Automobile accessory cleaning device and application method thereof

A technology for cleaning devices and auto parts, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of not being environmentally friendly, fully recycling resources, easily scratching staff, and having poor cleaning effects Good and other problems, to achieve the effect of small vibration, good cleaning effect, and avoid being scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

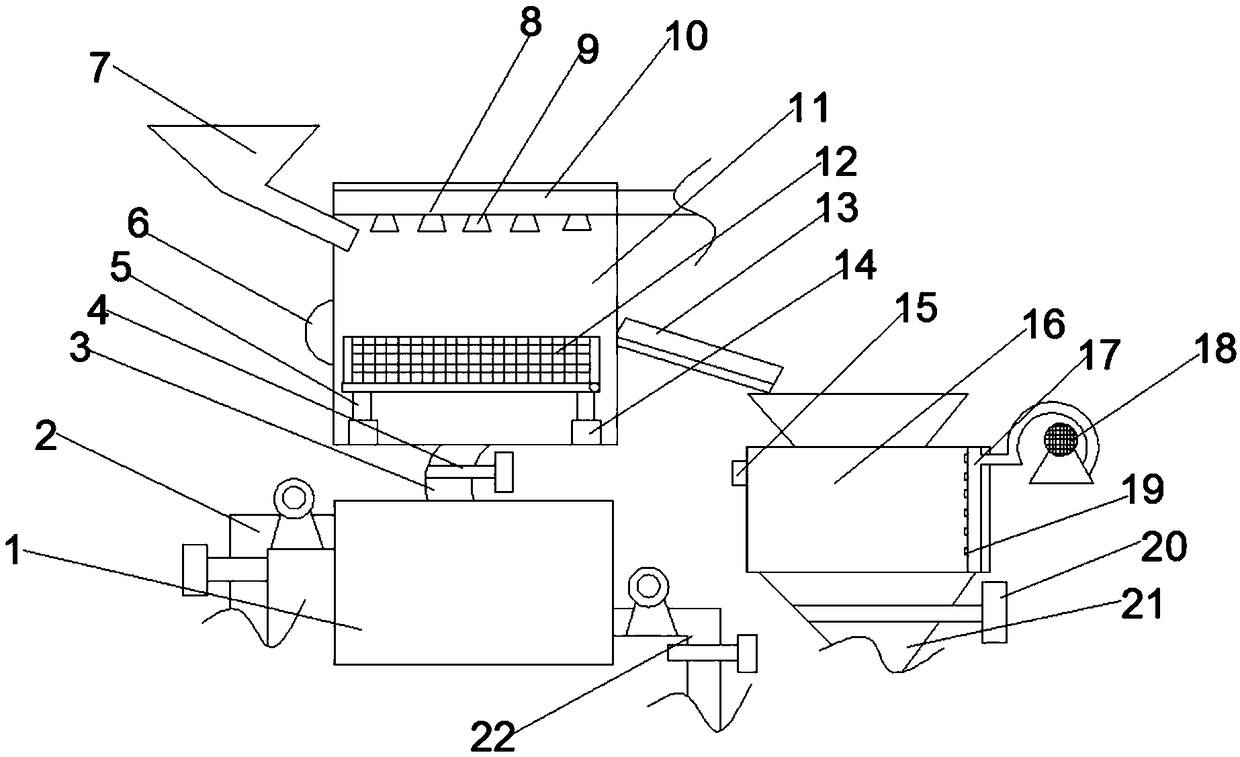

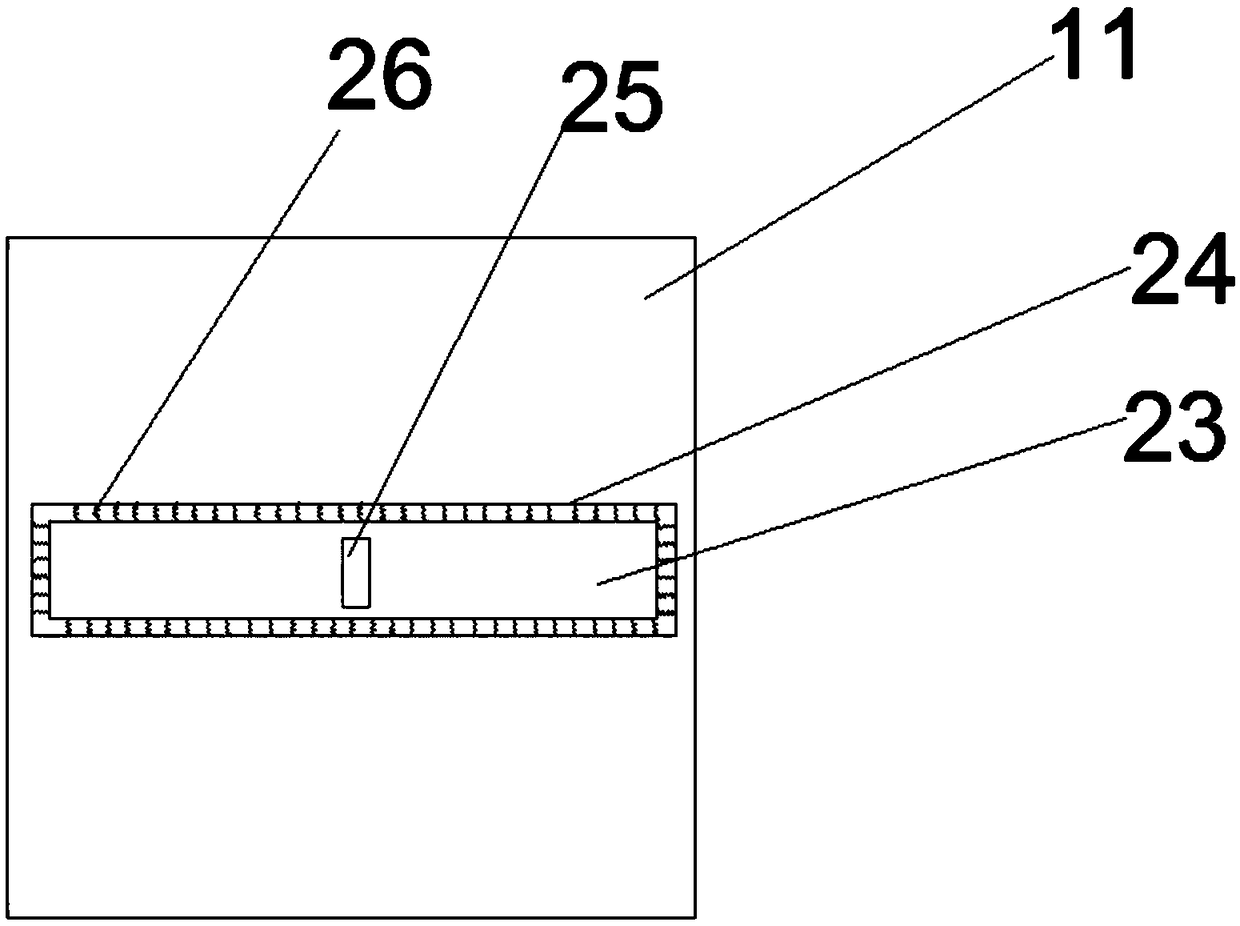

[0032] refer to Figure 1-2 , the present invention provides a cleaning device for auto parts, comprising a cleaning bucket 11, a water supply mechanism is connected to the top of the cleaning bucket 11, a water outlet pipe 3 is connected to the bottom of the cleaning bucket 11, a solenoid valve 4 is connected to the water outlet pipe 3, and the bottom of the cleaning bucket 11 Connected with a lifting mechanism, the lifting mechanism is connected with a screen slot 12, and the cleaning bucket 11 is connected with a feed port 7, and the side wall of the screen slot 12 away from the feed port 7 is hinged on the bottom of the screen slot 12, and the feed A discharge port is provided on the barrel wall of the relative cleaning barrel 11 of the mechanism, and the discharge port is connected with a sealing door 23, and the drying chamber 16 is provided with an exhaust port 15.

[0033] Working principle: when using the auto parts cleaning device of the present application, the auto...

Embodiment 2

[0036] Based on Example 1, with reference to Figure 1-2 , the lifting mechanism of this embodiment includes a hydraulic cylinder connected between the screen tank 12 and the bottom of the cleaning bucket 11, the piston rod of the hydraulic cylinder is connected to the screen tank 12, and the shell of the hydraulic cylinder is fixedly connected to the bottom of the cleaning bucket 11.

