Aluminum foil paper embossing device

A technology of aluminum foil paper and embossing, applied in the direction of machining/deformation, etc., can solve the problems of clogging, abnormal conveying of aluminum foil paper, unclear knurling on the surface of aluminum foil paper, etc., so as to avoid wear of parts, improve service life and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

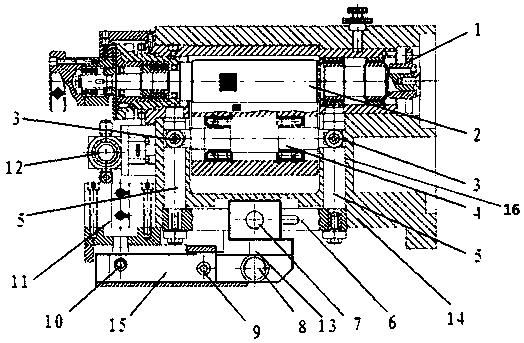

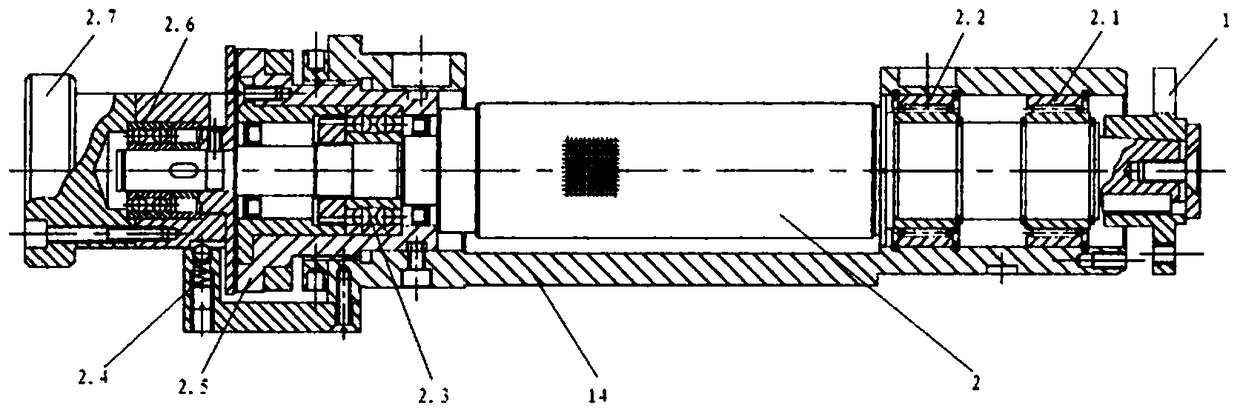

[0015] figure 1 Shown is a schematic structural diagram of one embodiment of the aluminum foil embossing device of the present invention, including a base 14, a coupling 1, a driving knurling roller 2, and a driven knurling roller 4, and the driving knurling roller 2 is installed on the base 14 On the top, both ends are supported by bearings 2.1, 2.2, 2.3 and one-way bearing 2.6 to form a rotating pair. The driven knurled roller 4 and the driving knurled roller 2 are arranged in parallel with a certain distance, and the two ends of the driven knurled roller 4 It is fixed on two sliding rods 5, and the sliding rods 5 can slide along the guide hole 16, and the guide hole 16 is arranged perpendicular to the axial direction of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com