Test device and test method for determining internal water pressure in cracks of water-injected coal seam

A test device, internal water technology, applied in the direction of measuring device, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., can solve the problem that water pressure cannot be accurately measured, and achieve the effect of improving the comprehensive disaster prevention effect of coal seam water injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention proposes a test device and test method for determining the internal water pressure of water-injected coal seam fissures. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

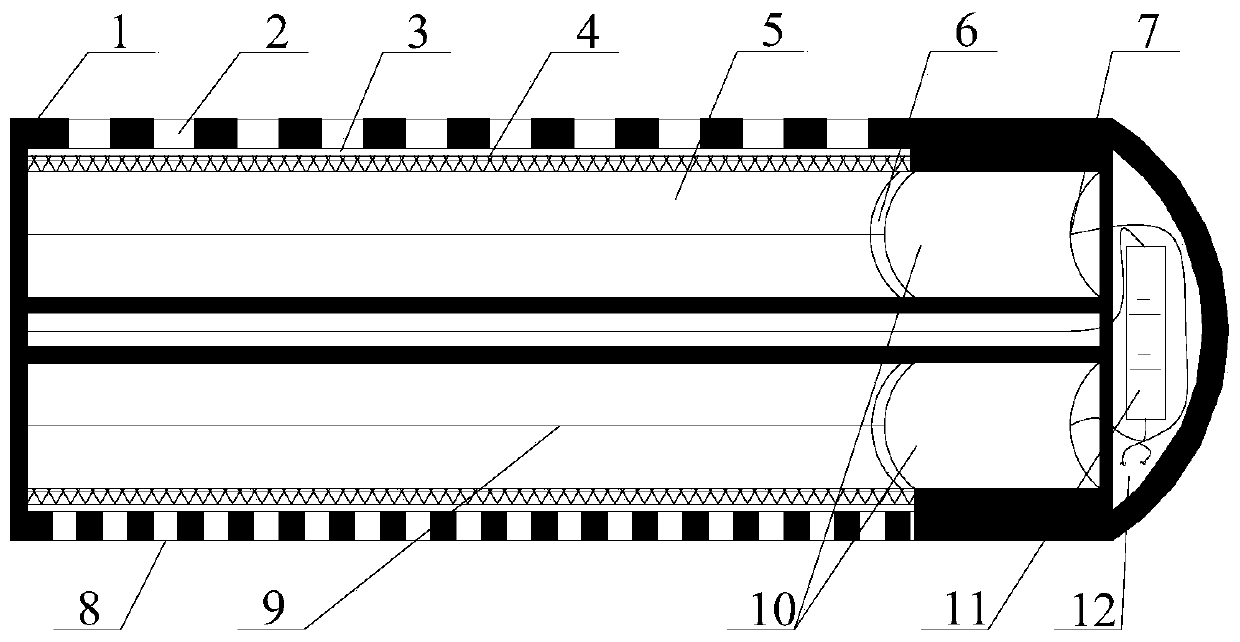

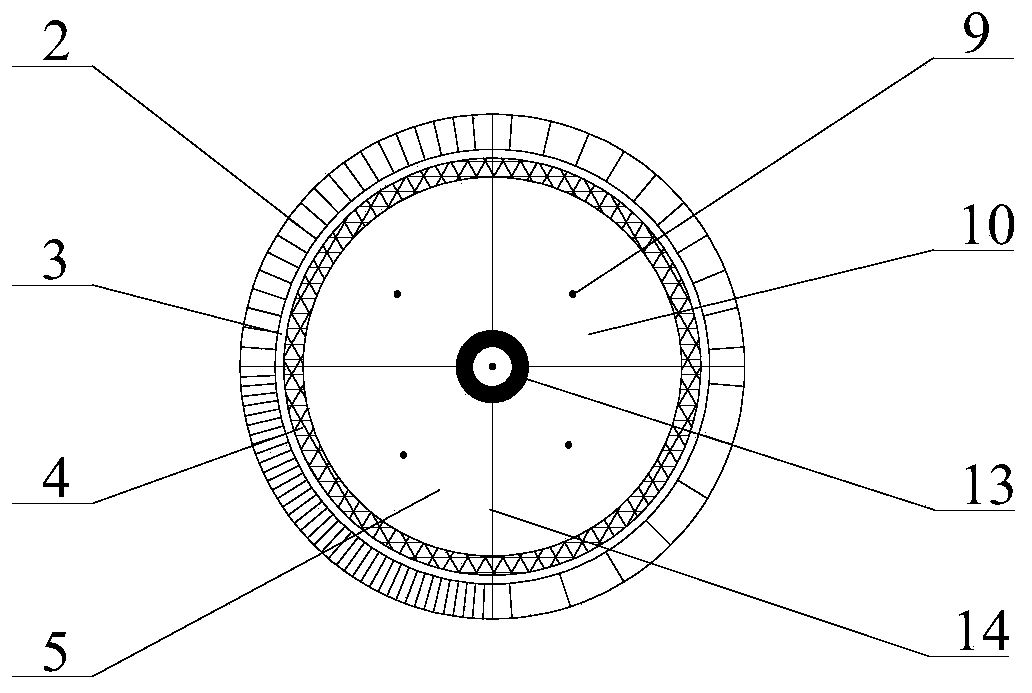

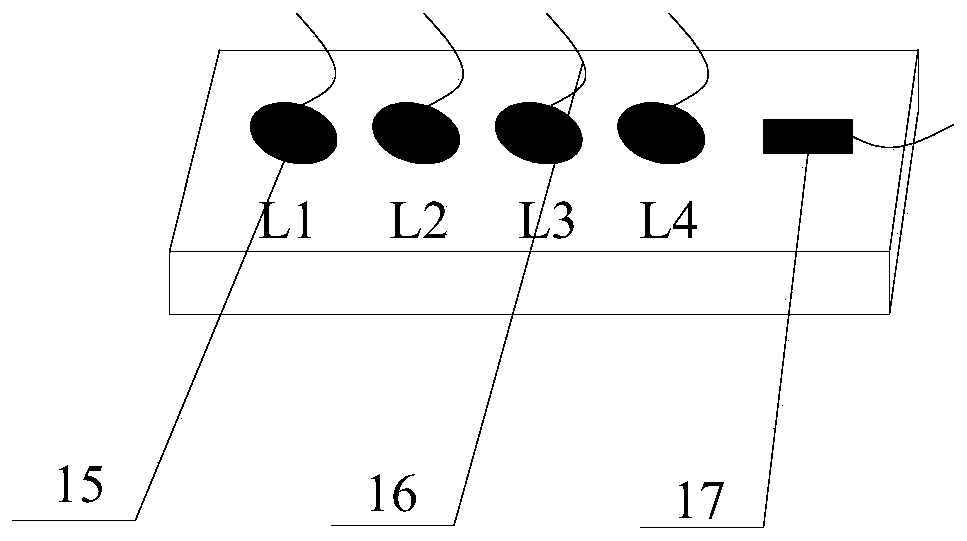

[0029] to combine Figure 1 to Figure 3 As shown, a test device for determining the internal water pressure of water-injected coal seam cracks includes a test mechanism and a display mechanism. Expansion rubber 5, positive electrode connection head 6, negative electrode connection head 7, small water inlet hole 8, wire 9, sealing chamber 10, explosion-proof power supply 11, power supply chamber 12, water-proof rubber tube 13 and partition 14, shell 1 The shape is cylindrical, and several water inlet holes with different apertures are arranged on the shell, that is, the larger water inlet hole 2 and the smaller water inlet hole 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com