Method for recycling single quartz and feldspar from gold flotation tailings

A technology for flotation of tailings and quartz, applied in flotation, solid separation and other directions, can solve the problems of feldspar loss, affecting flotation index, serious weathering of feldspar, etc., to reduce treatment costs, increase the number of operations, remove rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

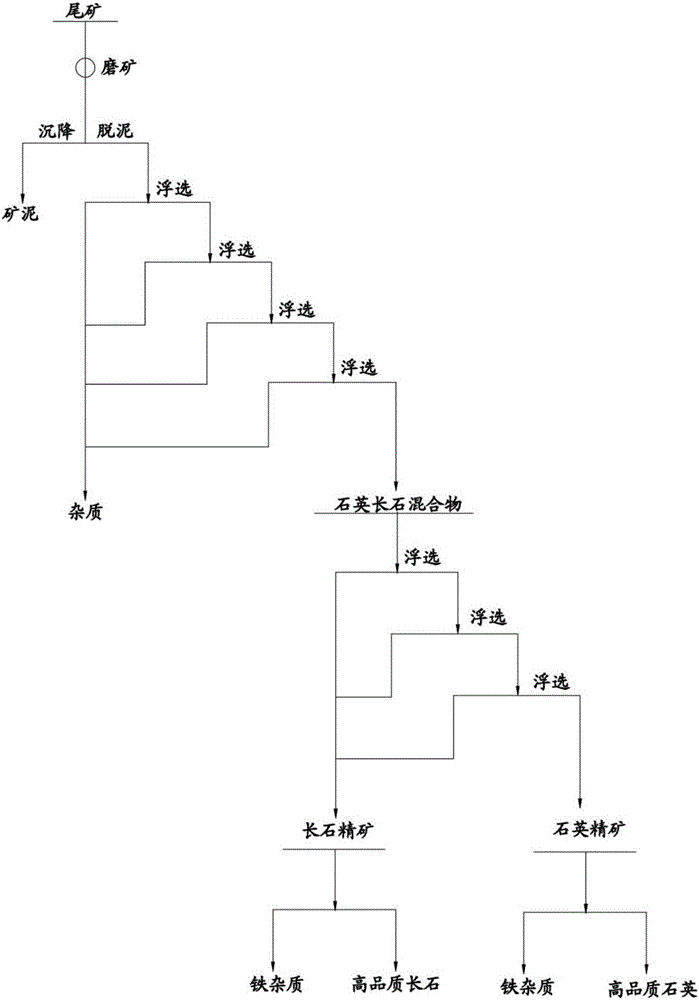

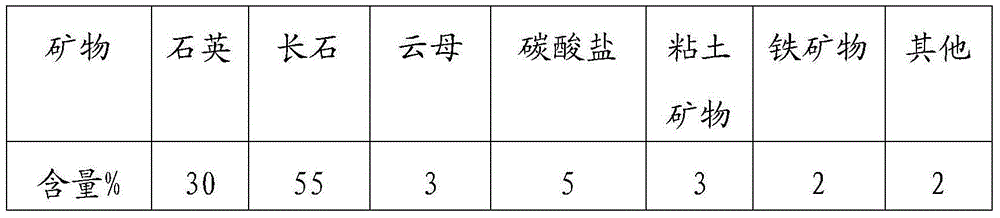

[0029] The method for recovering single quartz and feldspar from the tailings discharged from the Zhaoyuan Gold Mine in Shandong Province is as follows:

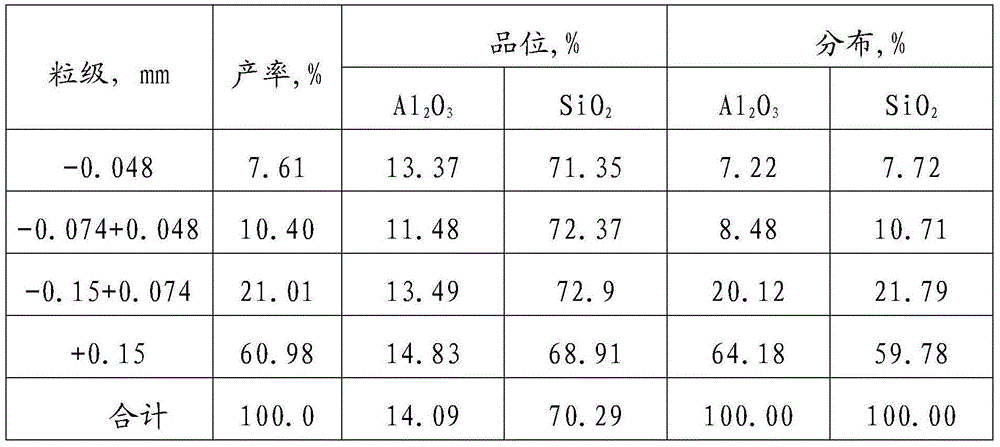

[0030] (1) Grinding: Grinding the gold flotation tailings until the fineness is -0.074mm and the particle size content accounts for 70%;

[0031] (2) Settling and desliming: adjusting the tailings in step (1) to a concentration of 26.10%, and settling and desliming for 2 minutes;

[0032] (3) Flotation removal of impurities: add 750g / t sodium carbonate and 300g / tYOA to the deslimed tailings slurry into the flotation machine, and perform the first flotation to obtain impurities and crude product I respectively; The crude product I is subjected to the second flotation, and 200g / t of YOA is added to obtain impurities and crude product II; the crude product II is subjected to the third flotation, and 200g / t of YOA is added to obtain impurities and crude product III; The crude product III is subjected to the fourth flotation, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com