A kind of preparation method of plasma-assisted superhydrophobic polyester fabric

A plasma and super-hydrophobic technology, applied in the direction of repelling fibers to liquids, ultrasonic/sonic fiber treatment, physical treatment, etc., can solve the problems of difficult processing, great influence on the moisture permeability and hand feeling of fabrics, and expensive clothing. , to achieve good mechanical friction stability, easy continuous industrial production, and stable super-hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

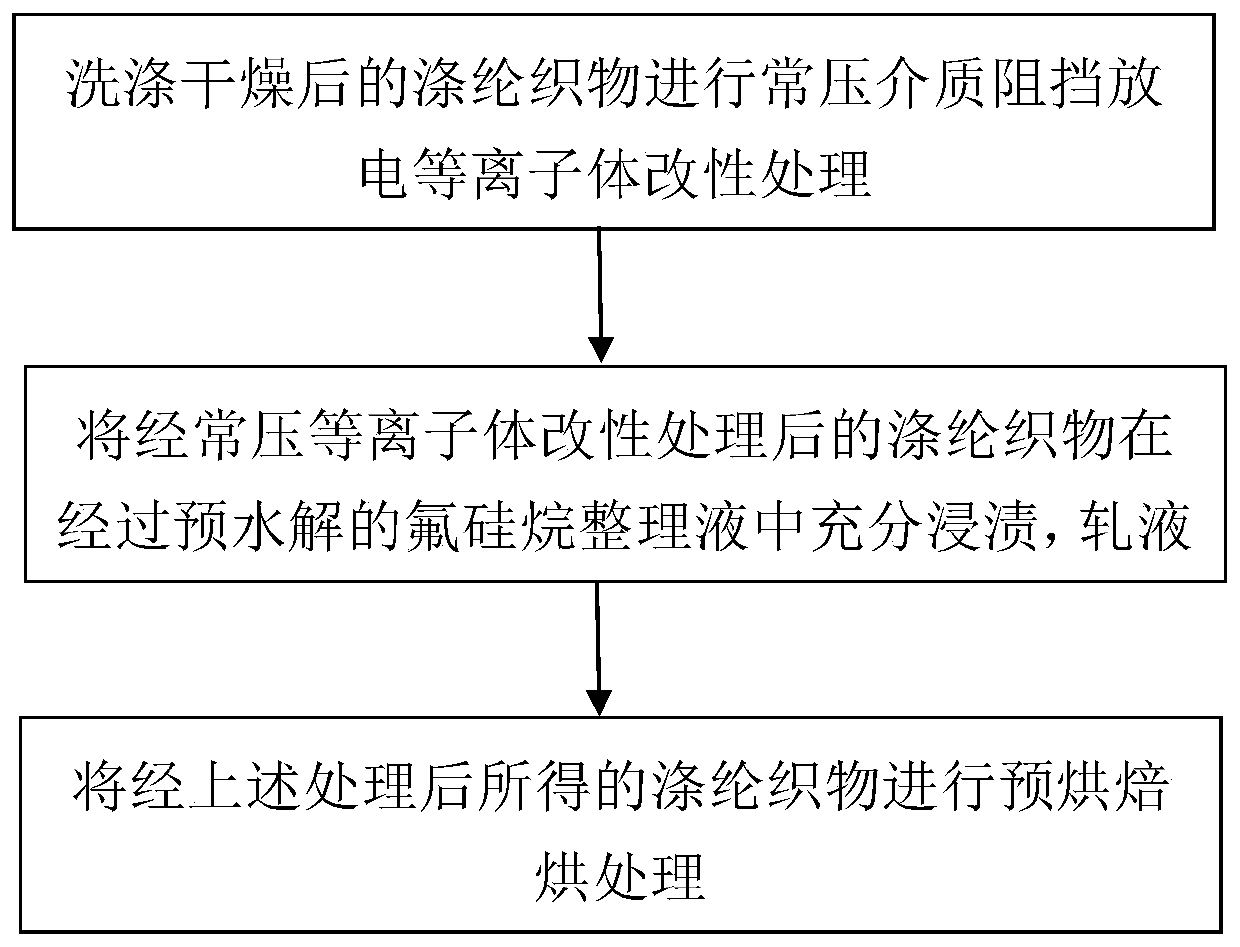

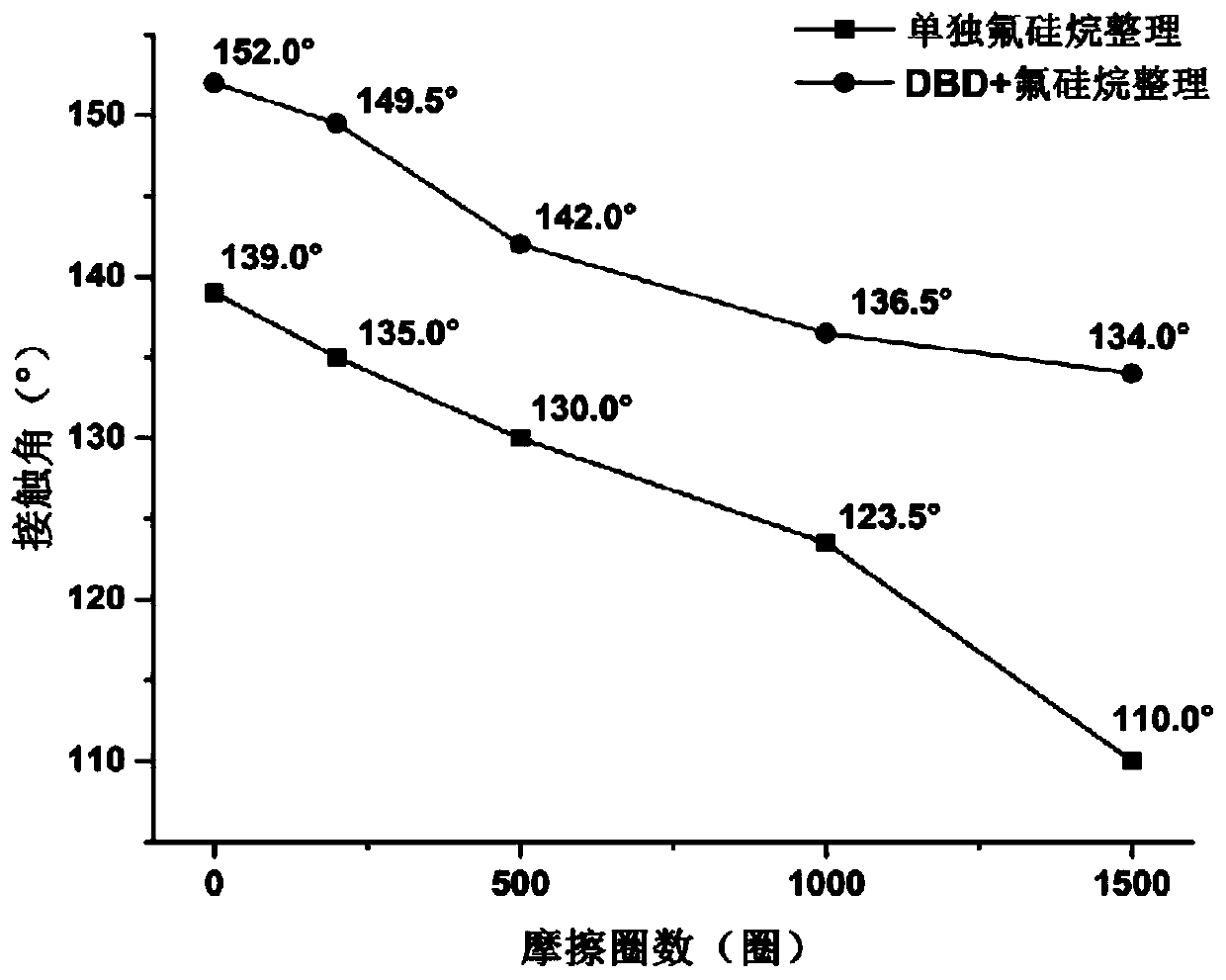

[0021] The invention provides a method for preparing a plasma-assisted superhydrophobic polyester fabric, which combines normal-pressure dielectric barrier discharge plasma and a fluorosilane finishing agent to modify the superhydrophobic performance of the polyester fabric. Atmospheric pressure plasma treatment of polyester fabrics generates a large number of free radicals on the surface of the fibers and introduces active groups. It is energy-saving, environmentally friendly, and easy to operate, which is conducive to the realization of continuous production. Fluorosilane finishing agent 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane is a bifunctional compound that is easy to hydrolyze under acidic conditions to release low-molecular alcohols, thereby forming active silanols, which can be combined with plasma Oxygen-containing groups such as hydroxyl groups on the surface of the treated polyester fibers produce stable chemical bonds, which can endow polyester fabrics with extre...

Embodiment 1

[0035] In this embodiment, the plasma-assisted superhydrophobic polyester fabric is prepared according to the following steps:

