Touch display device and driving method thereof

A technology of a touch display device and a driving method, which is applied in the fields of instruments, computing, and electrical and digital data processing, etc., can solve problems such as poor touch control, poor display, and short circuit of signal lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

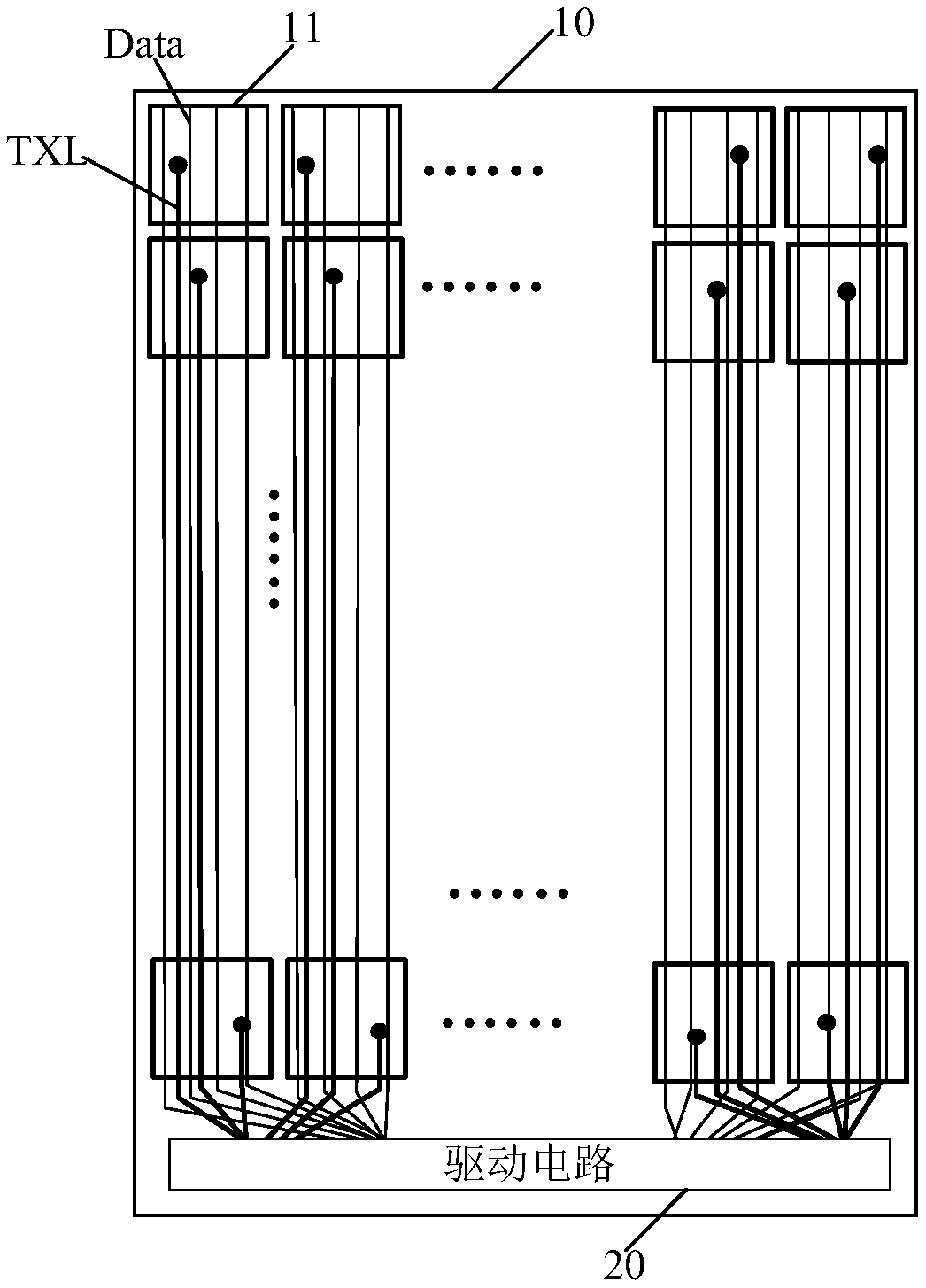

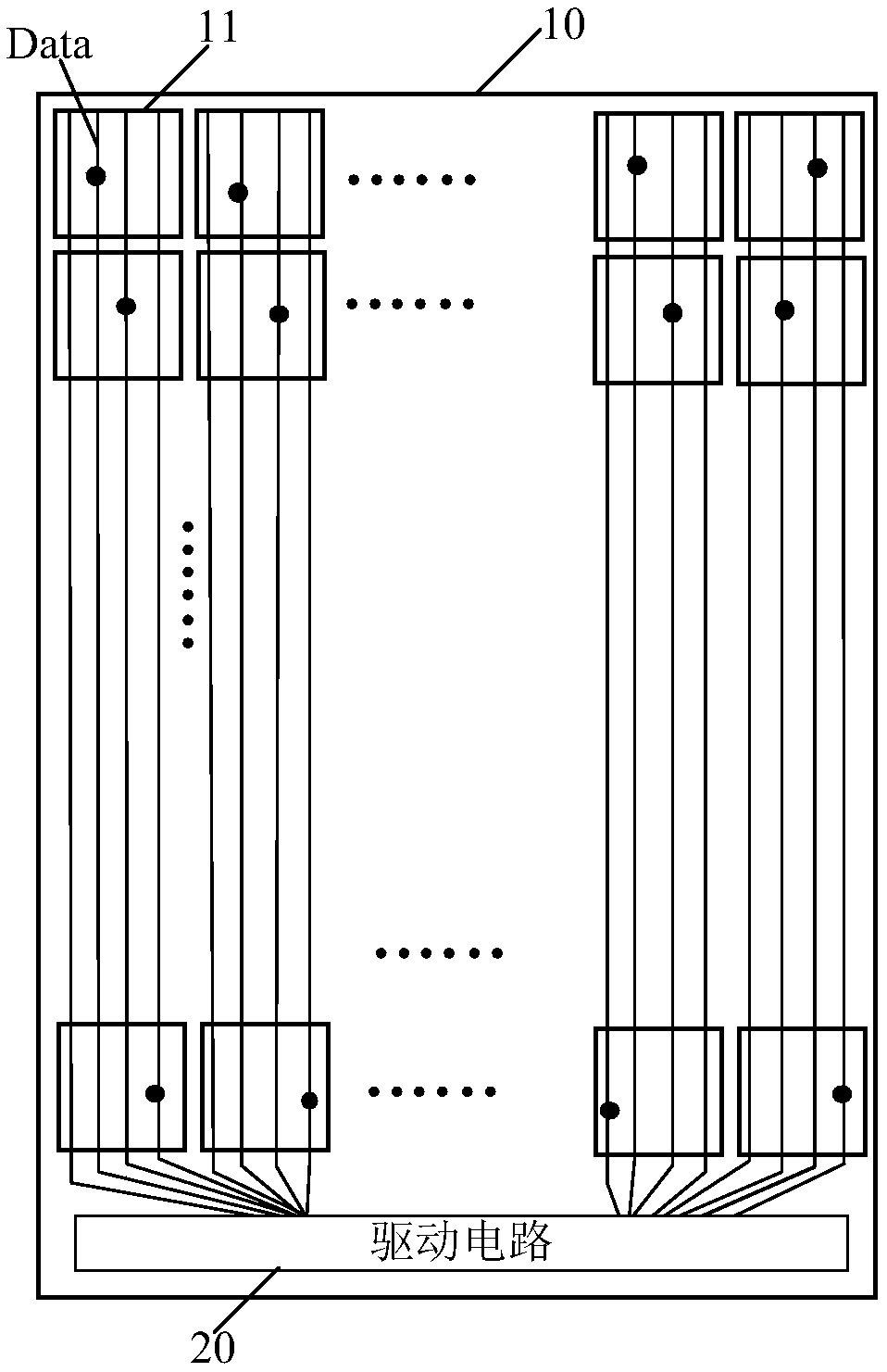

[0033] figure 2 It is a schematic diagram of the touch display device provided by Embodiment 1 of the present invention, as shown in figure 2 As shown, the touch display device includes a touch display substrate 10 and a driving circuit 20 , and the touch display substrate 10 includes a plurality of data lines Data and a plurality of common electrodes 11 . The common electrodes 11 are multiplexed as touch driving electrodes in the touch stage, and each common electrode 11 corresponds to one data line Data. The driving circuit 20 is used to provide display signals for the data lines Data in the display phase, and provide touch signals for the data lines corresponding to the common electrodes 11 in the touch phase.

