Self-locking type double-station thread drilling tool fixture

A tooling fixture and self-locking technology, which is applied in the direction of drilling molds for workpieces, etc., can solve the problems of inability to guarantee the accuracy of drilling processing positions, high labor intensity of workers, and low production efficiency, achieving a wide range of applications and simple structure Compact and easy to assemble and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

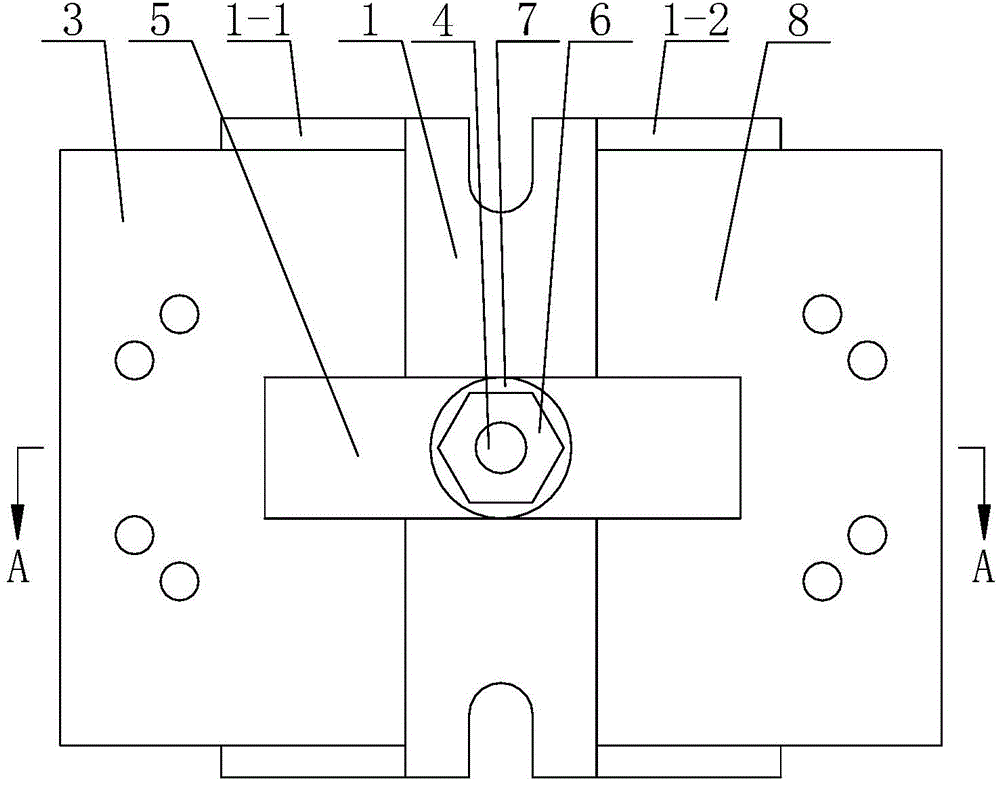

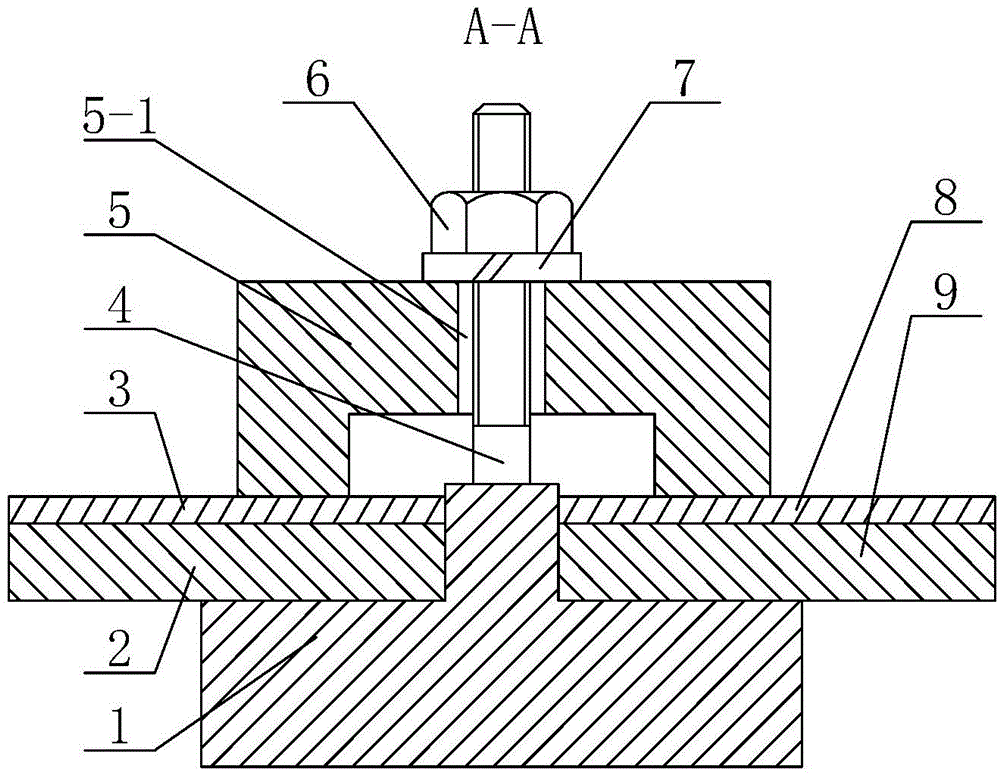

[0022] Such as figure 1 and figure 2 A double-station threaded self-locking tooling fixture for drilling is shown, which includes a base 1 that acts as a load bearing and is symmetrically provided with opening mounting grooves on both sides of the upper and lower sides, and a drilling template 1 for guiding the drill bit to process the drilling hole. Drill template two 8, also comprise the U-shaped hold-down plate 5 that is used to compress described drill template one 3 and described drill template two 8 and cooperate with each other to form thread pair and be used for compressing described U-shaped hold-down plate 5 screw 4 and nut 6; one side of the base 1 is provided with a positioning groove 1-1 for positioning the drill template 3 and the workpiece 2, and the positioning groove 1-1 is provided with the drill Template one 3, the other side of the base 1 is provided with a positioning groove two 1-2 for positioning the drilling template two 8 and the workpiece two 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com