A kind of industrialized production method of lycopene oleoresin

A technology of lycopene oil and production method, which is applied in the field of industrialized production of lycopene oleoresin, can solve the problems of low extraction rate of weak polar solvent, low total recovery rate, loss of color value, etc., and achieve significant economic benefits and low cost , The effect of less loss of color value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 50kg of tomato pomace, the color value is 0.56. After drying with a hot air dryer, the inlet air temperature is 200°C, the outlet air temperature is 60°C, the time is 10s, and the moisture content of the material is 45%. The seeds and skins are separated, and the tomato skins are dried in a fluidized bed at a temperature of 50°C for 100 seconds. They are milled and blown with cold wind to obtain tomato powder. The moisture content is 28%. The tomato powder is 9.5kg with a color value of 2.9 and a color value of 9.5 kg. The rate is 98.4%.

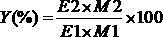

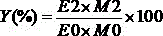

[0029] The obtained tomato powder was added to a 7-fold mixed solvent (butanone:n-hexane=24:76), and stirred and extracted 4 times in a water bath at 50°C, each time for 2 hours. Combine each extract, evaporate and concentrate under reduced pressure at a vacuum of -0.09MPa and a temperature of 45°C, and recover the solvent to obtain 329g of lycopene oleoresin with a color value of 83.2. The extraction yield of color value was 9...

Embodiment 2

[0031] Take tomato pomace 100kg, the color value is 0.63. After drying with a hot air dryer, the inlet air temperature is 400°C, the outlet air temperature is 90°C, the time is 20s, and the moisture content of the material is 35%. The seeds and skins were separated, and the tomato skins were dried in a fluidized bed at a temperature of 50°C for 40 seconds, then pulverized and blown with cold wind to obtain tomato powder with a moisture content of 15.0%. Obtain 14.7kg of tomato skin powder, the color value is 4.1, and the color value yield is 95.7%.

[0032] The obtained tomato powder was added to a 3-fold mixed solvent (acetone:n-hexane=15:85), and stirred and extracted 4 times in a water bath at 40°C, each time for 3 hours. Combine each extract, evaporate and concentrate under reduced pressure at a vacuum of -0.09MPa and a temperature of 45°C, and recover the solvent to obtain 700g of lycopene oleoresin with a color value of 85.7. The extraction yield of color value was 99....

Embodiment 3

[0034] Take 50kg of tomato pomace, the color value is 0.50. After drying with a hot air dryer, the inlet air temperature is 300°C, the outlet air temperature is 75°C, the time is 30s, and the moisture content of the material is 40%. The seeds and skins are separated, and the tomato skins are dried in a fluidized bed at a temperature of 45°C for 70 seconds. They are milled and blown with cold wind to obtain tomato powder. The moisture content is 21.4%, and 8.5 kg of tomato powder is obtained, with a color value of 2.9 and a color value of The rate is 98.6%.

[0035] The obtained tomato powder was added to a 5-fold mixed solvent (butanone:n-hexane=19:81), and stirred and extracted twice in a water bath at 45°C, each time for 2.5 hours. Combine each extract, evaporate and concentrate under reduced pressure at a vacuum of -0.09MPa and a temperature of 45°C, and recover the solvent to obtain 294g of lycopene oleoresin with a color value of 83.2. The extraction yield of color valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com