Asphalt felt laying frame

A technology of asphalt linoleum and rolled felt, which can be used in protection devices, buildings, infrastructure engineering, etc., and can solve the problems of laborious operation and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

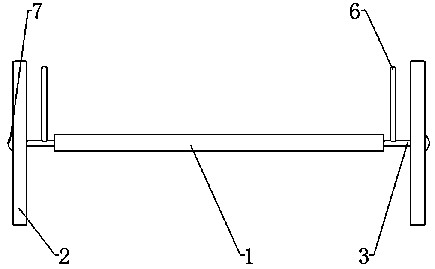

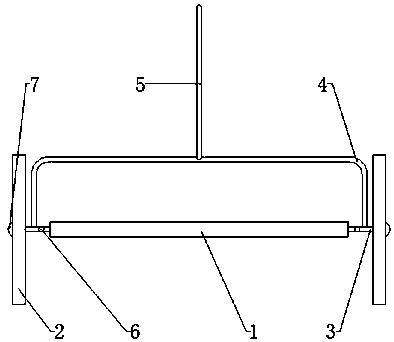

[0016] combine figure 1 with figure 2 , the asphalt felt laying frame includes a cylindrical felt roll shaft 1, two cylindrical installation rods 3 are arranged on both sides of the felt roll shaft 1, the diameter of the installation rods 3 is smaller than the diameter of the felt roll shaft 1, and the installation rods 3 and the roll The felt shafts 1 are all coaxial, and the two mounting rods 3 are respectively connected with two rollers 2 of the same size through rivets 7, and the two rollers 2 can rotate freely around the mounting rods 3, and two cylindrical limiters are arranged symmetrically and vertically on the two mounting rods 3. The position rod 6 and the two installation rods 3 are provided with a U-shaped rod-shaped U-shaped frame 4, and the center of the U-shaped frame 4 is vertically provided with a cylindrical handle 5. The handle 5 extends away from the felt rolling shaft 1 .

[0017] The felt rolling shaft 1 and the installation rod 3 are all made of alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com