Quick installation frame structure of variable-frequency cabinet

An installation frame, fast technology, applied in the direction of cabinet/cabinet/drawer parts, output power conversion device, electrical equipment shell/cabinet/drawer, etc., can solve the problem of low assembly efficiency, affecting stability, welding parts Disconnection and other problems, to achieve the effect of firm and reliable installation, high firmness, and enhanced skeleton structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

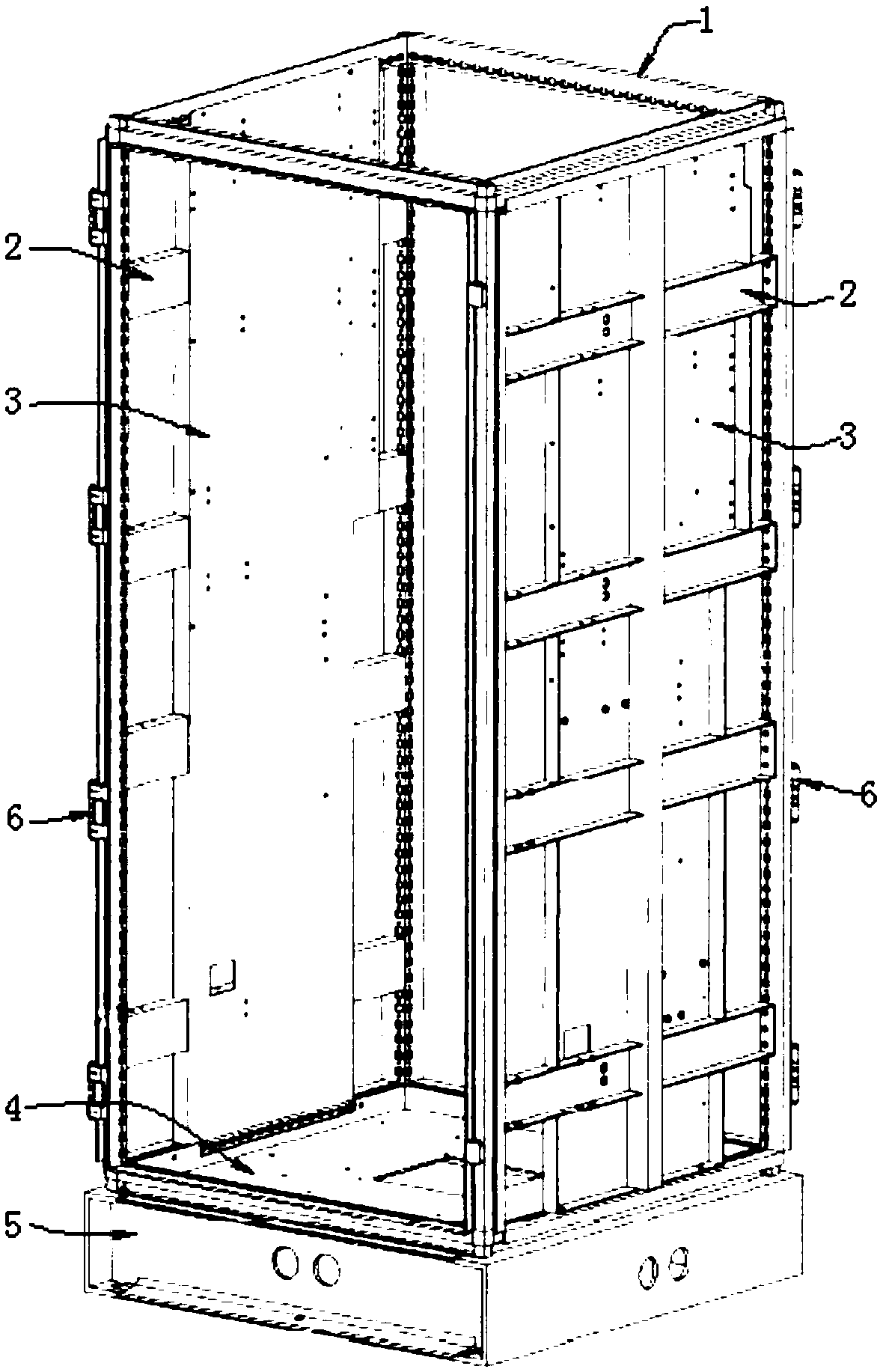

[0017] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail through the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not used to limit the scope of the present invention. In addition, in the following description, descriptions of well-known structures and technologies are omitted to avoid unnecessarily obscuring the concept of the present invention.

