A filter tightening limit structure and tightening process

A limit structure, filter technology, applied in the direction of machine/engine, charging system, liquid fuel feeder, etc., can solve the single torque control mode or angle control mode, reduce the yield of tightening operation, soft seal It is difficult for the ring to play a sealing role, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

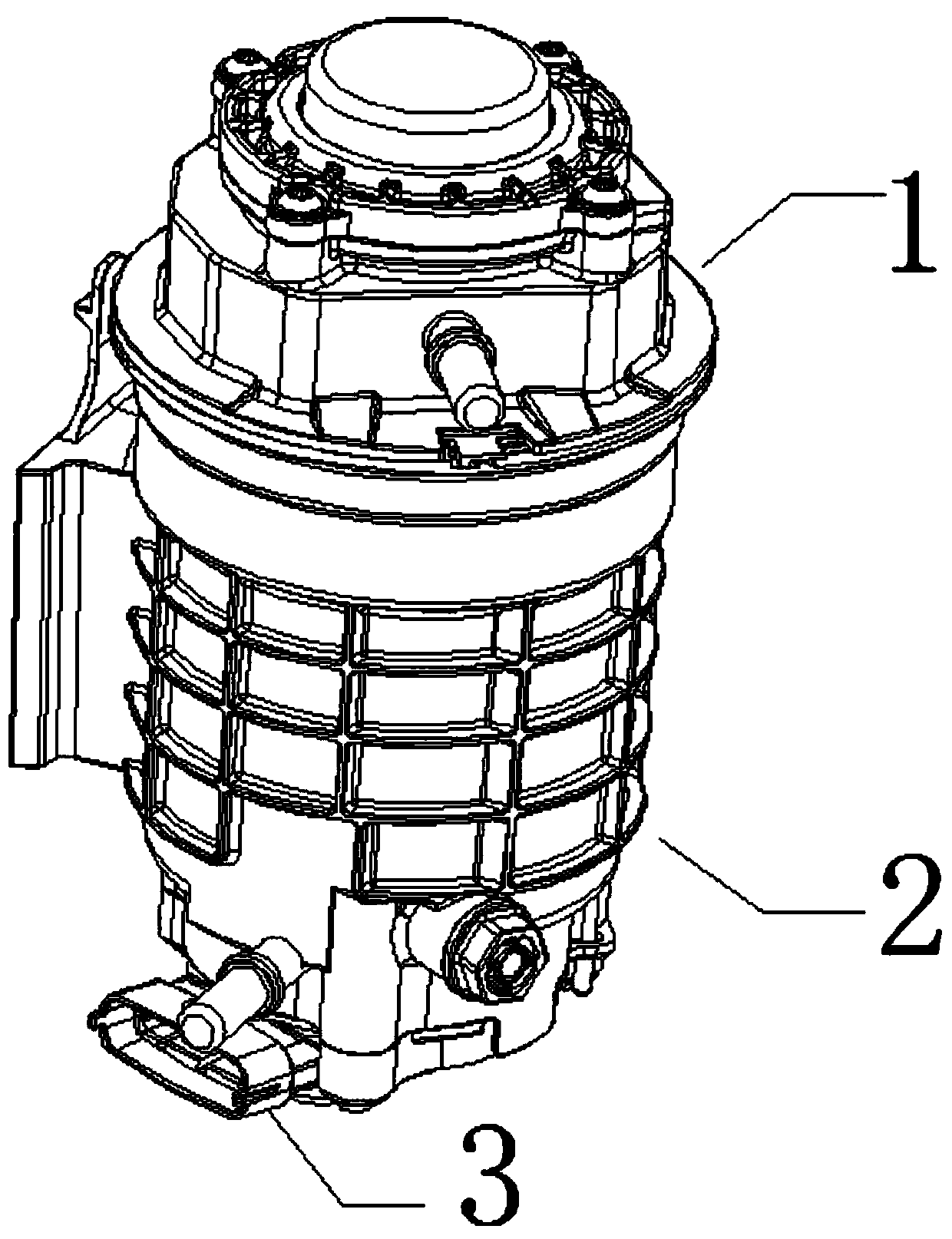

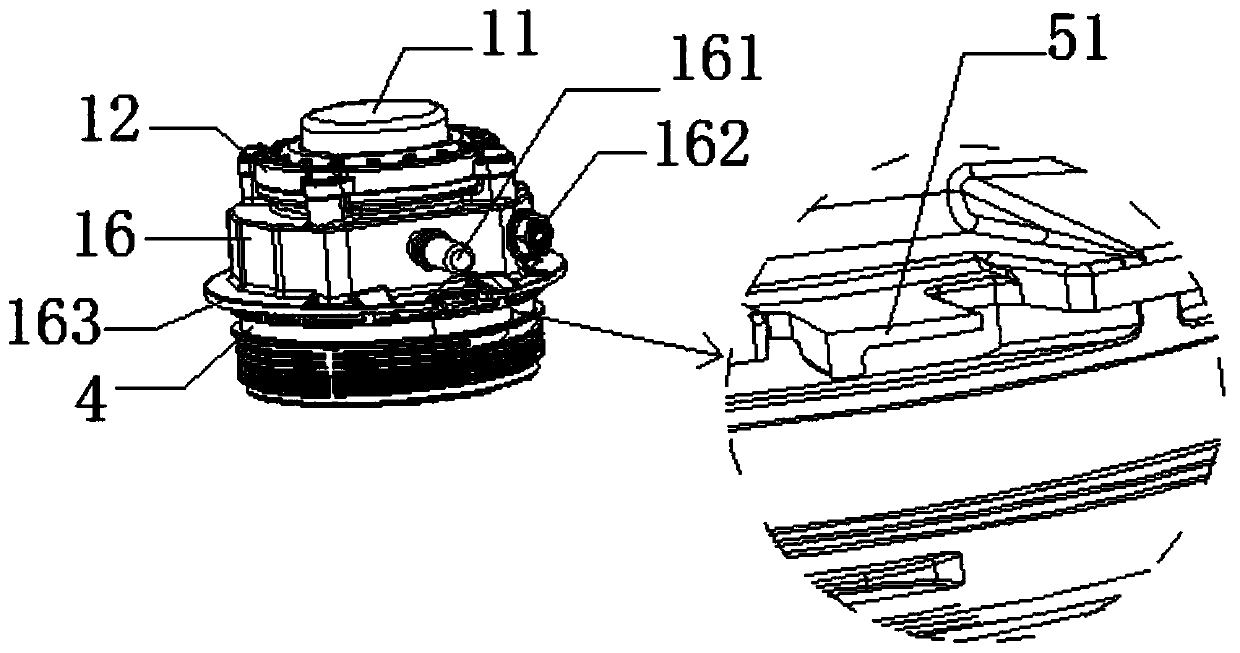

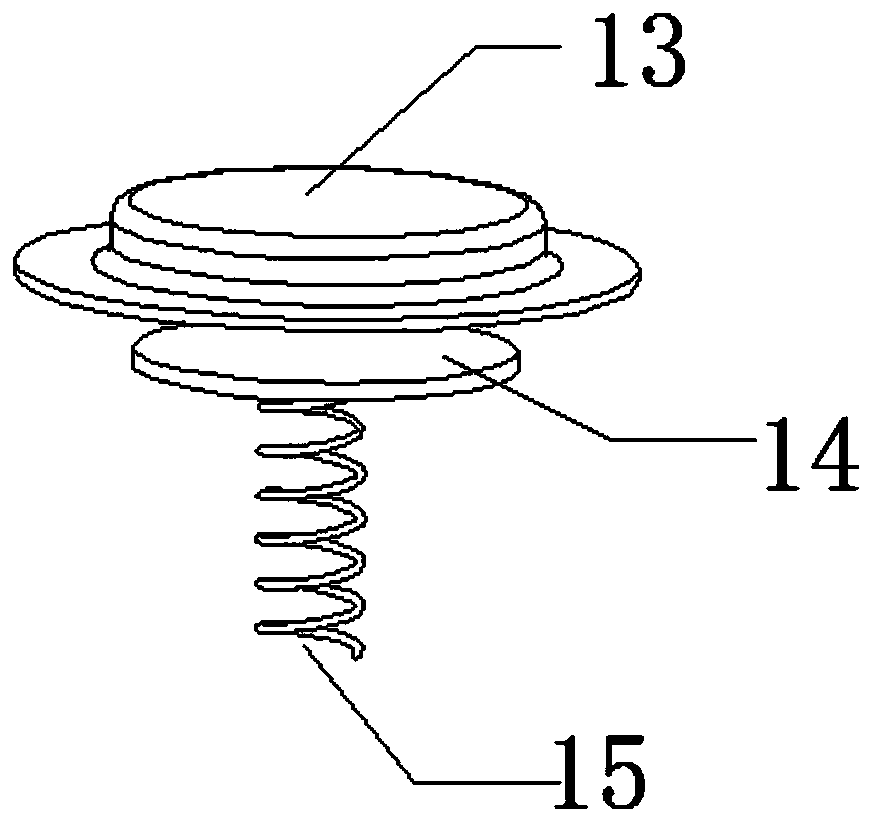

[0037] A tightening limit structure for a filter, comprising: an upper cover 1, a lower casing 2, and a combined sensor 3 installed on the base of the lower casing 2; the upper cover 1 sequentially includes a pressing handle 11, a hand The pump cover 12, diaphragm 13, support plate 14, spring 15, upper cover body 16, the support plate 14 with the spring 15 fixed on the lower end surface is placed in the upper convex cavity of the diaphragm 13, and the diaphragm 13 is installed on the upper cover The lower end of the push handle 11 is inlaid and fixed in the center hole of the hand pump cover 12 in the ring slot at the upper end of the body 16, and the upper end of the