Tractor loading running-in test stand

A loading test and tractor technology, which is applied in the field of tractors, can solve the problems that the running-in detection of tractor power output shafts cannot be known through observation of test phenomena, so as to improve test efficiency, realize automatic control, and reduce work content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

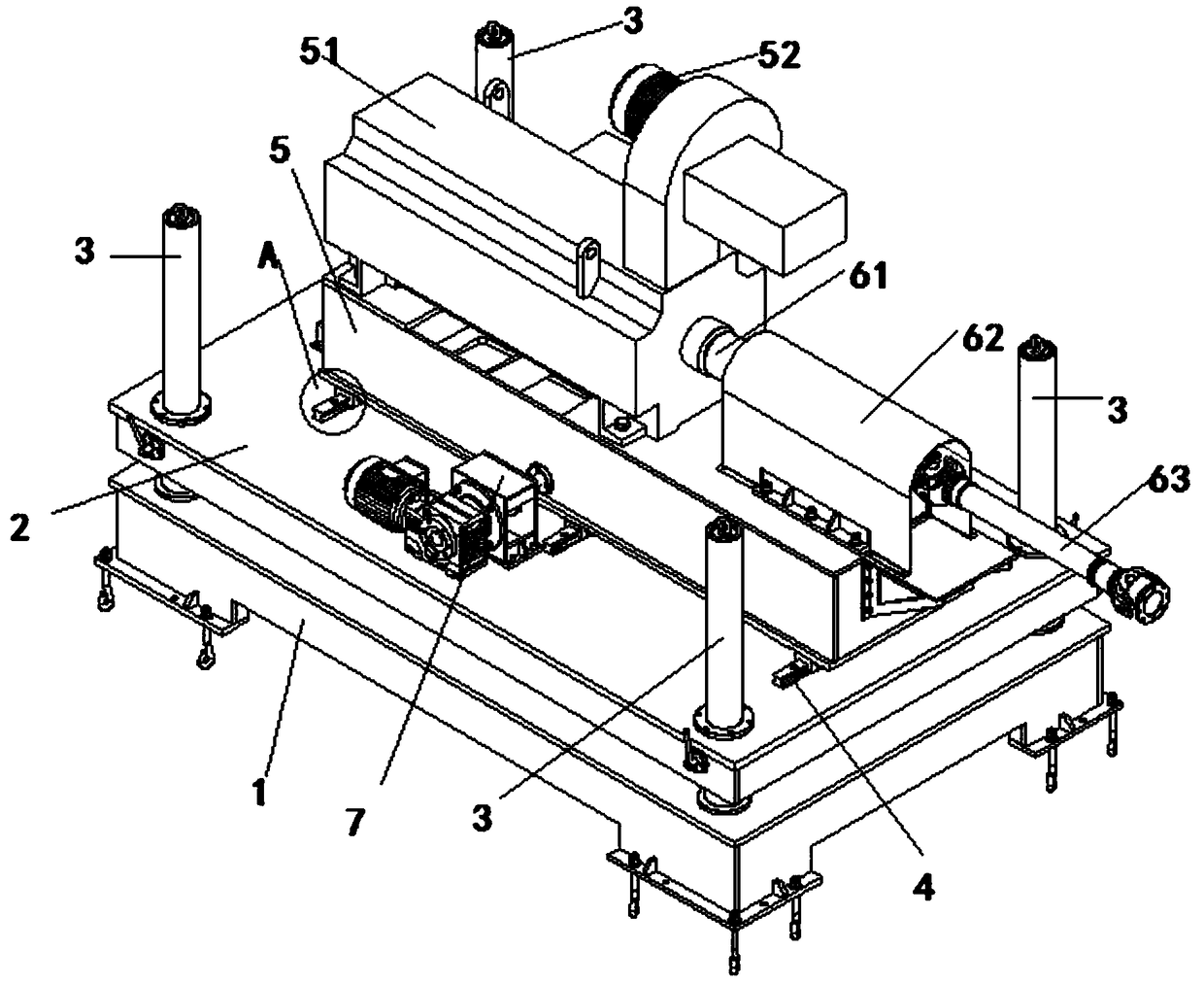

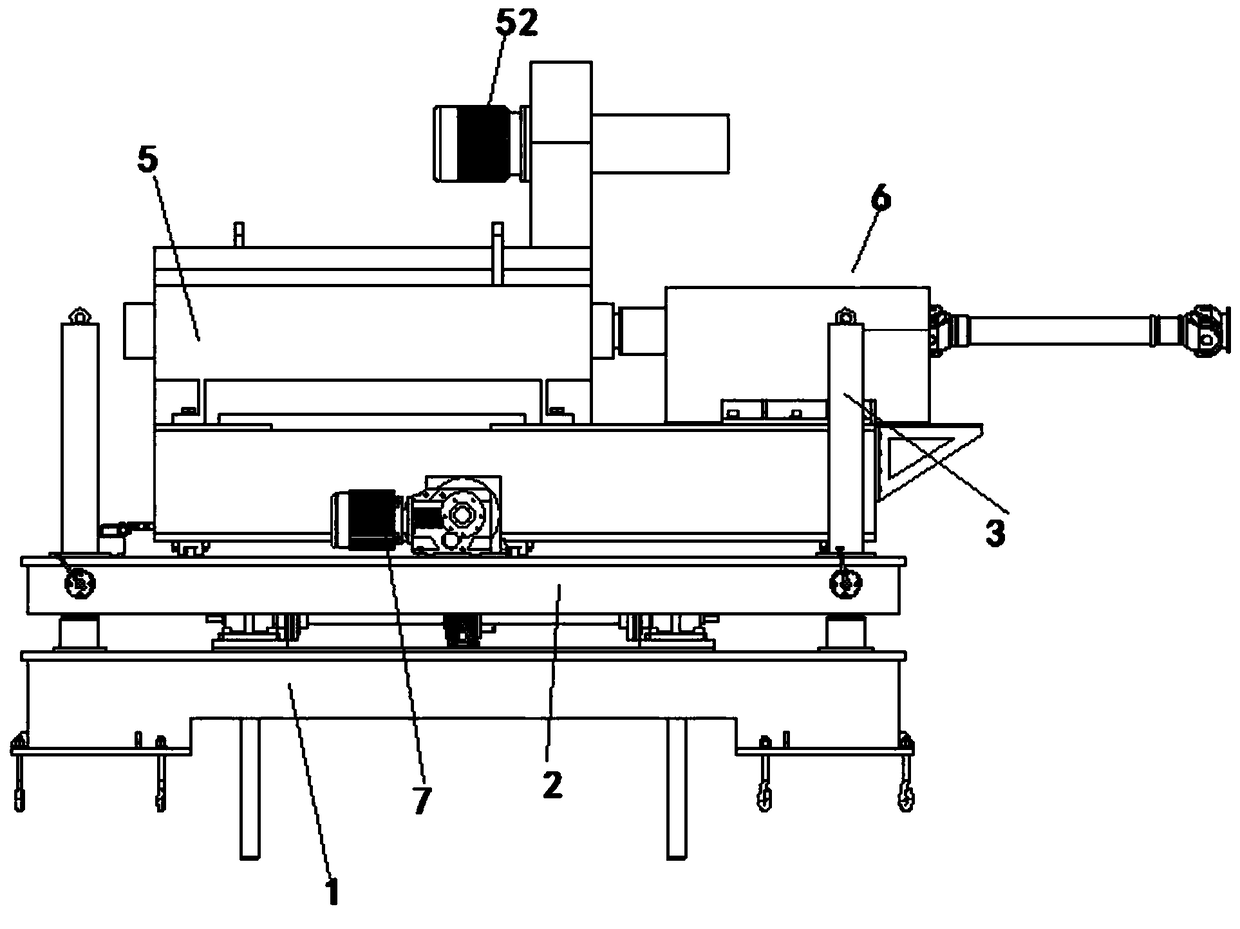

[0016] A tractor loading and running-in test bench, such as figure 1 and figure 2 As shown, it includes the base platform 1 and the test platform 2. There are two lifts in the middle of the surface of the base platform 1. The test platform 2 is installed and fixed on the power ends of the two lifts. At the same time, the four corners of the surface of the base platform 1 are fixed with lifting guide columns. 3. At the same time, the four corners of the surface of the test platform 2 are provided with guide holes that are slidingly matched with the lifting guide pillars 3. The two lifts drive the test platform 2 to move up and down, and at the same time slide in the guide holes through the four lifting guide pillars 3;