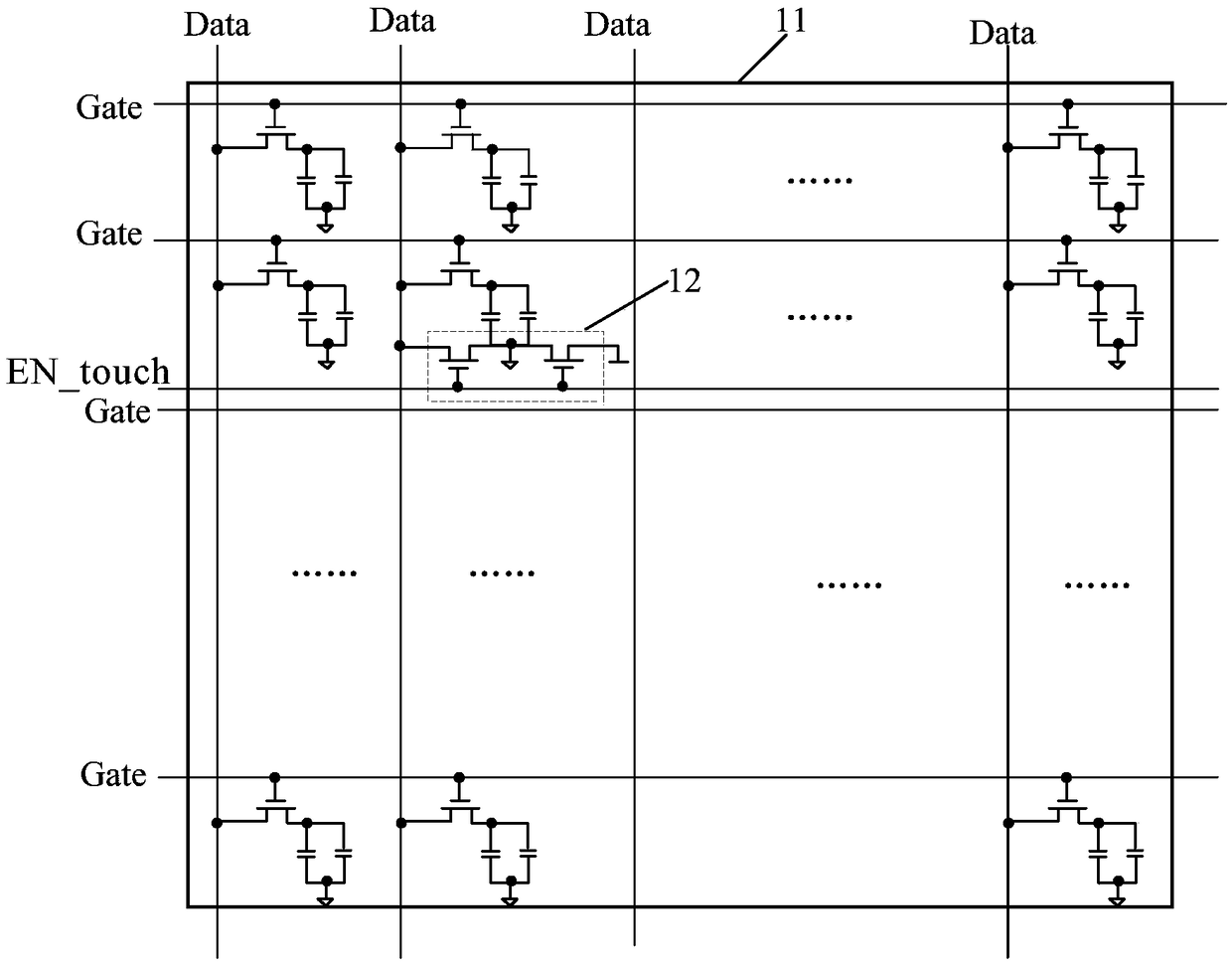

[0034] image 3 is a structural schematic diagram of the area where one of the common electrodes on the touch display substrate is located. Such as image 3 As shown, the touch display substrate 10 also includes a gate unit 12 corresponding to the common elect...

Embodiment 2

[0046] Embodiment 2 of the present invention provides a driving method of the above-mentioned touch display device, the driving method comprising:

[0047] In the display stage, the drive circuit provides display signals to each of the data lines, and the gate unit conducts the common electrode with the common signal terminal.

[0048] In a touch stage, the drive circuit provides a touch signal to the data line corresponding to the common electrode.

[0049] As mentioned above, the touch display substrate further includes a gate control line, and the gate unit includes a first transistor and a second transistor. At this time, the driving method further includes:

[0050] In the touch phase, the drive circuit provides a first control signal to the gate control line, the first control signal is used to control the first transistor to turn on, and control the second transistor to turn off .

[0051] In the display phase, the drive circuit provides a second control signal to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com