A flow test method and device for electric vehicle power battery thermal management pipeline

A technology of flow test device and power battery, which is applied in the field of automobiles, can solve the problems of flow pressure loss, difficult operation, time and material cost increase, etc., and achieve the effects of improved measurement accuracy, convenient and simple installation, and reduced connecting parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

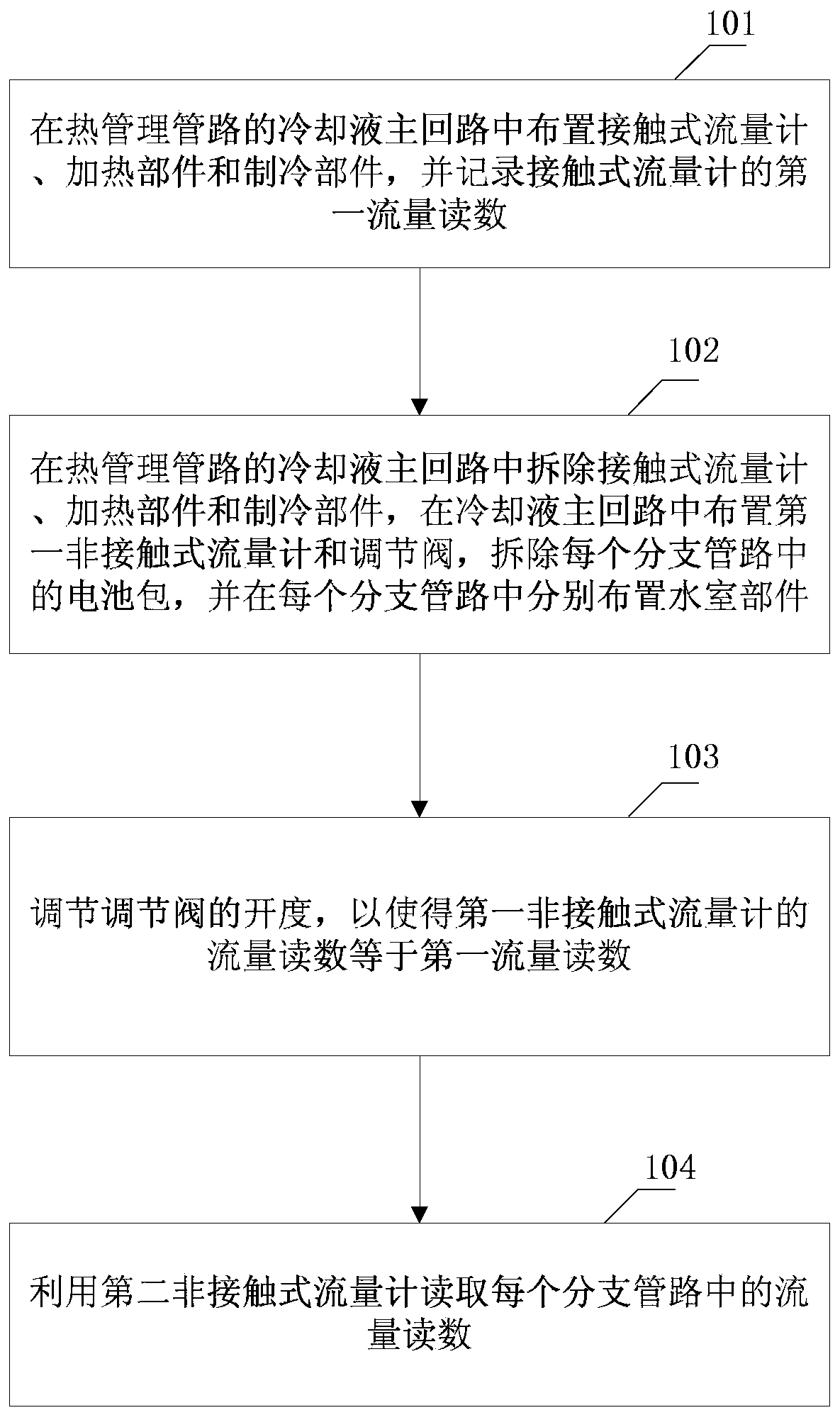

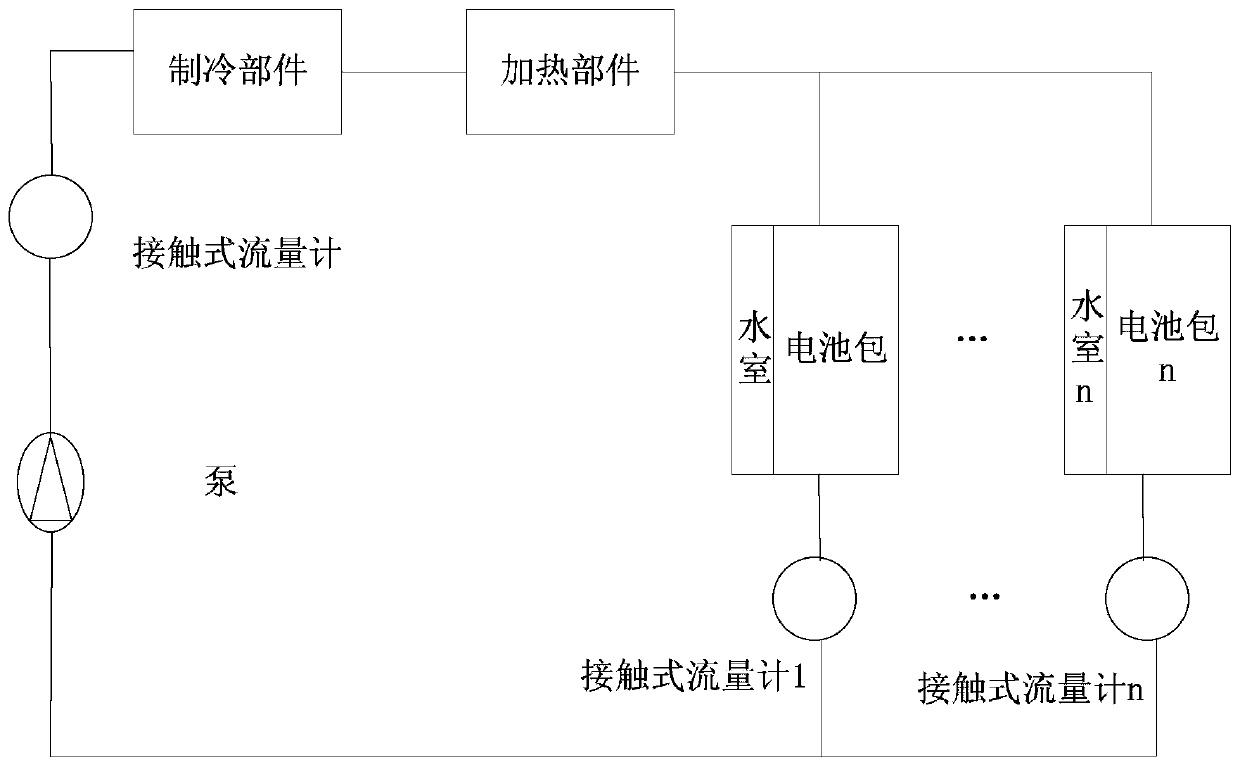

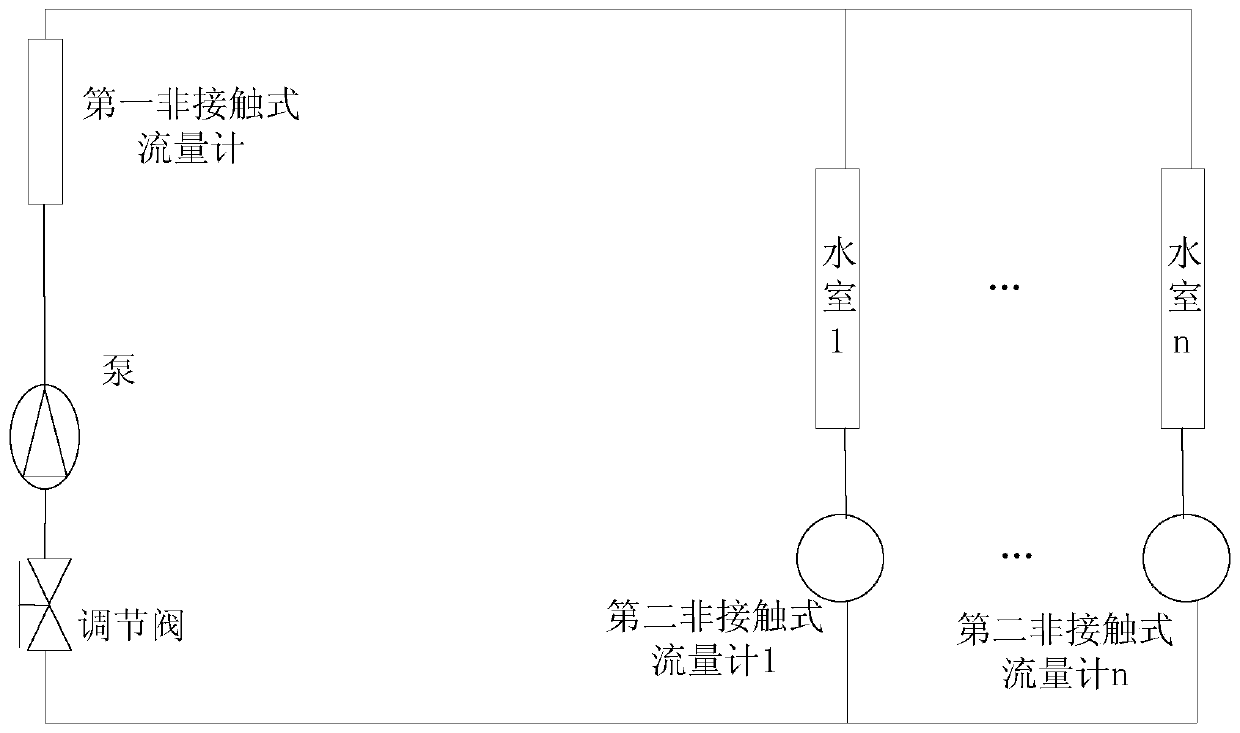

[0044] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same parts.

[0045] For the sake of brevity and intuition in description, the solution of the present invention is described below by describing several representative implementation manners. Numerous details in the embodiments are only used to help the understanding of the solutions of the present invention. But obviously, the technical solutions of the present invention may not be limited to these details when implemented. In order to avoid unnecessarily obscuring the solution of the present invention, some embodiments are not described in detail, but only a framework is given. Hereinafter, "including" means "including but not limited to", and "according to..." means "at least accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com