PE pipe installation device for air purification system

An air purification system and installation device technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve problems such as hole punching failure, main beam or wall damage, limited detection depth of metal detectors, etc., and achieve good results. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

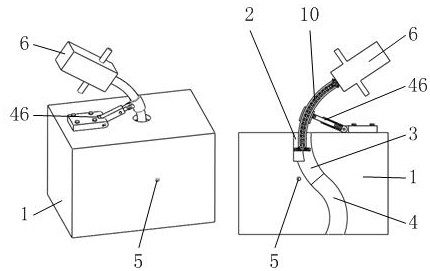

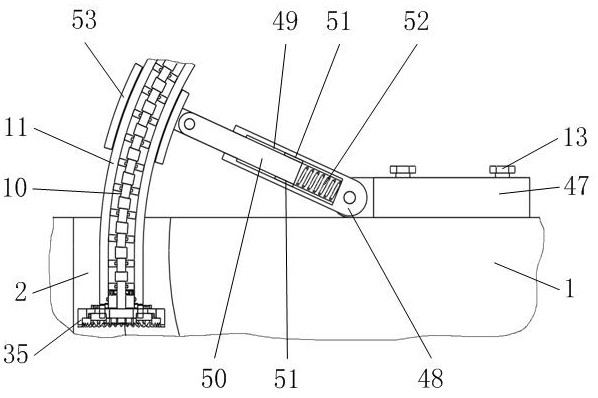

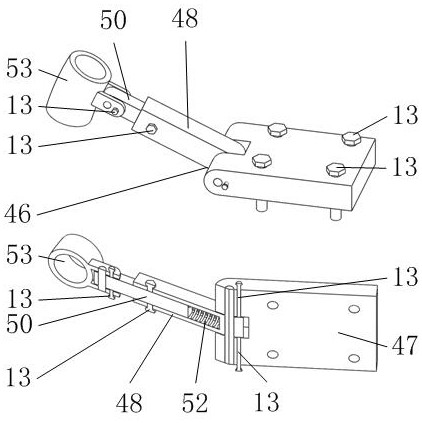

[0030] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0031] Such as figure 1 , 2As shown, it includes an electric device 6, a drill mechanism 10, and a guide mechanism 46, wherein the arc-shaped drill mechanism 10 fixed on the electric device 6 and connected to the electric shaft 7 on the electric device 6 is connected to the wall 1 or the main beam. Cooperate with the guide mechanism 46 on the top; under the traction of the guide mechanism 46, the drill mechanism 10 has been drilled on the wall 1 or the main beam around the center axis of the drill mechanism 10 under the traction of the guide mechanism 46. Groove 2 is drilled in depth by bypassing the steel bars 5 to form the curved groove A3; then the drill mechanism 10 is drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com