Semi-active dual-port mechanical element capable of online continuous control of proportionality coefficient

A semi-active, high-capacity technology, applied in the field of inertial capacity, can solve the problems of large energy consumption, large thrust, unfavorable engineering practical application, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

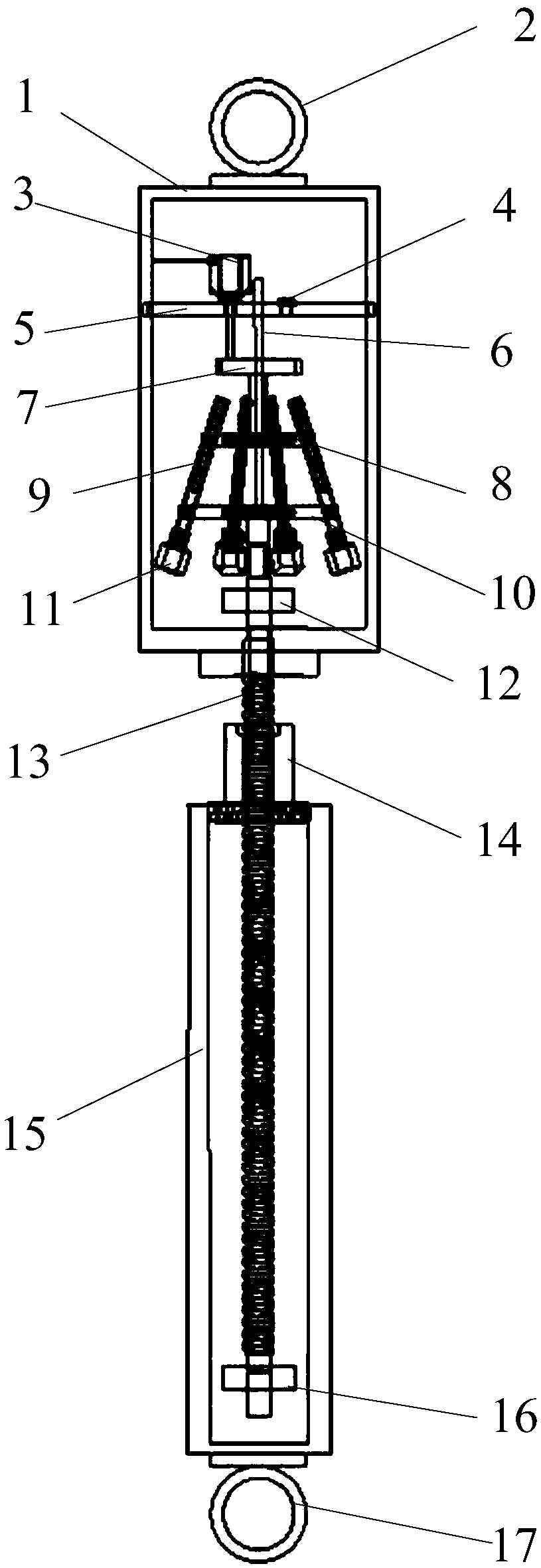

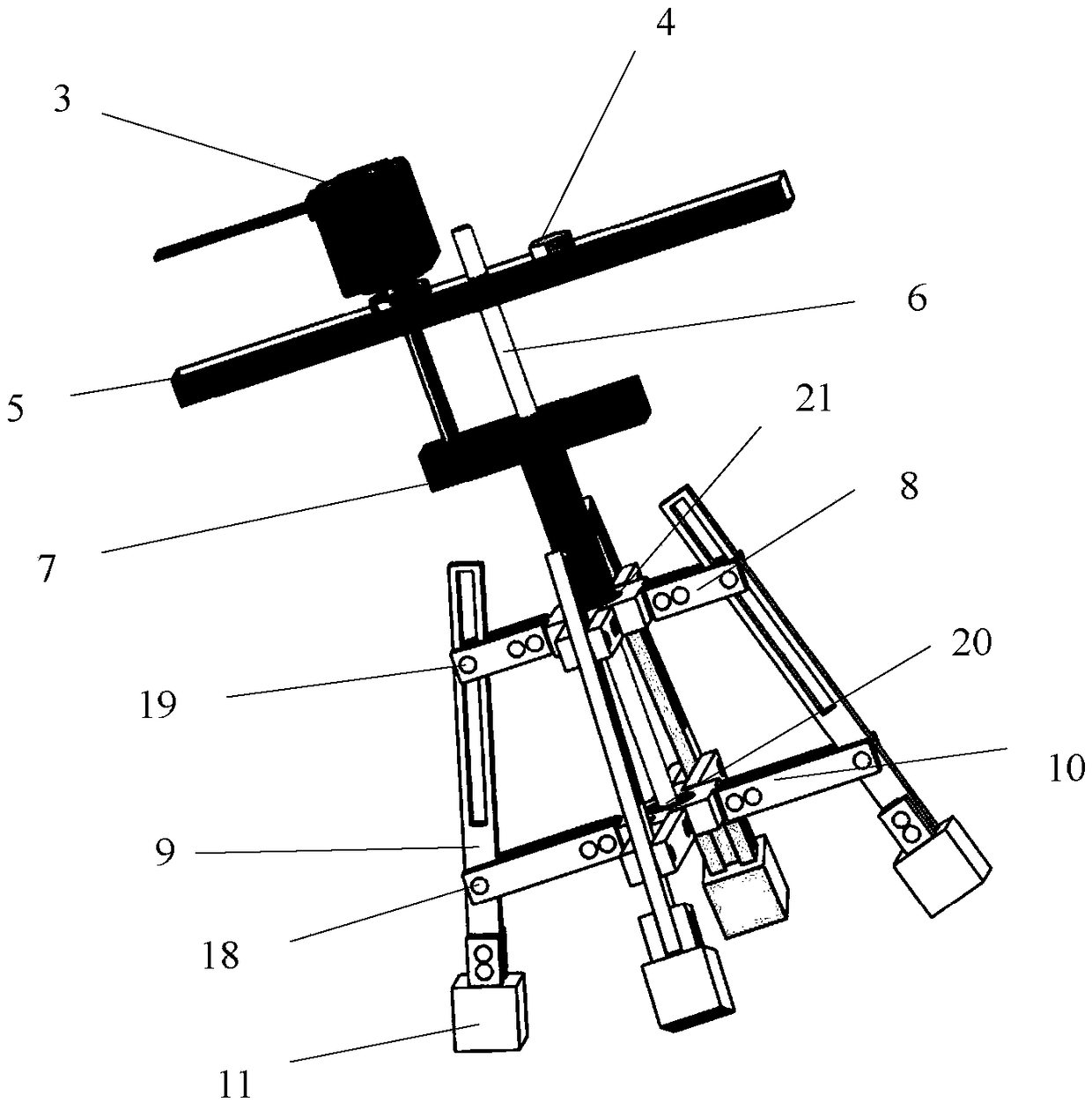

