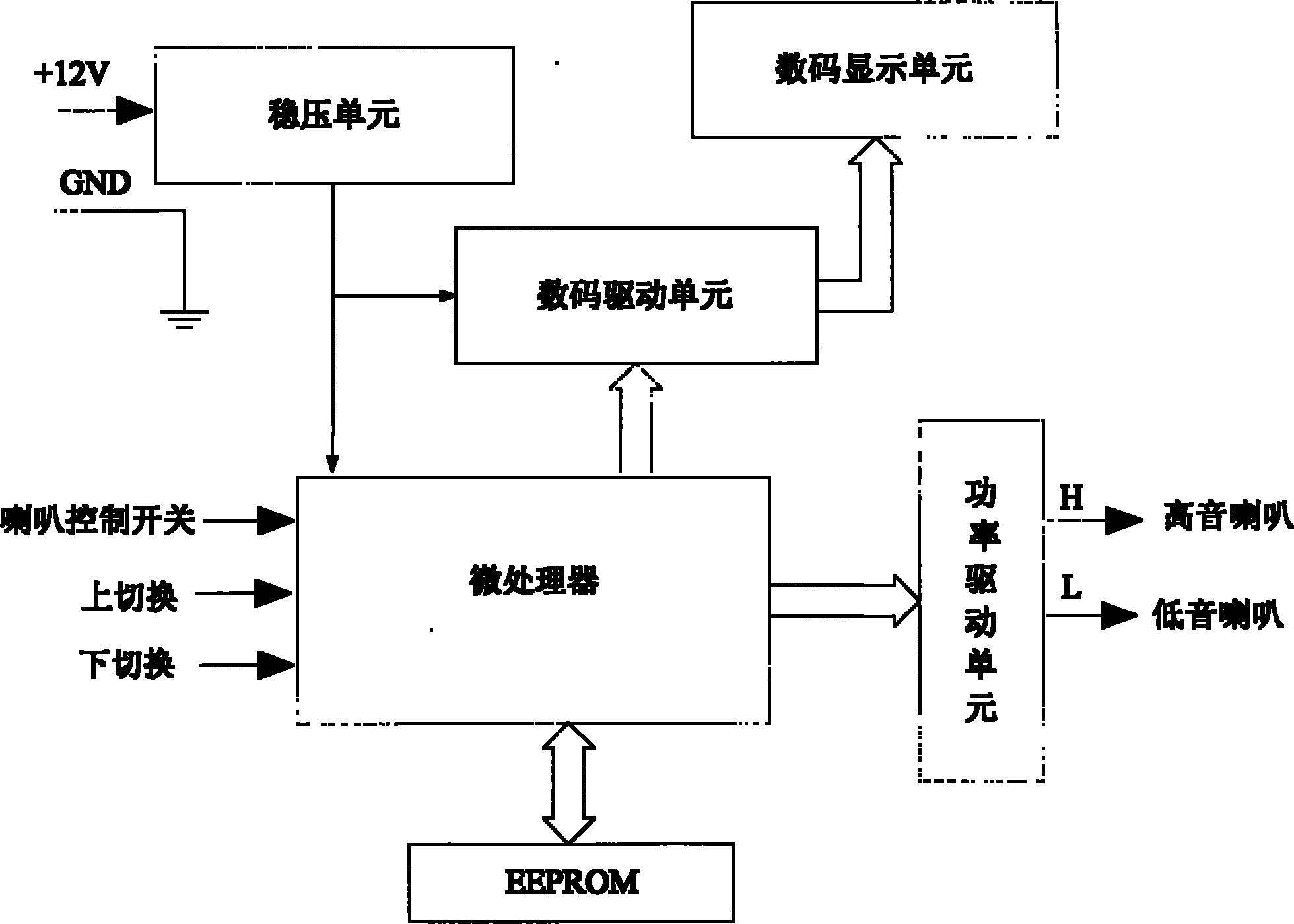

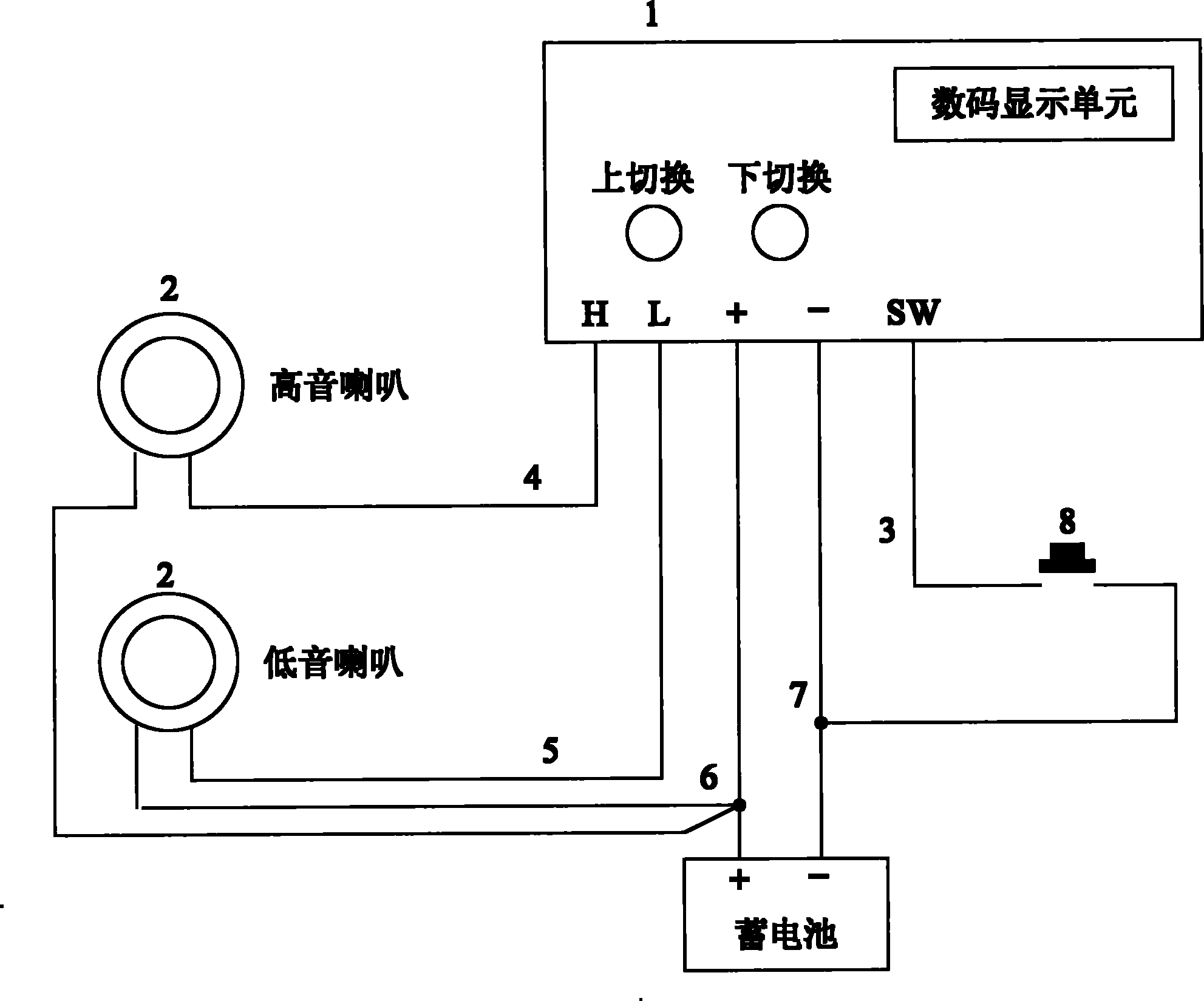

Touch type horn system with counting function

InactiveCN101901596AIncrease the number of jobsExtended service lifeAcoustic signal devicesSound producing devicesElectricityVehicle horn

