Magic cube, incremental molded surface rotation sensor and axis structure thereof

A rotational sensor, incremental technology, applied in the field of Rubik's Cube, which can solve the problems of single function of Rubik's Cube, inability to communicate with external electronic devices, and complex internal structure of Rubik's Cube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

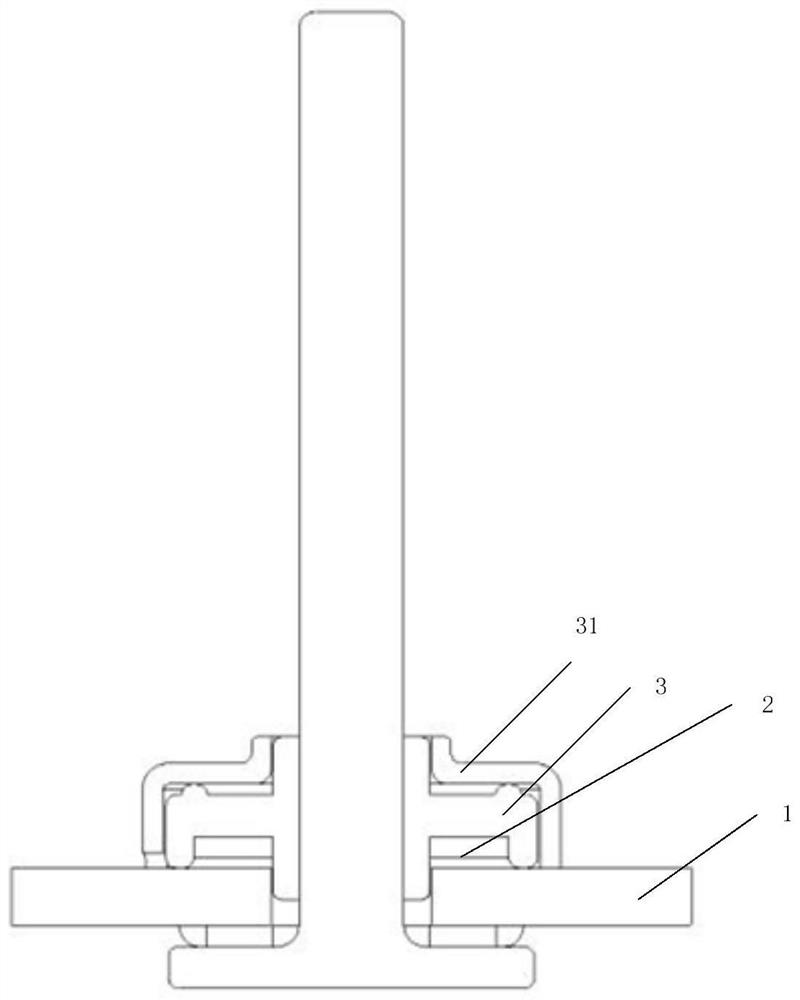

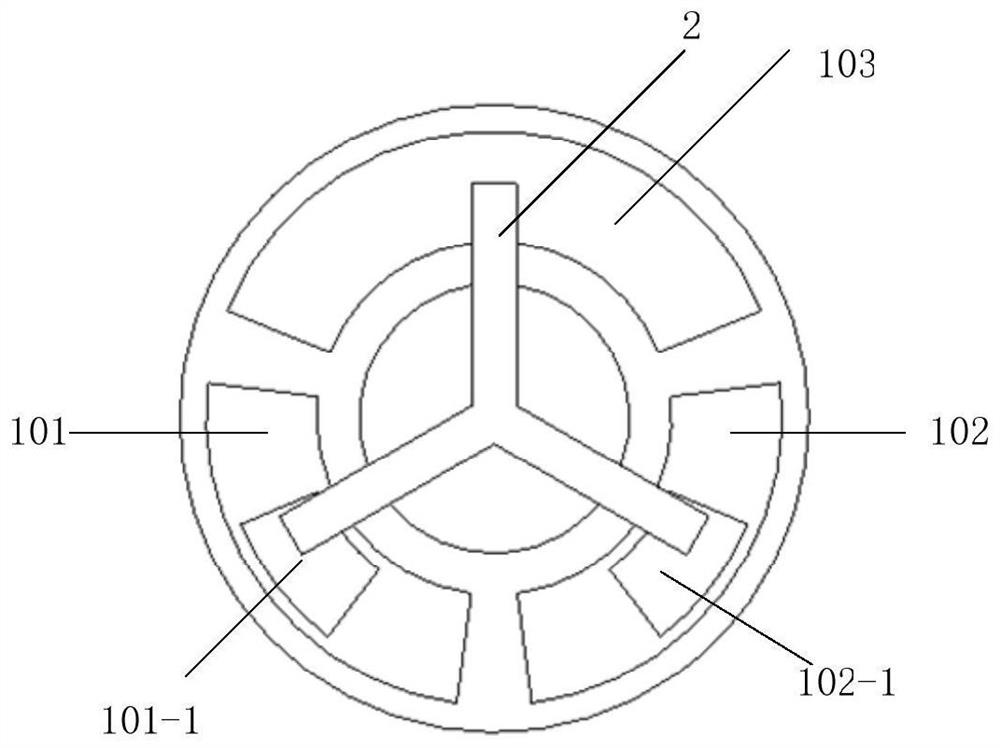

[0068] This embodiment discloses a Rubik's Cube incremental surface rotation sensor, such as figure 1 As shown, it includes a code wheel 1, a first brush 2 and a first rotor 3, the code wheel is provided with a first electrode, a second electrode and a third electrode, and the first electrode, the second electrode and the third electrode are arranged on the code wheel On the same circle of the disk surface, define the circle as the first circle; the first brush includes three endpoints, respectively the first endpoint, the second endpoint and the third endpoint, the first endpoint of the first brush, the second The end points and the third end points are arranged along the first circle and every two end points are spaced apart Arc; the first brush is installed on the first rotor and drives the three ends of the first brush to rotate along the first circumference relative to the first electrode, the second electrode and the third electrode through the first rotor, and the firs...

Embodiment 2

[0090] This embodiment discloses a surface rotation sensor of Rubik's Cube, which differs from the surface rotation sensor of Rubik's Cube in Embodiment 1 only in that Figure 5 As shown, the surface rotation sensor of Rubik's Cube in this embodiment also includes a second rotor 4 and