Patents

Literature

33results about How to "Easy to realize continuous industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formaldehyde-inhibiting composite clay adhesive filler

ActiveCN102344765AInhibitory releaseReduce releaseNon-macromolecular adhesive additivesMacromolecular adhesive additivesResin adhesiveUrea-formaldehyde

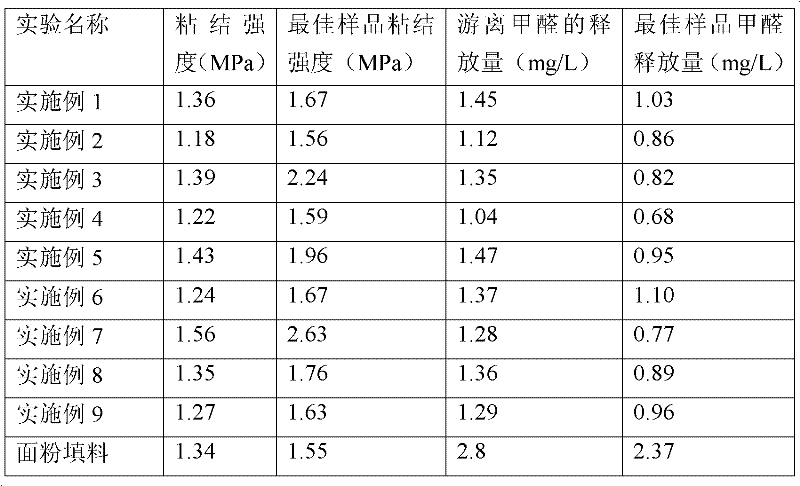

The invention discloses composite silica-magnesia clay urea-formaldehyde resin adhesive filler for inhibiting emission of free formaldehyde. The filler is prepared from 30-70 percent of modified attapulgite powder, 0-50 percent of modified sepiolite powder and 15-30 percent of vegetable protein powder, wherein the total percentage of the components is 100 percent. According to the composite silica-magnesia clay urea-formaldehyde resin adhesive filler disclosed by the invention, natural attapulgite and sepiolite mineral powder with abundant reservation, wide distribution range and low price are used as raw materials; urea with the characteristic of specifically absorbing the formaldehyde is infiltrated; the surface of the powder is modified by using a silane coupling agent with a function of improving the affinity of the filler and a urea-formaldehyde resin adhesive; and when the silane coupling agent is used for organic filler to fill the adhesive, the dispersability and the adhesiveness of the filler can be improved. The processing technique is easy to realize continuous industrial production and avoid three-waste discharge.

Owner:HEBEI UNIV OF TECH

Silicon-magnesium composite clay adhesive filling material and application thereof

ActiveCN102344764AWide variety of sourcesLow priceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSilicate mineralsNatural mineral

The invention discloses a silicon-magnesium composite clay adhesive filling material and an application thereof. The filling material comprises components of, by mass: 5% to 35% of silicate mineral, 35% to 50% of magnesium silicate mineral, 2% to 25% of wood chip powder, and 15 to 40% of vegetable protein powder. The total amount of the components takes 100% by mass. According to the invention, natural mineral powders with abundant reserves, wide sources, and cheap prices are adopted as raw materials; wastes such as serrago produced during a wood processing process are comprehensively utilized, and a small amount of vegetable protein powder is also adopted as an auxiliary material. With simple grinding and cladding, the materials can be prepared into a mineral composite filling material used for substantially improving the initial viscosity of an urea formaldehyde resin adhesive, improving cold compression intensity and cementation intensity of a plywood, and reducing mineral composite filling materials used during a cold compression period. Therefore, the filling material can be used for substituting flour, such that foodstuff is saved, and production cost is reduced. With the processing technology, continuous industrial production can be easily realized, and three-wastes are not discharged.