The invention relates to the field of acoustic equipment, in particular to a touch type horn system with a counting function. The invention overcomes the defects of short service life, unstable quality, old-fashioned appearance and single sound of a conventional automotive horn, and provides a horn system with long service life, stable quality, novel appearance and rich sounds. The horn system comprises a controller, contact horns, a horn trigger line, an althorn line and a sackbut line, wherein the number of the horn contacts is two, one of the horn contacts is connected with the controller through the althorn line, and the other horn contact is connected with the controller through the sackbut line, the horn trigger line is connected to the controller, the controller is provided with a sound type switching key for the counting display and nixie tubes for the sound types, and the use times and the sound type can be stored during power failure. The invention has reasonable design, obvious effects and wide application range.

Owner:RUIAN WEIDONG AUTO ELECTRIC APPLIANCE

Yaw control method and yaw hydraulic control system of wind power generator

ActiveCN105089930BIncrease the number of jobsSmall yaw errorWind motor controlFinal product manufactureMaintainabilityControl system

Owner:SANY ELECTRIC CO LTD

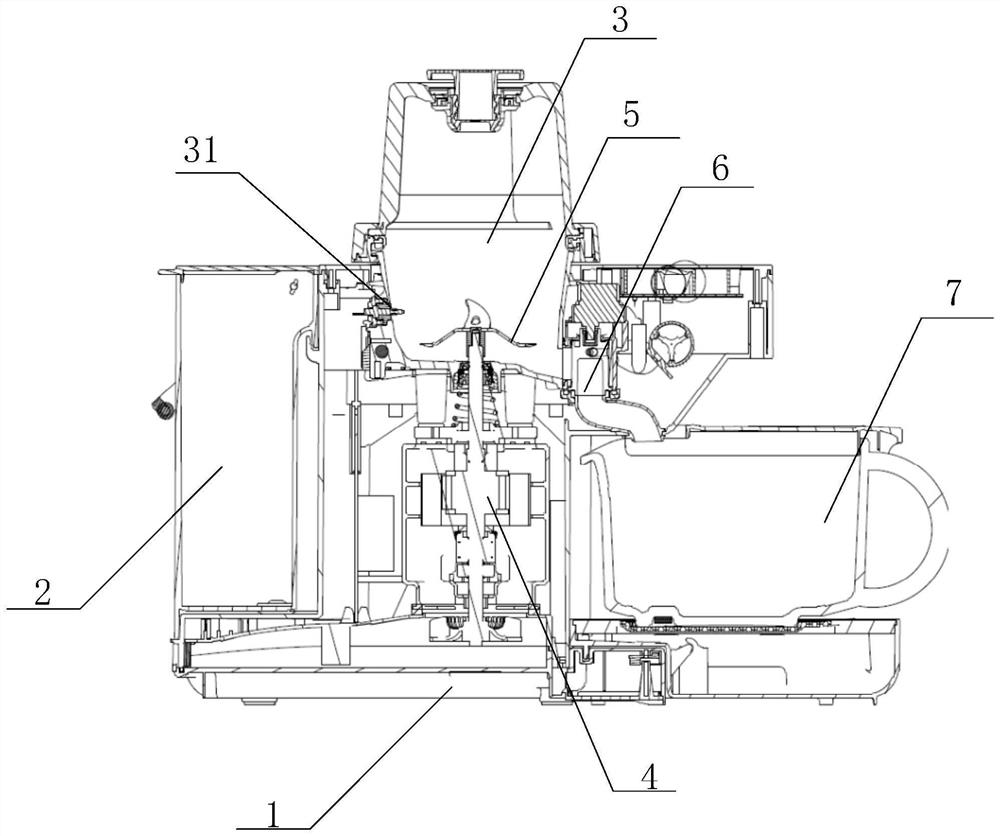

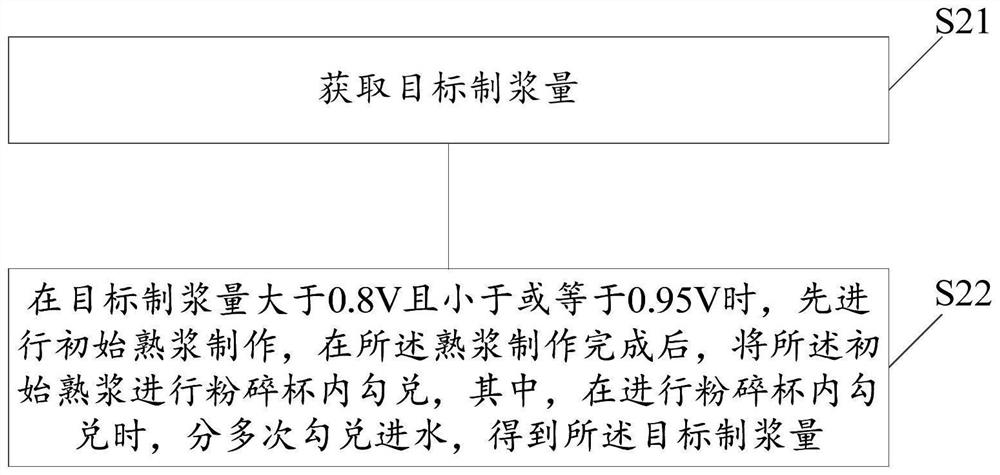

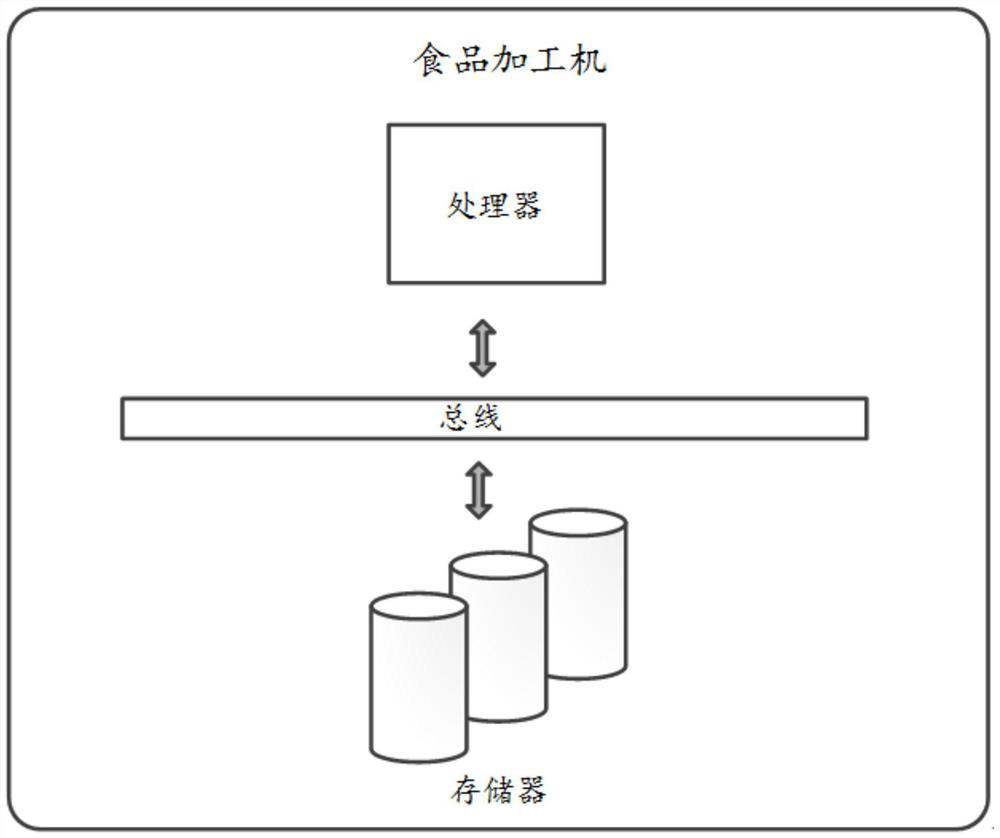

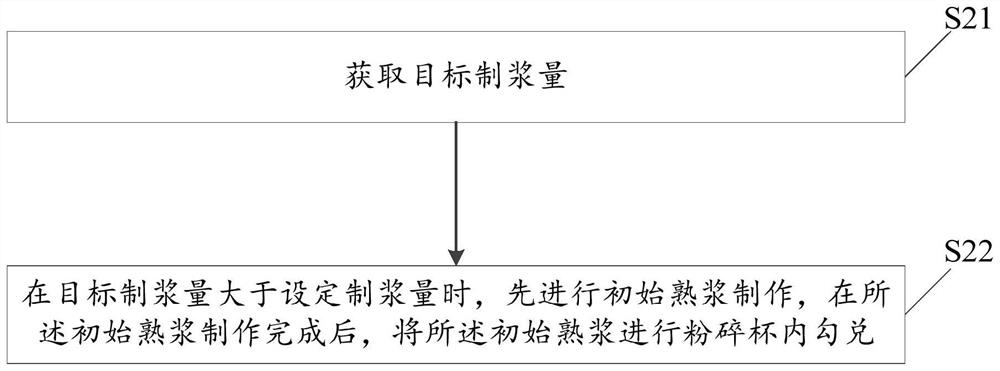

Food processing machine blending and pulping method and food processing machine

PendingCN114794921AImprove qualitySingle pass avoidanceKitchen equipmentProcess engineeringFood processing

Owner:HONGYANG HOME APPLIANCES

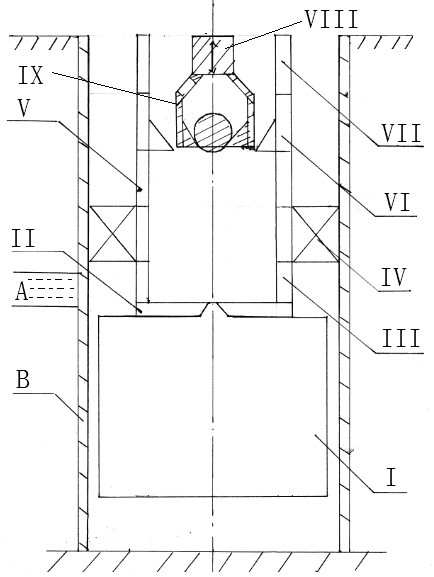

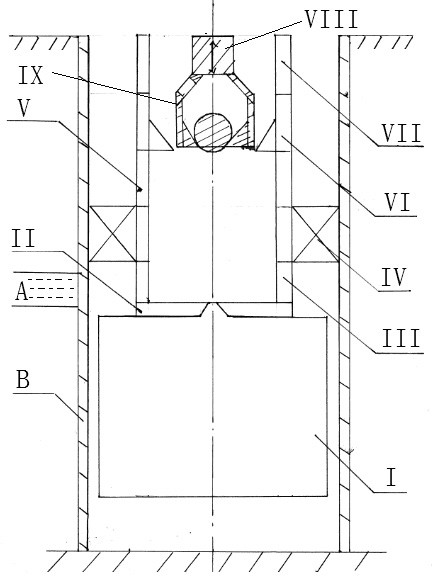

A heavy oil cold recovery device suitable for shallow wells

The invention relates to a heavy oil cold recovery device suitable for shallow well layers. The technical solution is: a reversing bypass valve is provided on the lower side wall of the oil pump of the oil pipe, and the gas generator is connected to the bottom of the oil pipe through a hydraulic switch and a reaction opener. The hydraulic switch corresponds to the oil production layer, and the gas generator Located in the lower part of the oil production layer, CaC2 is installed in the gas generator, and the CaC2 in the gas generator is controlled to react with water through the reaction opener, and the generated C2H2 gas is absorbed by the heavy oil in the oil production