Water wiping rake adjusting mechanism

An adjustment mechanism and wiper rake technology, which is applied to machine parts, cleaning machinery, manual floor scrubbing machinery, etc., can solve the problem of inability to ensure that the wiper rake is parallel to the ground, the angle of the wiper rake cannot be adjusted, and the effect of wiping is affected. problem, to achieve good wiping effect, large adjustment range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

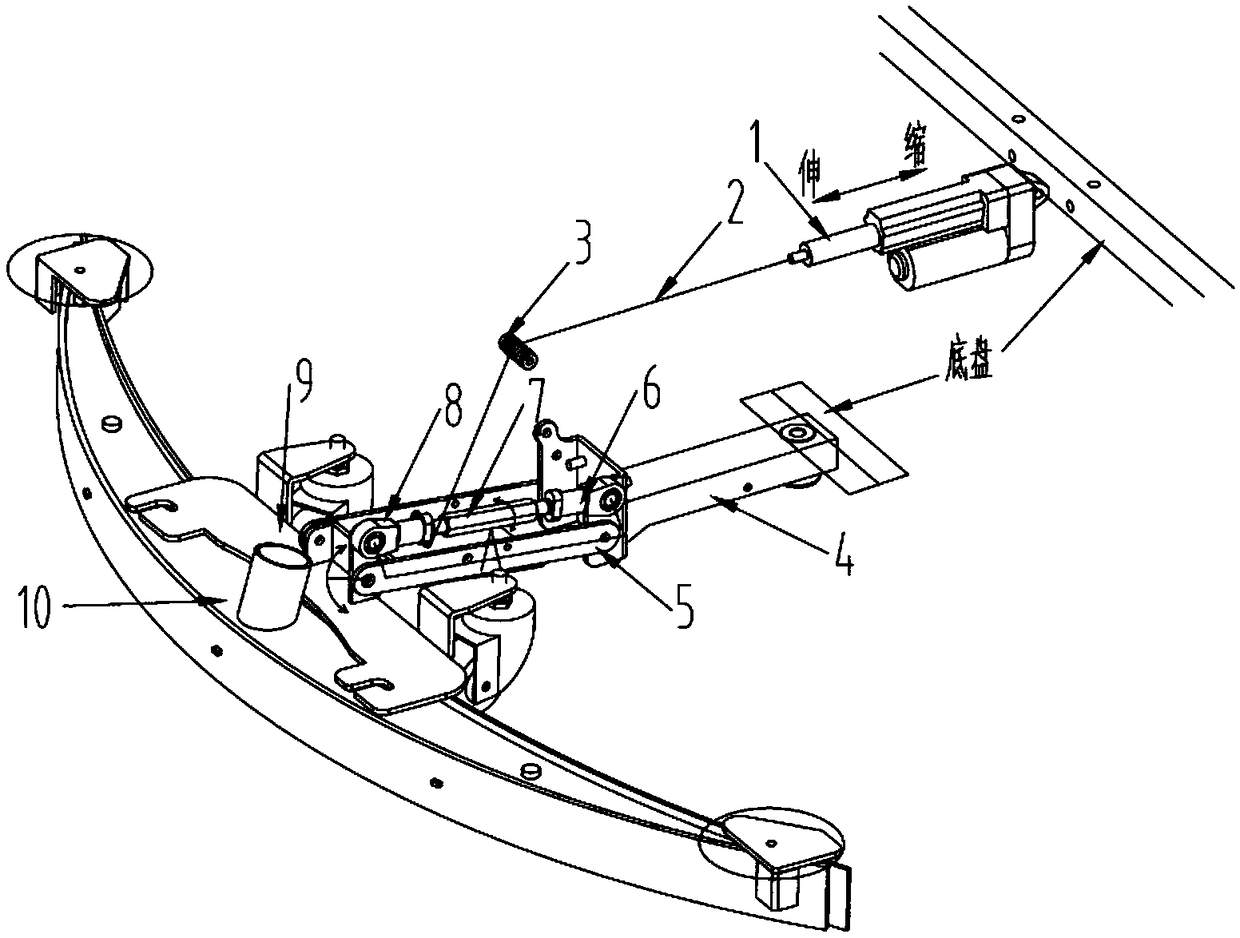

[0025] This mechanism uses the floor washing machine chassis as the carrier, the telescopic motor is fixed on the floor washing machine chassis through bolt connection, the cable is installed on the head of the telescopic motor, and the other end is installed on the wiper rake lifting frame through the pulley, and the pulley is installed on the chassis , the wiper rake rotating frame is connected with the chassis through the shaft sleeve and swings around the installation point. One end of the wiper rake elevating frame is connected with the wiper rake rotating frame through bolts and copper sleeves, and the other end is connected with the wiper rake fixed frame. One end of the adjustment rod It is processed with anti-tooth external thread, and the other end is processed with ortho-tooth external thread, which are respectively connected with anti-tooth joint bearing 6 and ortho-tooth joint bearing 8, and anti-tooth joint bearing 6 and tooth joint bearing 8 are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com