A torque booster motor

A technology of motor fixing and casing, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of difficult to meet the high torque output, and achieve the effect of compact structure, increase the number of jobs, and reduce the number of jobs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

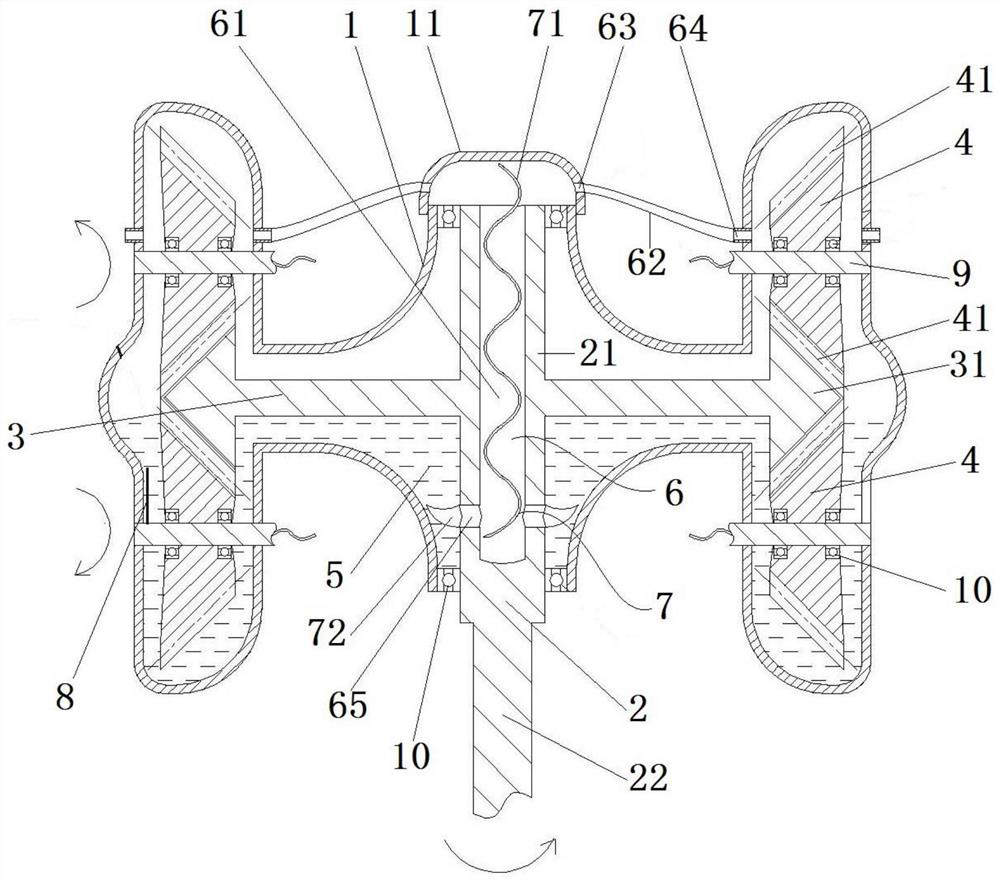

[0025] See figure 1 This embodiment provides a torque increasing motor, which is a motor that increases torque output through an even number of small motors acting on a special gear structure assembly at the same time. The casing 1 is provided with a power output shaft 2, a transmission gear 3 and two pairs of small motors 4. The power output shaft 2 is provided with an upper end 21 and a lower end 22. The upper end 21 is connected to the casing 1 through bearings provided on the top and bottom of the casing 1, and the lower end 22 extends out of the casing 1 and is connected to the load. In order to facilitate replacement or maintenance of parts, a detachable shell cap 11 is provided on the top of the casing 1 corresponding to the upper end 21 of the power output shaft.

[0026] The transmission gear 3 is a circular gear with gear teeth 31 on both sides of the outer circumference. The gear teeth 31 on both sides of the outer circumference form an angle of 45 degrees with the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com