Cap type ratchet self-locking device and steel support comprising same

A technology of self-locking device and steel support, which is applied in the field of steel support and can solve problems such as servo steel support failure and major accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

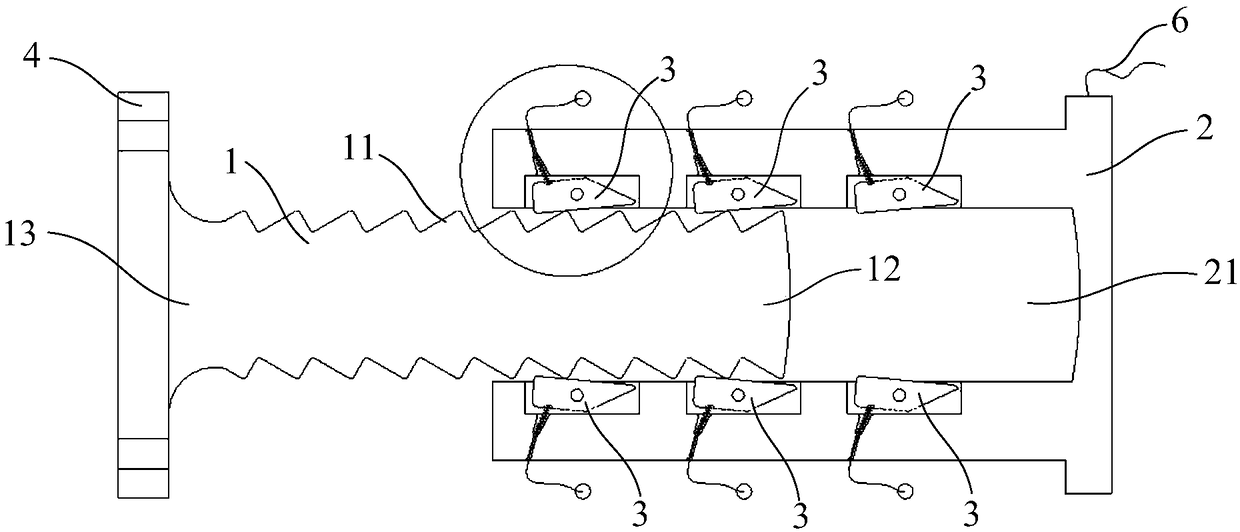

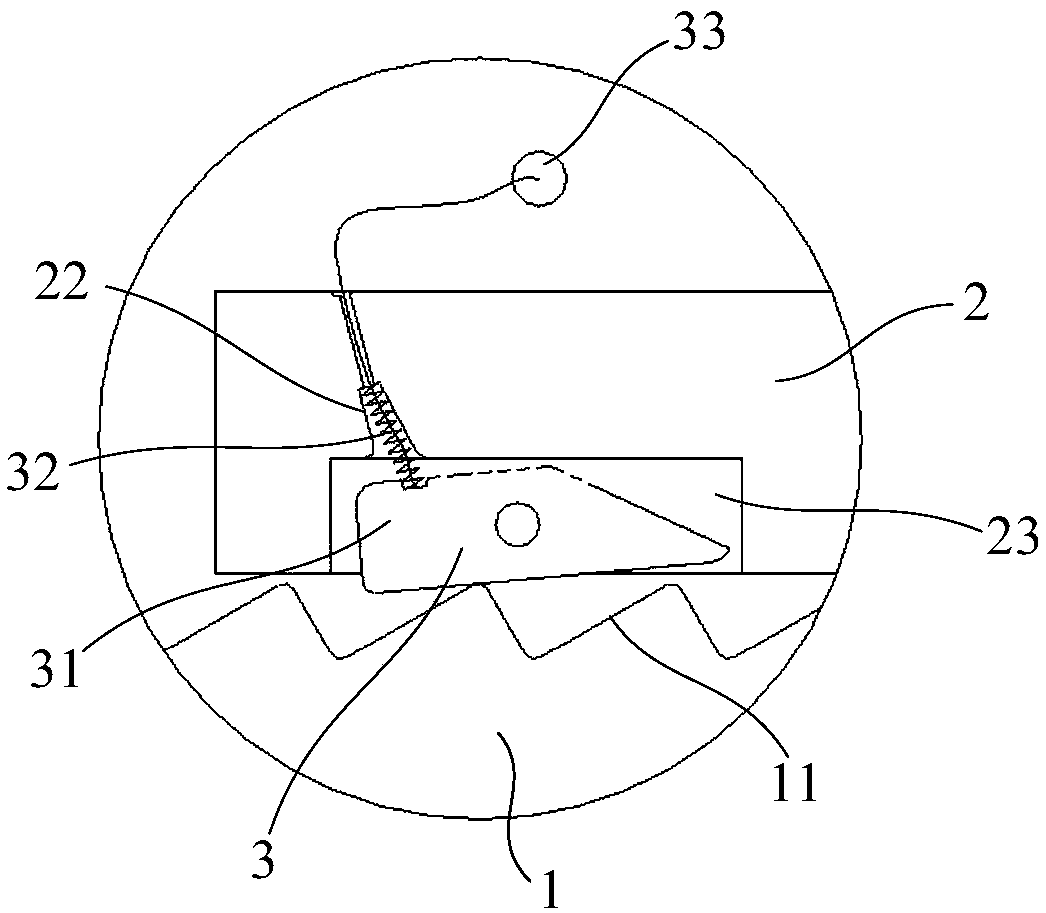

[0058] like Figure 1 to Figure 4 As shown, the cap type ratchet self-locking device of the present invention comprises an inner pin 1, a cap 2 and several wedge assemblies 3, the outer peripheral surface of the inner pin 1 is provided with a plurality of ratchets 11, and the ratchets 11 are arranged axially along the inner pin 1; the cap One end of 2 is provided with a mounting hole 21, the inner pin 1 can be inserted into the mounting hole 21, and the stop direction of the ratchet 11 is the direction in which the inner pin 1 is inserted into the mounting hole 21; several wedge assemblies 3 are arranged on the inner peripheral surface of the mounting hole 21 , the wedge assembly 3 includes a wedge 31, an elastic member 32 and a pull cable 33, the wedge 31 can rotate relative to the cap 2 and switch between the two states of deployment and retraction; when the wedge 31 is deployed, the wedge 31 can cooperate with the ratchet 11; when the wedge 31 retracts, the minimum distance...

