Intelligent placing device for seal ring frameworks

The technology of placing device and sealing ring is applied in the field of intelligent placing device of sealing ring frame, which can solve the problems of large workload, small size of sealing ring frame, low work efficiency, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with drawings and specific embodiments.

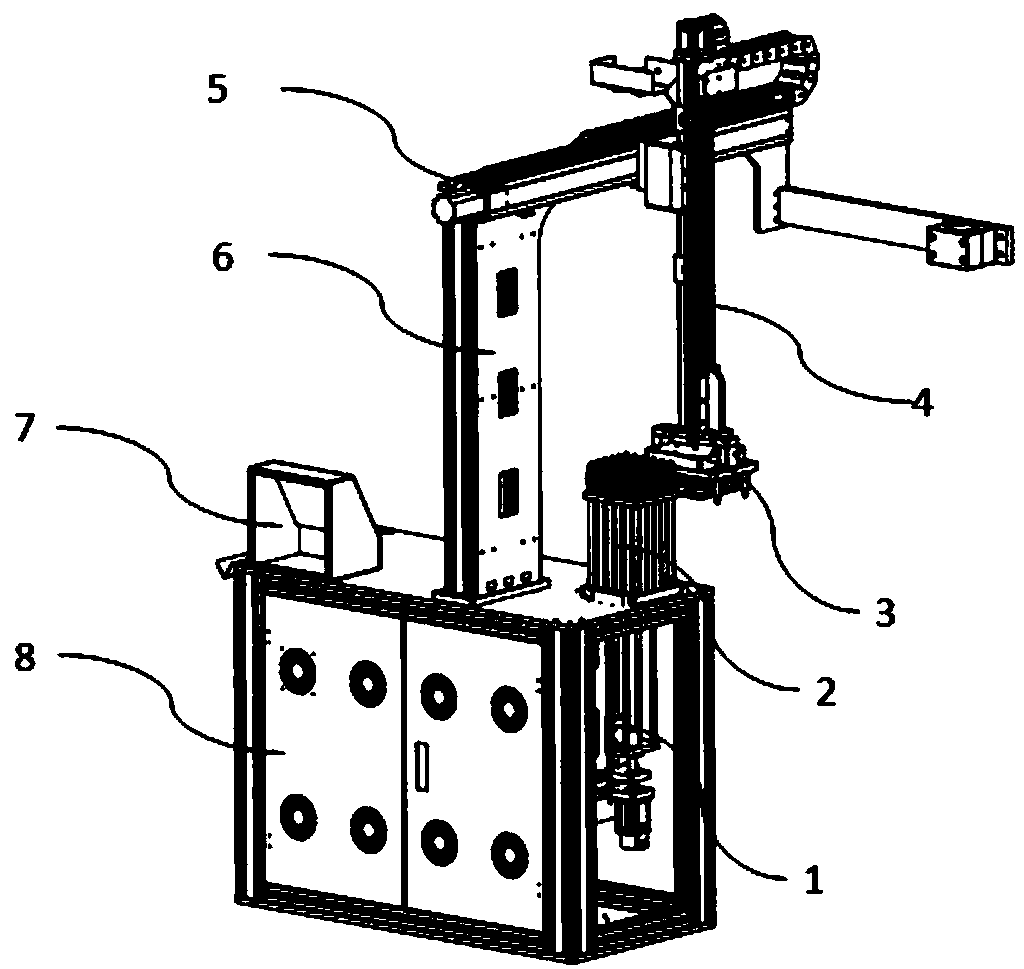

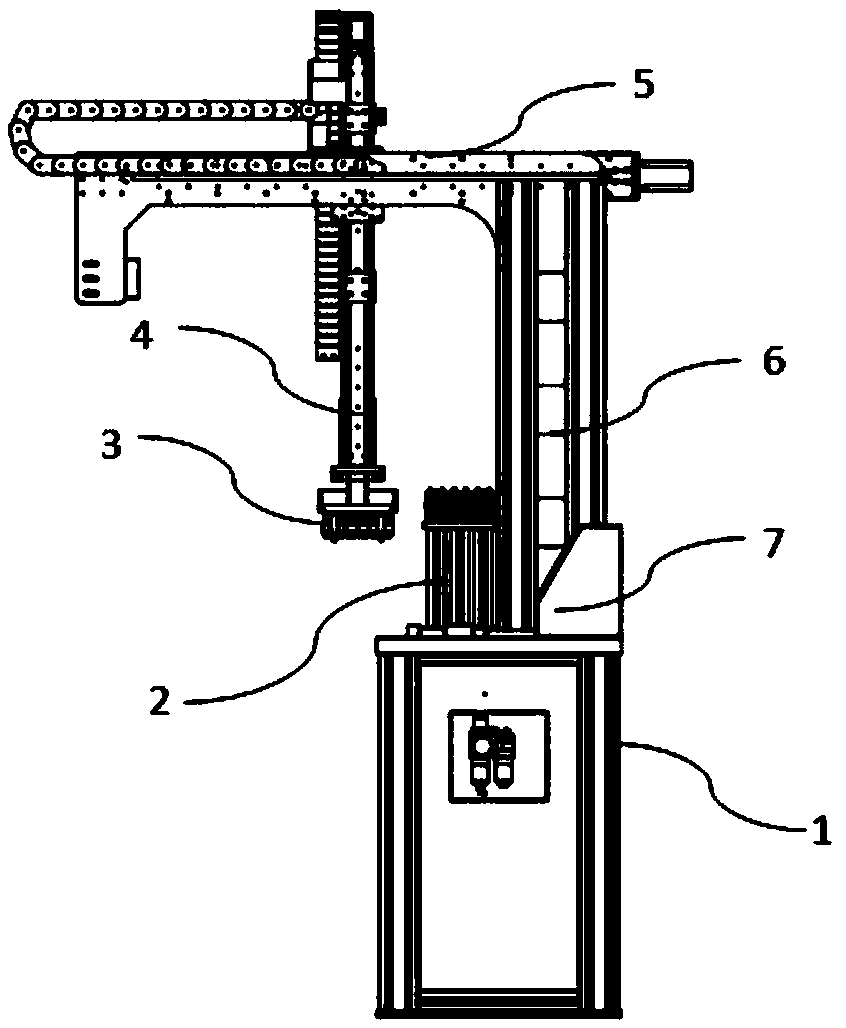

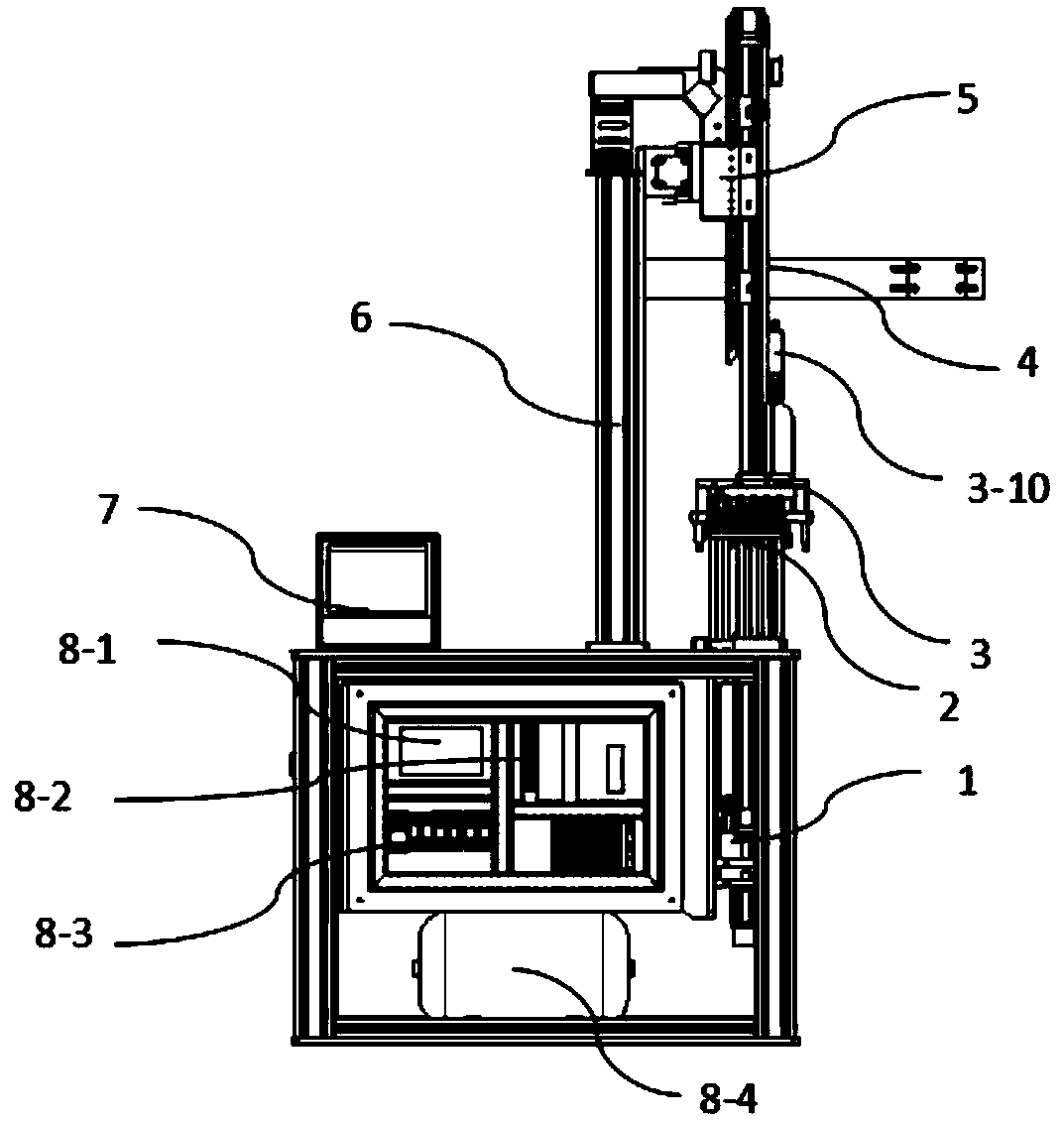

[0029] Such as figure 1 As shown, the embodiment of the present invention provides an intelligent placement device for sealing ring skeletons, including a jacking mechanism (1), a sealing ring skeleton stringing mechanism (2), a sealing ring skeleton suction cup mechanism (3), and a vertical guide rail ( 4), horizontal guide rail (5), fixed bracket (6), touch panel (7), box base (8), PLC (8-1), servo controller (8-2), control switch (8- 3).

[0030] Among them, see figure 1 and figure 2 , the PLC (8-1), the servo controller (8-2), the control switch (8-3) and the jacking mechanism (1) are installed in the box base (8), and the touch panel (7) passes through PLC (8-1), servo controller (8-2), and control switch (8-3) input control signals and control the operation of each module in combination with the built-in control program; the jacking mechanism (1) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com