Tire burst safety device, vehicle, and detection method of vehicle tires

A safety device and tire puncture technology, applied in tire measurement, vehicle parts, tire parts, etc., can solve the problems of dangerous driving of cars, difficulty in knowing the normal working state, easy tire puncture, etc., and achieve vehicle driving safety and easy working state. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

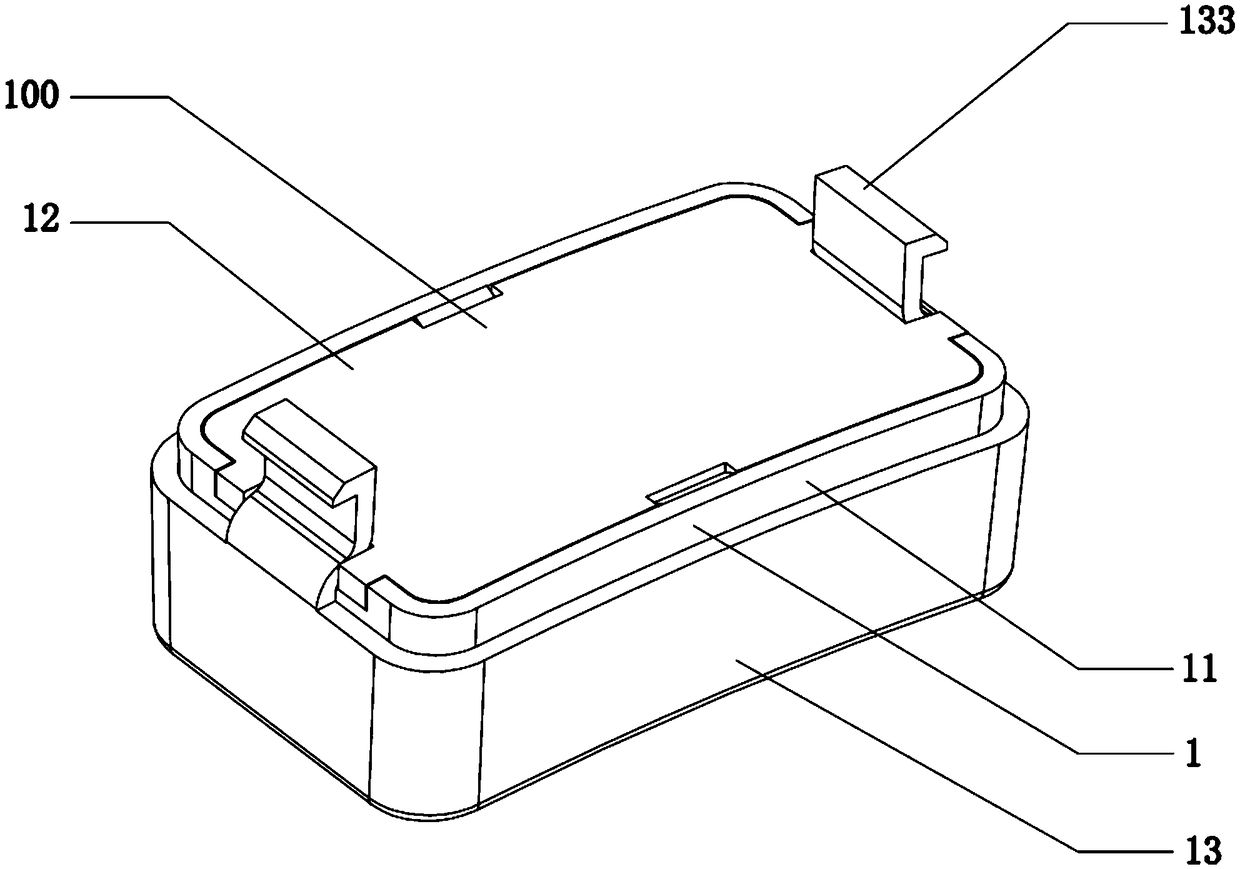

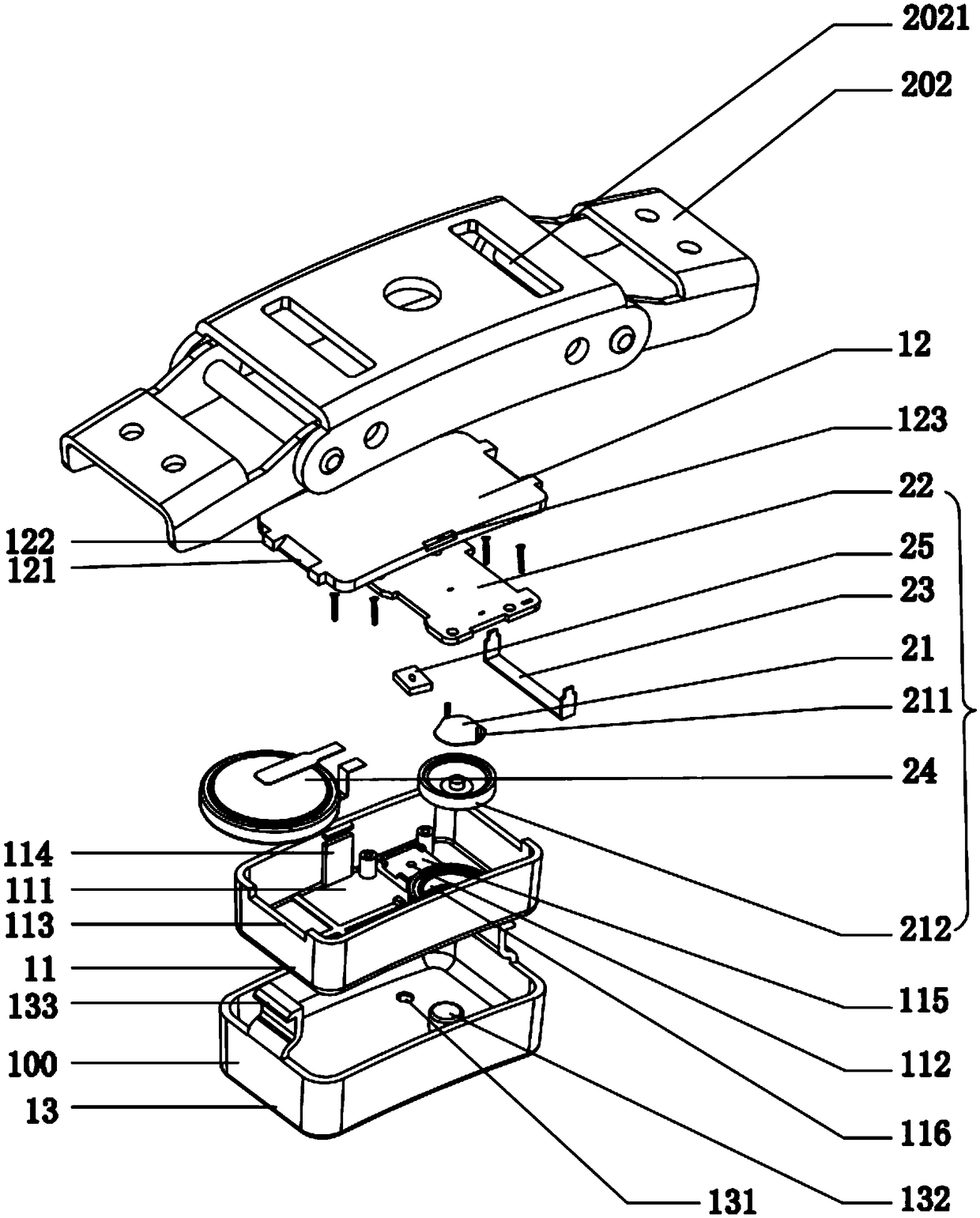

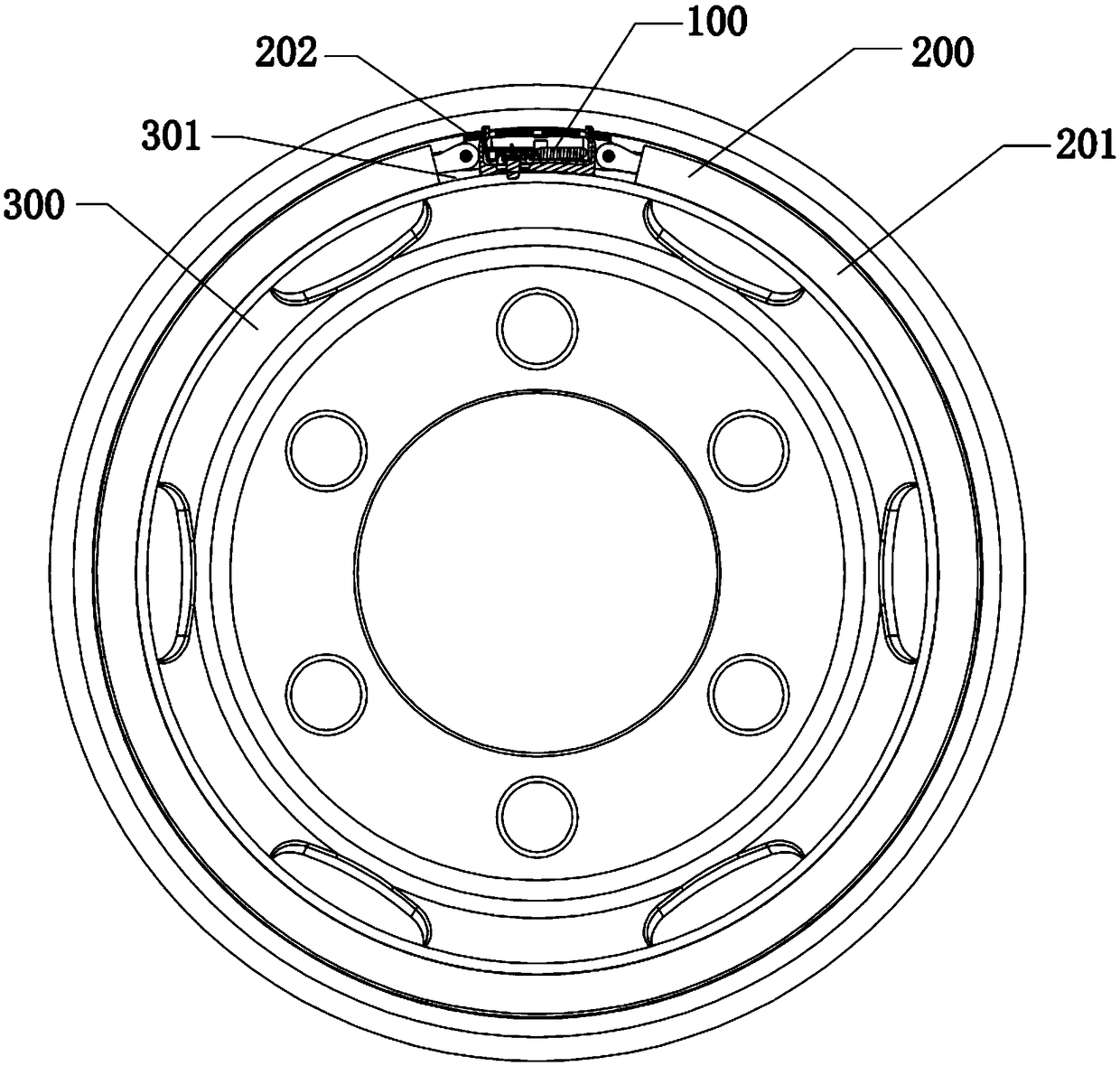

[0033] In this embodiment, the tire burst safety device is assembled on the vehicle, such as Figure 1-6As shown, the tire blowout safety device includes: a sensor 100, a strap installation structure 200 and a monitor 009, the sensor 100 is assembled on the wheel hub 300 of the tire through the strap installation structure 200, and the monitor 009 is assembled on the instrument panel in the cab of the vehicle Above, wherein the sensor 100 includes a casing 1 and a sensing component 2, the casing 1 is provided with an installation space 111, the sensing component 2 is assembled in the installation space 111, and the casing 1 is provided with an air hole, a switch operation structure 132 and a snap-in part 133 , the sensor assembly 2 includes a pressure switch assembly 21, and the pressure switch assembly 21 abuts against the switch operation structure 132; in this embodiment, the pressure switch assembly 21 is in a normally closed state when it is pressed and changes In other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com