Cleaning and turnover clamp

A technology of flipping jigs and jigs, which is applied in the direction of manufacturing tools, grinding machines, and grinding machine parts, etc., can solve the problems of high labor intensity, unstable cleaning quality, and low cleaning efficiency, so as to save manpower, improve work enthusiasm, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

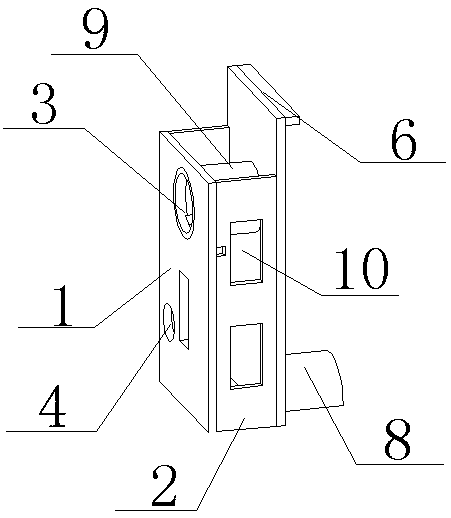

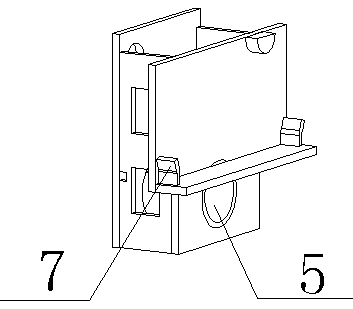

[0021] Such as figure 1 and 2 As shown, a cleaning and turning fixture includes a fixture base 1 on the cylinder horizontal turning cleaning platform, one side of the fixture base 1 is adjacent to the tooling plate on the cylinder horizontal turning cleaning platform, and the other side is In contact with the casting, when the fixture base 1 is on the horizontal turning cleaning platform of the cylinder body, the edge of the fixture base 1 can touch the pedal at the bottom of the horizontal turning cleaning platform of the cylinder body, and the fixture base 1 touches the casting The outer side of the splint on the side is provided with a clamping assembly for clamping the casting; the clamp base 1 is composed of a pair of splints and a reinforcement plate 2 connected between the two sides of the pair of splints, the clamp base 1 and the tooling The splints on the adjacent sides of the plate are respectively provided with positioning pin perforations 3 for the positioning pin...

Embodiment 2

[0029] Such as figure 1 and 2 As shown, a cleaning and turning fixture includes a fixture base 1 on the cylinder horizontal turning cleaning platform, one side of the fixture base 1 is adjacent to the tooling plate on the cylinder horizontal turning cleaning platform, and the other side is In contact with the casting, when the fixture base 1 is on the horizontal turning cleaning platform of the cylinder body, the edge of the fixture base 1 can touch the pedal at the bottom of the horizontal turning cleaning platform of the cylinder body, and the fixture base 1 touches the casting The outer side of the splint on the side is provided with a clamping assembly for clamping the casting; the clamp base 1 is composed of a pair of splints and a reinforcement plate 2 connected between the two sides of the pair of splints, the clamp base 1 and the tooling The splints on the adjacent sides of the plate are respectively provided with positioning pin perforations 3 for the positioning pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com