Water based lubricant

A water-based lubricant, methyl hydroxypropyl technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of difficult cleaning and heavy pollution of water-based graphite lubricants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

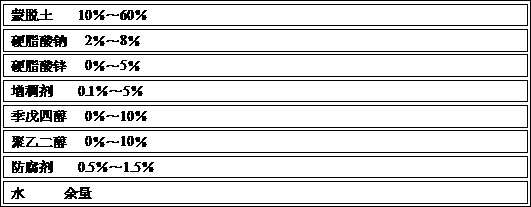

Method used

Image

Examples

Embodiment 1

[0011] A water-based lubricant prepared from the following raw materials in weight percent: montmorillonite 25%, sodium stearate 2%, zinc stearate 2%, methyl hydroxypropyl cellulose 0.3%, pentaerythritol 5%, Polyethylene glycol 5%, the balance is water.

[0012] The above-mentioned methyl hydroxypropyl cellulose and sodium stearate are first heated to 50°C in a solution of pentaerythritol, polyethylene glycol and water. o C. Stir to jelly, add other solid mixture and stir well to obtain a suspended liquid lubricant with good friction performance, good spraying effect and easy to clean and pollution-free.

Embodiment 2

[0014] A water-based lubricant prepared from the following raw materials in weight percent: montmorillonite 25%, sodium stearate 1.5%, zinc stearate 2%, methyl hydroxypropyl cellulose 0.1%, pentaerythritol 5%, Polyethylene glycol 5%, the balance is water.

[0015] The above-mentioned methyl hydroxypropyl cellulose and sodium stearate are first heated to 50°C in a solution of pentaerythritol, polyethylene glycol and water. o C. Stir to jelly, add other solid mixture and stir well to obtain a suspension liquid lubricant that has a good spraying effect and is easy to clean and pollution-free, but the viscosity is low, the fluidity is too good, and the thickness of the hanging film is relatively thin.

Embodiment 3

[0017] A water-based lubricant prepared from the following raw materials in weight percent: montmorillonite 25%, sodium stearate 3.8%, zinc stearate 2%, methyl hydroxypropyl cellulose 0.5%, pentaerythritol 5%, Polyethylene glycol 5%, the balance is water.

[0018] The above-mentioned methyl hydroxypropyl cellulose and sodium stearate are first heated to 50°C in a solution of pentaerythritol, polyethylene glycol and water. o C. Stir to a jelly, add other solid mixtures and stir well to obtain a suspending liquid lubricant with good friction performance, but high viscosity, poor fluidity, difficult to spray, and unable to perform spray lubrication operation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com