layer, and the heavy oil is diluted After that, it is extracted to the ground through oil pipelines and oil well pumps. The beneficial effects are: the production of the present invention is safe and reliable: through the use of the existing hydraulic switch, the production becomes more safe and reliable, the production is simple, and the formation will not be polluted; the economic benefit is good: the operation time is also short, and the mining efficiency is high; The oil is directly transported through the oil pipeline, which improves the transport efficiency and reduces the production cost.

Owner:JIANGSU LIKE GASOLINEEUM MACHINERY

Food processing machine blending and pulping method and food processing machine

PendingCN114794918AIncrease pulp productionImprove qualityBeverage vesselsProcess engineeringEngineering

Owner:HONGYANG HOME APPLIANCES

Automatic program design for heating furnace firing

ActiveCN111926172AIncrease the number of jobsAvoid damageFurnace typesHeat treatment process controlMaster controllerHeating furnace

The invention discloses an automatic program design for heating furnace firing. The automatic program design comprises a main controller, a first control valve, a second control valve, a circulator and a timer, wherein the main controller is connected with the first control valve and the second control valve, and the timer and the circulator are mounted inside the main controller; the first control valve is arranged on the east side of a heating furnace; the second control valve is arranged on the west side of the heating furnace; the circulator and the main controller are connected with the first control valve and the second control valve in a constructed mode; and the heating time of the west side of the heating furnace controlled by the second control valve is increased by 80 s comparedwith the heating time of the east side of the heating furnace controlled by the first control valve, so that the temperature of the west side of the heating furnace is higher by 50-80 DEG C comparedwith the temperature of the east side of the heating furnace. According to the automatic program design for heating furnace firing, the working frequency of the second control valve on the west side of the heating furnace is improved, so that the temperature on the west side of the heating furnace is higher than the combustion temperature on the east side of the heating furnace, and black tailingsteel caused by uneven heating of the rear half section of a billet is avoided.