[0037] When cleaning the auto parts on the screen slot 12, start the hydraulic cylinder, so that the piston rod on the hydraulic cylinder pushes the screen slot 12 to move up and down, so that the auto parts in the screen slot 12 and the cleaning bucket 11 can be The water is fully contacted, so that the auto parts in the screen tank 12 are cleaned more cleanly. The piston rod of the hydraulic cylinder drives the screen groove 12 to move up and down, so that the screen groove 12 is more stable during the moving process, and the vibration is small during the moving process, and the entire device...

Embodiment 3

[0039] Based on Example 2, refer to Figure 1-2 , the hydraulic cylinder of this embodiment includes a left hydraulic cylinder 5 connected near the feed port 7, a right hydraulic cylinder 14 connected near the discharge port, and the cleaning bucket 11 is externally connected with a hydraulic cylinder 5 for controlling the left hydraulic cylinder 5 and a right hydraulic cylinder. The controller 6 activated by the cylinder 14 is electrically connected to the left hydraulic cylinder 5 and the right hydraulic cylinder 14 .

[0040] After cleaning, the piston rods of the hydraulic cylinders on the left and right sides need to be stretched to different lengths so that the bottom of the screen groove 12 is in an inclined state, wherein the controller 6 is connected with the left control button for controlling the left hydraulic cylinder 5, and Control the right control button of the right hydraulic cylinder 14, the staff only needs to press the left control button to make the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com