Intelligent assembly trolley with direct-current impact type electric wrench

An electric wrench and assembling trolley technology, applied in workshop equipment, power tools, manufacturing tools, etc., can solve the problems of negative impact on users, safety accidents, high noise, etc., and achieve the effect of reducing work intensity and facilitating operation and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

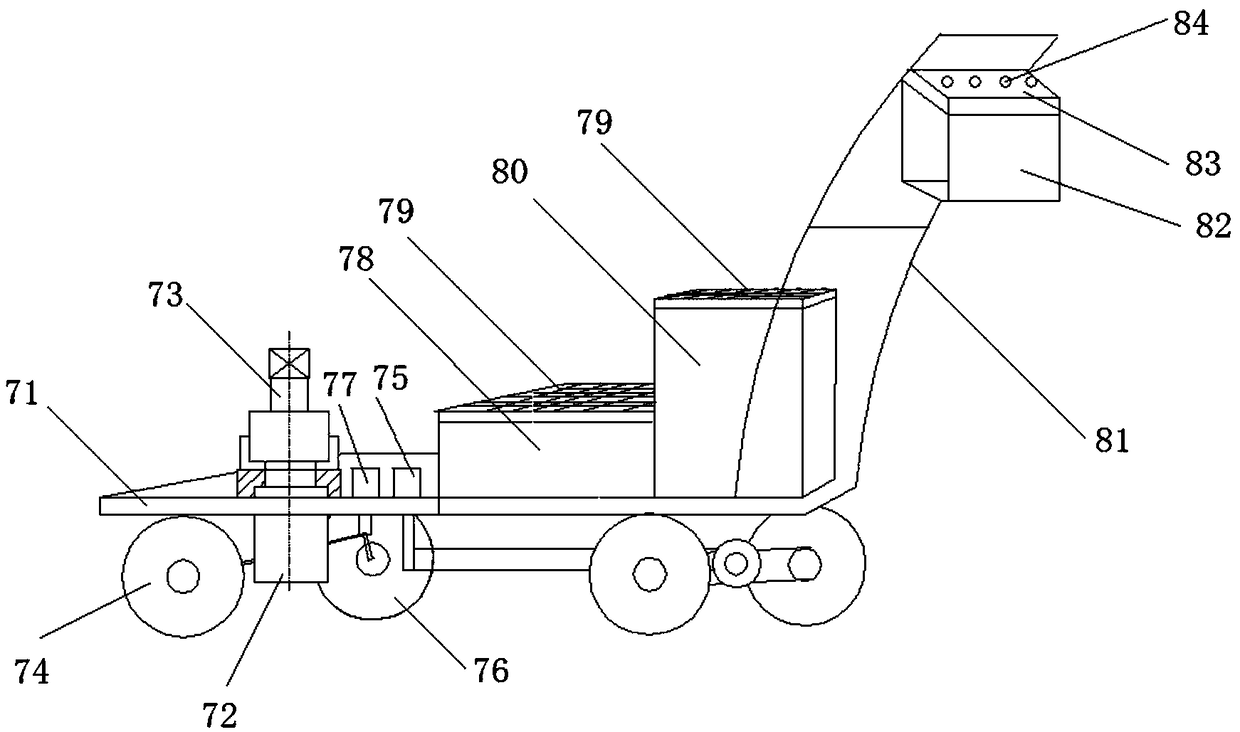

[0064] Such as figure 1 As shown, the present invention is an intelligent assembly car with a DC impact electric wrench, which includes a vehicle frame 71; an electric elevator 72 is installed on the vehicle frame 71, and a DC impact electric wrench 73 is installed on the lifting platform of the electric elevator 72; The vehicle frame 71 is also equipped with a DC motor-driven traveling device and a DC motor-driven steering device; the DC motor-driven traveling device includes road wheels 74 installed at the bottom of the frame, and is installed on the vehicle frame, connected with the road wheels 74, The DC walking driving motor 75 that can drive the walking wheels; the DC motor driving steering device includes a steering wheel 76 installed at the bottom of the frame, and a steering wheel that is installed on the frame, connected with the steering wheel 76, and can drive the steering wheel to turn. Direct current turns to drive motor 77. Described vehicle frame is provided w...