Owner:HEBEI UNIV OF TECH

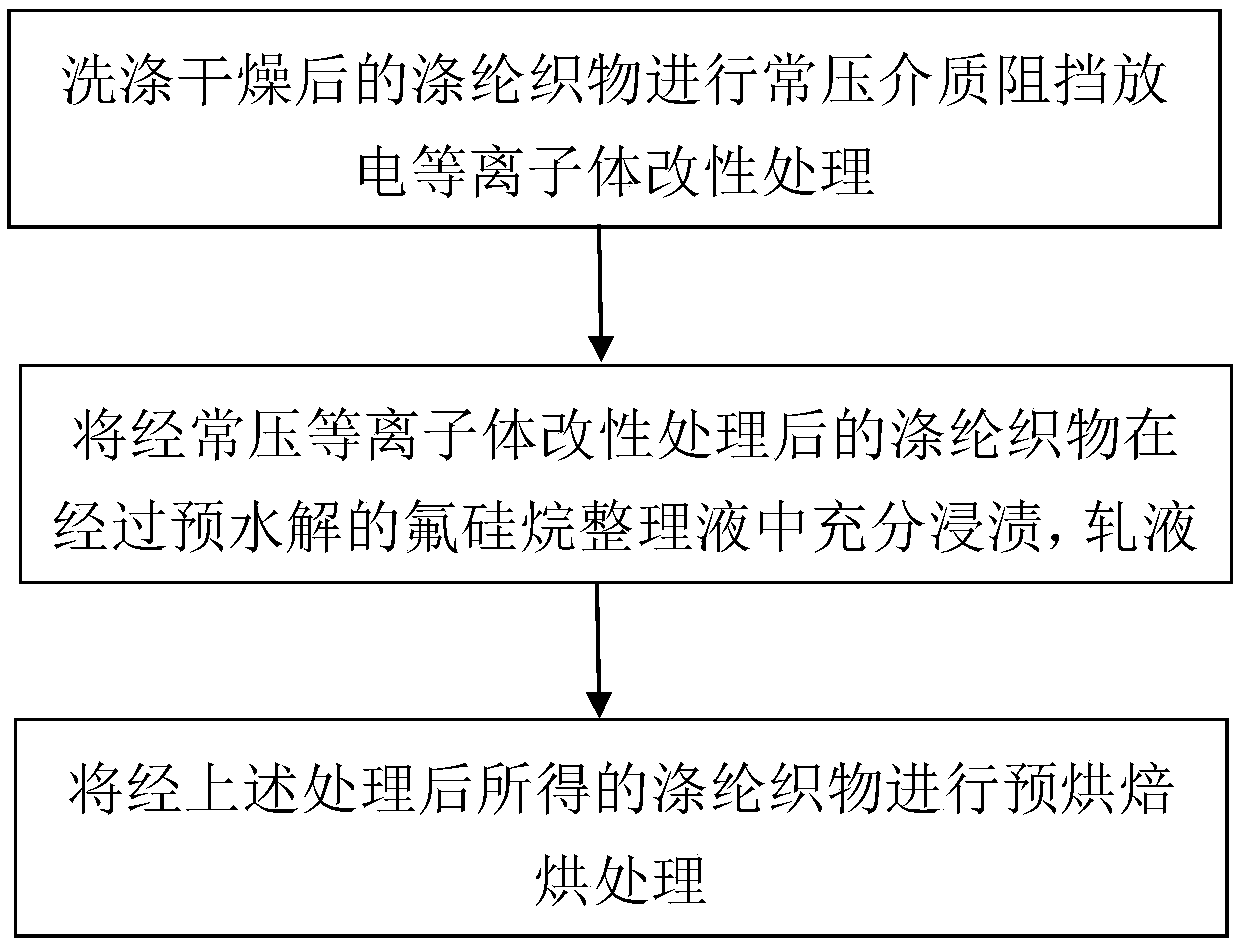

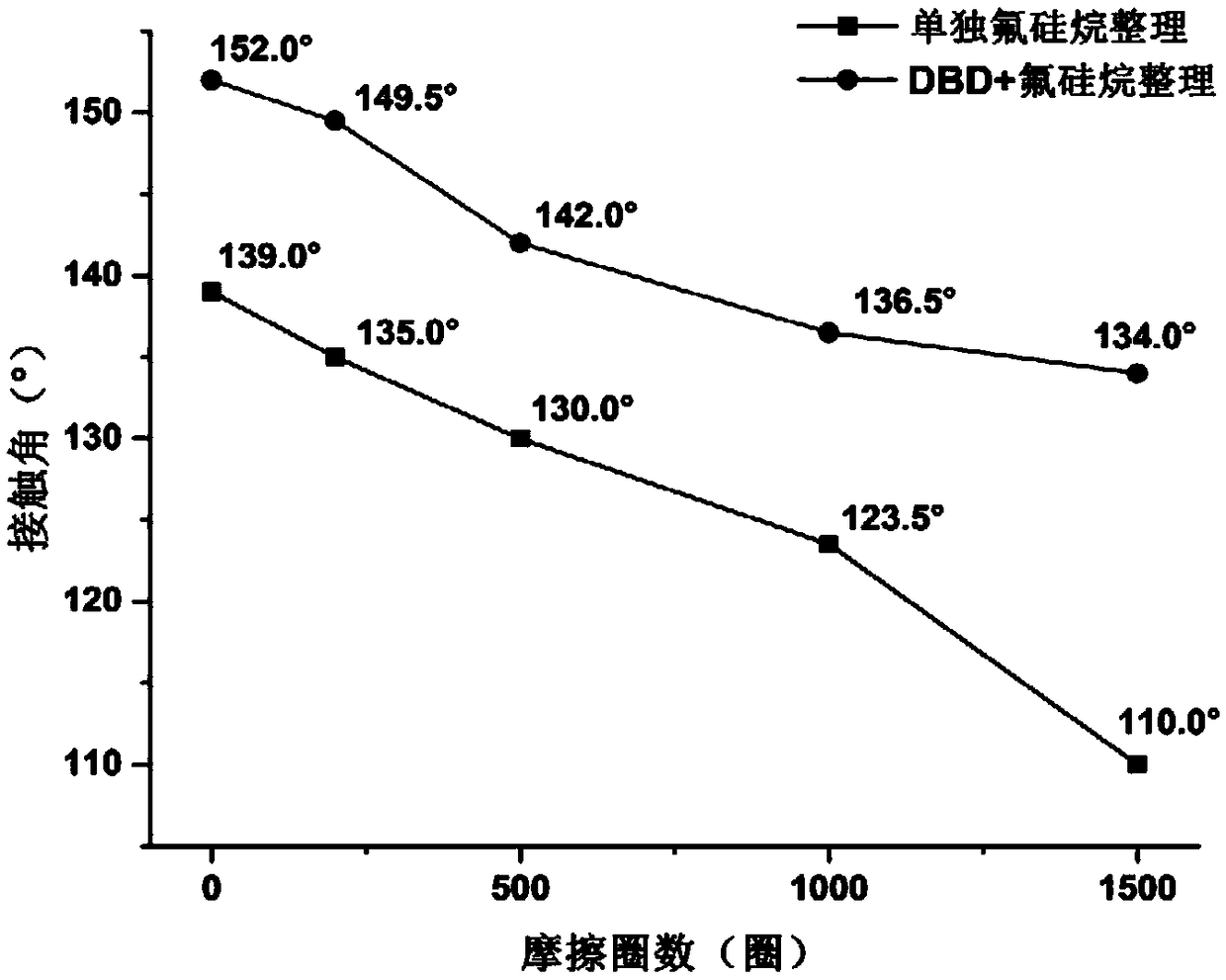

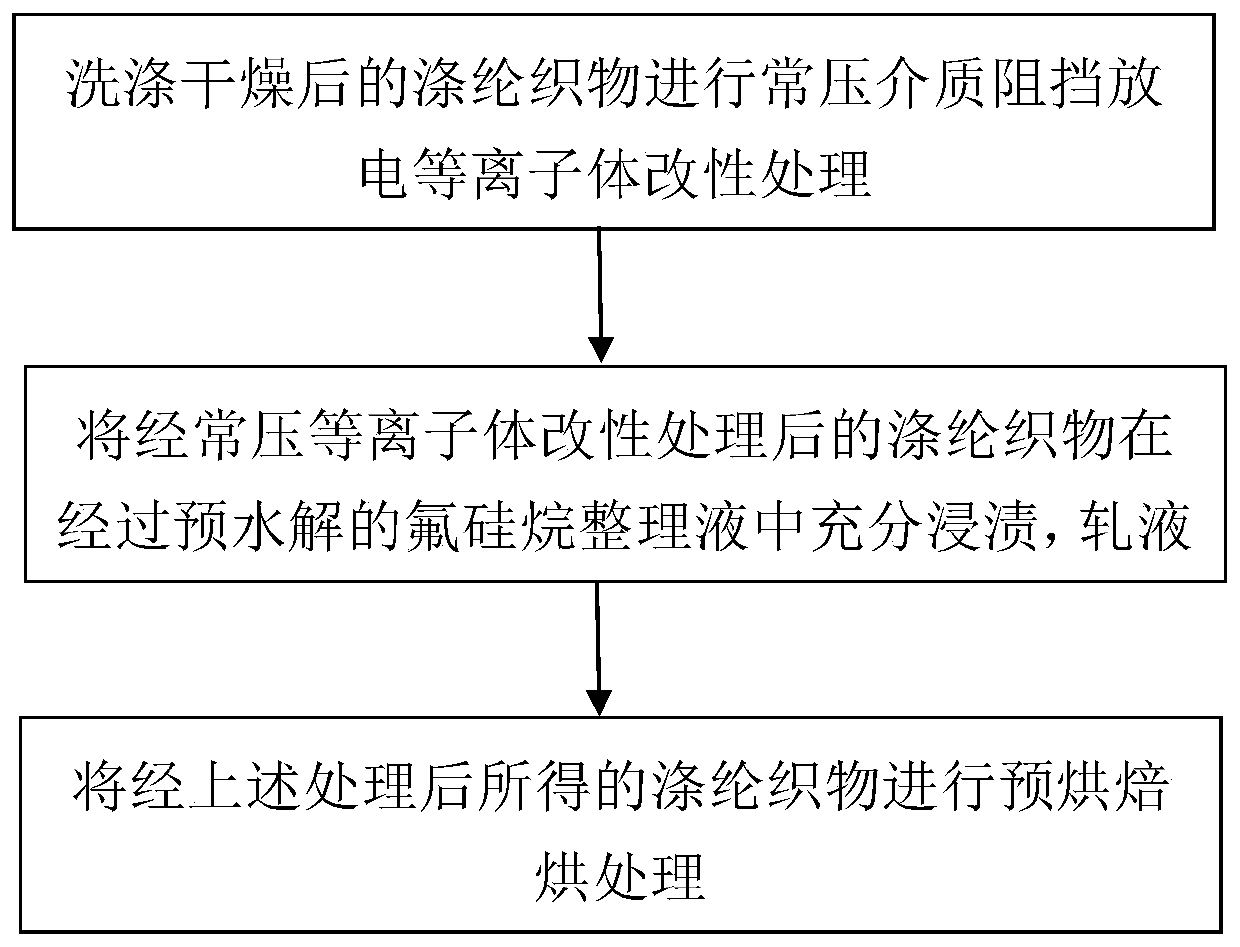

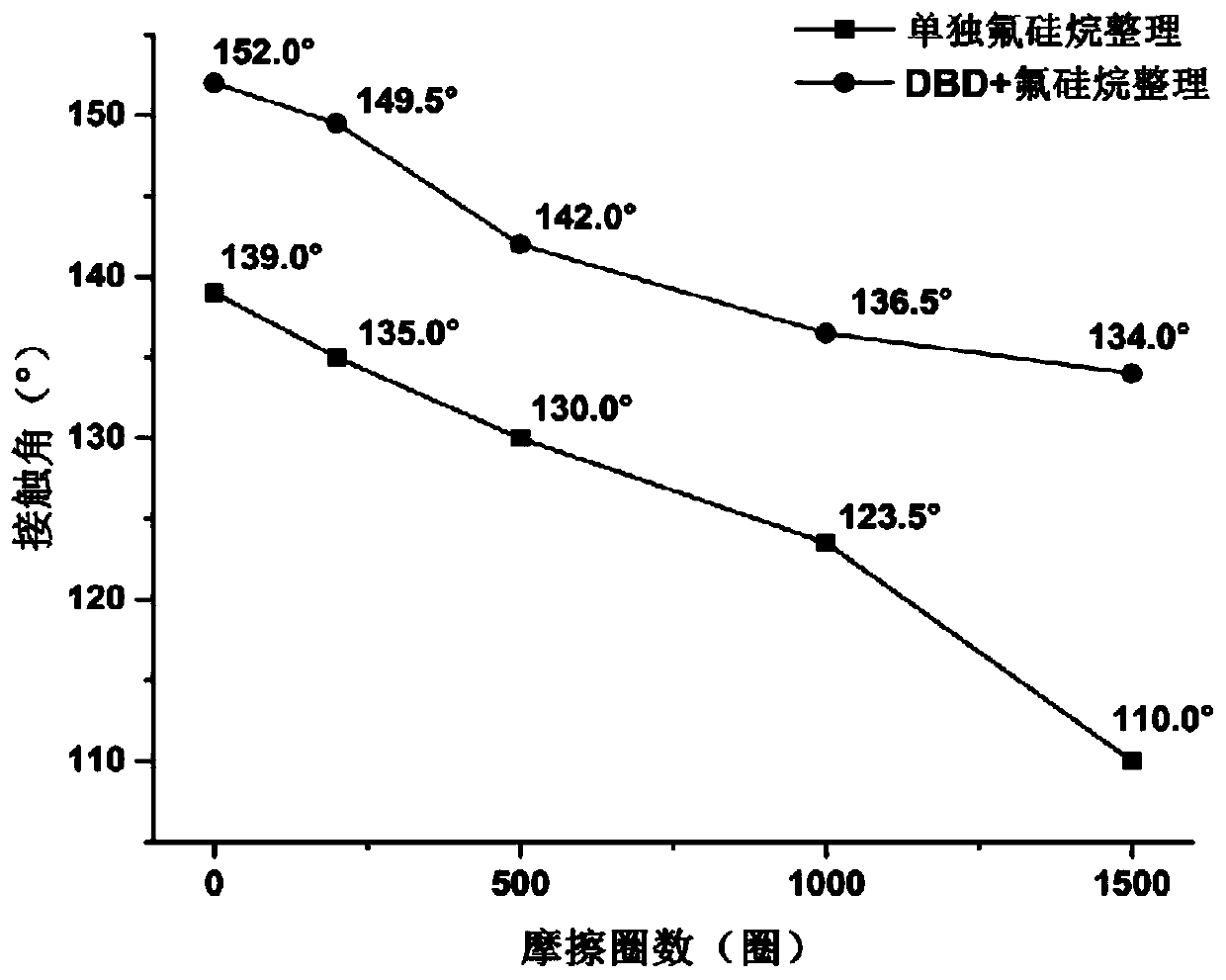

Preparation method of plasma assisted super-hydrophobic polyester fabric

ActiveCN108978173AStable super hydrophobic performanceGood stability against mechanical frictionUltrasonic/sonic fibre treatmentLiquid repellent fibresChemistryPolyester

The invention discloses a preparation method of plasma assisted super-hydrophobic polyester fabric. The preparation method comprises the following steps: carrying out dielectric barrier discharge atmospheric plasma modification treatment on polyester fabric after washing and drying; fully dipping the polyester fabric in pre-hydrolyzed fluorosilane finishing liquor, and squeezing; pre-baking and baking the polyester fabric through a baking oven, thus obtaining a final finished product. The polyester fabric prepared by the invention is wide in application, an atmospheric plasma technology is green and environment-friendly, the finished fabric is good in super-hydrophobicity, very good mechanical friction resistance and stability can be obtained, the operation is simple, and continuous industrial production can be easily realized.