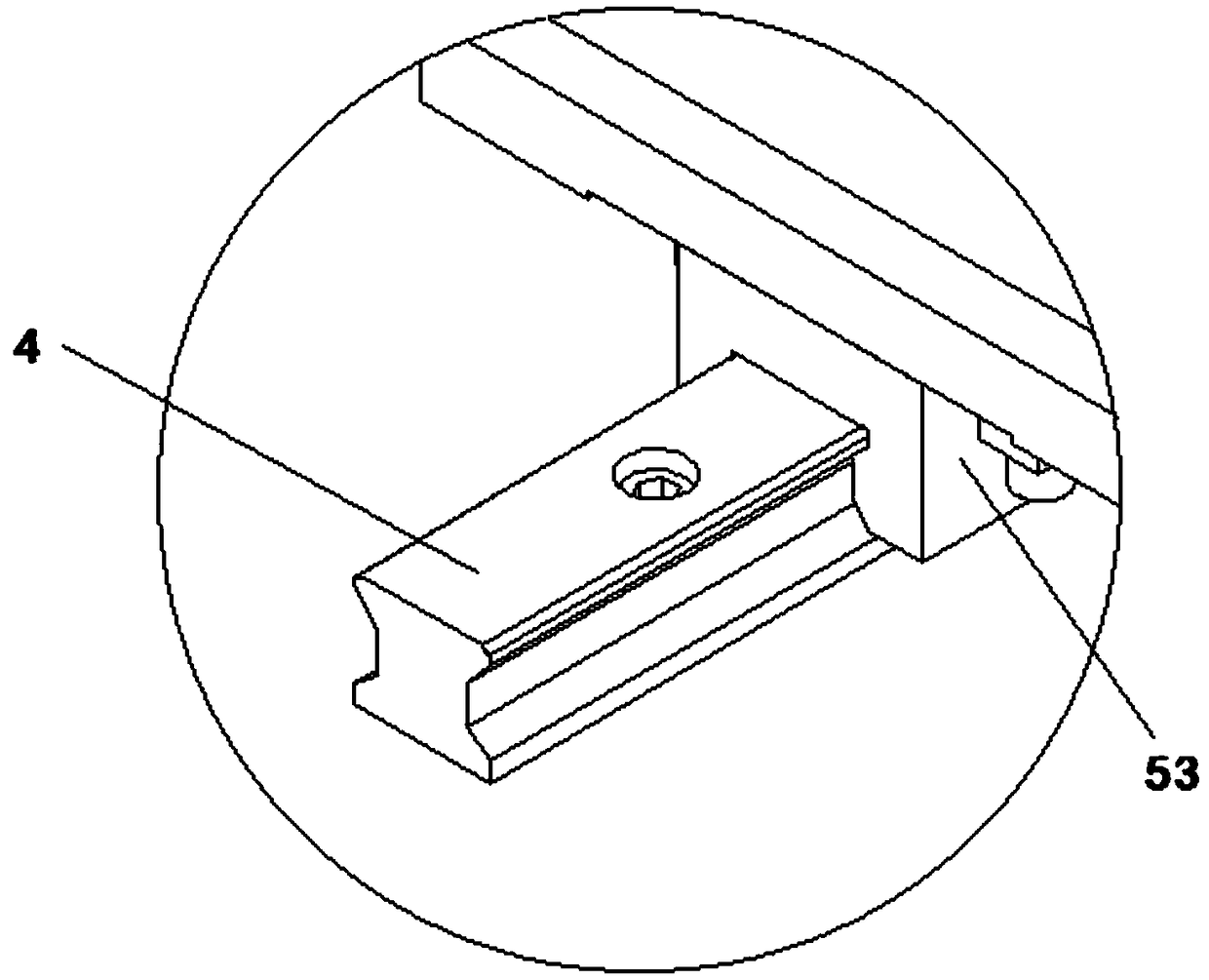

[0017] The surface of the test platform 2 is equipped with several slide rails 4 equidistantly, and several slide rails 4 are arranged in parallel. The loading test bench 5 is slidably installed on the slide rail 4, and a fixed table 51 is installed and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com