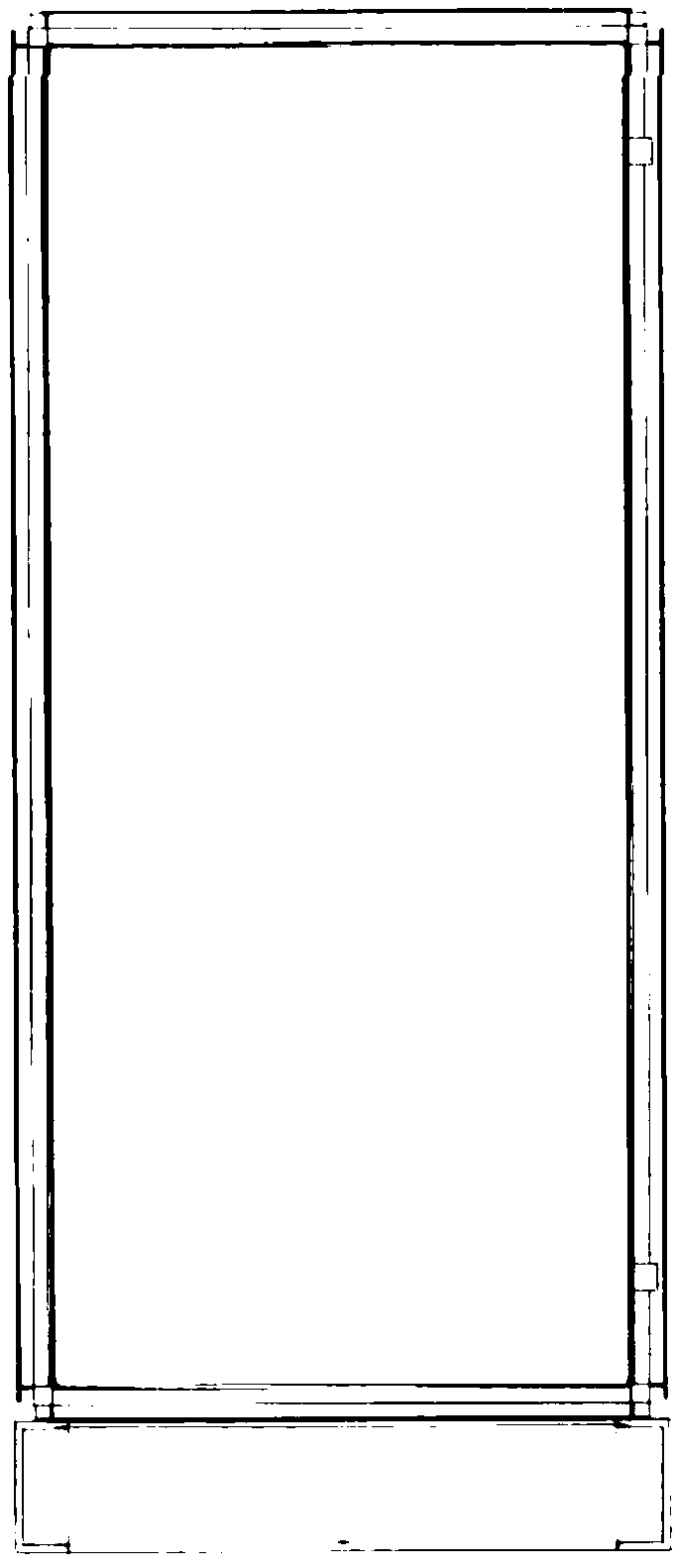

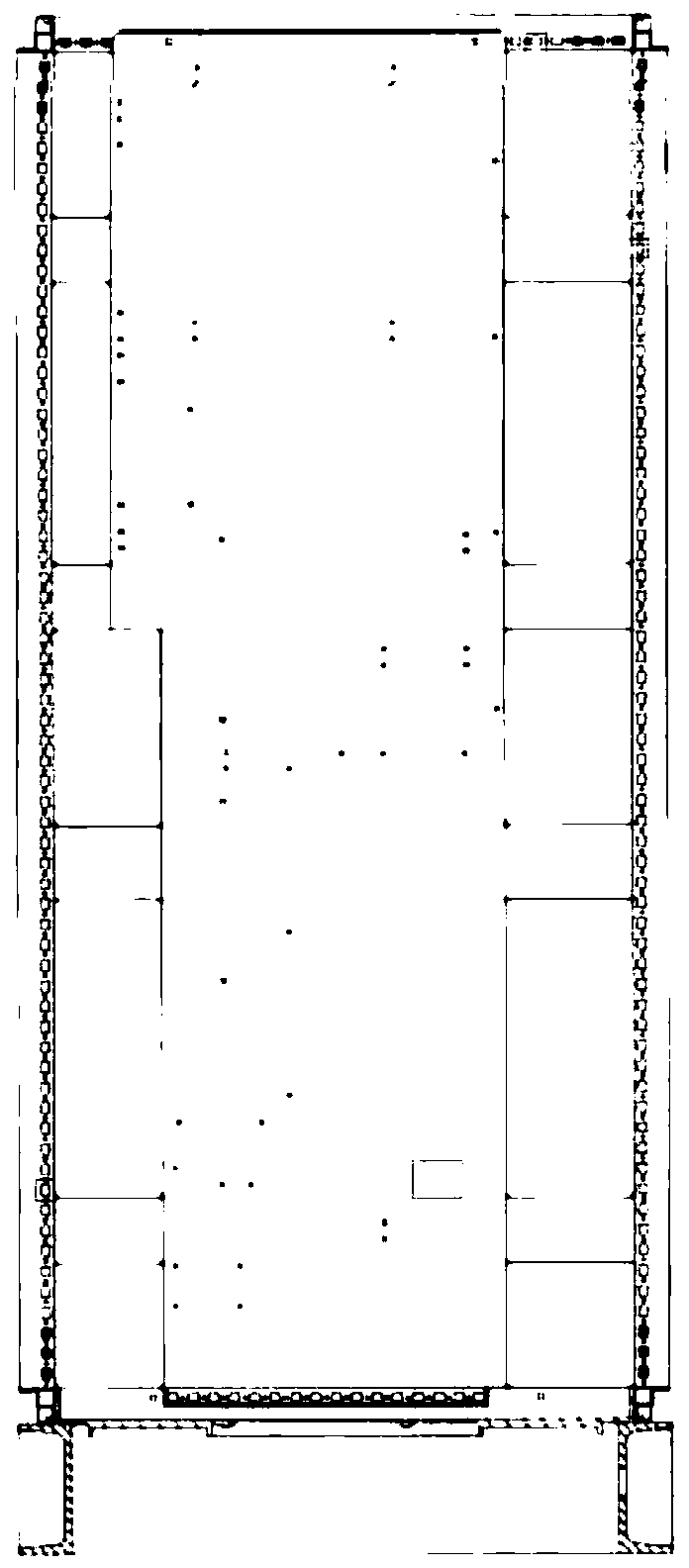

[0018] Refer to Figure 1 to Figure 4 The embodiment of the present invention provides a quick installation frame structure of a frequency conversion cabinet, which includes an assembled frame body 1, a side reinforcement plate 2, a side sub-assembly plate 3, a bottom plate 4, and a base 5. The left and right sides of the assembled frame body 1 Each side is connected to a side reinforcement plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap