Auxiliary windowing process for performing oriented blasting perforation on thick-walled casing

A technology of directional blasting and window opening technology, which is applied in wellbore/well components, earthwork drilling and production, etc. It can solve the problems of long window opening period, milling cone drill bit wear, and difficult window opening, etc., and achieves simple operation and reliable construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical features, objectives and beneficial effects of the present invention more clearly understood, the present invention will be further described in detail below in conjunction with the accompanying drawings. However, what has been described is only a part of the embodiments of the present invention, not all of the embodiments, and should not be construed as limiting the implementation scope of the present invention.

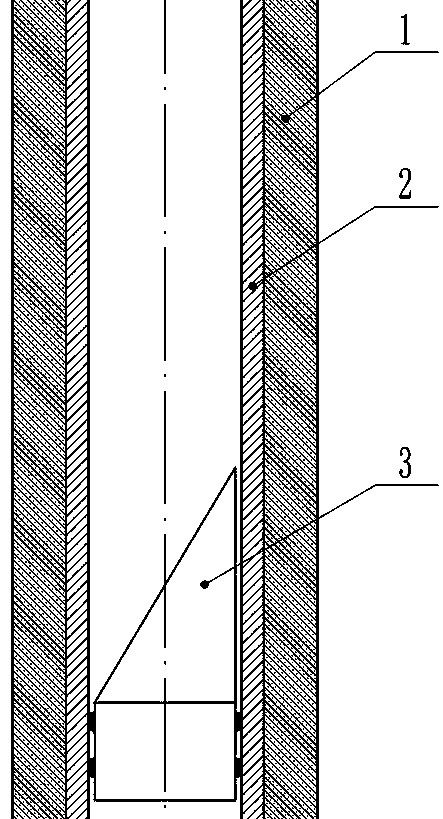

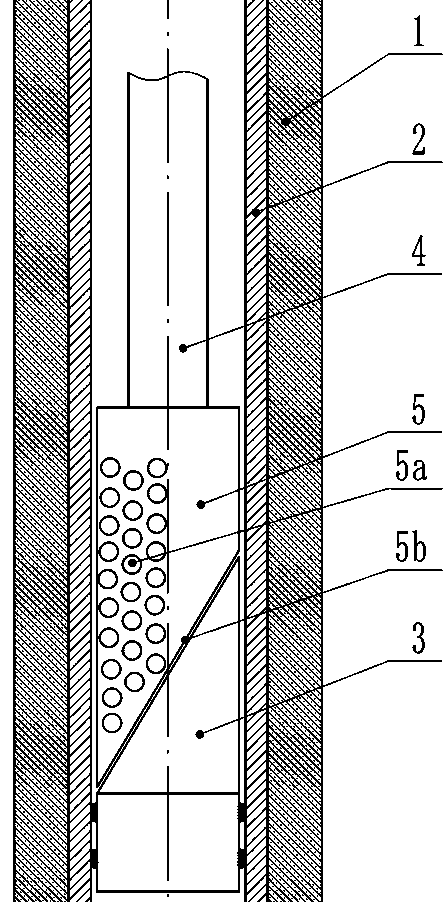

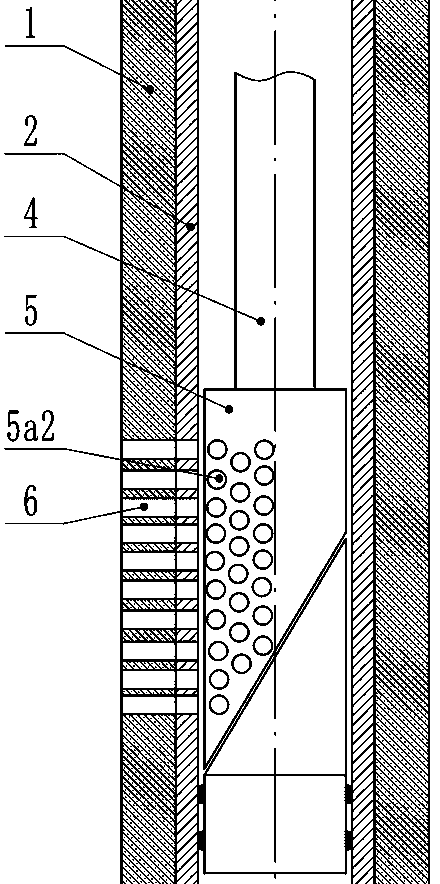

[0017] According to the angle and length of the support slope of the window opening whipstock 3 on the construction site, the inclination and length of the perforator orientation slope 5b are prepared, and the perforator orientation slope 5b of the large-aperture special orientation window perforator 5 is directly opposite The perforator holes 5a are distributed in the semi-cylindrical surface, so that the distribution density of the perforator holes 5a reaches the maximum value as much as possible. After the perforation tools ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com