press handle 11 extends out of the center hole of the hand pump cover 12 for a length, and the spring 15 is compressed After a certain distance, the hand pump cover 12 and the upper cover body 16 are tightly attached and screwed along the circumferential direction. The circumferential side of the upper cover body ...

specific Embodiment example 2

[0051] A tightening limit structure for a filter, comprising: an upper cover 1, a lower casing 2, and a combined sensor 3 installed on the base of the lower casing 2; the upper cover 1 sequentially includes a pressing handle 11, a hand The pump cover 12, diaphragm 13, support plate 14, spring 15, upper cover body 16, the support plate 14 with the spring 15 fixed on the lower end surface is placed in the upper convex cavity of the diaphragm 13, and the diaphragm 13 is installed on the upper cover The lower end of the push handle 11 is inlaid and fixed in the center hole of the hand pump cover 12 in the ring slot at the upper end of the body 16, and the upper end of the press handle 11 extends out of the center hole of the hand pump cover 12 for a length, and the spring 15 is compressed After a certain distance, the hand pump cover 12 and the upper cover body 16 are tightly attached and screwed along the circumferential direction. The circumferential side of the upper cover body ...

specific Embodiment example 3

[0065] A tightening limit structure for a filter, comprising: an upper cover 1, a lower casing 2, and a combined sensor 3 installed on the base of the lower casing 2; the upper cover 1 sequentially includes a pressing handle 11, a hand The pump cover 12, diaphragm 13, support plate 14, spring 15, upper cover body 16, the support plate 14 with the spring 15 fixed on the lower end surface is placed in the upper convex cavity of the diaphragm 13, and the diaphragm 13 is installed on the upper cover The lower end of the push handle 11 is inlaid and fixed in the center hole of the hand pump cover 12 in the ring slot at the upper end of the body 16, and the upper end of the press handle 11 extends out of the center hole of the hand pump cover 12 for a length, and the spring 15 is compressed After a certain distance, the hand pump cover 12 and the upper cover body 16 are tightly attached and screwed along the circumferential direction. The circumferential side of the upper cover body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com