Embodiment 2

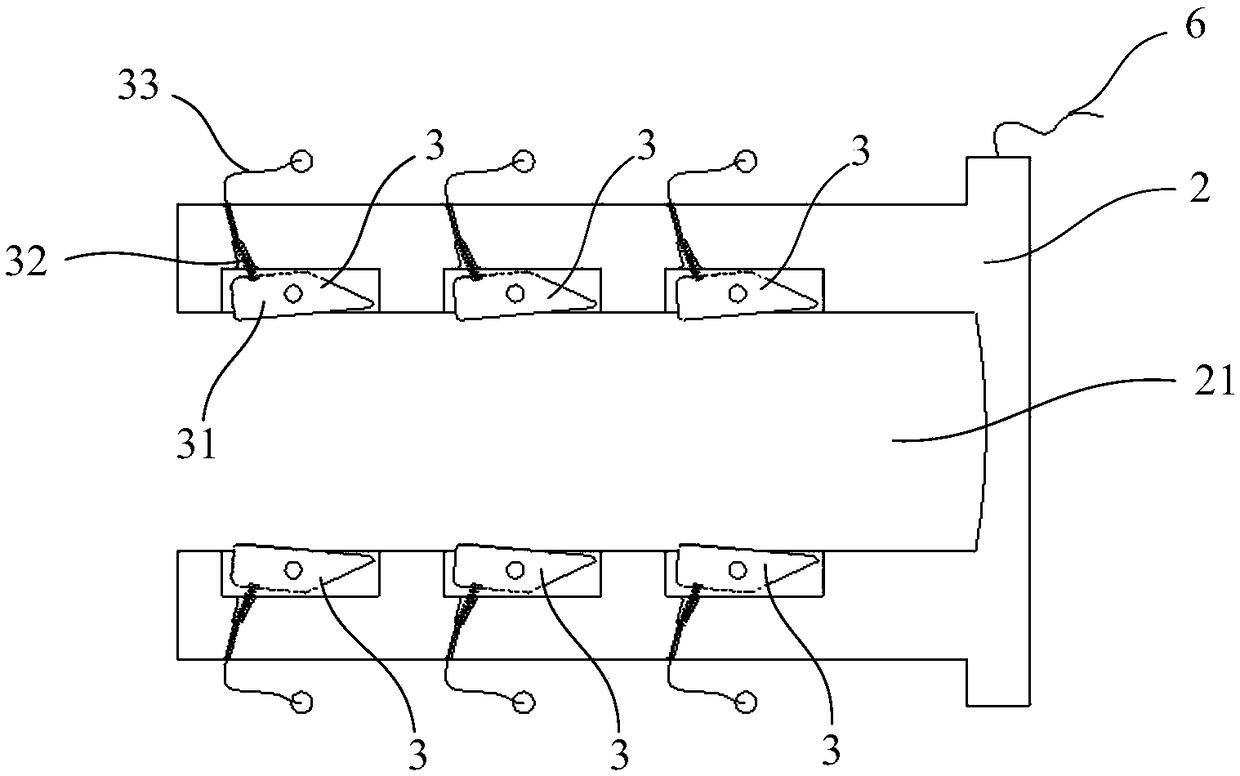

[0071] like Figure 7 to Figure 10 Shown is a schematic structural view of Embodiment 2 of the cap-type ratchet self-locking device of the present invention. The structure of the cap-type ratchet self-locking device of this embodiment is basically the same as that of Embodiment 1 except the cap 2. The mounting hole 21 of the cap 2 in this embodiment is not provided with an accommodating cavity 23, and the overall diameter of the inner peripheral surface of the mounting hole 21 is relatively large, and the support frame 5 can be installed on the inner peripheral surface of the mounting hole 21, and the wedge 31 is hinged on the The support frame 5 can also be rotated and switched between the two states of unfolding and retracting. The block cap 2 of this structure has a simple processing form and is easy to install.

[0072] like Figure 11 to Figure 12 Shown is a steel support with the above-mentioned cap-type ratchet self-locking device, and the method of applying the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com