Owner:SHANXI JINNAN IRON & STEEL GRP CO LTD

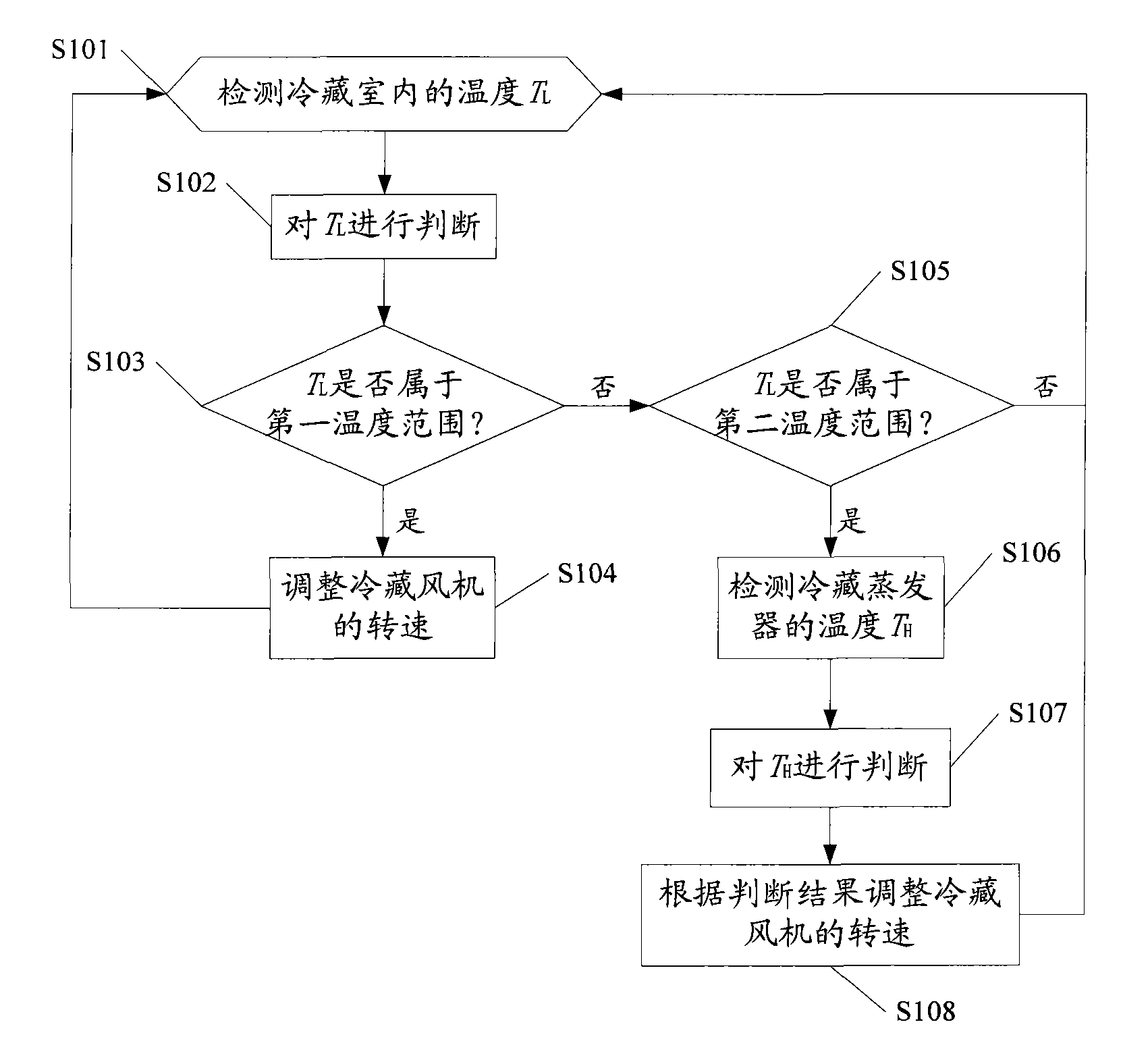

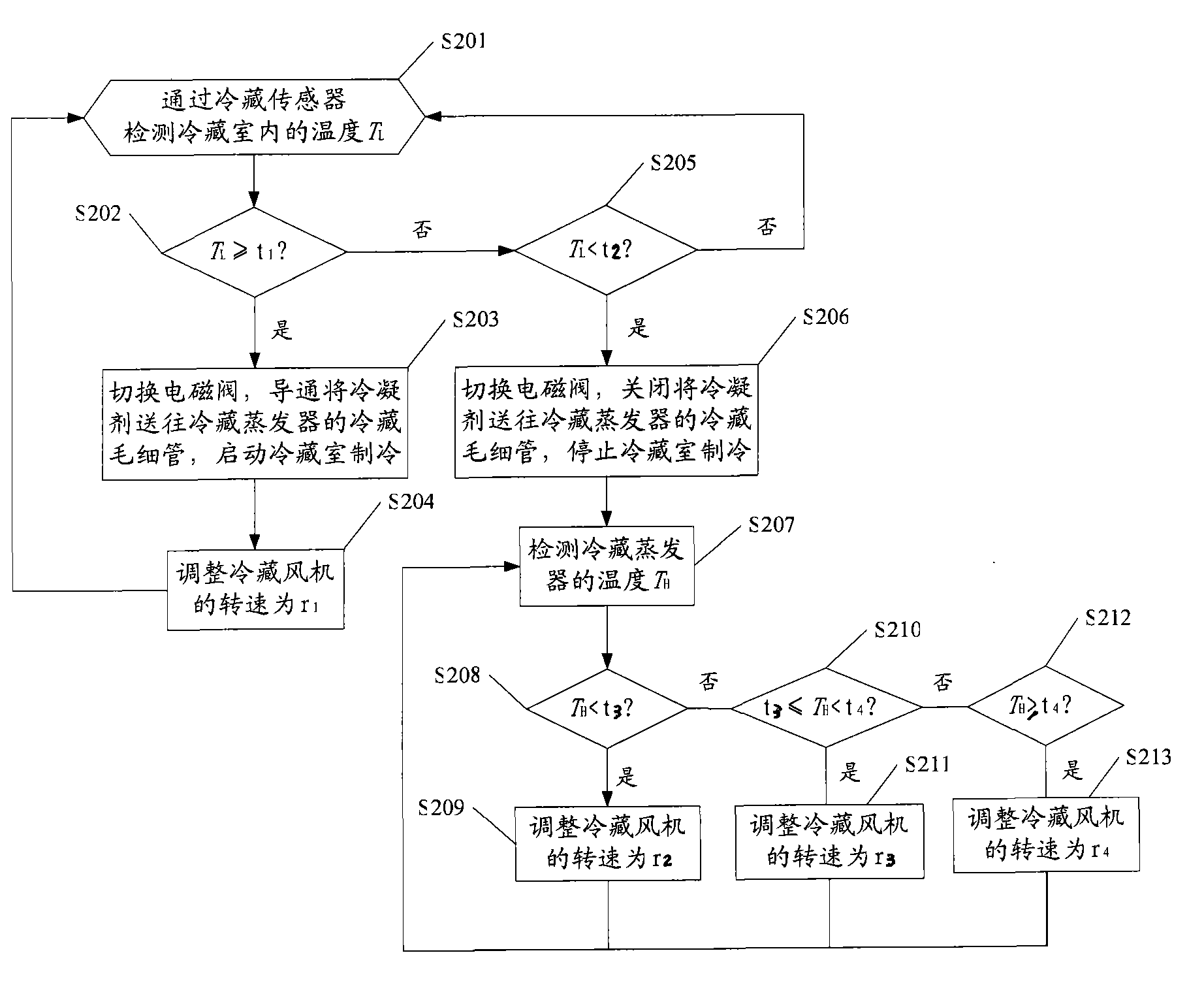

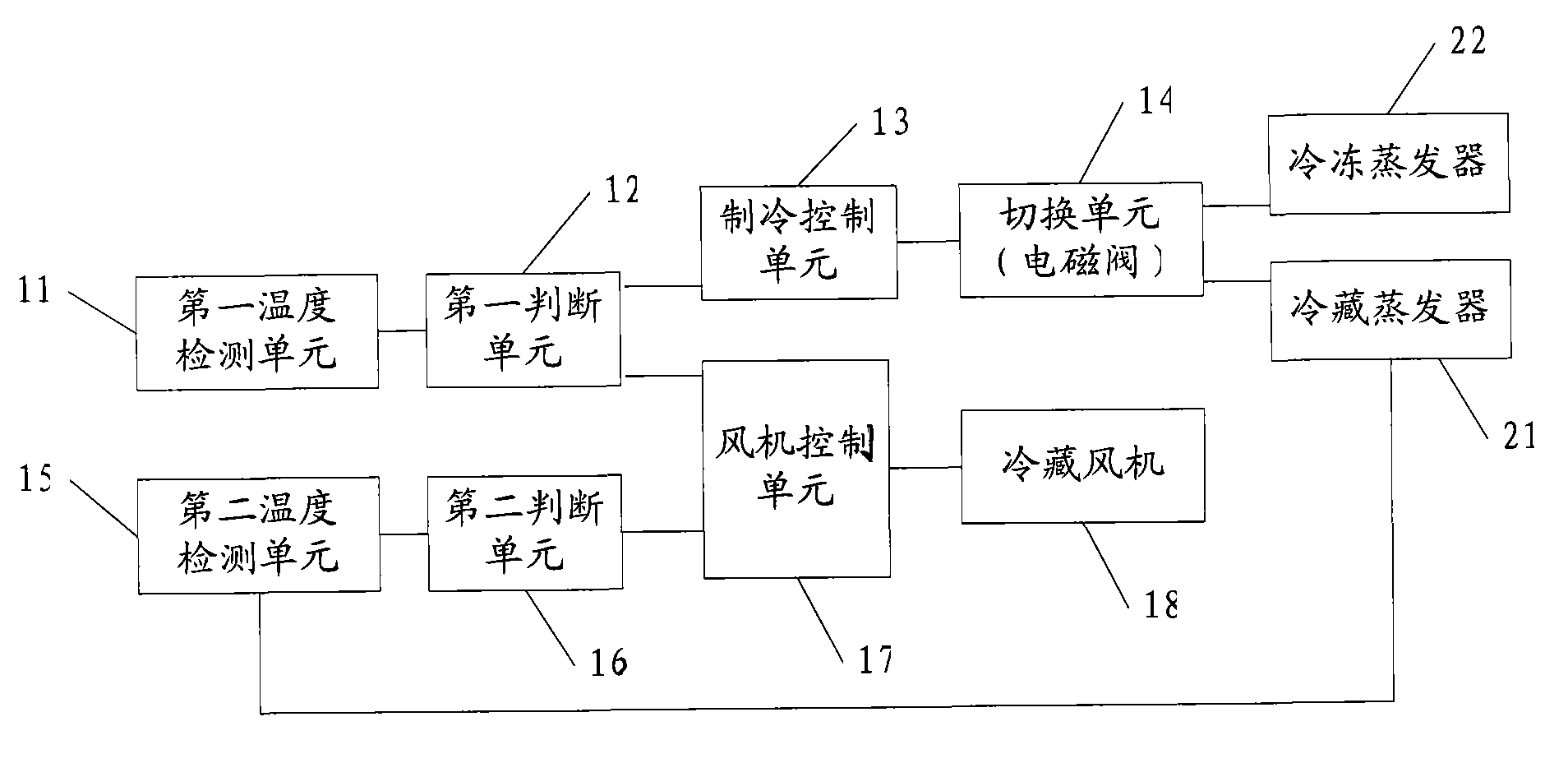

Air cooling refrigerator as well as moisture-preservation control method and system thereof

ActiveCN101937247BImprove the preservation effectReduce churnDomestic cooling apparatusLighting and heating apparatusCold storeControl theory

The invention discloses an air cooling refrigerator as well as moisture-preservation control method and system thereof. A chilling chamber is internally provided with a chilling evaporator and a chilling fan. The method comprises the steps of: step A, detecting the temperature TL in the chilling chamber; and step B, judging the magnitude of the TL, if the TL is within a first temperature range, adjusting the rotation speed of the chilling fan to be r1, returning to the step A and continuing detection. The invention can be used for carrying out reasonable and flexible moisture-preservation control on the chilling chamber of the air cooling refrigerator, increases the moisture of the chilling chamber, obviously improves the refreshment property of the chilling chamber, and reduces the energy consumption.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

A Method for Optimizing Job Running Parameters Applied to Supercomputing Cluster Scheduling

ActiveCN114048027BGood calculation efficiencyMake up for the lack of parameter configuration optimization capabilitiesResource allocationConfiguration optimizationScheduling (computing)

