Concentration desolvation method and apparatus of lycopene extraction mixed oil

A technology of lycopene and mixed oil, applied in the direction of solution crystallization, etc., can solve the problems of uncontinuous evaporation, different solvent content, uneven heating, etc., and achieve the effects of reduced heating time, low cost and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

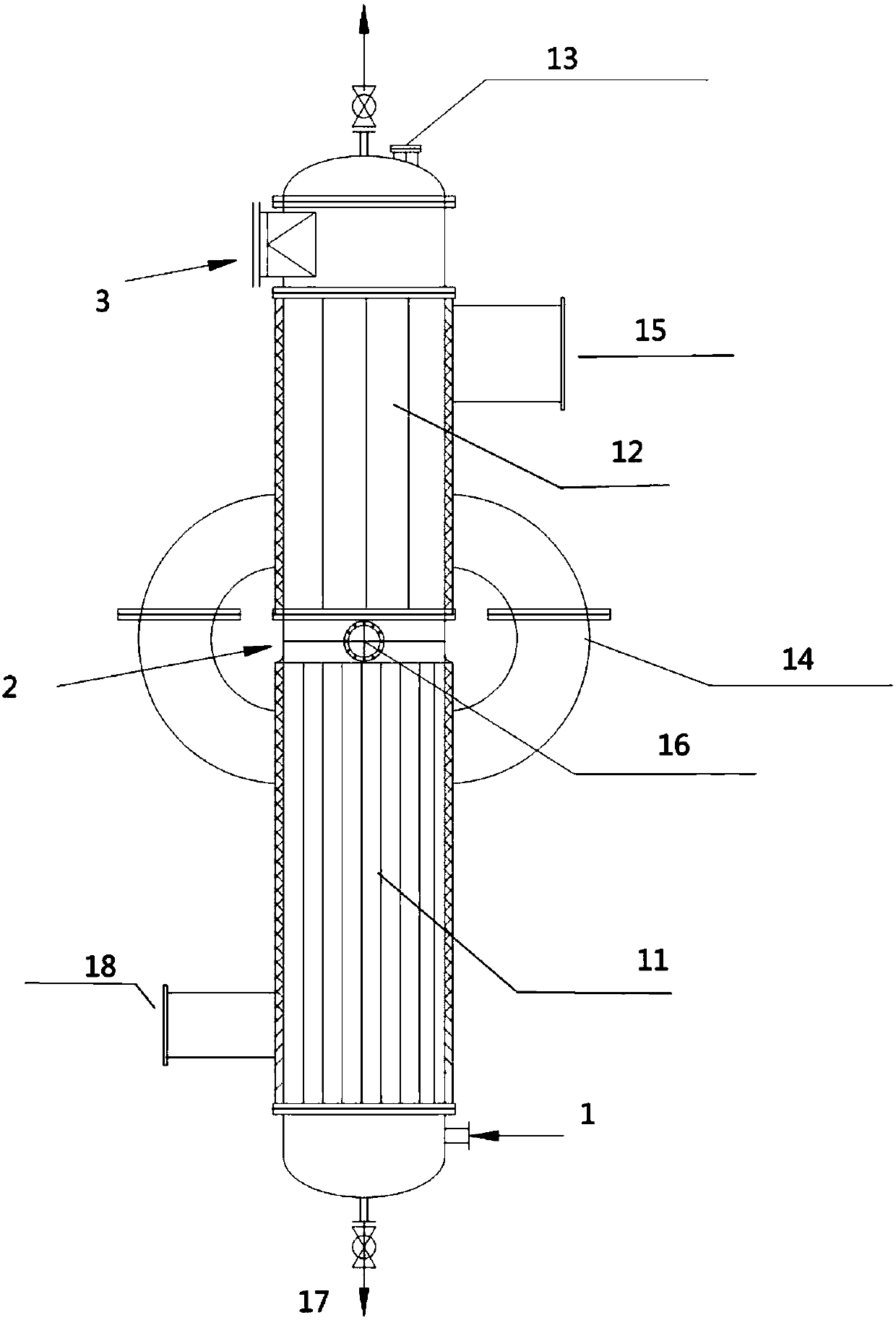

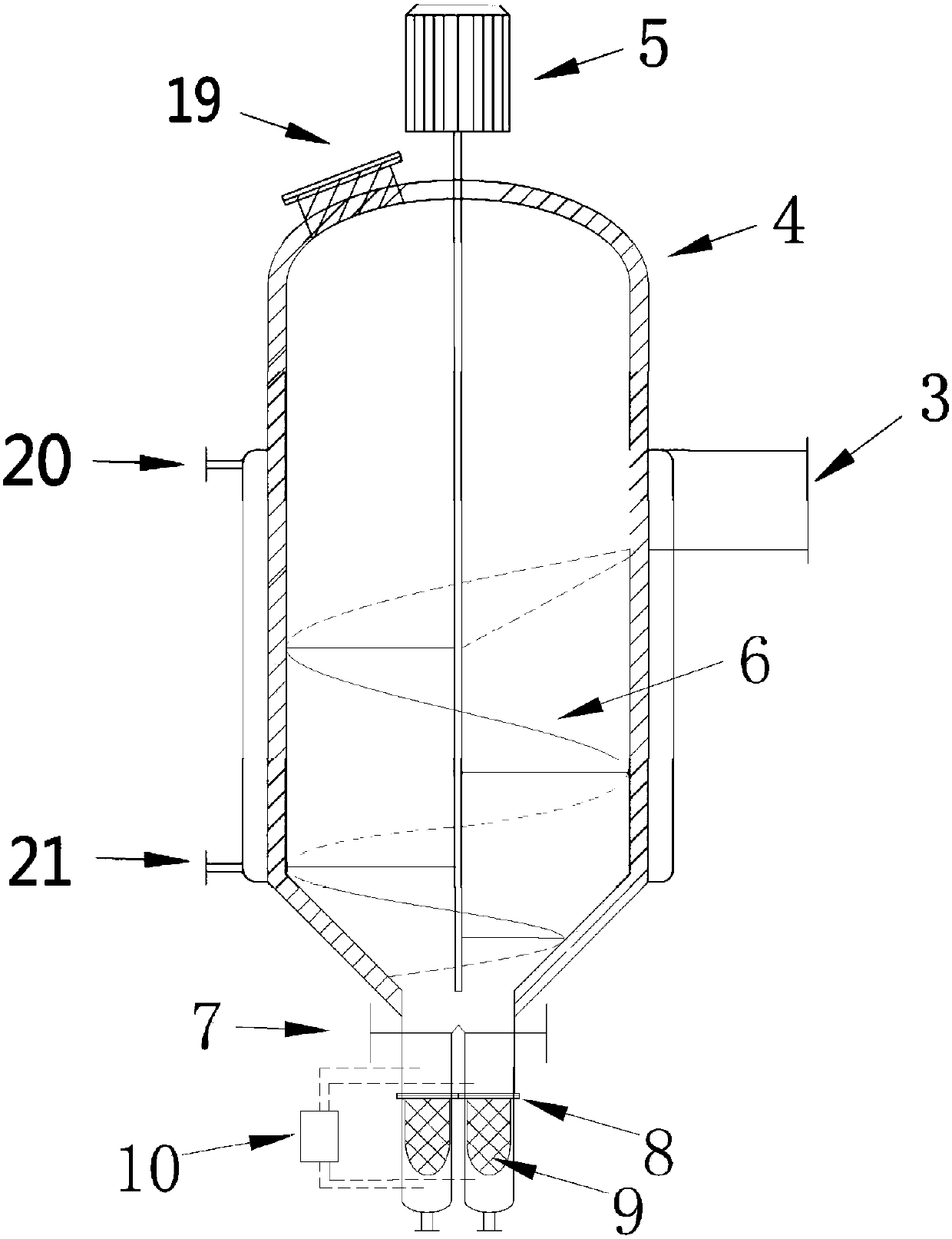

[0024] The lycopene mixed oil containing solvent (n-hexane:acetone volume ratio is 2:1) with a content of 95% is pumped into the inlet of the special evaporator by a liquid injection pump. -70°C hot water, pump a vacuum of -0.06 to -0.07MPA above the tubes, take a sample of the mixed oil from the evaporator into the flash box and test that the solvent content is 71.3%, pass 50-70°C hot water through the jacket of the flash box, and pump - 0.06 to -0.07MPA vacuum, use the outlet on the right side of the bottom of the flash box, take the mixed oil from the bottom of the filter bag to detect that the solvent content is 63.6%, after 42 hours of continuous evaporation, the PLC detects that the pressure difference between the upper and lower filter bags reaches the critical value, and automatically shuts down Electric butterfly valve on the right, open the butterfly valve on the left and send out an alarm message, manually replace the filter bag on the right and collect 15.6kg of lyc...

Embodiment 2

[0026] The lycopene mixed oil containing solvent (the volume ratio of n-hexane and acetone is 2:1) with a content of 98% is pumped in from the inlet of the special evaporator by a liquid injection pump. -70°C hot water, pump a vacuum of -0.06 to -0.07MPA above the tubes, the evaporator enters the flash box mixed oil sampling test solvent ratio is 71.8%, the flash box jacket is filled with 50-70°C hot water, and the top pumps - 0.06 to -0.07MPA vacuum, use the left outlet at the bottom of the flash box, take the mixed oil from the bottom of the filter bag to detect that the solvent ratio is 63.9%, after 72 hours of continuous evaporation, the PLC detects that the pressure difference between the upper and lower filter bags reaches a critical value, and it will automatically shut down The left electric butterfly valve opens the right butterfly valve and sends out an alarm message, manually replaces the left filter bag and collects 15.7kg of lycopene crystals from the left filter b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com