Owner:旷达纤维科技有限公司 +1

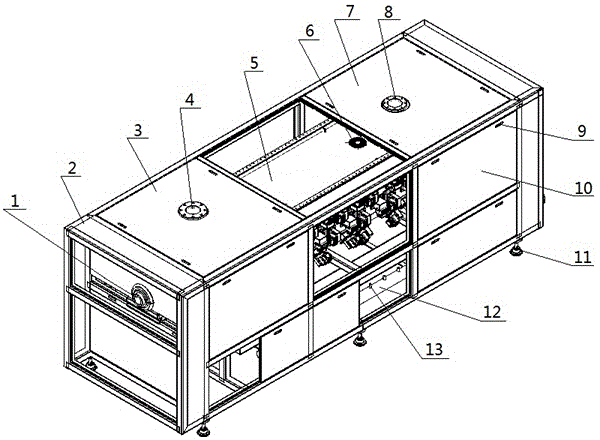

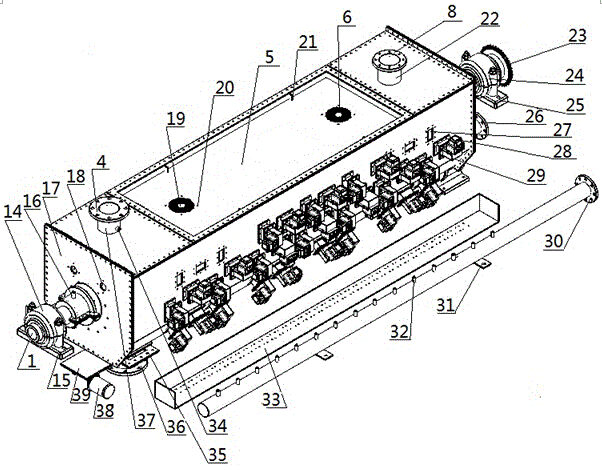

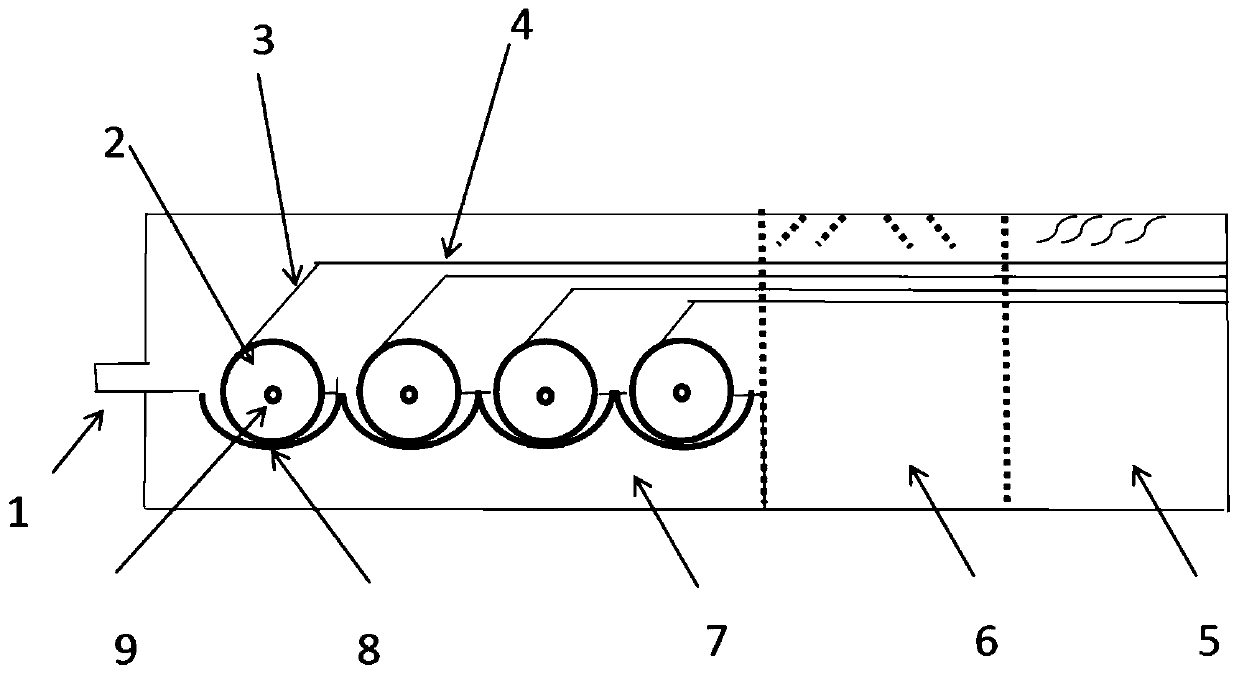

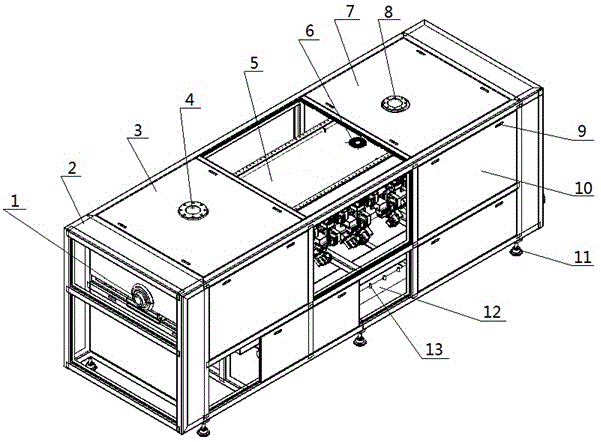

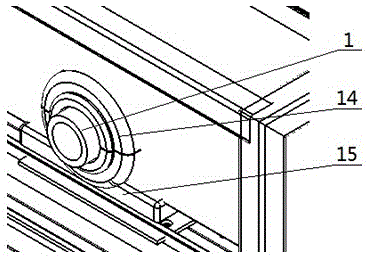

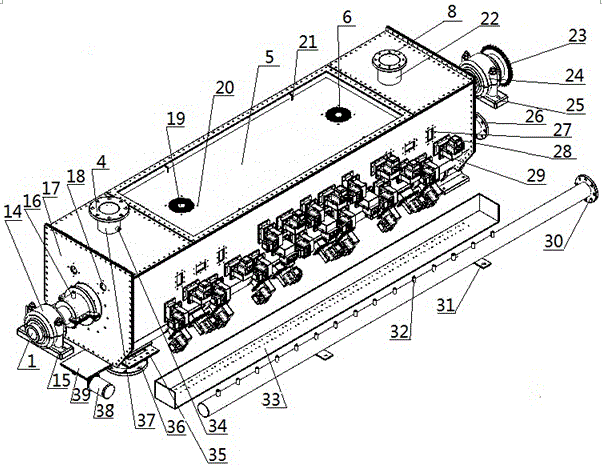

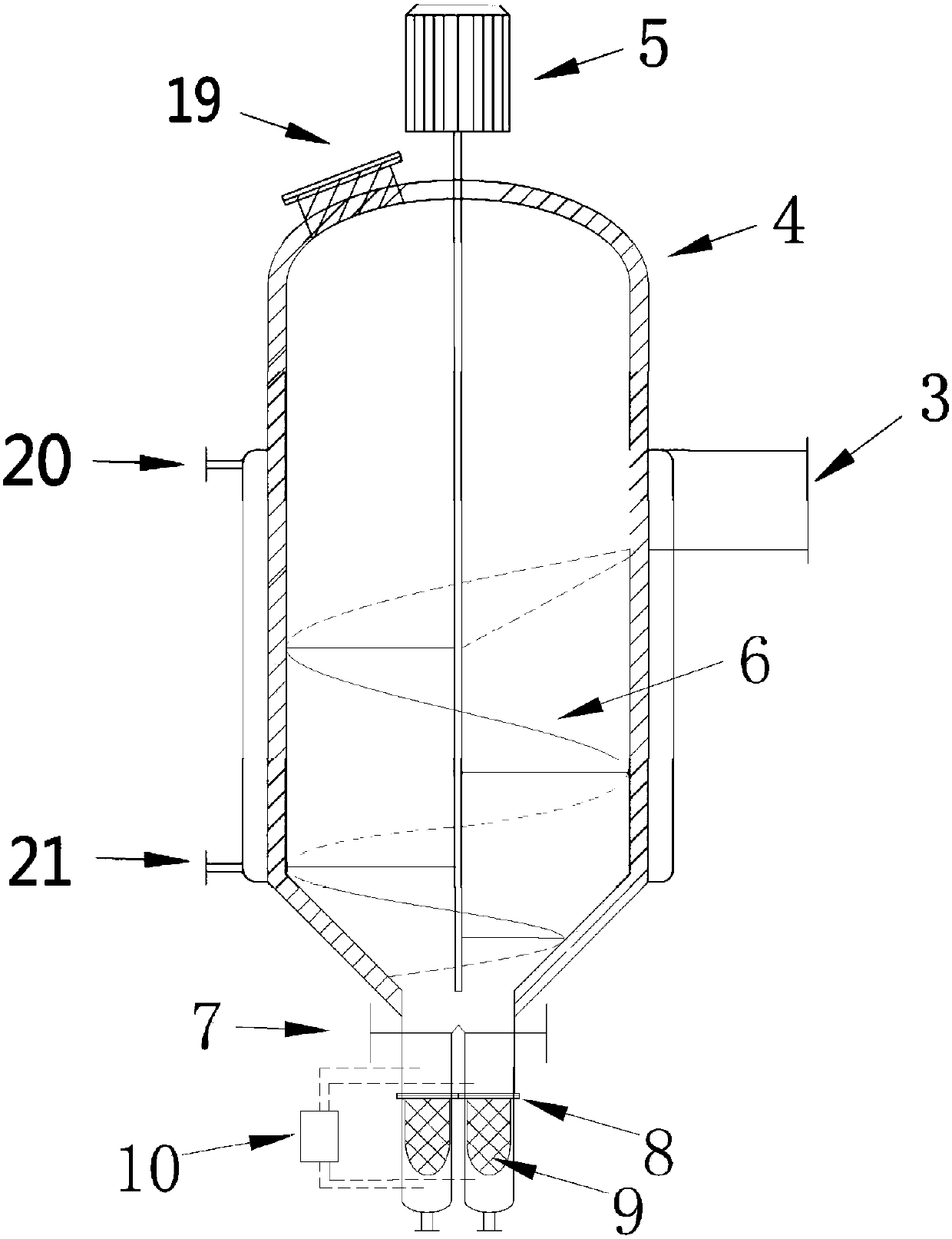

Microwave double-screw tube furnace and method for preparing ferromanganese alloy by using microwave double-screw tube furnace and submerged arc furnace in combined manner

ActiveCN104567370AReasonable layoutImprove energy utilizationCharge manipulationFurnace typesThermal energyMicrowave cavity

The invention relates to a microwave double-screw tube furnace and a method for preparing ferromanganese alloy by using the microwave double-screw tube furnace and a submerged arc furnace in a combined manner and belongs to the technical fields of microwave equipment and manganese metallurgy. The microwave double-screw tube furnace comprises three parts, namely a rack, a microwave cavity and a double-screw stirring device. The microwave double-screw tube furnace is adopted to pre-roast manganese ore so as to obtain a hot-state material, and then, the hot-state material is placed in the submerged arc furnace for smelting, so as to obtain the ferromanganese alloy. According to the tube furnace, microwave heating is adopted, so that the non-contact direct rapid heating of the material can be realized; due to the arrangement of reactor magnetrons, the efficiency of converting microwave energy into heat energy can be greatly increased; due to the combination and matching of a large number of low-power magnetrons, the successful research and development of a high-power microwave reactor for industrial production are realized; the method is short in production cycle and low in energy consumption, and various harmful phenomena caused due to the fact that cold materials enter the furnace can be properly overcome.

Owner:KUNMING UNIV OF SCI & TECH

Industrial method for efficiently producing lycopene crystals

ActiveCN102126911AHigh purityNo emissionsCrystallisation purification/separationLycopeneParaffin oils

The invention relates to an industrial method for purifying natural extracts, in particular to an industrial method for efficiently producing lycopene crystals. The method comprises the following steps of: (1) mixing 6-15 percent of lycopene oleoresin with a diolefine solvent in the mass ratio of 1:(3-7) and stirring the mixture to dissolve the mixture into mixed liquor; (2) standing the mixed liquor at the temperature of between 10 DEG C below zero and 20 DEG C and centrifuging the mixed liquor to obtain viscous paste; (3) mixing the viscous paste with the paraffin solvent, standing and centrifuging to obtain paste; (4) performing vacuum drying on the paste and removing solvent residues to obtain the lycopene crystals; and (5) and performing vacuum low-temperature concentration on filtrate obtained by centrifuging in the step (2) and the step (3) to obtain low-content lycopene oleoresin. The method has low environmental requirements, and an enriched high-content lycopene oleoresin component can be efficiently and continuously separated.

