Electrically controlled dryer assembly with ECU (Electronic Control Unit) controller and control method

A control method and dryer technology, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve problems such as complex line layout, control logic, input and output signal constraints, and shortened service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

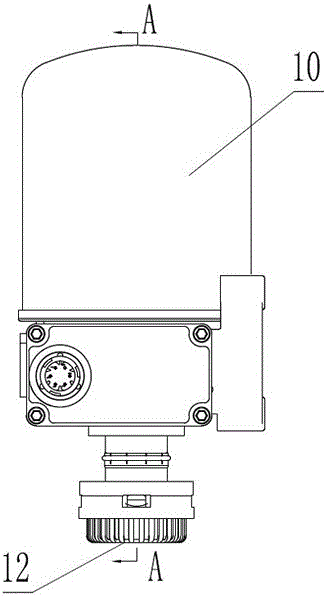

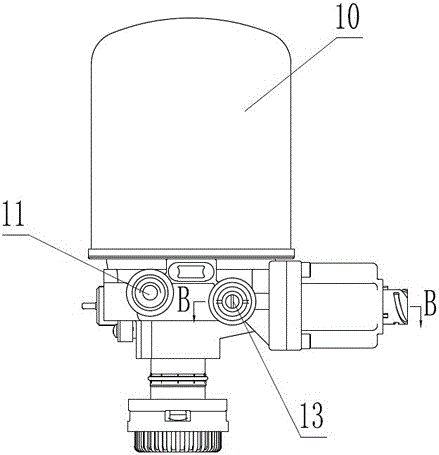

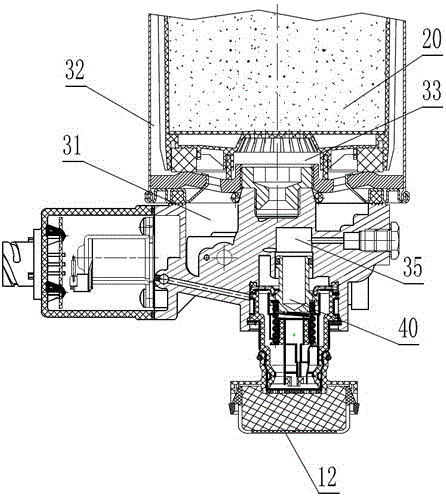

[0024] Such as Figure 1-4 As shown, an electronically controlled dryer assembly with an ECU controller in this embodiment includes a dryer body 10 and a drying tank 20 arranged in the dryer body 10, wherein the drying tank 20 is provided with a molecular sieve. The dryer body 20 of this embodiment is provided with an air inlet 11, an air outlet 13 and an air outlet 12.

[0025] In this embodiment, the dryer body 10 is also provided with a cavity A31, a cavity B32, a cavity C33, a cavity D34, a cavity E35, an unloading solenoid valve assembly 60, a blowback solenoid valve assembly 70, The ECU...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com