An oxidation reaction equipment for rural sewage treatment

A technology for oxidation reaction and rural sewage, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of lack of static devices, insufficient mixing of gas and sewage, etc., to achieve the effect of prolonging the oxidation reaction time, good mixing effect, and slowing down the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

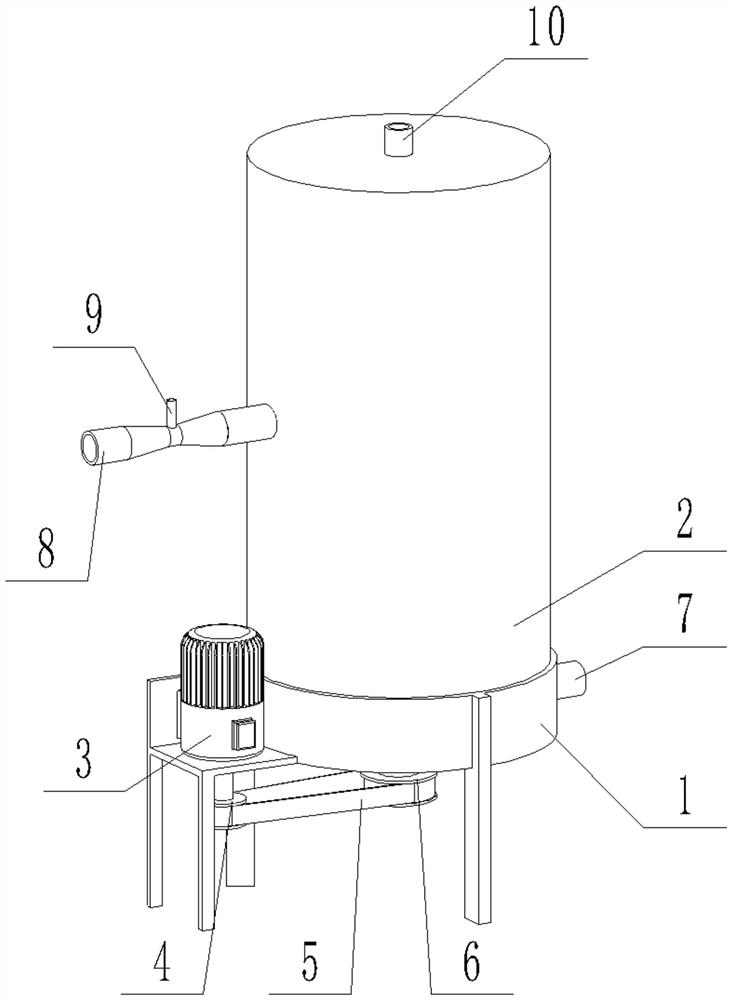

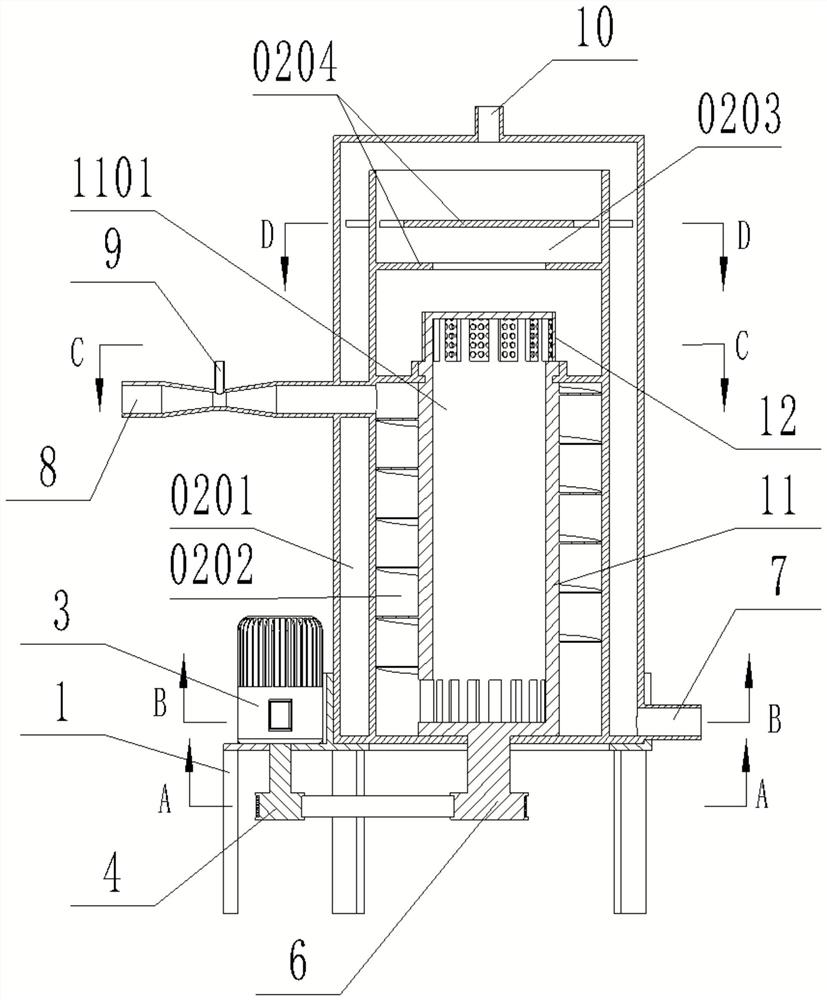

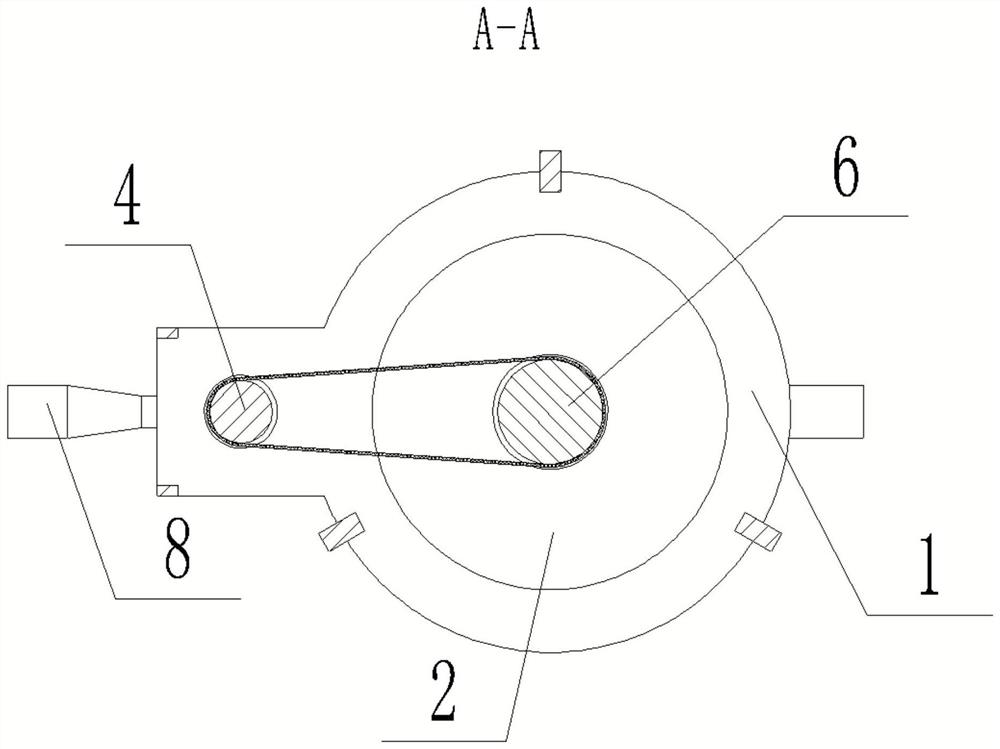

[0032] as attached figure 1 To attach Figure 8 Shown:

[0033] The present invention provides an oxidation reaction equipment for rural sewage treatment, including a base 1, an oxidation reaction barrel 2, a static chamber 0201, a stirring chamber 0202, a slow flow chamber 0203, a barrier plate 0204, a motor 3, a driving pulley 4, Drive belt 5, driven pulley 6, water outlet 7, water inlet 8, oxidizing gas inlet 9, exhaust gas outlet 10, stirring shaft 11, return chamber 1101, liquid return grid 1102, liquid outlet grid 1103, pushing A stirring paddle 1104 and a broken foam net 12; the top of the base 1 is fixedly connected with a group of the oxidation reaction barrels 2; the left side of the base 1 is fixedly connected with a group of the motors 3; A set of driving pulleys 4 is fixedly connected to the shaft; a set of driven pulleys 6 is axially connected to the bottom of the oxidation reaction barrel 2; A set of transmission belts 5 is wound; a set of water outlets 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com