Owner:UNIV OF SCI & TECH OF CHINA

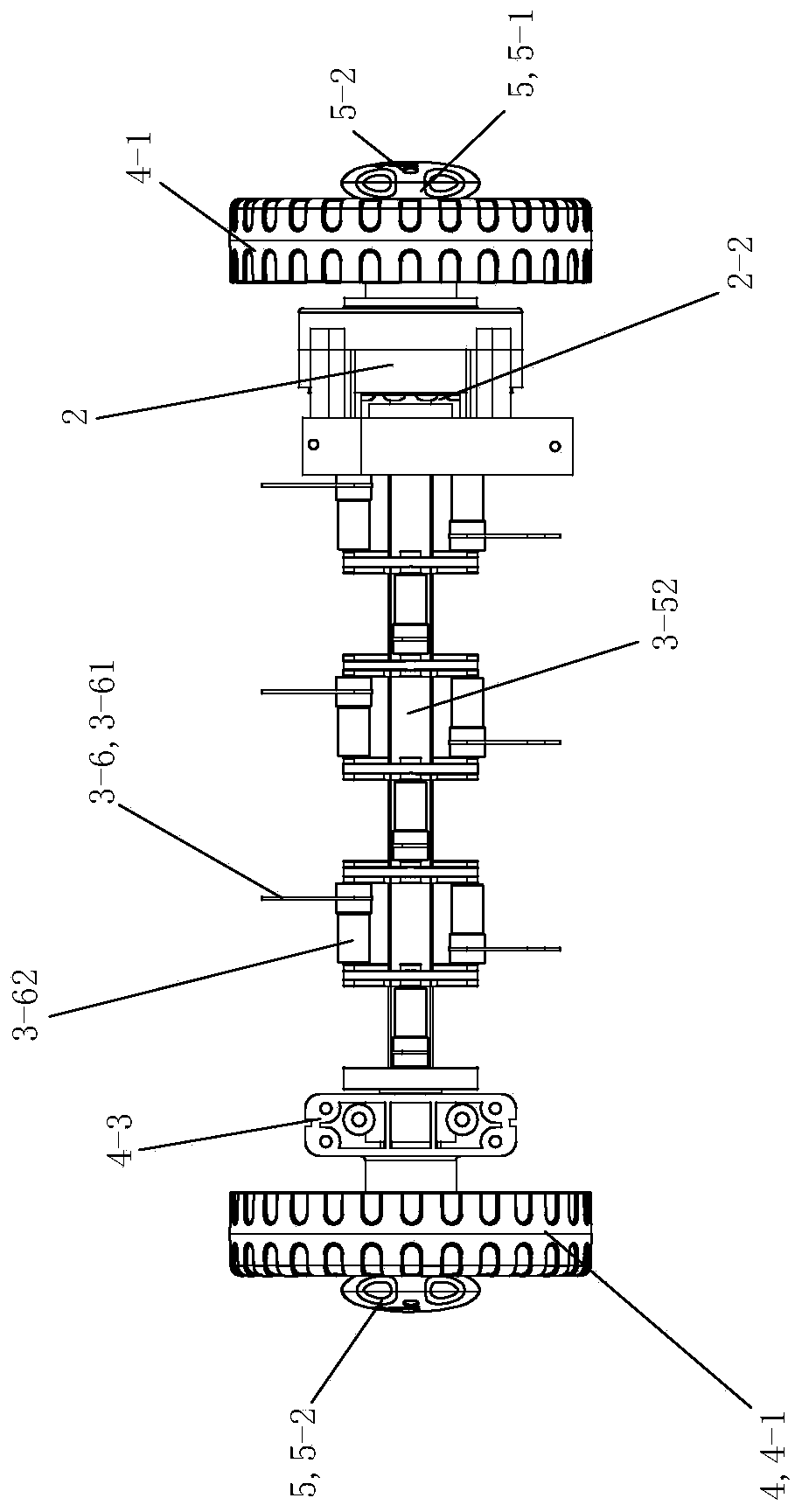

Lawn ventilator

PendingCN109845431ASimple structureReduce transmission structureAgricultural machinesAdjusting devicesEngineeringCentrifugal force

The invention discloses a lawn ventilator which comprises an enclosure, a motor, a soil loosening tool and a walking mechanism. The walking mechanism is arranged on the enclosure; a hand rail is arranged on the enclosure; an operation switch is arranged on the upper portion of the hand rail; the technical scheme includes that the soil loosening tool includes a rotating shaft rotatably arranged onthe enclosure and blades movably arranged on the rotating shaft. The motor shaft of the motor is in direct transmission connection with the rotating shaft of the soil loosening tool to drive the rotating shaft of the soil loosening tool to rotate to enable the blades on the rotating shaft to be swung out under the action of centrifugal force to conduct lawn loosening and aeration.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

An automatic device for firing a heating furnace

ActiveCN111926172BIncrease the number of jobsAvoid damageFurnace typesHeat treatment process controlHeating timeCombustion

The invention discloses a firing automation device for a heating furnace, which comprises a main controller, a first control valve, a second control valve, a circulator and a timer, and the main controller is connected with the first control valve and the second control valve , and the main controller is equipped with a timer and a circulator inside, the first control valve is set on the east side of the heating furnace, the second control valve is set on the west side of the heating furnace, the circulator is connected with the main controller and the second A connection is constructed between a control valve and a second control valve, the heating time of the west side of the heating furnace controlled by the second control valve is increased by 80s compared with the heating time of the east side of the heating furnace controlled by the first control valve, so that the temperature of the west side of the heating furnace is Compared with the temperature on the east side of the heating furnace, it is 50-80°C higher. In the present invention, by increasing the working times of the second control valve on the west side of the heating furnace, the temperature on the west side of the heating furnace is higher than the combustion temperature on the east side of the heating furnace, so as to avoid uneven heating of the second half of the billet to produce black tail steel.

Owner:SHANXI JINNAN IRON & STEEL GRP CO LTD

A shared bicycle for quick return

ActiveCN107054509BReduce the numberIncrease the number ofAnti-theft cycle devicesCycle standsVehicle frameReturn function

The invention belongs to the field of shared bicycles and particularly relates to a shared bicycle with a rapid returning function. The shared bicycle comprises a triangular front bicycle frame, a rear bicycle frame fixedly mounted behind the front bicycle frame and a double support leg mounted at the rear end of the rear bicycle frame; a filtering channel is formed in an upper pipe; a filtering piece is inserted in the filtering channel; a plurality of air pump assemblies distributed at equal intervals in the length direction of a lower pipe are mounted on the lower pipe; two baffles are symmetrically mounted on the two sides, located at the air pump assemblies, of the front bicycle frame; the upper pipe is rotatably connected with a clamping plate; an electromagnetic lock is mounted between the double support leg and the rear bicycle frame. After parking of the bicycle and locking of the electromagnetic lock, the bicycle is returned, the situation that a user forgets to lock or confirm bicycle returning to cause a failure of bicycle returning is avoided; when the shared bicycle is locked, because the double support leg enables a rear wheel to be separated from the ground, other people cannot use the bicycle in a non-unlocking state, and the shared bicycle can be prevented from being embezzled illegally by the other people.