Embodiment 2

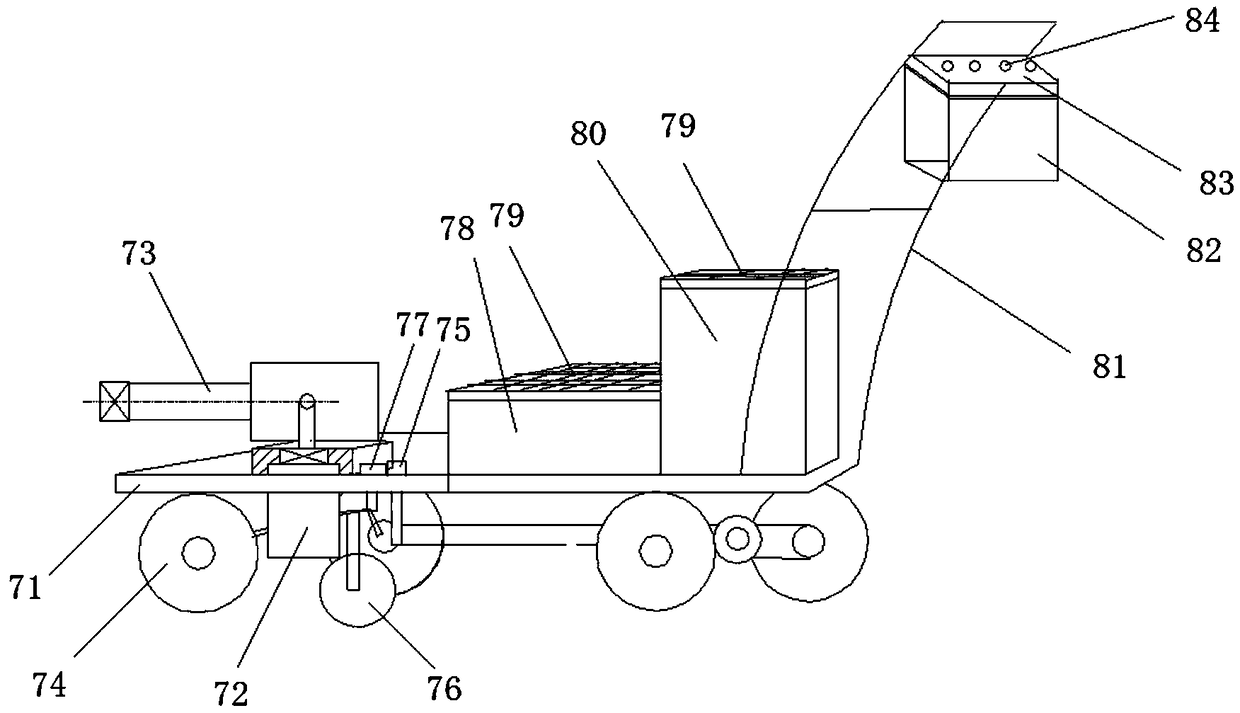

[0089] like figure 2 As shown, the present invention is an intelligent assembly car with a DC impact electric wrench, which includes a vehicle frame 71; an electric elevator 72 is installed on the vehicle frame 71, and a DC impact electric wrench 73 is installed on the lifting platform of the electric elevator 72; The vehicle frame 71 is also equipped with a DC motor-driven traveling device and a DC motor-driven steering device; the DC motor-driven traveling device includes road wheels 74 installed at the bottom of the frame, and is installed on the vehicle frame, connected with the road wheels 74, The DC walking driving motor 75 that can drive the walking wheels; the DC motor driving steering device includes a steering wheel 76 installed at the bottom of the frame, and a steering wheel that is installed on the frame, connected with the steering wheel 76, and can drive the steering wheel to turn. Direct current turns to drive motor 77. The vehicle frame is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com