Microwave double-screw tube furnace and method for preparing ferromanganese alloy by using microwave double-screw tube furnace and submerged arc furnace in combined manner

A double-screw and tube furnace technology, which is applied in the field of microwave equipment and manganese metallurgy, can solve the problems of long production cycle, heavy furnace load, and low productivity, and achieves reduced deadweight loss, high energy utilization rate, and fast heating rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

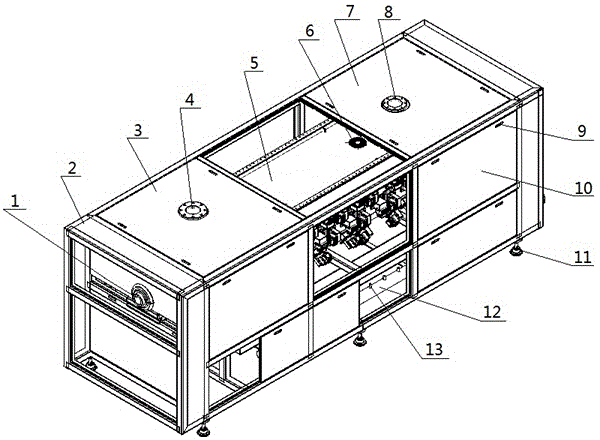

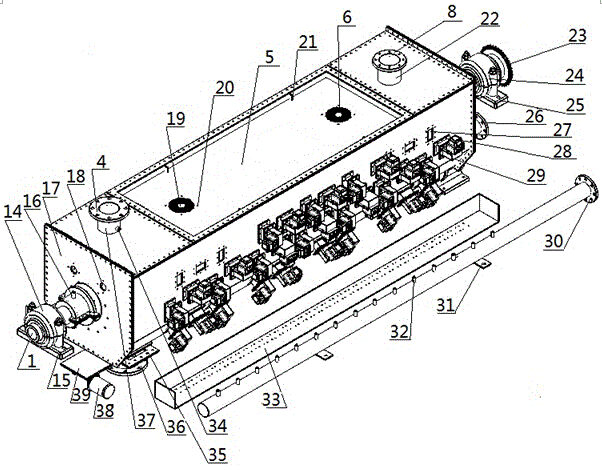

[0043] Such as Figures 1 to 8 As shown, the microwave double-helix tube furnace includes three parts: a frame 2, a microwave cavity and a double-helix stirring device;

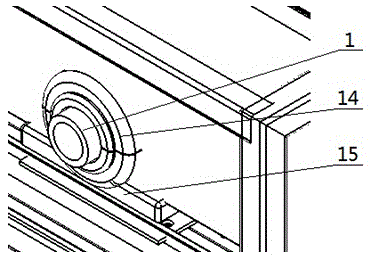

[0044] Described frame 2 is made up of the frame encapsulation top plate A3 of upper end surface and frame encapsulation top plate B7, the frame encapsulation side plate A10 of front and rear left and right sides, the frame encapsulation bottom plate of lower bottom surface, and the surface of rack encapsulation side plate A10 is provided with Pull button 9, frame support feet 11 are provided on the bottom plate of the frame package;

[0045] The microwave cavity is located on the upper side inside the frame 2, and the microwave cavity includes microwave cavity side plates A56 and microwave cavity side plates B58 on the front and rear sides, microwave cavity end covers 17 on the left and right sides, and microwave cavity inlets. The material end plate 57, the microwave cavity top plate 5 at the top and the m...

Embodiment 2

[0053] Such as Figures 1 to 8 As shown, the microwave double-helix tube furnace includes three parts: a frame 2, a microwave cavity and a double-helix stirring device;

[0054] Described frame 2 is made up of the frame encapsulation top plate A3 of upper end surface and frame encapsulation top plate B7, the frame encapsulation side plate A10 of front and rear left and right sides, the frame encapsulation bottom plate of lower bottom surface, and the surface of rack encapsulation side plate A10 is provided with Pull button 9, frame support feet 11 are provided on the bottom plate of the frame package;

[0055] The microwave cavity is located on the upper side inside the frame 2, and the microwave cavity includes microwave cavity side plates A56 and microwave cavity side plates B58 on the front and rear sides, microwave cavity end covers 17 on the left and right sides, and microwave cavity inlets. The material end plate 57, the microwave cavity top plate 5 at the top and the m...

Embodiment 3

[0063] Such as Figures 1 to 8 As shown, the microwave double-helix tube furnace includes three parts: a frame 2, a microwave cavity and a double-helix stirring device;

[0064] Described frame 2 is made up of the frame encapsulation top plate A3 of upper end surface and frame encapsulation top plate B7, the frame encapsulation side plate A10 of front and rear left and right sides, the frame encapsulation bottom plate of lower bottom surface, and the surface of rack encapsulation side plate A10 is provided with Pull button 9, frame support feet 11 are provided on the bottom plate of the frame package;

[0065] The microwave cavity is located on the upper side inside the frame 2, and the microwave cavity includes microwave cavity side plates A56 and microwave cavity side plates B58 on the front and rear sides, microwave cavity end covers 17 on the left and right sides, and microwave cavity inlets. The material end plate 57, the microwave cavity top plate 5 at the top and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com