Owner:江苏杭源机电设备有限公司

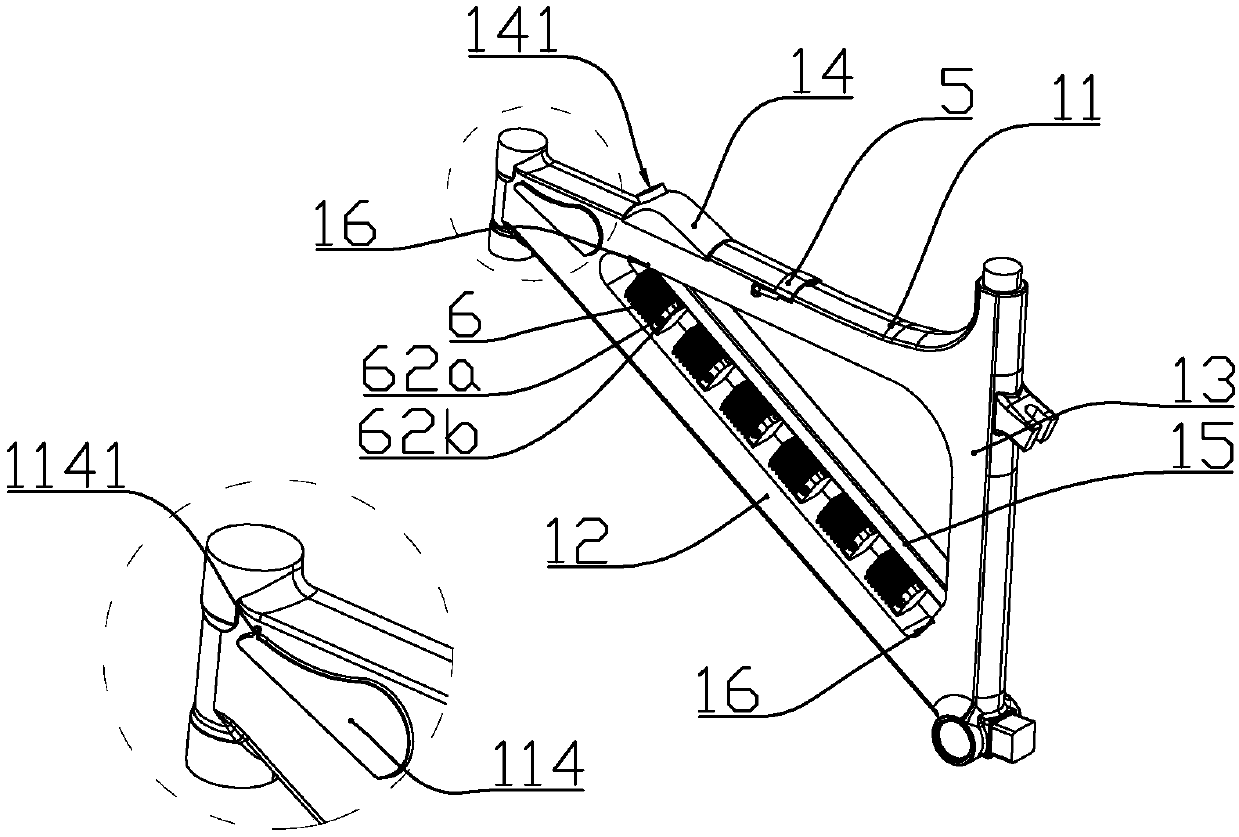

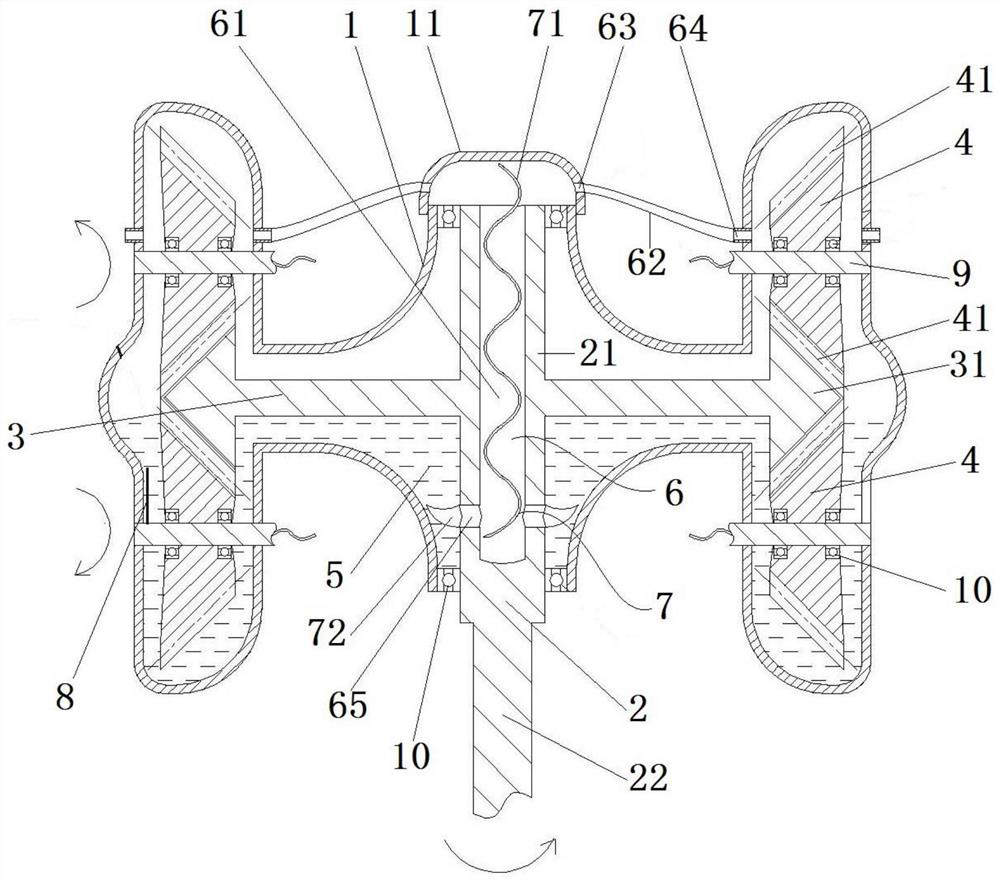

A torque booster motor

ActiveCN109194025BCompact structureIncrease time lagMechanical energy handlingGear wheelElectric machinery

The invention provides a torque-increasing motor, comprising a casing, wherein the casing is provided with a power output shaft; the power output shaft is provided with an upper end and a lower end; the upper end is connected with the casing through bearings arranged at the top and bottom of the casing; the lower end protrudes out of the casing; and the power output shaft is provided with an upperend and a lower end. A transmission gear sleeved and fixedly connected to the output shaft, and gear teeth are arranged on two sides of the outer periphery of the transmission gear; Several pairs ofmotors, each pair of the motors is respectively arranged on the upper and lower sides of the transmission gear. The output shaft of the motor is provided with hub teeth which are meshed with the wheelteeth, the rotation directions of the motor are mutually perpendicular to the rotation directions of the transmission gears, the rotation directions of the motor located on the same side of the transmission gears are the same, and the rotation directions of the motor located on different sides of the transmission gears are opposite. The torque-increasing motor provided by the invention can improve the torque output of the motor in a multiple relation through the lever principle.

Owner:吴志雄

A Heavy Oil Cold Recovery Technology Applicable to Shallow Well Formation

The invention relates to a heavy oil cold recovery process suitable for shallow well layers. The technical solution is: a reversing bypass valve is provided on the lower side wall of the oil pump of the oil pipe, and the gas generator is connected to the bottom of the oil pipe through a hydraulic switch and a reaction opener. The hydraulic switch corresponds to the oil production layer, and the gas generator Located in the lower part of the oil production layer, CaC2 is installed in the gas generator, and the CaC2 in the gas generator is controlled to react with water through the reaction opener, and the generated C2H2 gas is absorbed by the heavy oil in the oil production layer, and the heavy oil is diluted After that, it is extracted to the ground through oil pipelines and oil well pumps. The beneficial effects are: the production of the present invention is safe and reliable: through the use of the existing hydraulic switch, the production becomes more safe and reliable, the production is simple, and the formation will not be polluted; the economic benefit is good: the operation time is also short, and the mining efficiency is high; The oil is directly transported through the pipeline, which improves the transport efficiency and reduces the production cost.

