A high-speed motor rotor position detection device and processing method

A technology of rotor position and processing method, which is applied in the direction of electronic commutator, etc., can solve the problems of incorrect rotor position angle, long transmission distance of resolver feedback signal, easy interference of feedback signal, etc., and achieve the effect of improving anti-interference performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0050] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

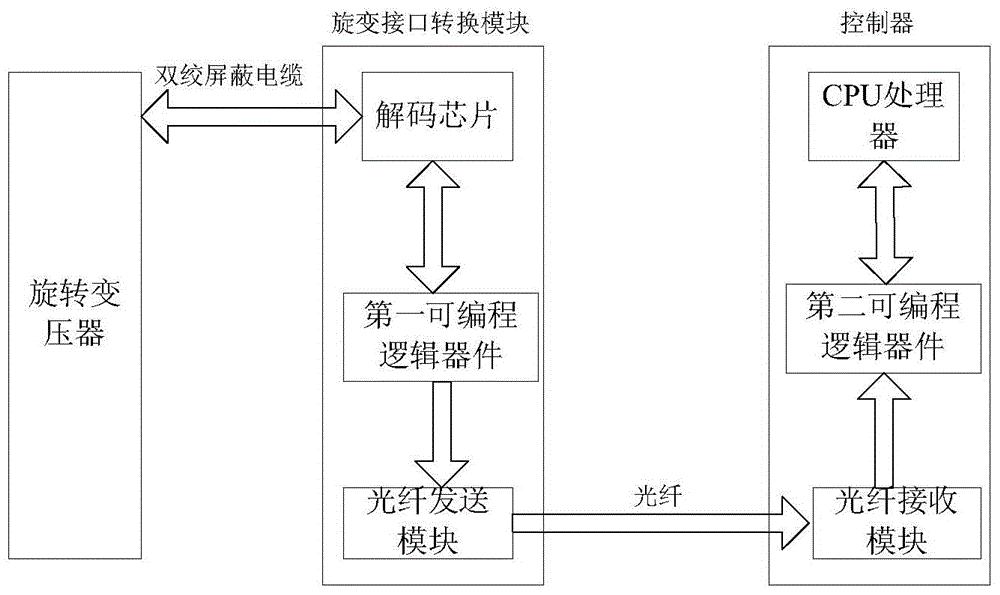

[0051] image 3 It is a block diagram of the realization of the scheme of this embodiment. The detection device includes: a rotary transformer, which is used to connect with the synchronous motor, and feeds back the rotor position signal after receiving the excitation signal;

[0052] sender, including:

[0053] The decoding chip provides the excitation signal for the resolver, and calculates the digital signal corresponding to the rotor according to the signal fed back by the resolver; at the same time, it judges whether the signal feedback is normal, and outputs the above signal through a parallel bus or a serial bus;

[0054] The first programmable lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com