Beam penetrating sleeve positioning construction method for fabricated building

A construction method and prefabricated technology, which are applied in the on-site preparation of building components, construction, building construction, etc., to achieve the effects of improving stability and positioning accuracy, increasing strength, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

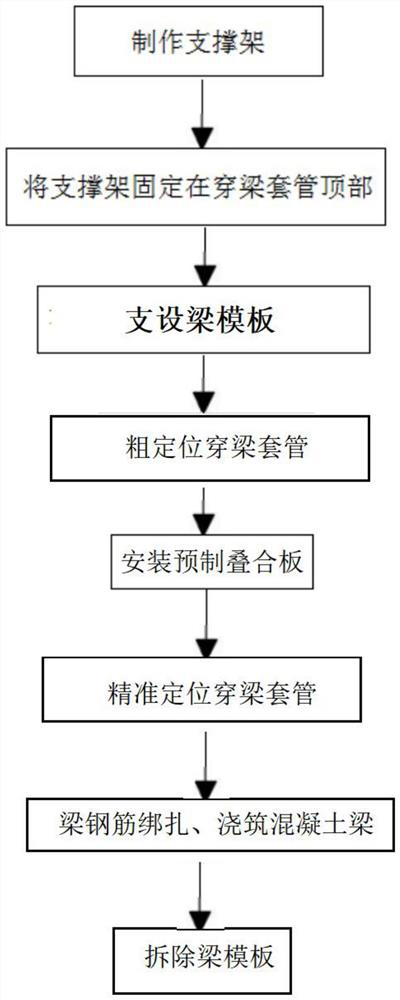

[0038] The present invention provides a construction method for the positioning of beam-piercing casings for prefabricated buildings, such as figure 1 shown, including the following steps:

