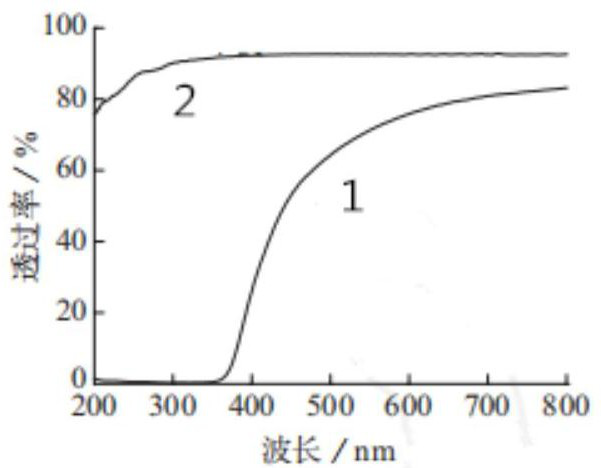

An agricultural vegetable greenhouse film that can specifically filter light waves below 390nm

A vegetable greenhouse and light wave technology, applied in the field of polymer film materials, can solve the problems of no positive effect on agricultural pest control, not suitable for the use of greenhouse films, poor filtering effect of ultraviolet filter glass powder, etc., to achieve excellent tensile properties, accelerate Degradation, anti-erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

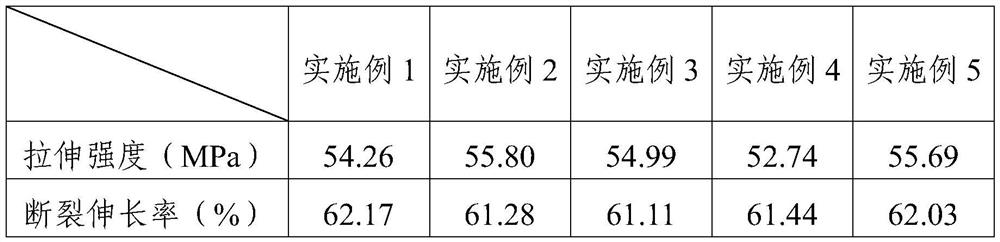

Embodiment 1

[0036] An agricultural vegetable greenhouse film capable of specifically filtering light waves below 390nm, comprising the following components in parts by weight:

[0037] 85 parts of polyvinyl chloride resin, 42 parts of polyvinylidene fluoride resin, 15 parts of nano zinc oxide coated with cerium oxide, 0.4 parts of dicumyl peroxide, 12 parts of bismaleamic acid, 6 parts of starch, 4 parts of chitin , 2 parts of polyoxyethylene lauryl ether, 0.6 parts of tricresyl phosphate, 1.2 parts of leveling agent BYK-346, 3.5 parts of dispersant, 2 parts of BYK-011, 14 parts of toughening filler, phthalic acid di(2 -8 parts of ethylhexyl ester.

[0038] The preparation method of nano zinc oxide coated with cerium oxide is as follows:

[0039]Add nano-zinc oxide and KH550 into its ionized water, ultrasonically oscillate and stir for 30 minutes, add ethanol solution of cerium nitrate, raise the temperature to 45°C, add aqueous oxalic acid solution dropwise, keep stirring for 1.2 hours,...

Embodiment 2

[0047] An agricultural vegetable greenhouse film capable of specifically filtering light waves below 390nm, comprising the following components in parts by weight:

[0048] 90 parts of polyvinyl chloride resin, 50 parts of polyvinylidene fluoride resin, 18 parts of nano zinc oxide coated with cerium oxide, 0.2 parts of dicumyl peroxide, 10 parts of bismaleamic acid, 5 parts of starch, 4 parts of chitin , 3 parts of polyoxyethylene lauryl ether, 0.5 parts of tricresyl phosphate, 1.6 parts of leveling agent BYK-346, 4.5 parts of dispersant, 3 parts of BYK-017, 15 parts of toughening filler, dioctyl phthalate 9 servings.

[0049] The preparation method of nano zinc oxide coated with cerium oxide is as follows:

[0050] Add nano-zinc oxide and KH550 into its ionized water, ultrasonically oscillate and stir for 30 minutes, add ethanol solution of cerium nitrate, raise the temperature to 40°C, add aqueous oxalic acid solution dropwise, keep stirring for 2 hours, adjust the pH to 11...

Embodiment 3

[0058] An agricultural vegetable greenhouse film capable of specifically filtering light waves below 390nm, comprising the following components in parts by weight:

[0059] 85 parts of polyvinyl chloride resin, 43 parts of polyvinylidene fluoride resin, 12 parts of nano zinc oxide coated with cerium oxide, 0.3 parts of dicumyl peroxide, 12 parts of bismaleamic acid, 6 parts of starch, 1 part of chitin , 1 part of polyoxyethylene lauryl ether, 0.6 parts of tricresyl phosphate, 1.3 parts of leveling agent BYK-346, 4 parts of dispersant, 2 parts of BYK-025, 6 parts of toughening filler, di-n-octyl phthalate 15 parts of ester.

[0060] The preparation method of nano zinc oxide coated with cerium oxide is as follows:

[0061] Add nano-zinc oxide and KH550 into its ionized water, ultrasonically oscillate and stir for 30 minutes, then add ethanol solution of cerium nitrate, raise the temperature to 50°C, add aqueous oxalic acid solution dropwise, keep stirring for 2 hours, adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com