A heavy oil cold recovery device suitable for shallow wells

A heavy oil, cold recovery technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of difficult packer manufacturing, high packer requirements, and low viscosity of heavy oil. Achieve safe and reliable production, improve efficiency, and reduce processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

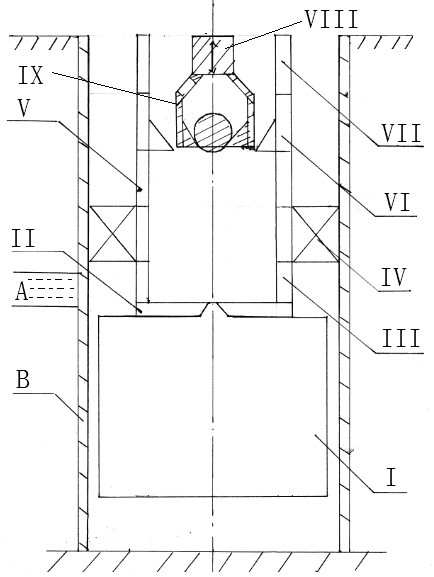

[0028] Example 1, reference attached figure 1 The present invention has a heavy oil cooling apparatus suitable for use in a shallow well layer, and the technical solution is: including a packer IV, an oil pump VI, a tubing VII, an oil collecting layer A, an oil well sleeve B, the oil well cover The tube B is fixed by a packer VII. The oil pipe VII is attached to the oil pipe VII, and the packer IV is located on the upper side of the oil production layer A. It is also: also includes a gas generator I, a reaction opening device II, Hydraulic switch III and reverse bypass valve V. The lower side wall of the oil pipe VII of the oil pipe VII is provided with a reversible bypass valve V, and the gas generator is connected by hydraulic switch III and reaction opening II at the bottom of the tubing VII. I, the hydraulic switch III corresponds to the oil production layer A, and the gas generator 1 is in the lower portion of the oil production layer A, and Cac is mounted in the gas generato...

Embodiment 2

[0046] Embodiment 2, referring to the accompanying drawings, the present invention is different from that of Example 1:

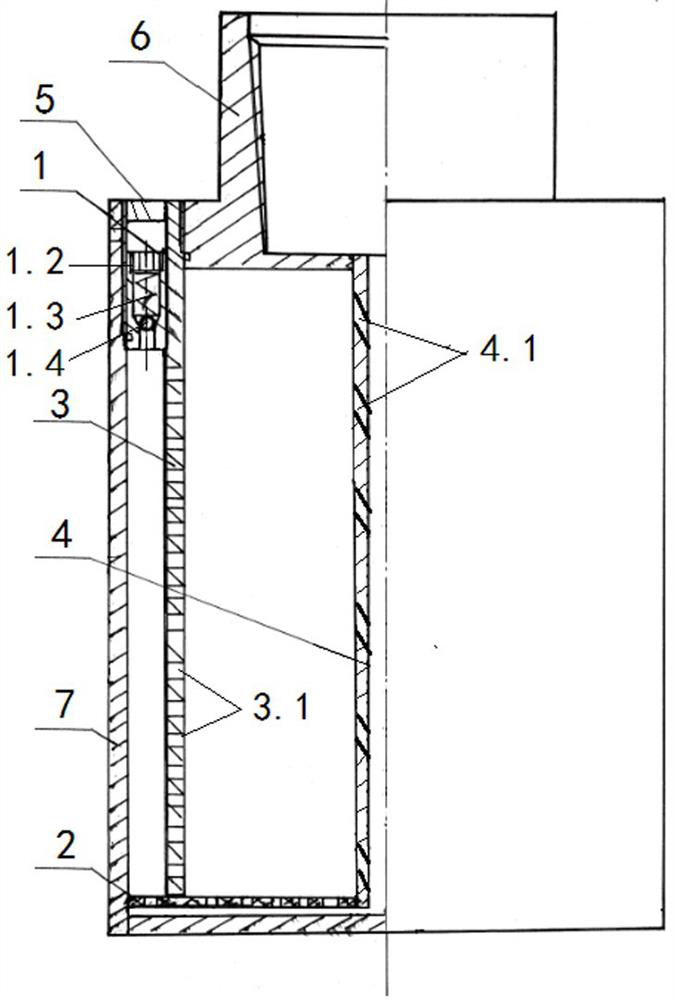

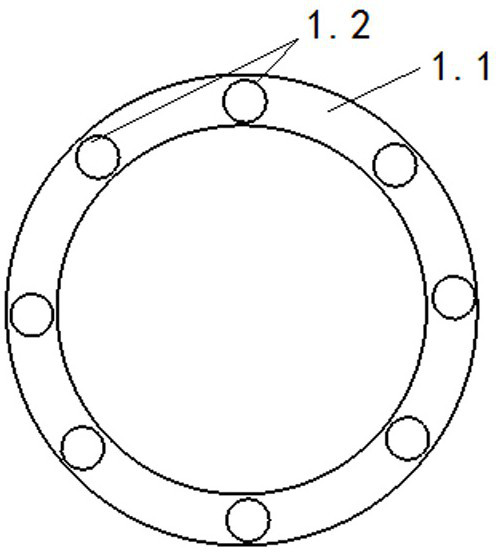

[0047] The gas generator 1 of the present invention includes a reaction limiter 1, an exhaust plate 2, a chemical reactor 3, a reaction drip pipe 4, an air orientation plate 5, a docking joint 6, a gas barrel 7, and the upper portion of the collector cylinder 7 There is a docking joint 6, and the inner cavity of the gas tube 7 is provided with a chemical reactor 3, and the inner cavity of the chemical reactor 3 is equipped with Cac. 2 The vent 2 is provided with an exhaust plate 2 at the bottom of the chemical reactor 3, and the upper portion of the annular cavity formed between the chemical reactor 3 and the gas cylinder 7 is provided, from the docking joint 6 into the reaction drip pipe 4. Water enters the chemical reactor 3 at the bottom and CAC in the chemical reactor 3 2 Reaction, generated C 2 Hide 2 The gas is removed along the annular cavity formed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com