Owner:CHENGUANG BIOTECH GRP CO LTD

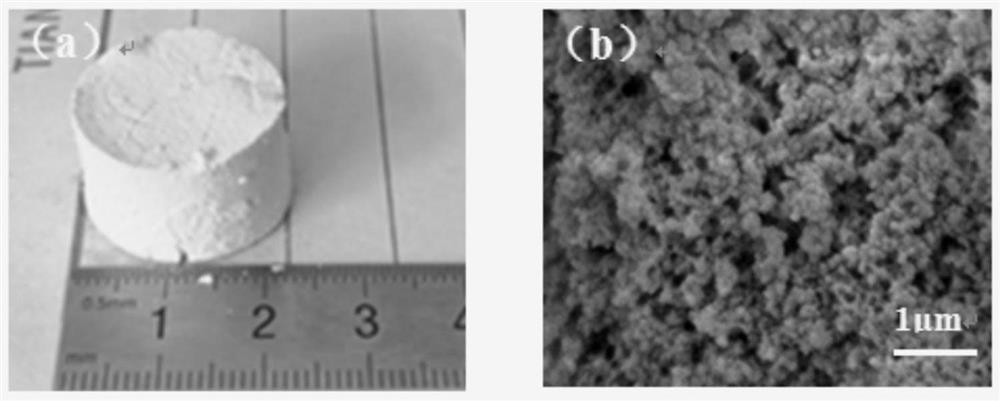

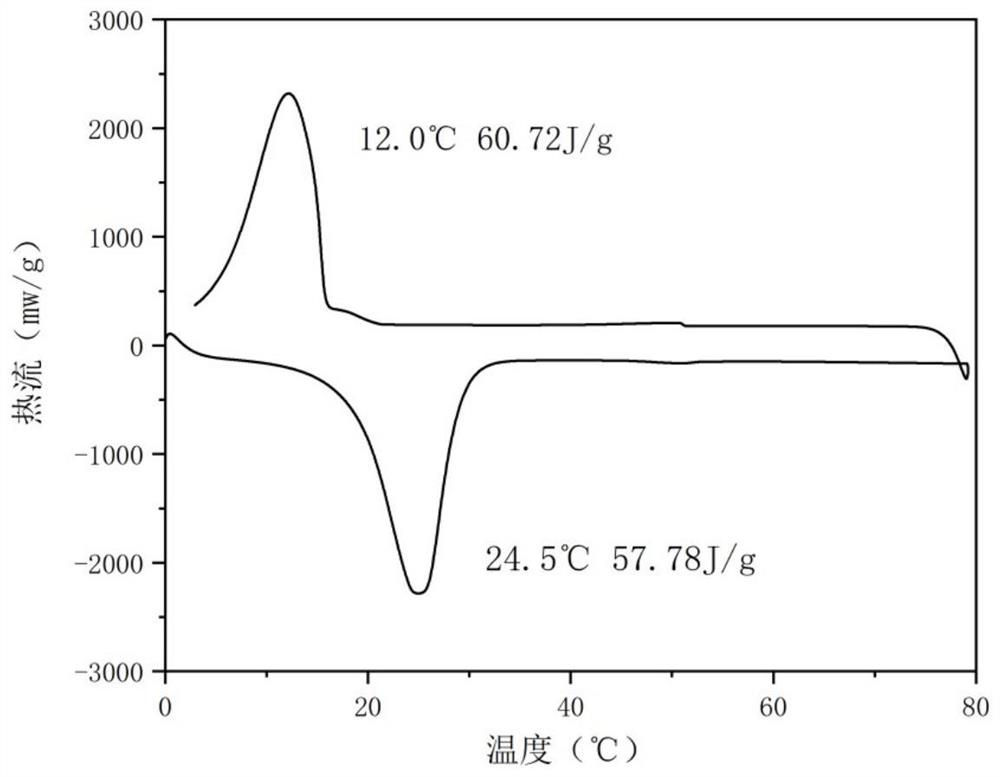

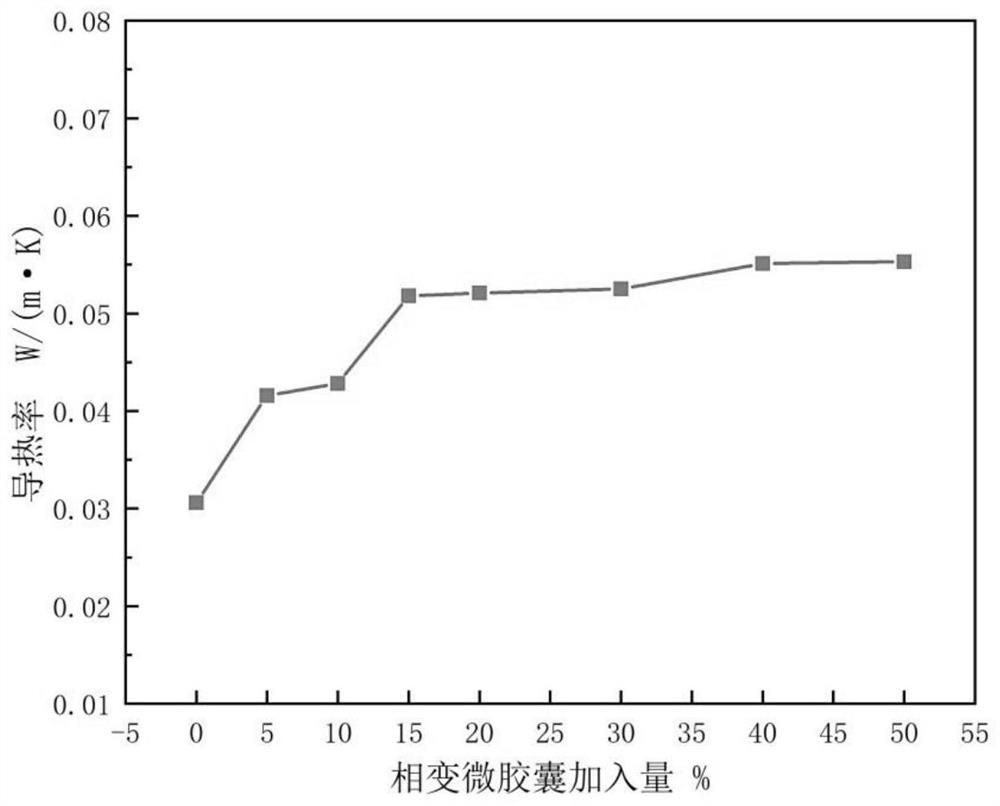

Phase-change composite aerogel and preparation method thereof

The invention provides a phase-change composite aerogel and a preparation method thereof. The preparation method comprises the steps of: mixing a silicon source 1 and a silicon source 2 and then dissolving the mixture in an aqueous solution of ethyl alcohol, performing mechanical stirring at room temperature till uniform mixing, then adding an acid catalyst into dispersion liquid, and adjusting the pH of the dispersion liquid to be 1-3, thus obtaining a silicon dioxide sol; adding a basic catalyst into the silicon dioxide sol prepared in the step 1, adjusting the pH value of the silicon dioxide sol to 7-10, adding phase-change microcapsules and fibers into the sol, performing mechanical stirring at room temperature until the materials are uniformly mixed, pouring the mixed sol into a mold,conducting standing to obtain wet gel, removing the wet gel from the mold, performing soaking in an anhydrous ethanol solution, performing aging for 10-40h, and finally conducting drying at 25-65DEGC for 20-30h to obtain the phase-change composite aerogel. The phase-change microcapsules are loaded in the silicon dioxide aerogel, and the nanofibers with good heat-conducting property are added toenhance the heat-conducting property of the aerogel skeleton, so that the phase-change microcapsules and the silicon dioxide aerogel are optimized.

Owner:TIANJIN CHENGJIAN UNIV

Colored glass and manufacturing method thereof

The invention relates to a manufacturing method of colored glass, in particular to a method for manufacturing the colored glass through silicon iron ash, and belongs to the field of inorganic materials. The colored glass is composed of, by weight, 118-280 parts of SiO2, 37-97 parts of Na2O, 19-51 parts of CaO, 20-50 parts of Al2O3 and 0.001-5 parts of coloring agents. The colored glass is manufactured with the silicon iron ash as the raw materials, the process is simple, cost is low, the colored glass is environmentally friendly, and continuous and industrial production is achieved easily. The colored glass obtained according to the method is rich in color.

