Preparation method of polyester fabric with water-and-oil repellent and anti-bacterial functions

A water-repellent, oil-repellent, polyester technology, applied in the field of polyester fabric preparation, can solve the problems of expensive garments, low adhesion fastness, no oil repellency, etc., and achieve easy continuous industrial production and good mechanical friction stability , the effect of less physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

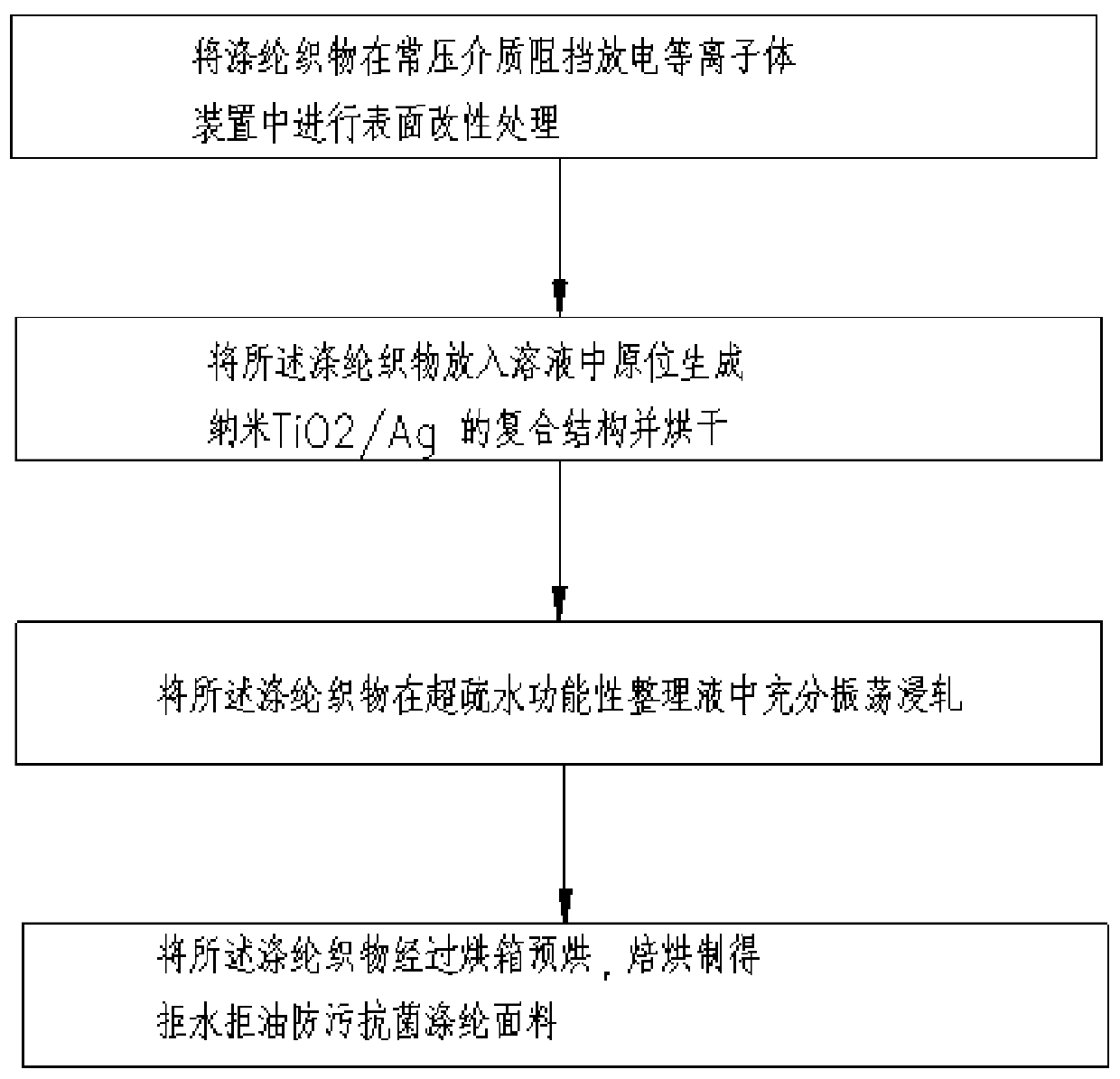

[0024] see Figure 1-3 , the present invention provides a technical solution: a method for preparing a polyester fabric with water-repellent, oil-repellent and antibacterial functions, comprising the following steps:

[0025] A, polyester fabric is carried out surface modification treatment in atmospheric pressure dielectric barrier discharge plasma device;

[0026] B, putting the polyester fabric into the solution to generate nano-TiO2 / Ag composite structure in situ and drying;

[0027] C, fully oscillating and padding the polyester fabric in the super-hydrophobic functional finishing liquid;

[0028] D. Pre-baking the polyester fabric in an oven to obtain a water-repellent, oil-repellent, antifouling, and antibacterial polyester fabric.

[0029] In this embodiment, the treatment atmosphere of the surface modification treatment in step A is Ar gas, the gas flow rate is 1 L / min, the treatment power is 1 KW, and the treatment time is 90 s.

[0030] In this embodiment, the po...

Embodiment 2

[0039] A method for preparing a polyester fabric with water-repellent, oil-repellent and antibacterial functions, comprising the following steps:

[0040] A, polyester fabric is carried out surface modification treatment in atmospheric pressure dielectric barrier discharge plasma device;

[0041] B, putting the polyester fabric into the solution to generate nano-TiO2 / Ag composite structure in situ and drying;

[0042] C, fully oscillating and padding the polyester fabric in the super-hydrophobic functional finishing liquid;

[0043] D. Pre-baking the polyester fabric in an oven to obtain a water-repellent, oil-repellent, antifouling, and antibacterial polyester fabric.

[0044] In this embodiment, the treatment atmosphere of the surface modification treatment in step A is Ar gas, the gas flow rate is 1 L / min, the treatment power is 1 KW, and the treatment time is 180 s.

[0045] In this embodiment, the polyester fabric described in step B and the butyl titanate solution are ...

Embodiment 3

[0054] A method for preparing a polyester fabric with water-repellent, oil-repellent and antibacterial functions, comprising the following steps:

[0055] A, polyester fabric is carried out surface modification treatment in atmospheric pressure dielectric barrier discharge plasma device;

[0056] B, putting the polyester fabric into the solution to generate nano-TiO2 / Ag composite structure in situ and drying;

[0057] C, fully oscillating and padding the polyester fabric in the super-hydrophobic functional finishing solution;

[0058] D. Pre-baking the polyester fabric in an oven to obtain a water-repellent, oil-repellent, antifouling, and antibacterial polyester fabric.

[0059] In this embodiment, the treatment atmosphere of the surface modification treatment in step A is Ar gas, the gas flow rate is 1 L / min, the treatment power is 1 KW, and the treatment time is 100 s.

[0060] In this embodiment, the polyester fabric described in step B and the butyl titanate solution ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com