[0039] Step 1: Make the support frame

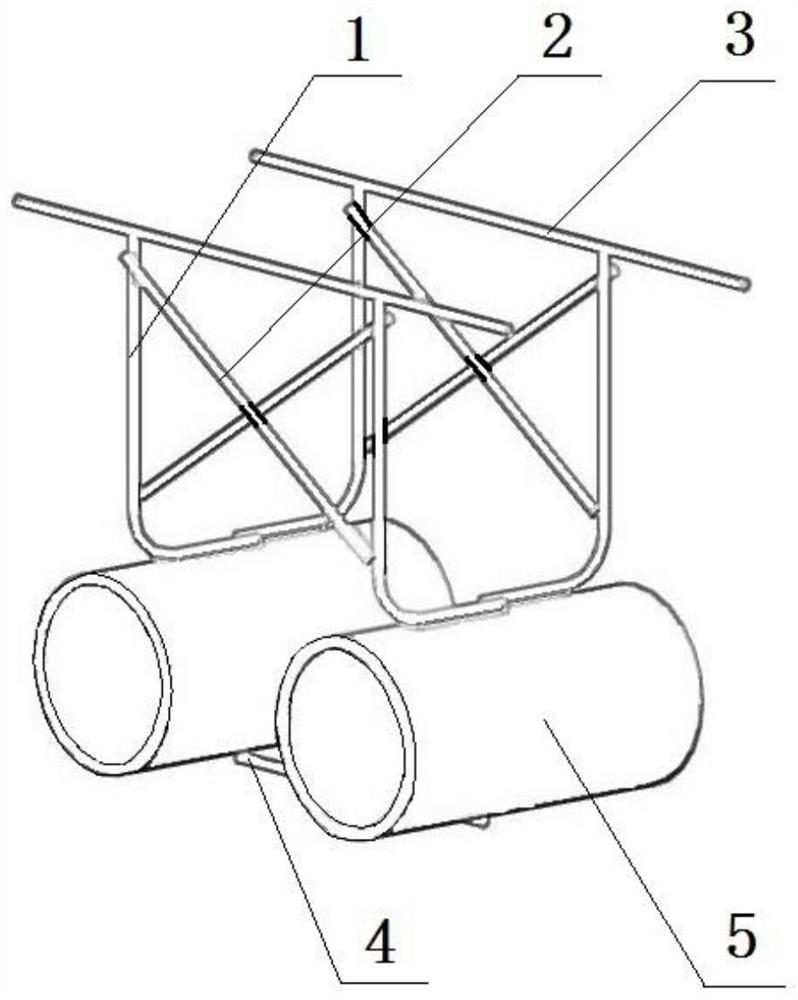

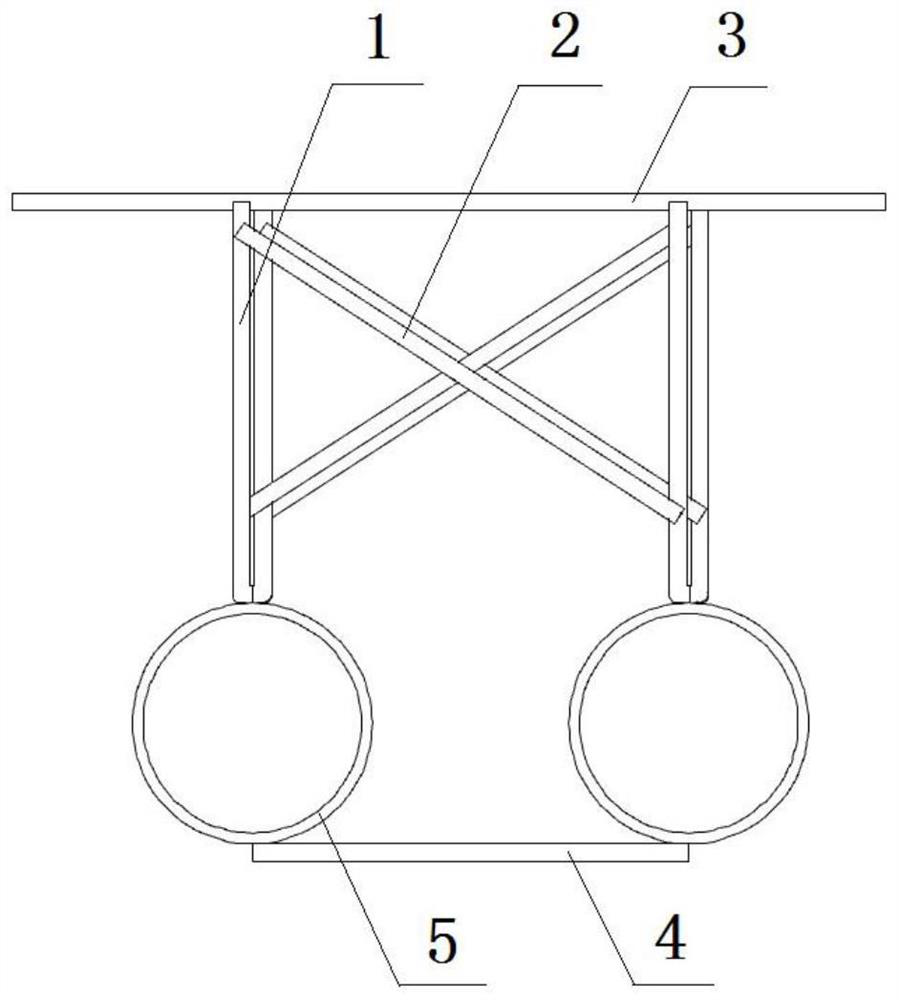

[0040] like Figure 2 to Figure 5 As shown, the support frame includes a cross bar 3 and a vertical bar 1. There are two vertical bars 1 and are vertically spaced symmetrically. The bottom ends of the two vertical bars 1 are respectively fixed on the through beams. The top end of the casing 5 along the axis direction, the top end of each vertical rod 1 is respectively fixed with the transverse rod 3 , and the transverse rod 3 is perpendicular to the axis of the beam-penetrating casing 5 . The support frame is simple and firm in structure, convenient in manufacture and low in cost.

[0041] First determine the horizontal position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com