Owner:PANZHIHUA UNIV

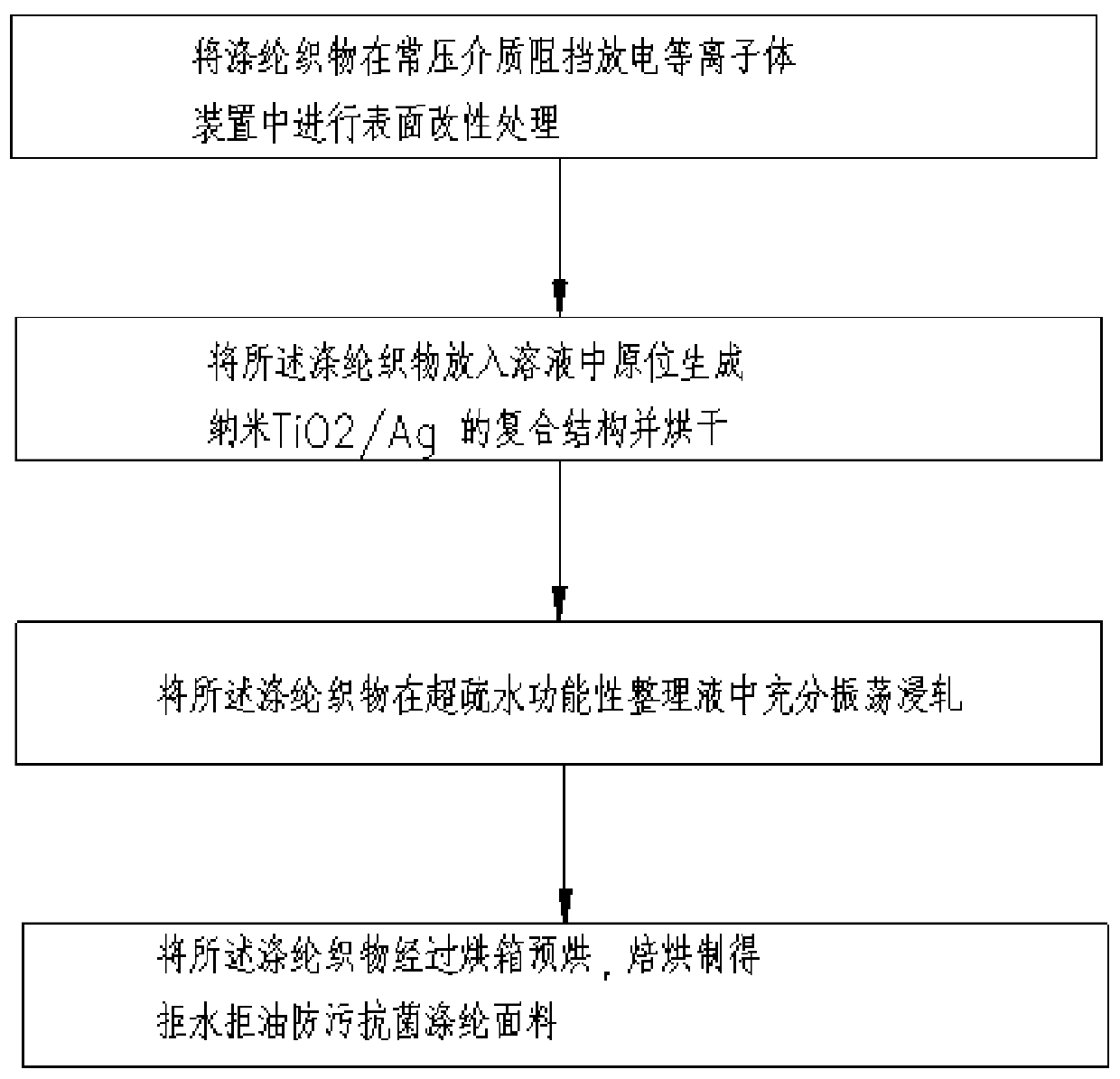

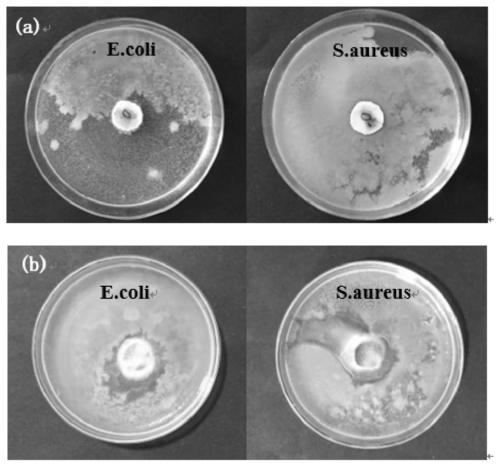

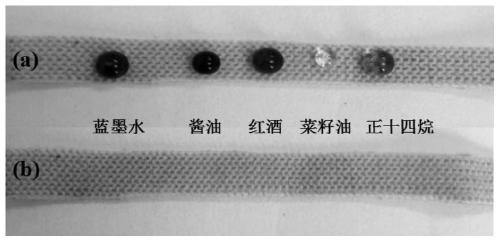

Preparation method of polyester fabric with water-and-oil repellent and anti-bacterial functions

InactiveCN111304904AStable superhydrophobic antibacterial propertiesGood stability against mechanical frictionPhysical treatmentBiochemical fibre treatmentPolyesterFiber

The invention discloses a preparation method of a polyester fabric with water-and-oil repellent and anti-bacterial functions. The method comprises the following steps of A, carrying out surface modification treatment on a polyester fabric in an atmospheric-pressure dielectric-barrier discharge plasma device; B, putting the polyester fabric into a solution for in-situ generation of a TiO2 / Ag nanocomposite structure and drying the TiO2 / Ag nanocomposite structure; C, fully oscillating and padding the polyester fabric in a super-hydrophobic functional finishing liquor; and D, pre-baking and bakingthe polyester fabric through an oven to prepare a water-and-oil repellent, anti-fouling and anti-bacterial polyester fabric. According to the method, an anti-bacterial function is combined with a water-and-oil repellent function, the TiO2-Ag nanocomposite structure is constructed in situ on the surface of a polyester fiber by adopting a sol-gel method, and atmospheric-pressure plasma treatment iscombined with fluoroalkyl silane treatment, so that the polyester fabric has stable super-hydrophobic anti-bacterial property, has good stability of mechanical friction resistance, is efficient, energy-saving and environment-friendly in an operation process, has less impact on other physical properties of the fabric and has good development space, and continuous industrial production is easy to achieve.

Owner:NANTONG UNIVERSITY

Method for extracting latex by extremely-strong electric field roller pole

The invention discloses a method for extracting latex by an extremely strong electric field roller pole. The method comprises the following steps: feeding the latex into an extremely strong electric field roller electrode electrogenerated extraction device from a latex inlet in one side; adjusting the direct-current voltage and the distance between the positive electrode roller and the negative electrode tank to form an extremely strong electric field, extracting latex through a plurality of positive and negative electrode cells to obtain clear liquid and rubber sheets, continuously introducing the rubber sheets condensed on the positive electrode roller into a cleaning device through a traction device for cleaning, drying the rubber sheets to constant weight through a drying device, and packaging the rubber sheets to obtain finished rubber. The method is simple in process, different from a traditional flocculation process and a uniform electric field extraction device, free of a flocculation process, environmentally friendly and capable of saving cost, rubber components obtained through flocculation are completely reserved, the performance of the rubber product is excellent, few process human influence factors exist, the product quality is stable, energy consumption is low, efficiency is high, and continuous industrial production is easy to achieve.

Owner:BEIJING UNIV OF CHEM TECH

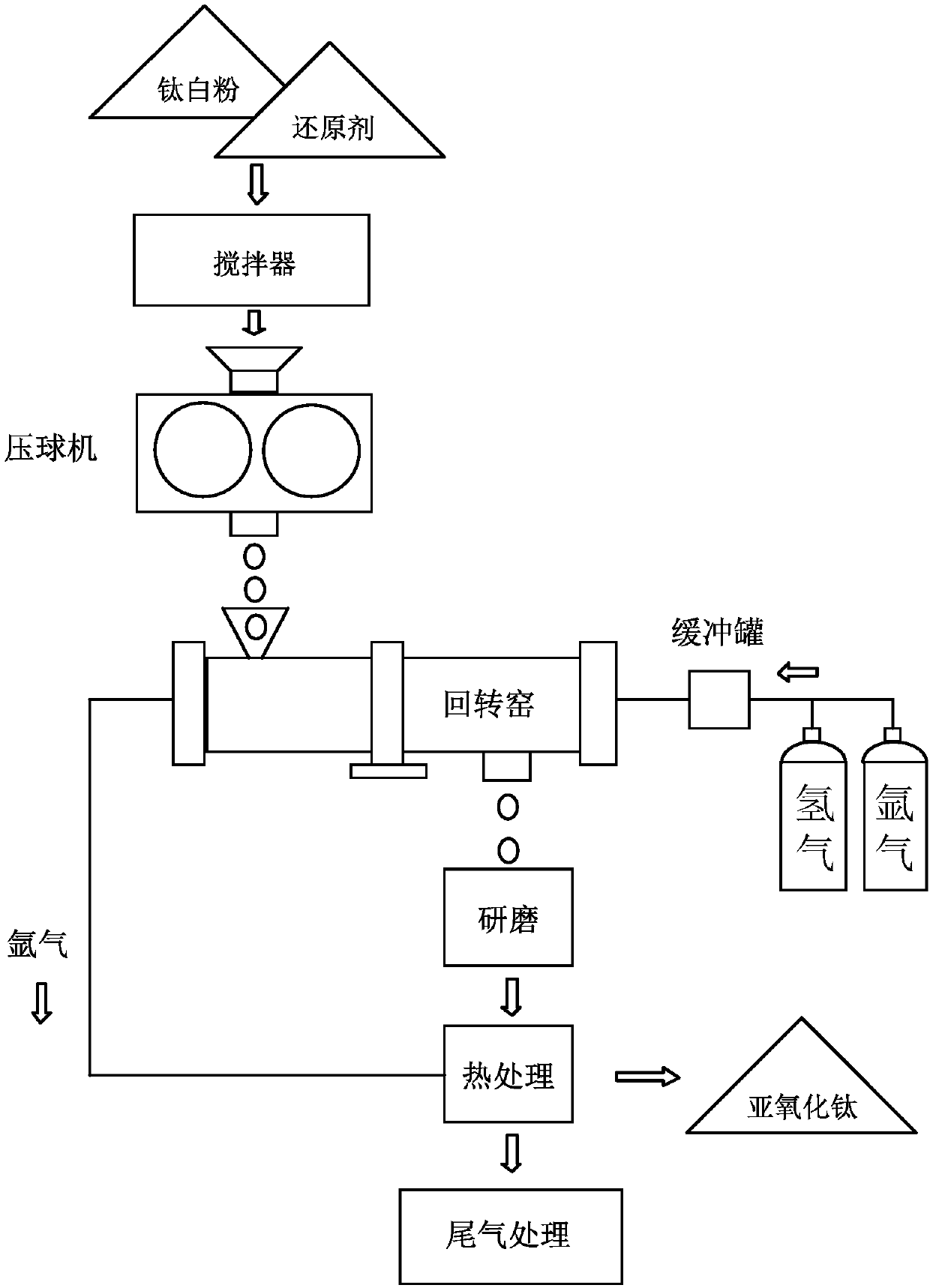

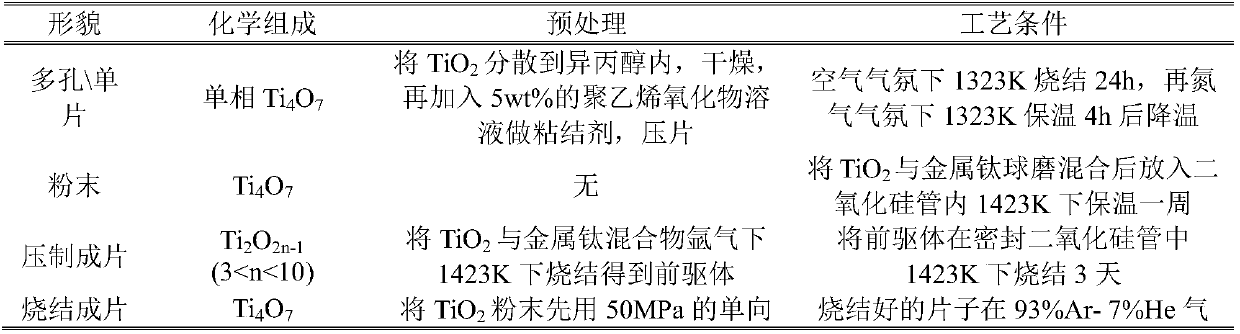

Method used for preparing high purity nanoscale titanium sub-oxides at low temperature

InactiveCN107720808AThe preparation process is shortIncrease productivityMaterial nanotechnologyTitanium suboxidesL&D processRotary kiln

The invention relates to a method used for preparing high purity nanoscale titanium sub-oxides at low temperature. The method comprises following steps: nanoscale rutile titanium dioxide, a reducing agent, and a wetting agent are subjected to uniform mixing and pelletizing so as to obtain pellets; the pellets are dried at 105 DEG C for 2 to 4h; the dried pellets are introduced into a microwave rotary kiln at a non-oxidizing atmosphere, are heated to 700 to 900 DEG C, the temperature is maintained for 20 to 60min, and cooling is carried out under the action of a reducing gas flow; after reduction, the pellets are smashed, and are introduced into a ball mill for 20 to 60min of grinding; after grinding, an obtained powder is subjected to 2 to 4h of heat treatment at 200 to 400 DEG C so as toobtain the high purity nanoscale titanium sub-oxides. According to the method, the high purity nanoscale titanium sub-oxides are prepared from rutile titanium dioxide at a relatively low temperature,the preparation process is short, the production efficiency is high, and the method is convenient for continuous industrialized production.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

