Punching machine double valve automatic detection safety circuit

An automatic detection and safety circuit technology, applied in electrical program control, instrumentation, program control in sequence/logic controllers, etc., and can solve problems such as safety accidents, burnout of contacts, and accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

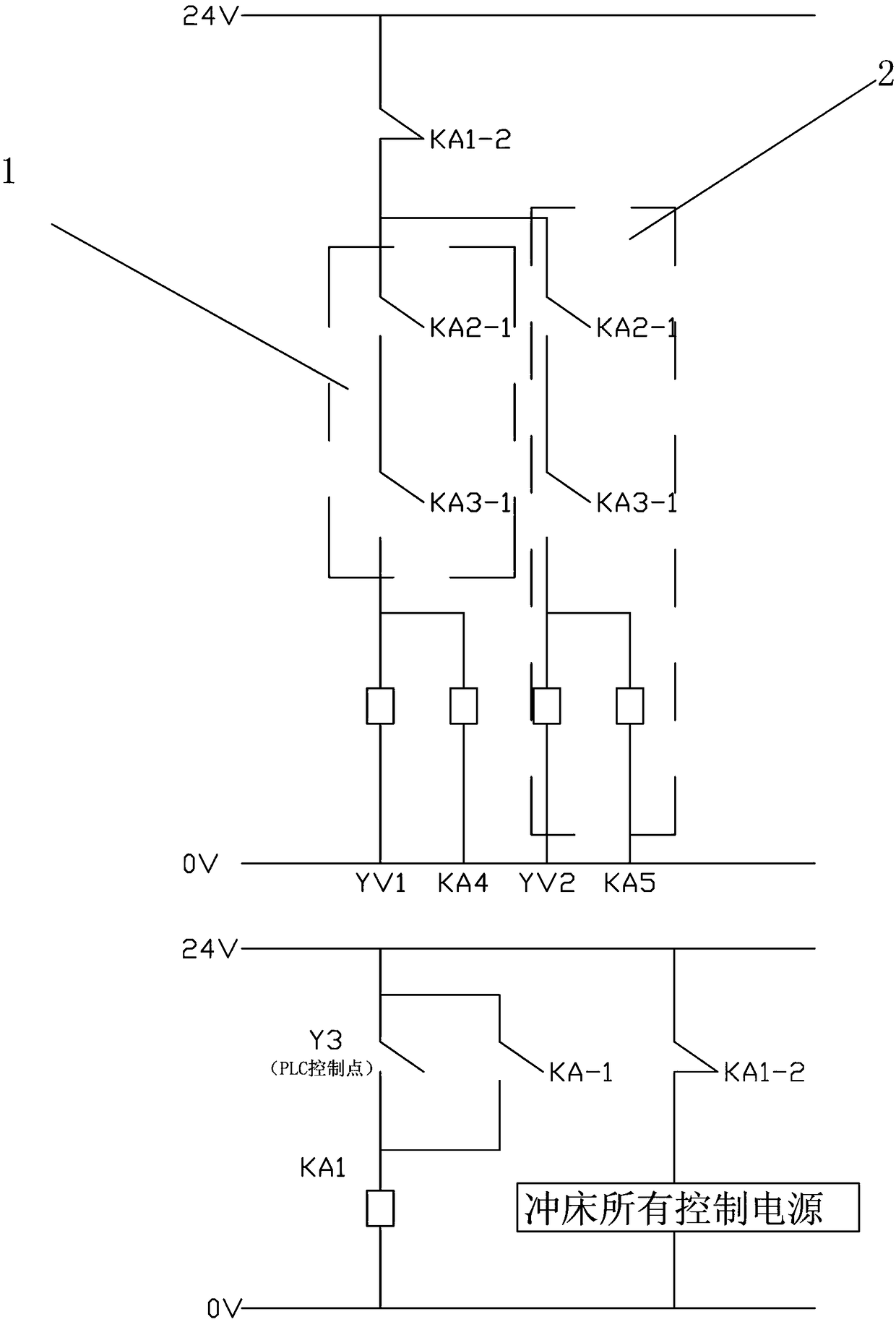

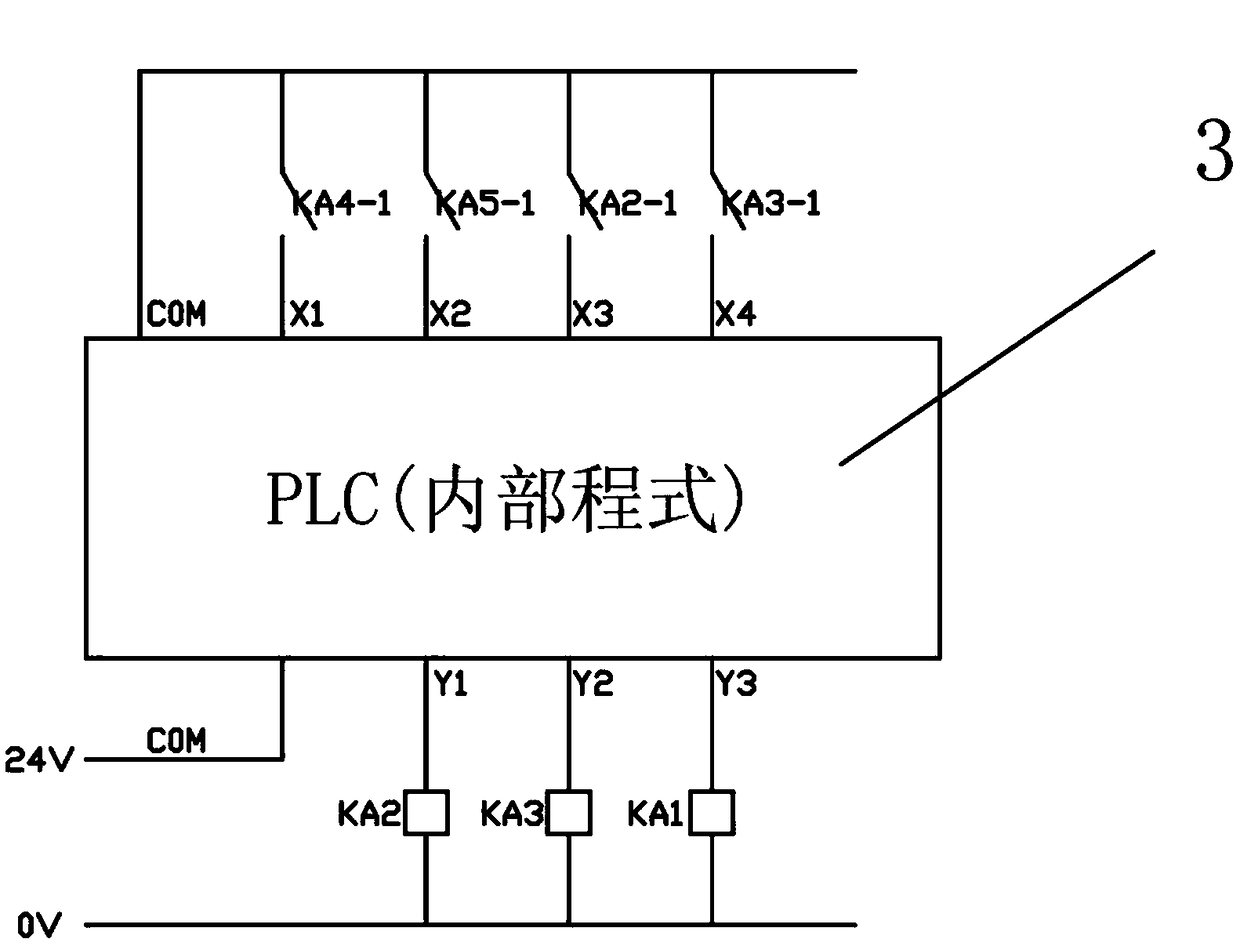

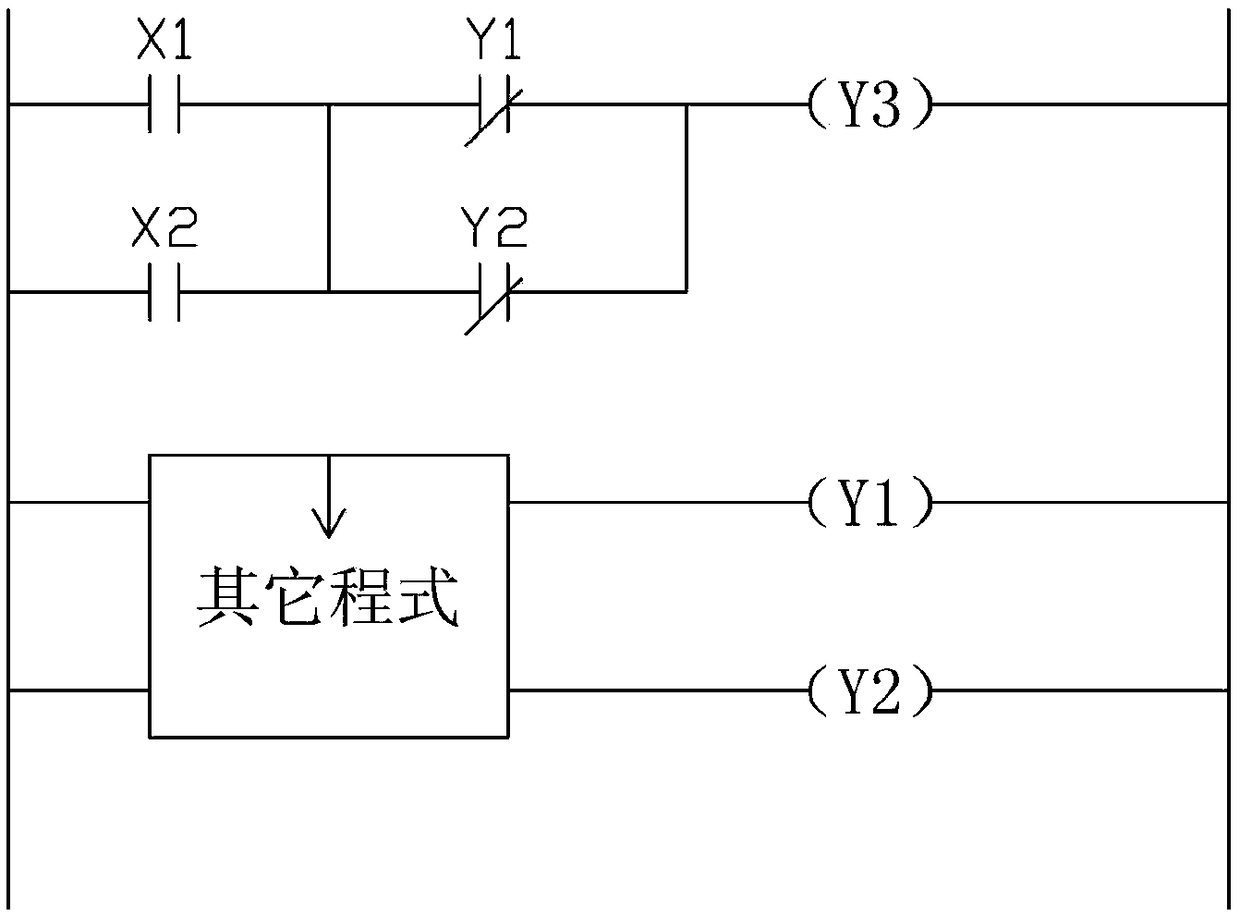

[0018] Such as figure 1 , figure 2 , image 3 As shown, the double-valve automatic detection safety circuit for a press provided in this embodiment includes a PLC controller 3, a fourth intermediate relay, a fifth intermediate relay, a second intermediate relay, a third intermediate relay, a self-locking protection relay and two A double solenoid valve that can control the work of the punch press after being powered on at the same time, and the two double solenoid valves are respectively represented by the first double solenoid valve YV1 and the second double solenoid valve YV2, and the first double solenoid valve YV1 And the second double-connected solenoid valve YV2 is connected in series with a first group consisting of the second normally open contact KA2-1 of a second intermediate relay and the third normally open contact KA3-1 of a third intermediate relay in series. Branch 1, the first double solenoid valve YV1 is connected in series with a corresponding first branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com