Water Based Clay Lubricant

A soil lubricant and water-based technology, applied in the field of mandrel lubricant preparation, can solve the problems of heavy pollution and difficult cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

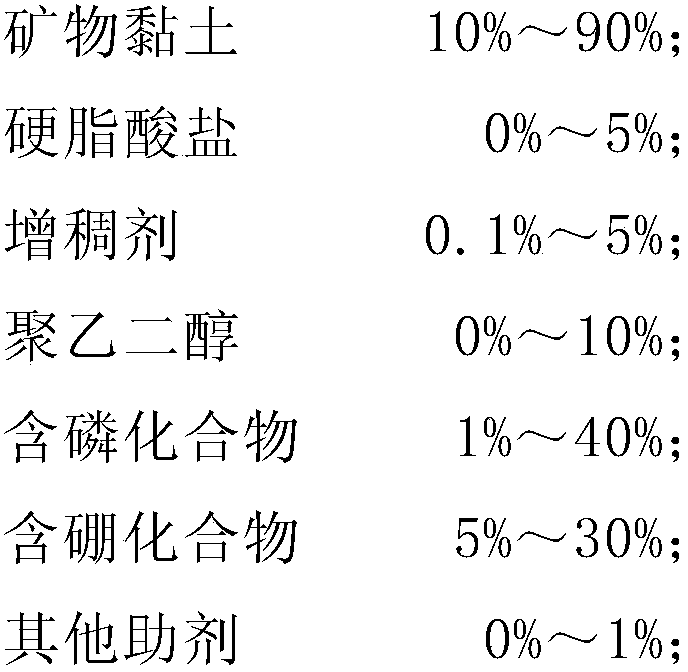

Method used

Image

Examples

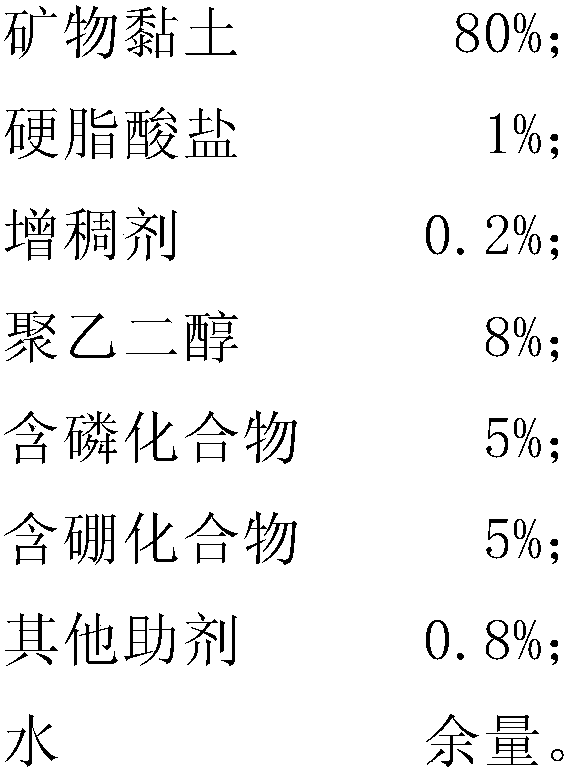

Embodiment 1

[0029] Water-based clay lubricant, prepared from the following raw materials in weight percent: talcum powder 30%, sodium carboxymethylcellulose 0.2%, diatomaceous earth 0.5%, sodium pyrophosphate 5%, aluminum stearate 1%, borax 5% %, polyethylene glycol 8%, monoglyceride stearate 0.8%, and the balance is water.

[0030] Stir the above thickener in the solution of borax and water until it becomes jelly, then add other solid mixtures and monoglyceride stearate, and stir thoroughly to obtain a suspended liquid lubricant with good friction performance and good spraying effect And easy to clean without pollution.

Embodiment 2

[0032] Talc 30%, polyvinyl alcohol 0.2%, bentonite 0.5%, sodium tripolyphosphate 5%, calcium stearate 1%, anhydrous sodium borate 5%, polyethylene glycol 8%, monoglyceride stearate 0.8% , the water balance.

[0033] Stir the above-mentioned thickener in the solution of anhydrous sodium borate and water until it becomes jelly, add other solid mixtures and monoglyceride stearate, and the suspension liquid lubricant obtained after fully stirring has better friction performance and is easy to absorb. Cleaning without pollution, but the low viscosity leads to thin film formation.

Embodiment 3

[0035] Talc 30%, Sodium Carboxymethylcellulose 0.6%, Sepiolite 0.5%, Sodium Pyrophosphate 5%, Aluminum Stearate 1%, Borax 5%, Polyethylene Glycol 8%, Ethylene Distearate Amide 0.8%, the balance is water.

[0036] Stir the above thickener into the solution of borax and water until it becomes jelly, add other solid mixtures and ethylene bisstearamide, and stir the obtained suspension liquid lubricant with poor friction performance and high viscosity. It is not easy to spray and does not meet the requirements of rolling pipes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com