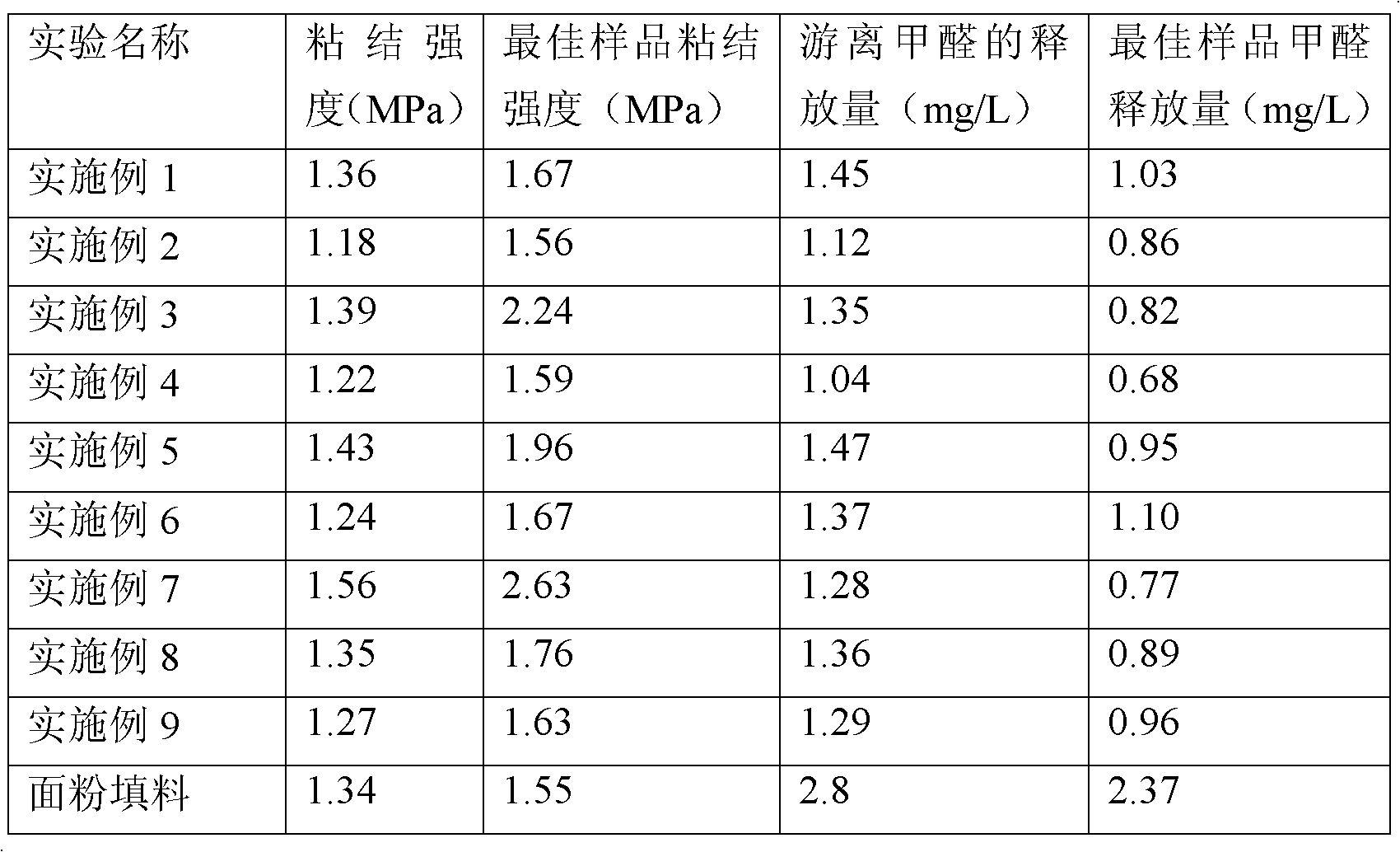

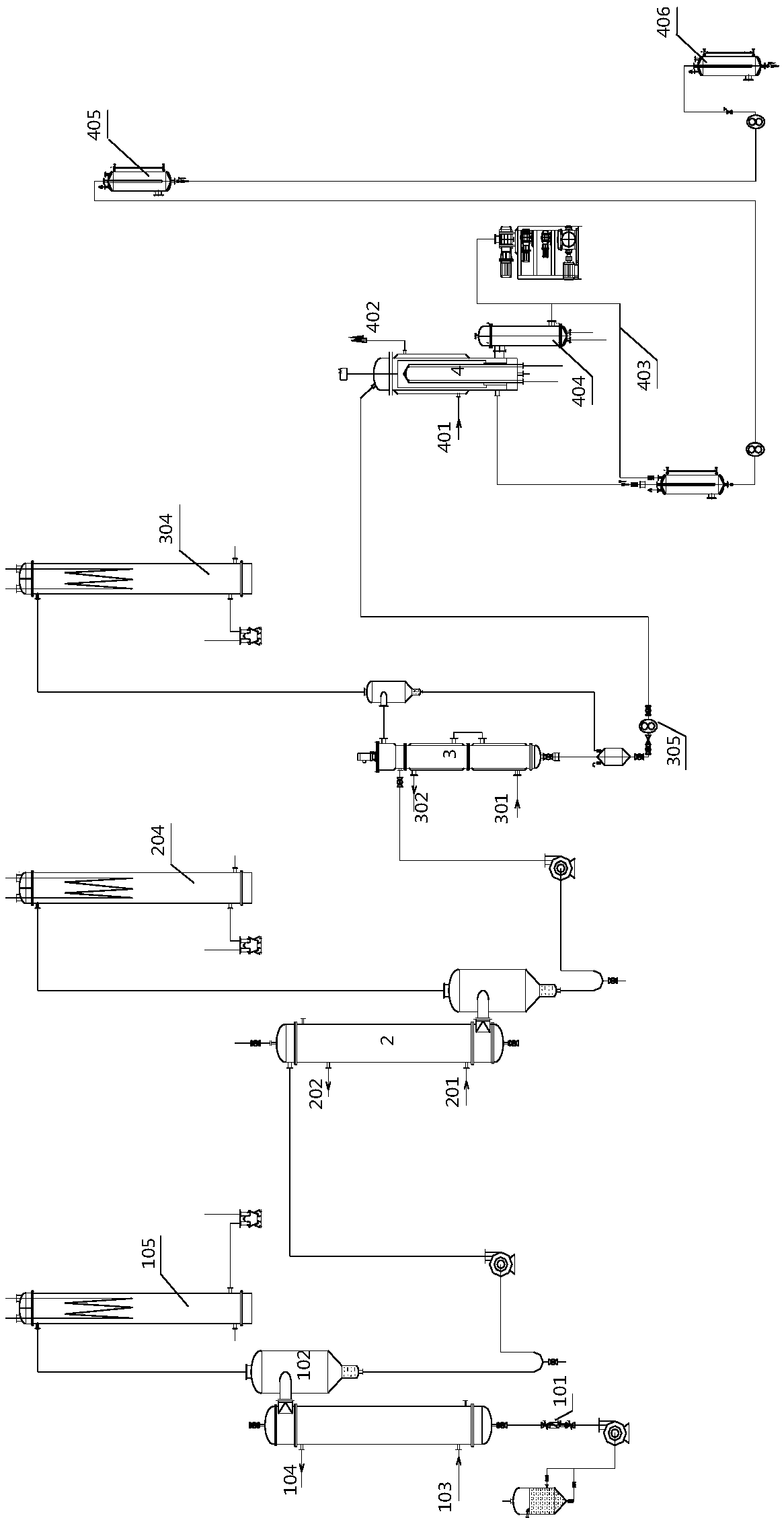

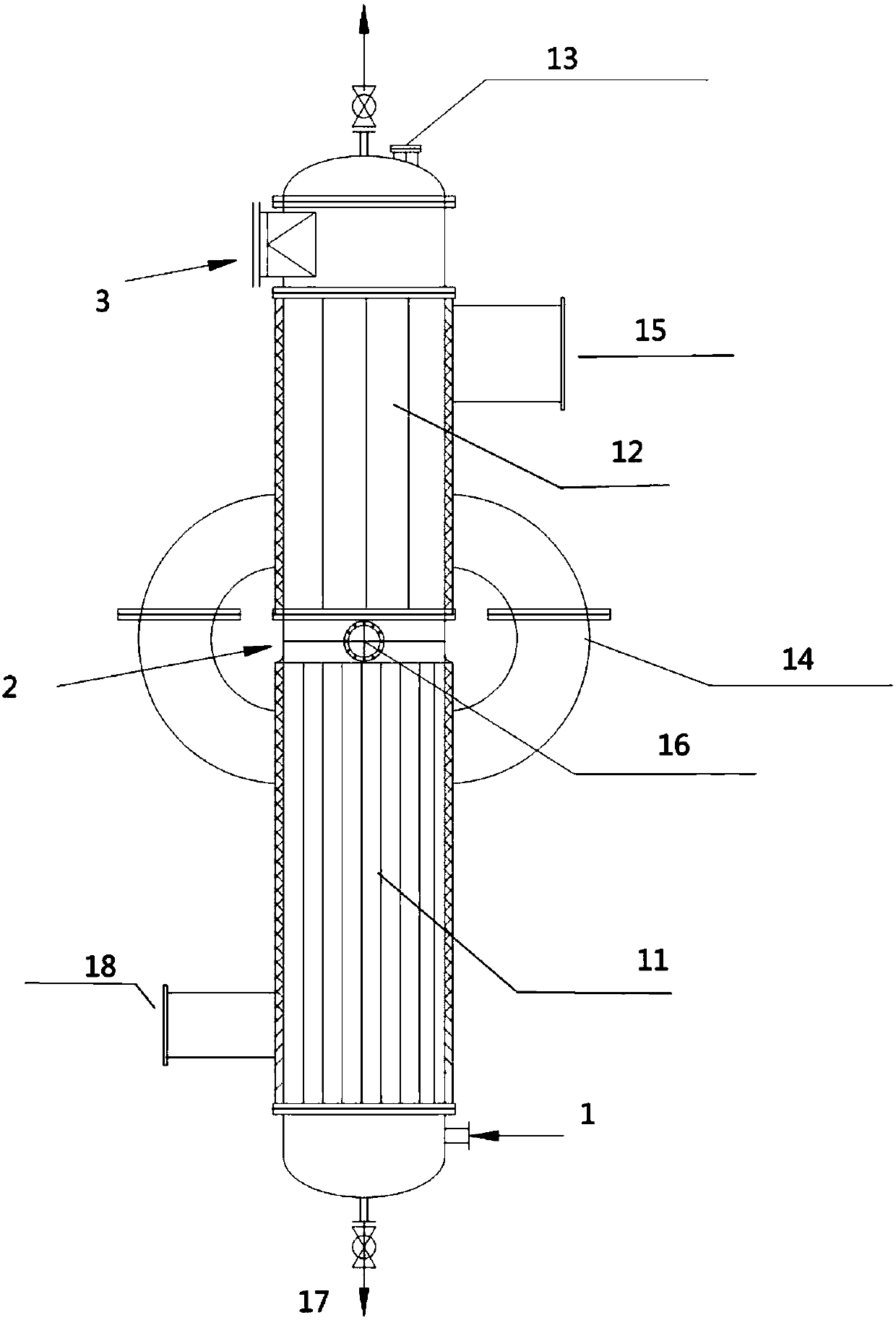

Capsanthin solvent extracting solution evaporation method and device

ActiveCN106634037ALess color lossReduce the temperatureChemical industryEvaporationDistillationSolvent