a second brush 5, the code disc is provided with a fourth electrode, a fifth electrode and a sixth electrode, and the fourth electrode, the fifth electrode and the sixth electrode The six electrodes are arranged on the same circumference of the code disk surface, and this circumference is defined as a second circumference; the second circumference is located on the outer circumference of the first circumference.

[0091] In this embodiment, the second brush includes three terminals, namely a first terminal, a second terminal and a third terminal, and the first terminal, the second terminal and the third terminal of the second brush are all along the The second circle is arranged and every two end...

Embodiment 3

[0107] This embodiment discloses a surface rotation sensor of Rubik's Cube, such as Figure 9 As shown, the only difference with the surface rotation sensor of Rubik's Cube in Embodiment 1 is that the surface rotation sensor of Rubik's Cube in this embodiment also includes a second rotor 4, a second brush 5, a third rotor 6 and a third brush 7, The code wheel is provided with a fourth electrode, a fifth electrode, a sixth electrode, a seventh electrode, an eighth electrode and a ninth electrode, and the fourth electrode, the fifth electrode and the sixth electrode are arranged on the same circumference of the code wheel surface, defined This circle is the second circle; the seventh electrode, the eighth electrode and the ninth electrode are arranged on the same circle of the code disc surface, and this circle is defined as the third circle; the second circle is in the outer circle of the first circle, and the third circle is in the first circle. The outer circumference of two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com