Tool and machining method of special static blade installing hole socket of central machine shell

A central casing and processing method technology, applied in the direction of the boring head, etc., can solve the problems of structural limitations, the inability to design a reverse scribing tool that meets the requirements, and the difficulty in ensuring the accuracy and efficiency of the processing of the special stationary vane installation holes of the central casing. , to achieve remarkable results and improve processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

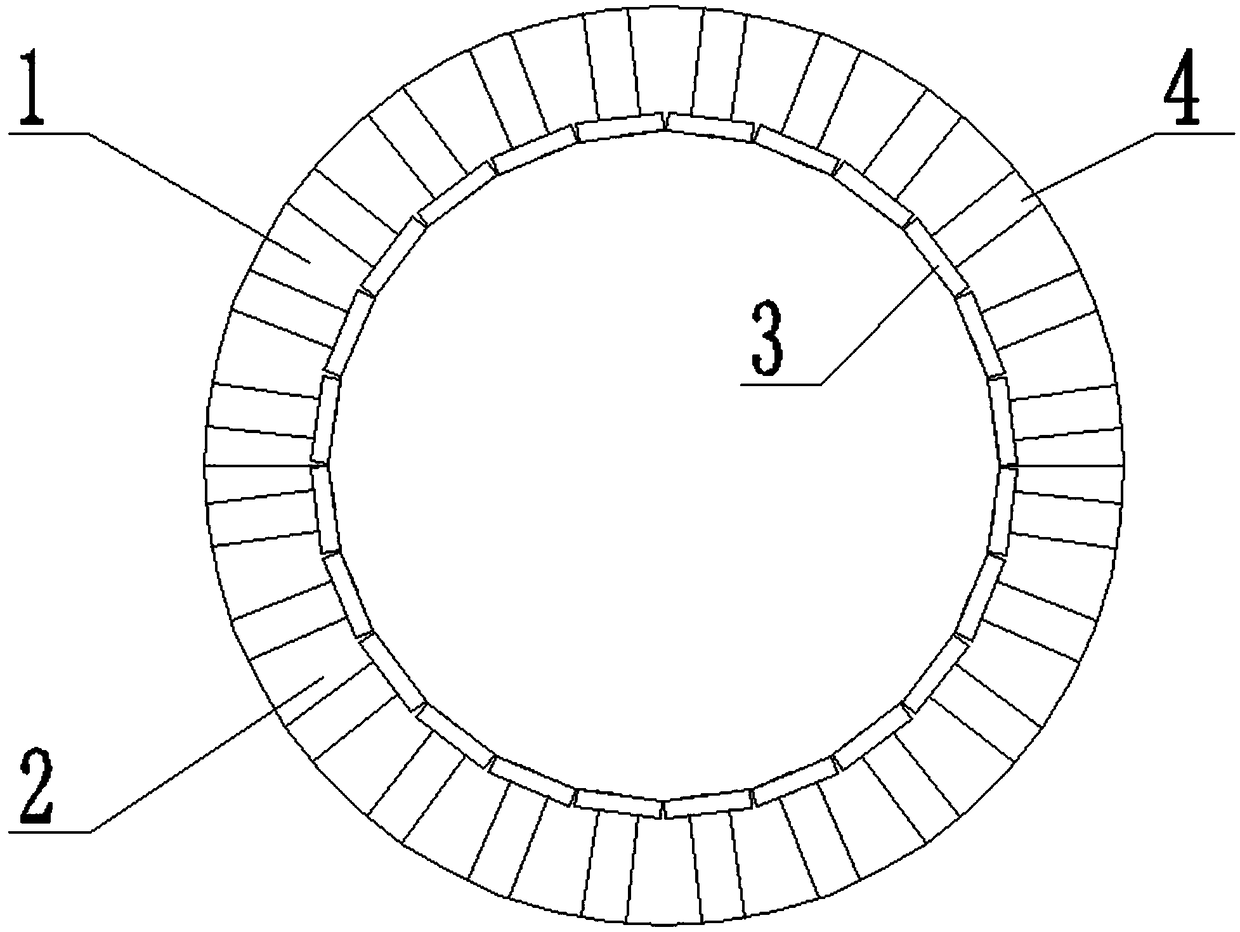

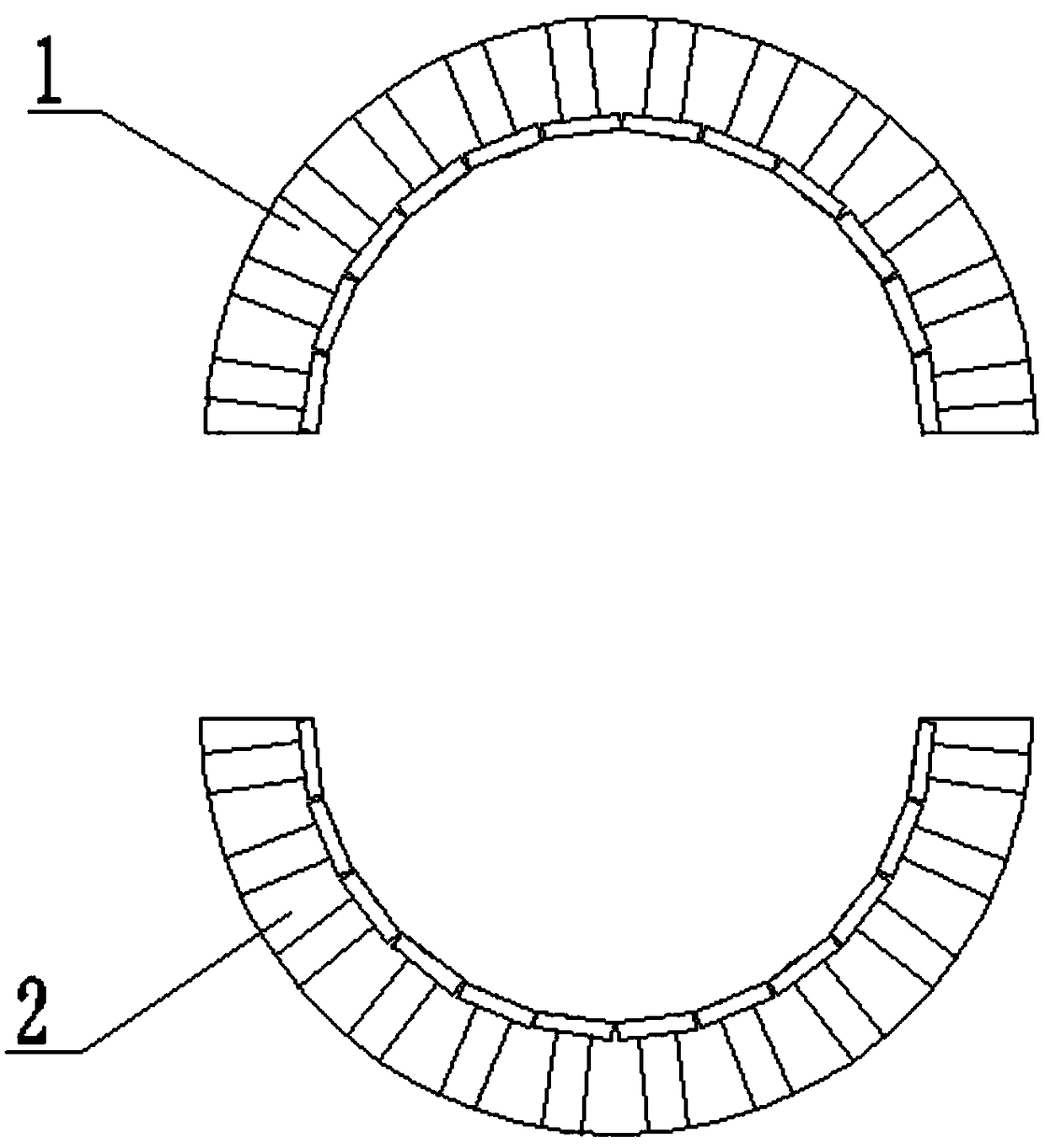

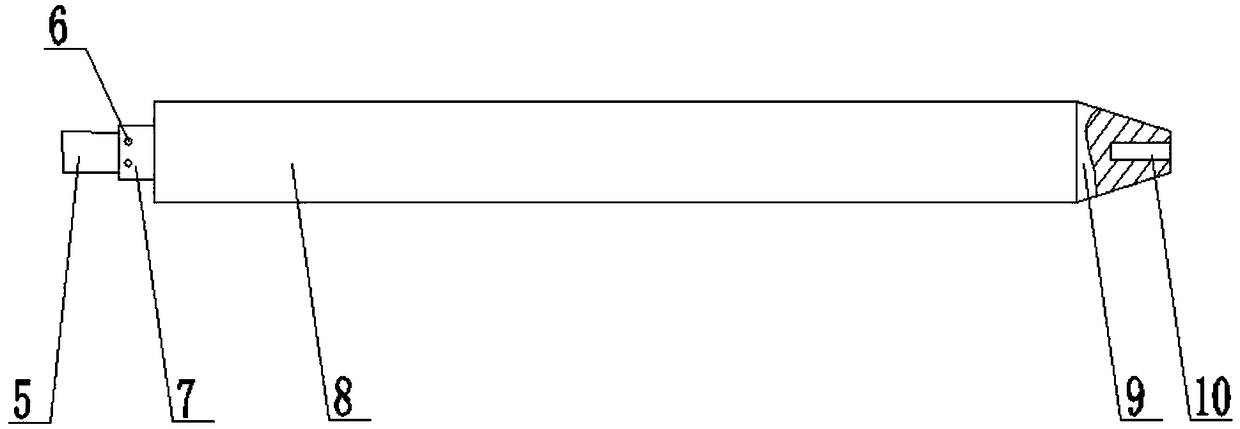

[0037] refer to Figure 1 to Figure 6 , the central casing is a two-half combined structure, that is, it is composed of the bottom plane of the upper central casing 1 and the top plane of the lower central casing 2. A series of holes 3 are arranged on the central casing in a circular shape. The bottom of the socket 3 is provided with a base hole 4, and the axis of rotation of the socket 3 and the axis of rotation of the base hole 4 coincide in space.

[0038] For the hole 3 far away from the split surface of the central casing, the processing steps are as follows:

[0039] A. Refer to figure 1 , figure 2 , using the central casing as a two-half structure, the central casing is disassembled along the split plane;

[0040] B. On the CNC boring machine, use the facet in the casing to find the alignment;

[0041] C. Use the spindle of the boring machine to process the holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com