The invention provides a capsanthin solvent extracting solution evaporation method. The method comprises the following steps that 1, a capsanthin solvent extracting solution enters a climbing film evaporator at first, and vacuum evaporation is performed; 2, a liquid phase obtained after flashing is performed in the step 1 enters a falling film evaporator, flows from top to bottom in the tube pass of the falling film evaporator, and is subjected to heat exchange with hot water under the temperature of 70-80 DEG C inside the shell pass of the falling film evaporator; 3, the liquid phase drained by the falling film evaporator enters a rotary film evaporator, and vacuum evaporation is performed; 4, the liquid phase at the bottom of the rotary film evaporator enters a molecular distillation evaporator, and distillation is performed under the vacuum condition. According to the method, climbing film evaporation, falling film evaporation, rotary film evaporation and molecular distillation evaporation equipment and operation technological conditions are reasonably set, the evaporation temperature is low, energy consumption is lowered, the treatment efficiency is high, the solvent consumption is small, the cost is greatly lowered, and continuous industrial production is achieved easily.

Owner:CHENGUANG BIOTECH GRP CO LTD

Industrial method for producing tomato red by using tomato peel residues

ActiveCN102526334ASimple processShort processAntinoxious agentsImmunological disordersOrganic solventZoology

The invention discloses an industrial method for producing tomato red by using tomato peel residues. The method comprises the following process steps of: (1) performing hydrocyclone separation on the tomato peel residues containing tomato seeds to obtain tomato peel, wherein the seed content of dried tomato peel is below 0.3 percent by weight; (2) smashing the tomato peel, and adjusting into tomato peel paste with 50-55 percent by weight of water; (3) extracting the tomato peel paste with an organic solvent, and separating to obtain an extracting solution, wherein the organic solvent is n-hexane, No.6 light petrol and / or petroleum ether; and (4) concentrating and deodorizing the extracting solution to obtain tomato red. Due to the adoption of the method, high-quality natural tomato red can be obtained; and the method has the advantages of simple process, short flow, small loss, high yield, low comprehensive cost, good product quality and easiness for realizing continuous industrial production.

Owner:晨光生物科技集团焉耆有限公司

Preparation method of colored glass wall brick or glass tile

The invention relates to a preparation method of colored glass wall bricks or glass tiles, comprising the following steps: (1) preparing raw materials, wherein, the raw materials comprise 74-90 wt% of waste glass, 4-6 wt% of flousper powder, 4-15 wt% of feldspar powder, and 2-6 wt% of soda ash; (2) mixing the ingredients in the step (1), then adding a coloring agent in an amount of 0.1-0.4 wt% based on the total weight of the raw materials, and sintering the mixture into a glass liquid at a temperature of 1050-1100 DEG C; (3) putting the glass liquid obtained in the step (2) in a die for pressing into shape; and (4) annealing the pressed product at a temperature of 400-600 DEG C, and cooling. The preparation method has the advantages of simple process, low cost, and low energy consumption, and the prepared product has abundant color and wide application.

Owner:田长生

Formaldehyde-inhibiting composite clay adhesive filler

ActiveCN102344765BInhibitory releaseReduce releaseNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveVegetable Proteins

The invention discloses composite silica-magnesia clay urea-formaldehyde resin adhesive filler for inhibiting emission of free formaldehyde. The filler is prepared from 30-70 percent of modified attapulgite powder, 0-50 percent of modified sepiolite powder and 15-30 percent of vegetable protein powder, wherein the total percentage of the components is 100 percent. According to the composite silica-magnesia clay urea-formaldehyde resin adhesive filler disclosed by the invention, natural attapulgite and sepiolite mineral powder with abundant reservation, wide distribution range and low price are used as raw materials; urea with the characteristic of specifically absorbing the formaldehyde is infiltrated; the surface of the powder is modified by using a silane coupling agent with a function of improving the affinity of the filler and a urea-formaldehyde resin adhesive; and when the silane coupling agent is used for organic filler to fill the adhesive, the dispersability and the adhesiveness of the filler can be improved. The processing technique is easy to realize continuous industrial production and avoid three-waste discharge.

Owner:HEBEI UNIV OF TECH

Cottonseed protein production technology

The invention discloses a cottonseed protein production technology. The technology comprises the following steps: degreasing unexpanded cotton embryos through 6# solvent oil, carrying out low temperature drying, and processing the dried cotton embryos through a bulking machine to obtain expanded cotton embryos; and carrying out methanol solvent gossypol removal treatment on the expanded cotton embryos, centrifuging the phenol removed cotton embryos, and drying the centrifuged cotton embryos at a temperature of 150DEG C or less to obtain finished cottonseed proteins. The production technology has the advantages of simplicity, less loss, small energy consumption and low cost, obtaining of the high-quality cottonseed proteins with the free gossypol content being smaller than 400ppm and the protein solubility being greater than 55%, and easy realization of continuous industrial production.

Owner:新疆晨光生物科技股份有限公司 +1

A kind of capsanthin solvent extraction liquid evaporation method and evaporation equipment

ActiveCN106634037BLess color lossReduce the temperatureChemical industryEvaporationDistillationSolvent

The invention provides a capsanthin solvent extracting solution evaporation method. The method comprises the following steps that 1, a capsanthin solvent extracting solution enters a climbing film evaporator at first, and vacuum evaporation is performed; 2, a liquid phase obtained after flashing is performed in the step 1 enters a falling film evaporator, flows from top to bottom in the tube pass of the falling film evaporator, and is subjected to heat exchange with hot water under the temperature of 70-80 DEG C inside the shell pass of the falling film evaporator; 3, the liquid phase drained by the falling film evaporator enters a rotary film evaporator, and vacuum evaporation is performed; 4, the liquid phase at the bottom of the rotary film evaporator enters a molecular distillation evaporator, and distillation is performed under the vacuum condition. According to the method, climbing film evaporation, falling film evaporation, rotary film evaporation and molecular distillation evaporation equipment and operation technological conditions are reasonably set, the evaporation temperature is low, energy consumption is lowered, the treatment efficiency is high, the solvent consumption is small, the cost is greatly lowered, and continuous industrial production is achieved easily.

Owner:CHENGUANG BIOTECH GRP CO LTD

Stained glass and its preparation method

The invention relates to a manufacturing method of colored glass, in particular to a method for manufacturing the colored glass through silicon iron ash, and belongs to the field of inorganic materials. The colored glass is composed of, by weight, 118-280 parts of SiO2, 37-97 parts of Na2O, 19-51 parts of CaO, 20-50 parts of Al2O3 and 0.001-5 parts of coloring agents. The colored glass is manufactured with the silicon iron ash as the raw materials, the process is simple, cost is low, the colored glass is environmentally friendly, and continuous and industrial production is achieved easily. The colored glass obtained according to the method is rich in color.

Owner:PANZHIHUA UNIV

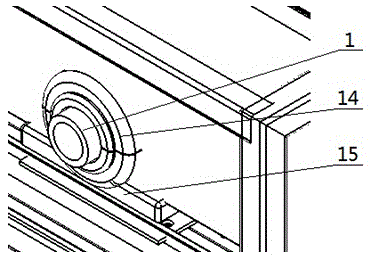

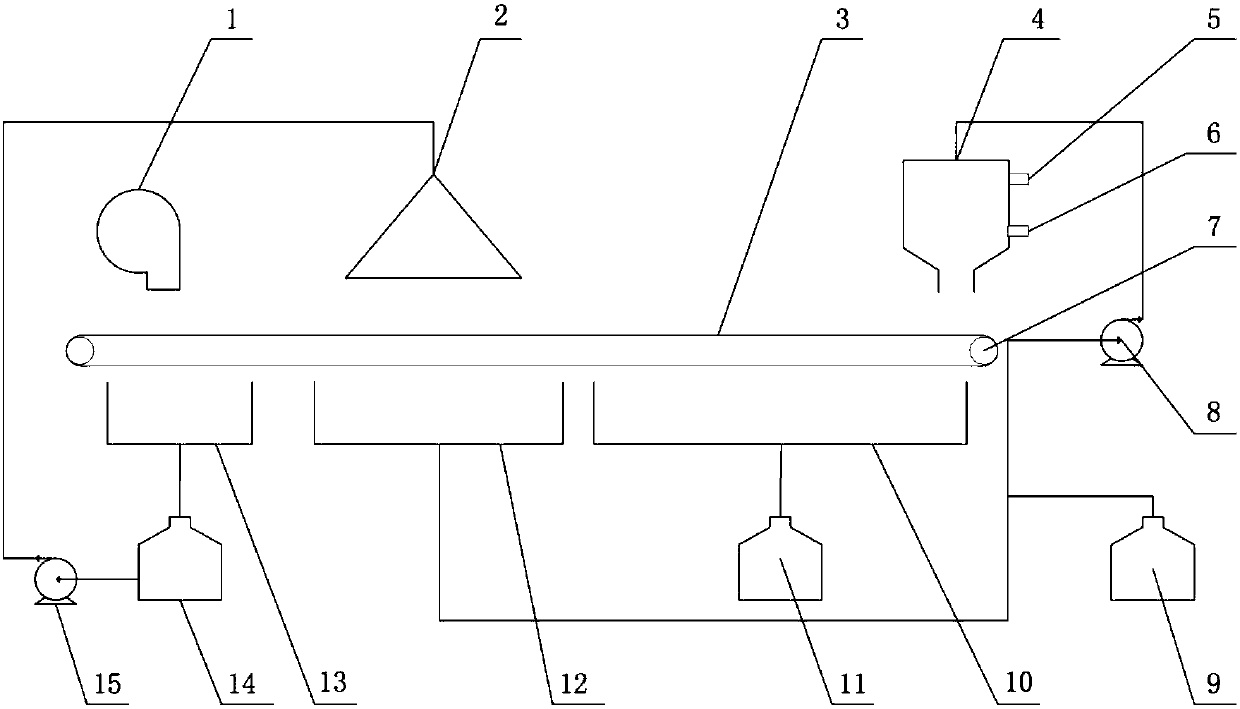

Continuous type seawater freezing-desalinization device

PendingCN107720866AHighly integratedMeet different fresh water volumesGeneral water supply conservationSeawater treatmentSprayerFresh water

The invention discloses a continuous type seawater freezing-desalinization device. The continuous type seawater freezing-desalinization device comprises a hot-air blower, a sprayer, a porous crawler,a seawater freezing crystallizer, a coolant outlet, a coolant inlet, a driving device, a seawater pump, a seawater tank, a concentrated seawater collecting tank, a concentrated seawater tank, a washing water collecting tank, a fresh water collecting tank, a fresh water tank and a fresh water pump. Seawater is crystallized by the seawater freezing crystallizer, then, ice crystals and concentrated seawater are separated by the porous crawler, the concentrated seawater enters the concentrated seawater tank through the concentrated seawater collecting tank, the ice crystals are washed through thesprayer, washing water and seawater in the seawater tank enter the seawater freezing crystallizer together through the seawater pump, and the washed ice crystals are melted into fresh water through hot air blown from the hot-air blower. The device is high in integration level, the requirements on different fresh water volumes and fresh water qualities can be met, and continuous industrial production is easy to achieve.

