Liquid gas storage tank decompression leakage safety valve and using method thereof

A technology of liquefied gas tank and safety valve, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of unreliable operation of safety valve, inability to automatically close the valve, explosion loss, etc., to avoid explosion and personnel poisoning, Stable and reliable valve operation and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

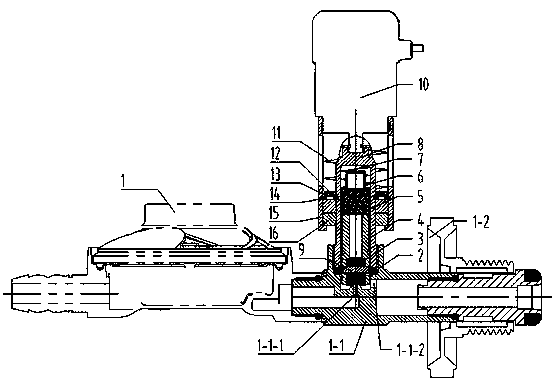

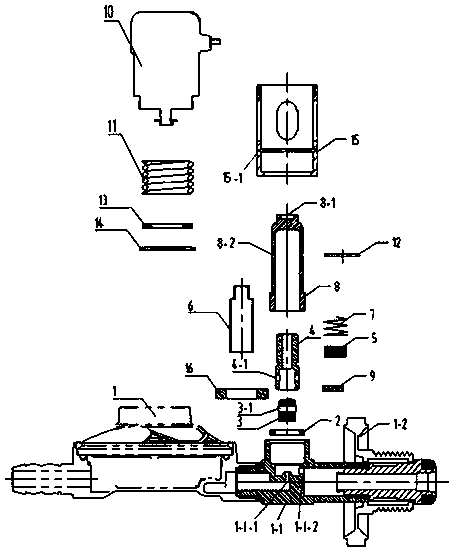

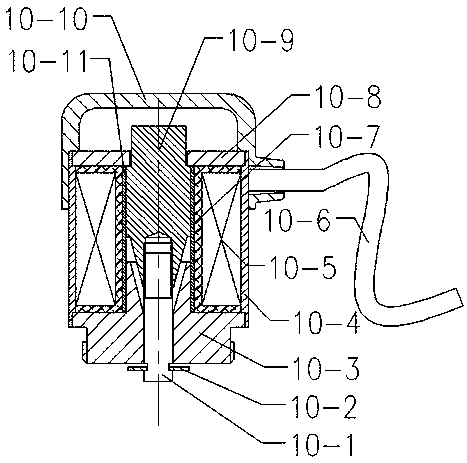

[0031] Such as Figure 1 to Figure 4 As shown, a liquefied gas tank decompression leakage safety valve includes a valve body 1, a gasket 2, a sealing cap 3, a valve stem 4, a magnetic core 5, a magnetic core sleeve 6, a small spring 7, a sealing sleeve 8, a temperature sensing Element 11, small circlip 12, gasket 13, large circlip 14, valve cover 15, magnetic ring 16, small valve body 1-1, handwheel connector 1-2 also include stainless steel pin 9, electromagnet 10.

[0032] The sealing cap 3 is a cylinder, and the middle position of the sealing cap 3 is horizontally provided with a pin hole I3-1.

[0033] The valve rod 4 is cylindrical, and a pin hole II4-1 is horizontally provided on the wall of the lower end of the valve rod 4 .

[0034] The sealing sleeve 8 is barrel-shaped, and a circular pit 8-1 is arranged on the upper end surface of the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com