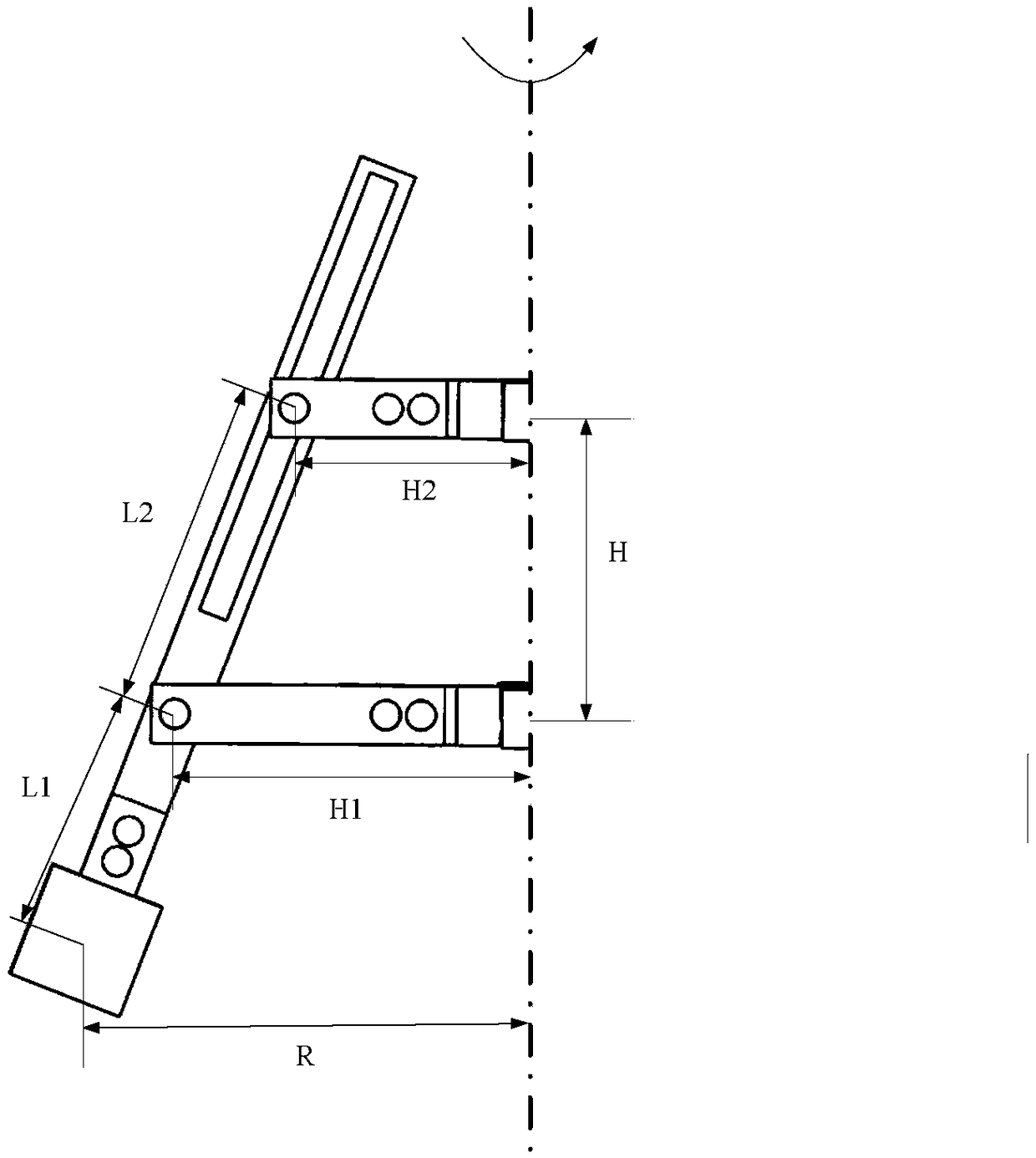

[0018] A semi-active inertial capacity that can continuously control the inertial capacity online, such as figure 1 As shown, it includes a rotating flywheel placed in the flywheel end housing 1 and a ball screw 13 placed in the screw housing 15. The top surface of the rotating flywheel and the bottom surface of the screw housing 15 are respectively provided with terminals 2 and 17, which are Ports for connection to other mechanical components. The bottom surface of the flywheel end housing 1 is provided with a bearing, and the top of the leading screw 13 passes through the bearing to be connected, that is, the leading screw 13 rotates around the axis of the leading screw 13 but can not move up and down relative to the flywheel end housing 1.

[0019] The screw 13 is equipped with a nut 14 that drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com