Owner:QINGDAO UNIV OF SCI & TECH

Industrial method for efficiently producing lycopene crystals

ActiveCN102126911BHigh purityNo emissionsCrystallisation purification/separationLycopeneParaffin oils

The invention relates to an industrial method for purifying natural extracts, in particular to an industrial method for efficiently producing lycopene crystals. The method comprises the following steps of: (1) mixing 6-15 percent of lycopene oleoresin with a diolefine solvent in the mass ratio of 1:(3-7) and stirring the mixture to dissolve the mixture into mixed liquor; (2) standing the mixed liquor at the temperature of between 10 DEG C below zero and 20 DEG C and centrifuging the mixed liquor to obtain viscous paste; (3) mixing the viscous paste with the paraffin solvent, standing and centrifuging to obtain paste; (4) performing vacuum drying on the paste and removing solvent residues to obtain the lycopene crystals; and (5) and performing vacuum low-temperature concentration on filtrate obtained by centrifuging in the step (2) and the step (3) to obtain low-content lycopene oleoresin. The method has low environmental requirements, and an enriched high-content lycopene oleoresin component can be efficiently and continuously separated.

Owner:CHENGUANG BIOTECH GRP CO LTD

A kind of preparation method of plasma-assisted superhydrophobic polyester fabric

ActiveCN108978173BStable super hydrophobic performanceGood stability against mechanical frictionUltrasonic/sonic fibre treatmentLiquid repellent fibresPolyesterPolymer science

Owner:旷达纤维科技有限公司 +1

Material for selectively adsorbing platinum and preparation method and application thereof

ActiveCN112206749AEasy to prepareLow costOther chemical processesProcess efficiency improvementSelective adsorptionPolyvinyl alcohol

The invention relates to a material for selectively adsorbing platinum and a preparation method and application of the material, and the material for selectively adsorbing platinum is prepared by thefollowing method: taking macroporous silicon dioxide spherical particles as a matrix, filling a platinum extracting agent into pores of the matrix in an ultrasonic impregnation manner, and then coating a layer of polyvinyl alcohol film, the soaking the coated impregnated silicon dioxide in a crosslinking agent solution to crosslink polyvinyl alcohol, carrying out solid-liquid separation, and repeatedly heating and cooling the coated impregnated silicon dioxide to vitrify the coating film, thereby obtaining the material capable of selectively adsorbing platinum. The material for selectively adsorbing platinum is low in preparation cost, is used for efficiently and selectively enriching platinum in a high-acidity and low-concentration platinum-containing solution, is short in process flow and high in recovery rate, and does not have the problems of loss of an extracting agent and the like.

Owner:CENT SOUTH UNIV

A kind of preparation method of high-purity capsaicin

ActiveCN104529806BHigh purityNo loss of spicinessCarboxylic acid amide separation/purificationBulk chemical productionNatural productMedicinal chemistry

The invention relates to a method for preparing high-purity capsaicin and belongs to the field of refining of natural products. According to the method, a low-pungency degree capsicum oleoresin is taken as a raw material, and the high-purity natural capsaicin is prepared by combining supercritical CO2 extraction and a crystallization technology. The purity of the obtained capsaicin crystal is more than 98 percent, and the pungency degree yield of the product is more than 70 percent. The supercritical secondary extraction isolate can be directly used as decolorized oleoresin capsicum, and the pungency degree loss is basically avoided. The method is easy to operate, and the continuous industrial production is easily realized.

Owner:CHENGUANG BIOTECH GRP HANDAN CO LTD

A microwave double-helix tube furnace and a method for combining the microwave double-helix tube furnace and the submerged arc furnace to prepare ferromanganese alloy

ActiveCN104567370BReasonable layoutImprove energy utilizationCharge manipulationIncreasing energy efficiencyMicrowave cavityTube furnace

The invention relates to a microwave double-screw tube furnace and a method for preparing ferromanganese alloy by using the microwave double-screw tube furnace and a submerged arc furnace in a combined manner and belongs to the technical fields of microwave equipment and manganese metallurgy. The microwave double-screw tube furnace comprises three parts, namely a rack, a microwave cavity and a double-screw stirring device. The microwave double-screw tube furnace is adopted to pre-roast manganese ore so as to obtain a hot-state material, and then, the hot-state material is placed in the submerged arc furnace for smelting, so as to obtain the ferromanganese alloy. According to the tube furnace, microwave heating is adopted, so that the non-contact direct rapid heating of the material can be realized; due to the arrangement of reactor magnetrons, the efficiency of converting microwave energy into heat energy can be greatly increased; due to the combination and matching of a large number of low-power magnetrons, the successful research and development of a high-power microwave reactor for industrial production are realized; the method is short in production cycle and low in energy consumption, and various harmful phenomena caused due to the fact that cold materials enter the furnace can be properly overcome.

Owner:KUNMING UNIV OF SCI & TECH

A kind of material that selectively adsorbs platinum and its preparation method and application

ActiveCN112206749BEasy to prepareHighly selective adsorptionOther chemical processesProcess efficiency improvementPlatinumPolyvinyl alcohol

A material for selectively adsorbing platinum and its preparation method and application. The material for selectively adsorbing platinum is made by the following method: using macroporous silica spherical particles as a matrix, and filling the matrix with a platinum extractant by ultrasonic impregnation In the hole, and then coated with a layer of polyvinyl alcohol film, and then soak the coated impregnated silica in the cross-linking agent solution to cross-link the polyvinyl alcohol, after solid-liquid separation, the coated impregnated silica Silicon oxide is repeatedly heated and cooled to vitrify the coating film, and a material that selectively adsorbs platinum is obtained. The preparation cost of the material for selectively adsorbing platinum is low, and it is used for efficient and selective enrichment of platinum in a solution containing high acidity and low concentration of platinum.

Owner:CENT SOUTH UNIV

Method for extracting latex from pole-strength electric field

The invention discloses a method for extracting latex from a pole-strength electric field. Latex is introduced into a pole-strength electric field extracting device from a latex inlet in one side, thedistance and current between two poles is regulated to form the pole-strength electric field, the latex is extracted from the pole-strength electric field to obtain a clear liquor and a rubber sheet,a film condensed on a positive pole roller continues to be introduced into a clean device through a traction device to be cleaned, dried in a drying device to obtain constant weight, and packaged into finished rubber. The technology for extracting latex from the pole-strength electric field is simpler, the extraction efficiency is higher, the cost is lower, different from the traditional flocculation technology, no flocculation process is needed, the technology is environmentally friendly, the cost is saved, the rubber ingredient obtained after flocculation is completely reserved, the rubberproduct is excellent in performance, few artificial affect factors of the technology are caused, the product quality is stable, and continuous industrial production is easy to obtain.

Owner:BEIJING UNIV OF CHEM TECH

A kind of industrialized production method of lycopene oleoresin

ActiveCN105694527BReduce oxidation rateLess color lossNatural dyesHydrocarbonsWater bathsFluidized bed drying

The invention relates to an industrial producing method of lycopene oil resin. The method includes the following steps of firstly, preprocessing raw materials, wherein tomato peel dregs are dried by a hot air drier, tomato seeds and peels are separated, and tomato peels are dried and ground by a fluidized bed to obtain tomato powder; secondly, conducting extracting, wherein tomato powder is added to alkane and low-molecular ketone mixed solvent to be stirred and extracted under the water bath condition; thirdly, conducting concentrating, wherein an extraction solution is subjected to decompressed evaporation and concentration under the vacuum conditions, solvent is recovered, and then lycopene oil resin is obtained. Tomato peel dregs serve as the raw material, tomato powder is prepared through the high-temperature rapid drying method, and color value loss is little. Extraction of mixed solvent can adapt to the material with high water content, and the method is high in extraction yield, low in cost, more suitable for continuous mass production and remarkable in economic benefit.

Owner:CHENGUANG BIOTECH GRP CO LTD

Silicon-magnesium composite clay adhesive filling material and application thereof

ActiveCN102344764BWide variety of sourcesLow priceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSilicate mineralsResin adhesive

The invention discloses a silicon-magnesium composite clay adhesive filling material and an application thereof. The filling material comprises components of, by mass: 5% to 35% of silicate mineral, 35% to 50% of magnesium silicate mineral, 2% to 25% of wood chip powder, and 15 to 40% of vegetable protein powder. The total amount of the components takes 100% by mass. According to the invention, natural mineral powders with abundant reserves, wide sources, and cheap prices are adopted as raw materials; wastes such as serrago produced during a wood processing process are comprehensively utilized, and a small amount of vegetable protein powder is also adopted as an auxiliary material. With simple grinding and cladding, the materials can be prepared into a mineral composite filling material used for substantially improving the initial viscosity of an urea formaldehyde resin adhesive, improving cold compression intensity and cementation intensity of a plywood, and reducing mineral composite filling materials used during a cold compression period. Therefore, the filling material can be used for substituting flour, such that foodstuff is saved, and production cost is reduced. With the processing technology, continuous industrial production can be easily realized, and three-wastes are not discharged.

Owner:HEBEI UNIV OF TECH

Concentration desolvation method and apparatus of lycopene extraction mixed oil

InactiveCN107583302AIncrease flow rateContinuous productionSolution crystallizationLycopeneEvaporation

The invention discloses a concentration desolvation method and apparatus of lycopene extraction mixed oil. The method comprises performing evaporation with a tube evaporator and performing secondary evaporation crystallization with a flashing case. The method is characterized in that in the tube evaporator, a first group of tubes are used for evaporation, uniform mixing is carried out, and a second group of tubes are used for evaporation, wherein the flow rate of mixed oil in the second group of tubes is larger than that in first group of tubes, and the tube evaporator allows the solvent content to be reduced from 90-99% to 70-72%, and finally a flashing case is used for secondary evaporation crystallization. The method and apparatus allow a solvent in lycopene extraction mixed oil to be efficiently continuously evaporated.

Owner:新疆晨曦椒业有限公司

A kind of cottonseed protein production process

Owner:新疆晨光生物科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com