Formaldehyde-inhibiting composite clay adhesive filler

A technology of clay and adhesive, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc., to achieve the effects of no three wastes discharge, abundant reserves, and inhibited formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

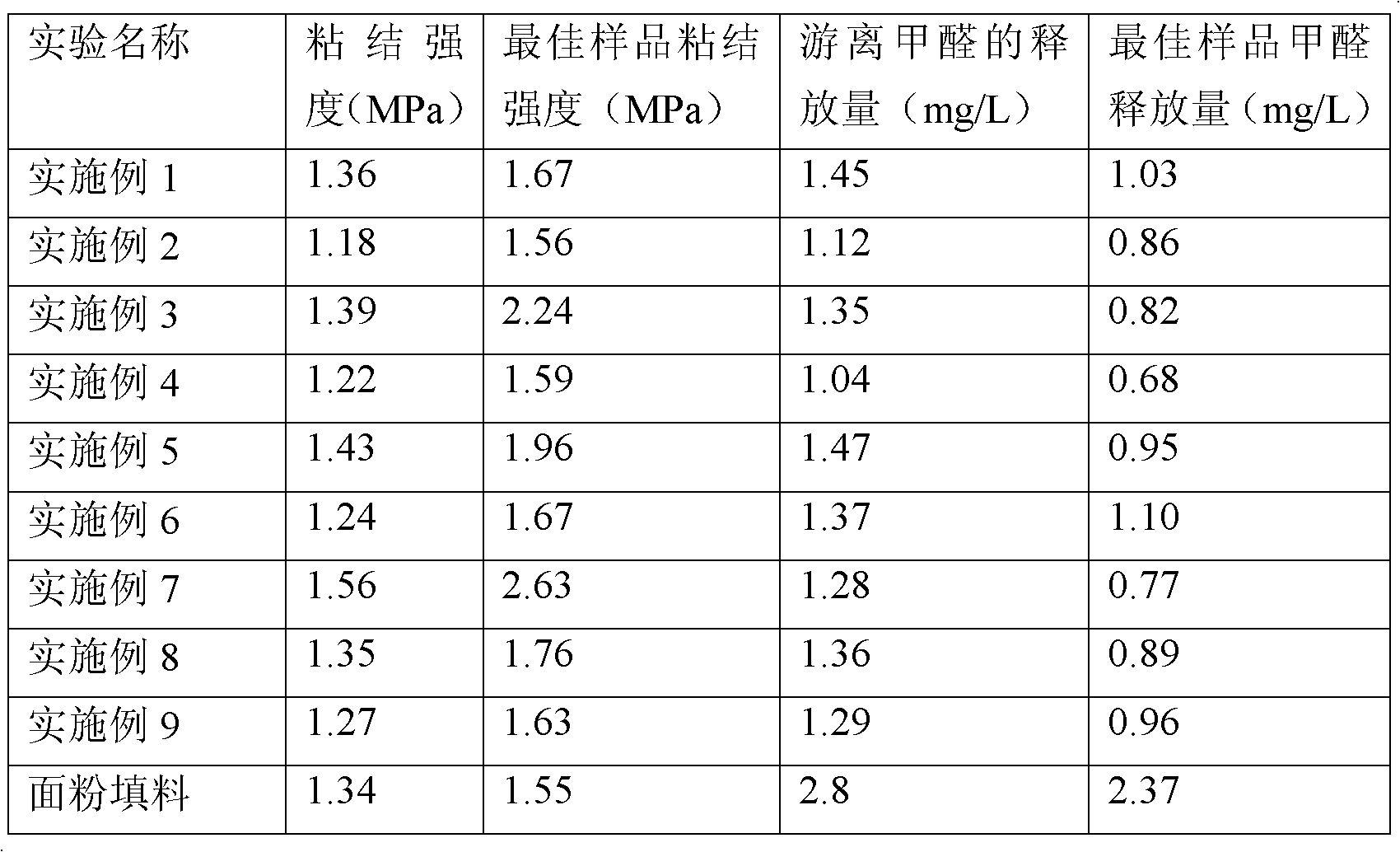

Examples

Embodiment 1

[0032] The first step is the preparation of mineral powder

[0033] The dry attapulgite and sepiolite mineral particles are respectively crushed with a jaw crusher, and squeezed into a powder with a particle size of less than 2mm by pair of rollers. The attapulgite mineral involved in the present invention is attapulgite produced in Linze, Gansu, and the sepiolite mineral fiber is sepiolite produced in Xishan, Henan, and the like.

[0034] The second step of clay mineral removal

[0035]Add 100L of aqueous solution containing 2% hydrochloric acid to the two mixing tanks, start the mixer, and add 15kg of attapulgite powder and 15kg of sepiolite powder obtained in the previous step respectively at a stirring speed of about 50rpm, and then adjust Rotate at 1250 rpm, stir for 30 minutes, and let stand for 4 hours. The upper layer of pulp is separated by siphon method, and the solid sediment in the lower layer is discarded. After the pulp is dehydrated by a centrifuge with a rot...

Embodiment 2

[0057] The first step to the third step are completely with embodiment 1. the fourth step

[0058] The fourth step is the surface modification of mineral powder silane coupling agent

[0059] In the 1.0kg urea soaked attapulgite powder and / or sepiolite ore powder prepared in the third step, add an acetone solution (diphenyldimethoxysilane) containing 40g diphenyldimethoxysilane (ZH-1106) The mass percentage of methoxysilane is 5% to 10%), adjust the mixer speed to 1250rpm, disperse for 30 minutes, let stand for more than 4h, dry at 105°C, and ball mill to obtain attapulgite powder modified by silane coupling agent 1.04kg or 1.04kg of sepiolite powder modified by silane coupling agent.

[0060] The fifth step is the preparation of composite modified powder filler

[0061] Add 700g of attapulgite powder modified by silane coupling agent into the ball mill jar, put 150g of sepiolite powder modified by silane coupling agent into the ball mill, add 2400g of ceramic balls, keep t...

Embodiment 3

[0064] The first step to the third step are completely with embodiment 1.

[0065] The fourth step is the surface modification of mineral powder silane coupling agent

[0066] In the 1.0kg urea soaked attapulgite powder and / or sepiolite ore powder prepared in the third step, add an acetone solution (diphenyl dimethoxysilane) containing 30g diphenyl dimethoxysilane (ZH-1106) The mass percentage of methoxysilane is 5% to 10%), adjust the mixer speed to 1250rpm, disperse for 30 minutes, let stand for more than 4h, dry at 105°C, and ball mill to obtain attapulgite powder modified by silane coupling agent 1.03kg or 1.03kg of sepiolite powder modified by silane coupling agent.

[0067] The fifth step is the preparation of composite modified powder filler

[0068] Add 500g of attapulgite powder modified by silane coupling agent into the ball mill jar, put 200g of sepiolite powder modified by silane coupling agent into the ball mill, add 2400g of ceramic balls, keep the speed at 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com