A reinforcing structure for connecting a rear suspension towing arm with a vehicle body

A technology for strengthening the structure and trailing arm, applied to the cantilever, suspension, vehicle parts and other directions installed on the pivot, can solve the problems of unsatisfactory effect, increase the weight of the whole vehicle, fail to achieve rear impact energy and ease the impact, etc. Achieve the effect of improving NVH performance and safety performance, improving the rigidity and strength of the installation point, and simplifying the stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

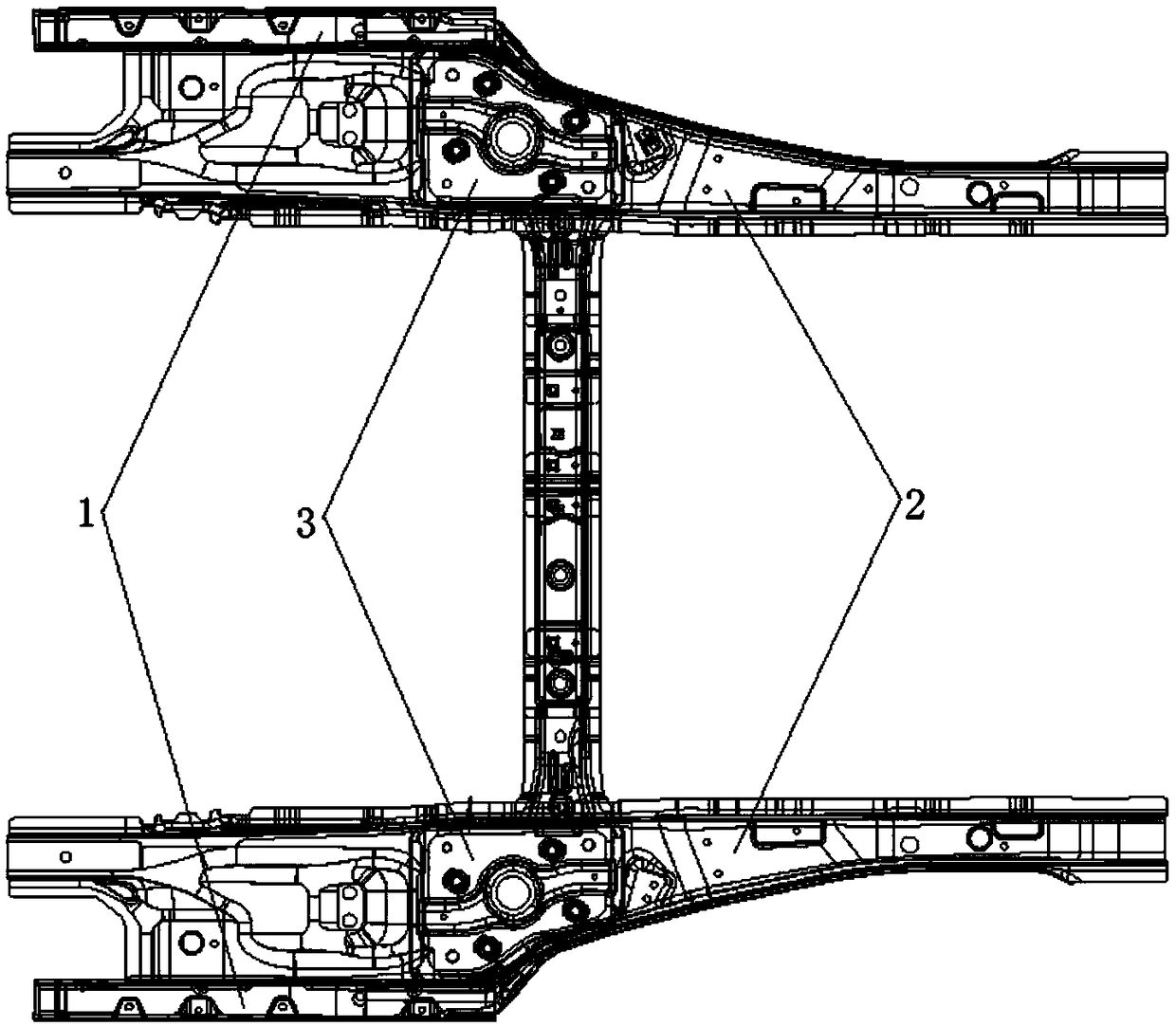

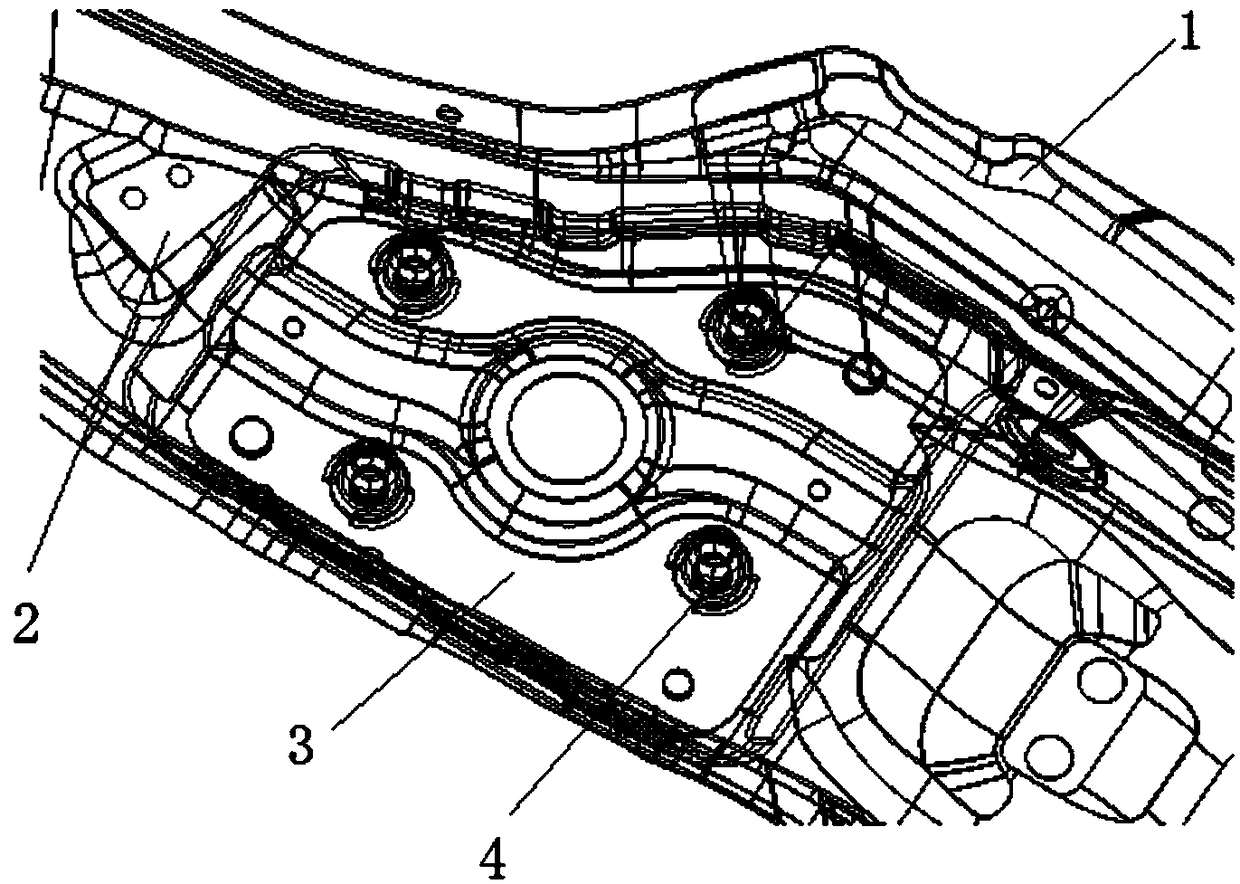

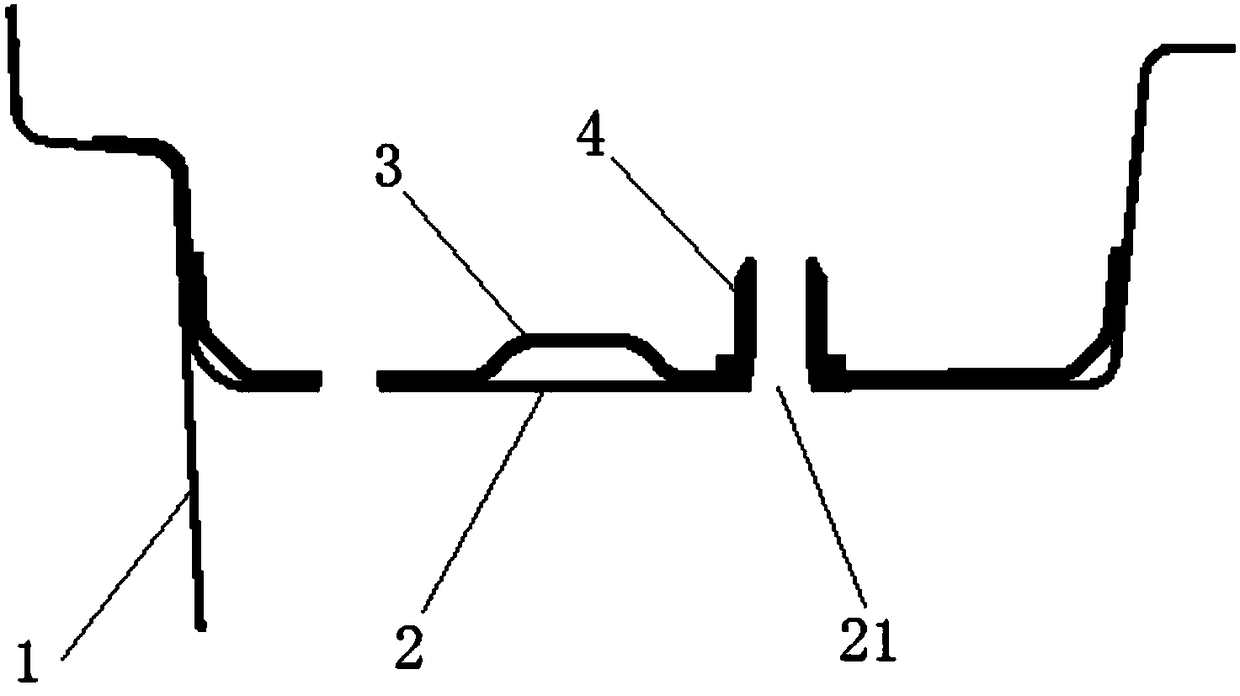

[0024] The reinforcing structure that the rear suspension trailing arm of the present invention is connected with the vehicle body, such as figure 1 , 2 As shown, it includes a rear longitudinal beam body 2 connected to the rear section 1 of the door sill, and a trailing arm installation reinforcing plate 3 is provided on the rear longitudinal beam body 2, and a nut seat 4 for installing the trailing arm is provided on the trailing arm installation reinforcing plate 3. The reinforcement structure connecting the trailing arm of the rear suspension to the vehicle body includes the rear section 1 of the door sill, the rear longitudinal beam body 2 and the trailing arm installation reinforcing plate 3, and the trailing arm installation reinforcing plate 3 and the rear section 1 of the door sill and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com