Owner:YANCHENG RUIDE PETROCHEM MACHINERY CO LTD

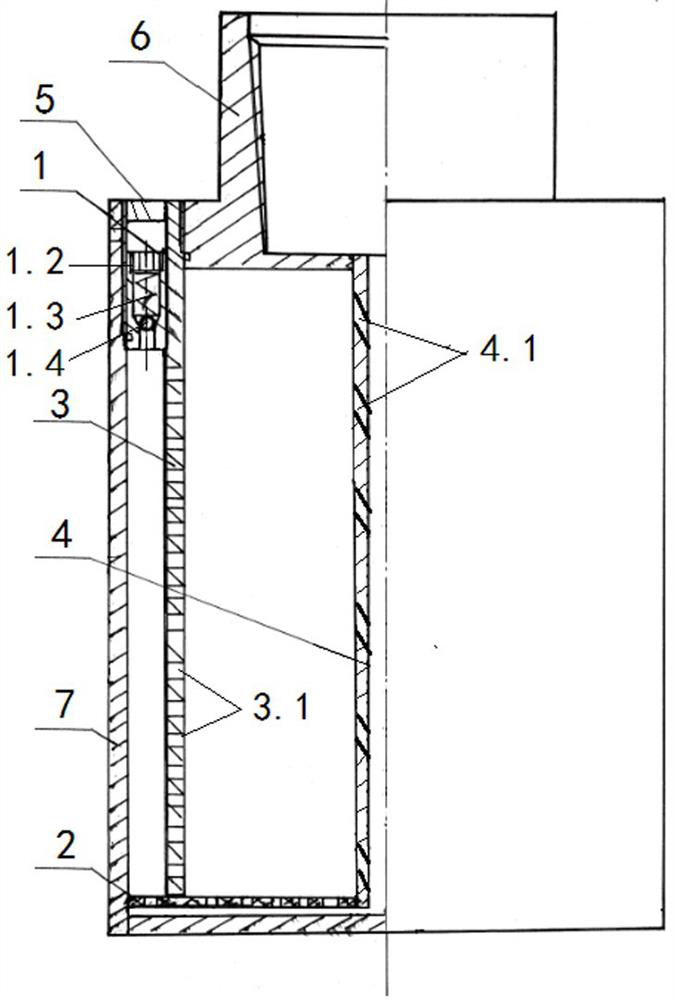

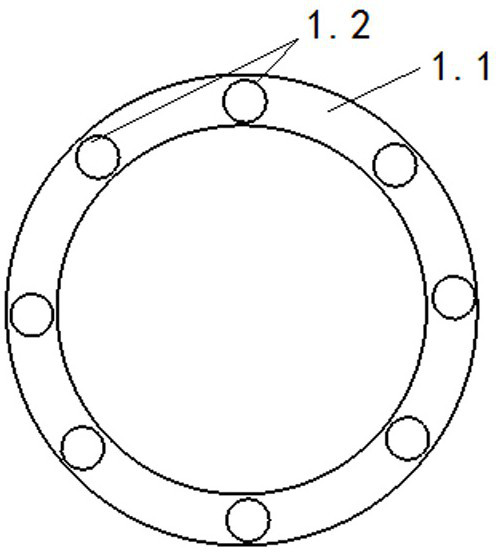

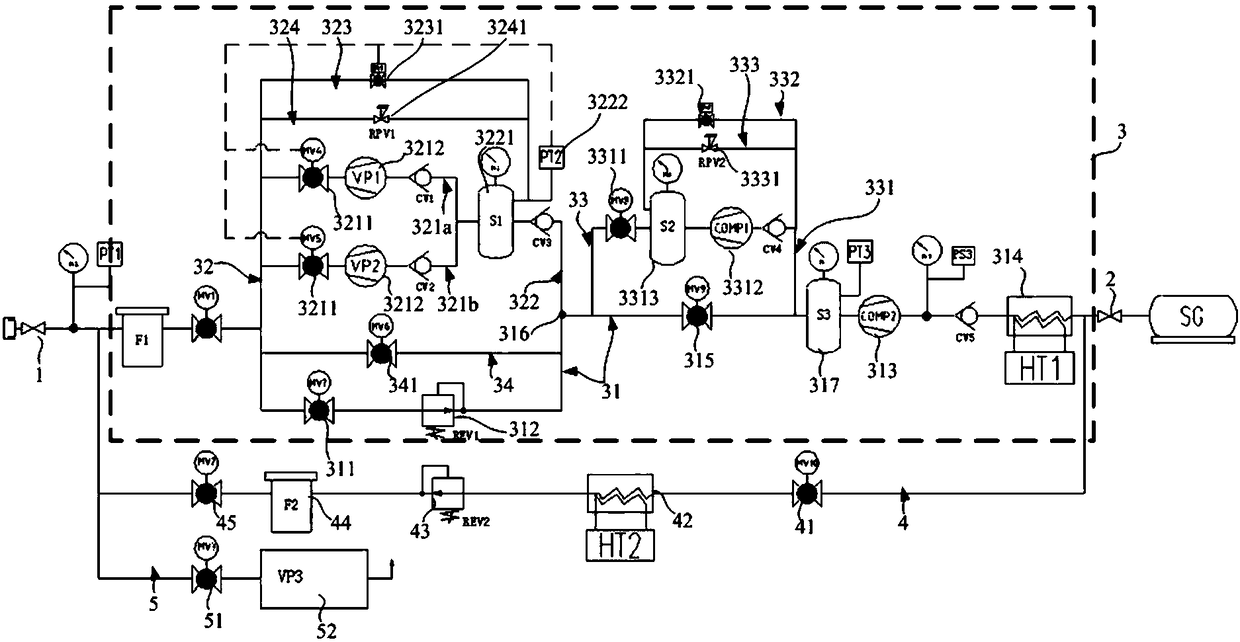

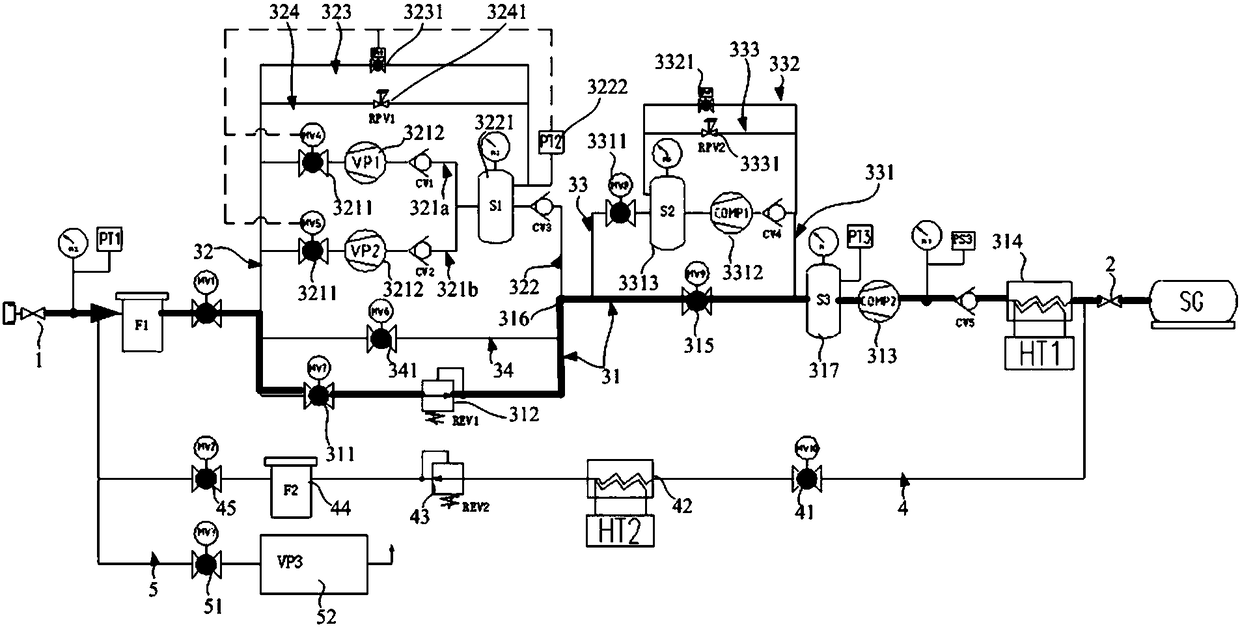

Insulating gas treatment device and control method thereof

PendingCN108386713AIncrease the number of jobsLarge displacementVessel mounting detailsGas handling/storage effectsProduct gasEngineering

The invention discloses an insulating gas treatment device and a control method thereof, and relates to the technical field of insulating gas treatment. The insulating gas treatment device and the control method thereof are invented for solving the problems that when an existing insulating gas treatment device recycles insulating gases, the recycling efficiency is low. The insulating gas treatmentdevice comprises a first connector, a second connector and a recycling branch. The recycling branch comprises a first branch and a second branch. The first branch is connected between the first connector and the second connector, and the first branch is sequentially provided with a first control valve, a pressure reduction valve, a first compressor and a heat exchanger in the direction from the upstream to the downstream. The second branch comprises a plurality of branch paths connected in parallel, one end of each branch path is connected with the part, on the upstream side of the first control valve, of the first branch, the other end of each branch path is connected to the part, between the pressure reduction valve and the first compressor, of the first branch, and each branch path issequentially provided with a second control valve and a vacuum pump in the direction from the upstream to the downstream. The insulating gas treatment device and the control method thereof can be usedfor recycling and other treatment on SF6 and other insulating gases.

Owner:STATE GRID CORP OF CHINA +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com