[0036] The surface of the polyester fabric is cleaned and dried at a drying temperature of 90°C. The cleaned polyester fabric was subjected to surface treatment in a dielectric barrier discharge atmospheric pressure plasma device. The plasma treatment atmosphere was Ar gas, the gas flow rate was 1L / min, the treatment power was 1KW, and the treatment time was 120s. The polyester fabric after normal pressure plasma modification treatment is fully padded in the pre-hydrolyzed finishing solution, and the solution is configured according to the bath ratio of 1:40. The finishing solution includes the following raw materials (by mass parts): fluorosilane finishing agent 1H, 1 part of 1H, 2H, 2H-perfluorooctyltriethoxysilane, 99 parts of absolute ethanol, 100 parts of deionized water, and 1 part of acetic acid, wherein the fluorosilane was pre-hydrolyzed for...

Embodiment 2

[0039] In this embodiment, the plasma-assisted superhydrophobic polyester fabric is prepared according to the following steps:

[0040] Wash and dry the surface of the polyester fabric at a temperature of 95°C. The cleaned polyester fabric was surface-treated in a dielectric barrier discharge atmospheric pressure plasma device. The plasma treatment atmosphere was Ar gas, the gas flow rate was 1L / min, the treatment power was 1KW, and the treatment time was 90s. The polyester fabric after normal pressure plasma modification treatment is fully padded in the pre-hydrolyzed finishing solution, and the solution is configured according to the bath ratio of 1:40. The finishing solution includes the following raw materials (by mass parts): fluorosilane finishing agent 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane 1 part, absolute ethanol 99 parts, deionized water 100 parts, acetic acid 1 part, fluorosilane pre-hydrolysis for 30min. Two dipping and two rolling, the padding pressure is 2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com